Agricultural product screening machine

A technology for screening machines and agricultural products, which is applied in various fields of the Ming Dynasty, can solve the problems of long time required for screening operations, troublesome efficiency, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

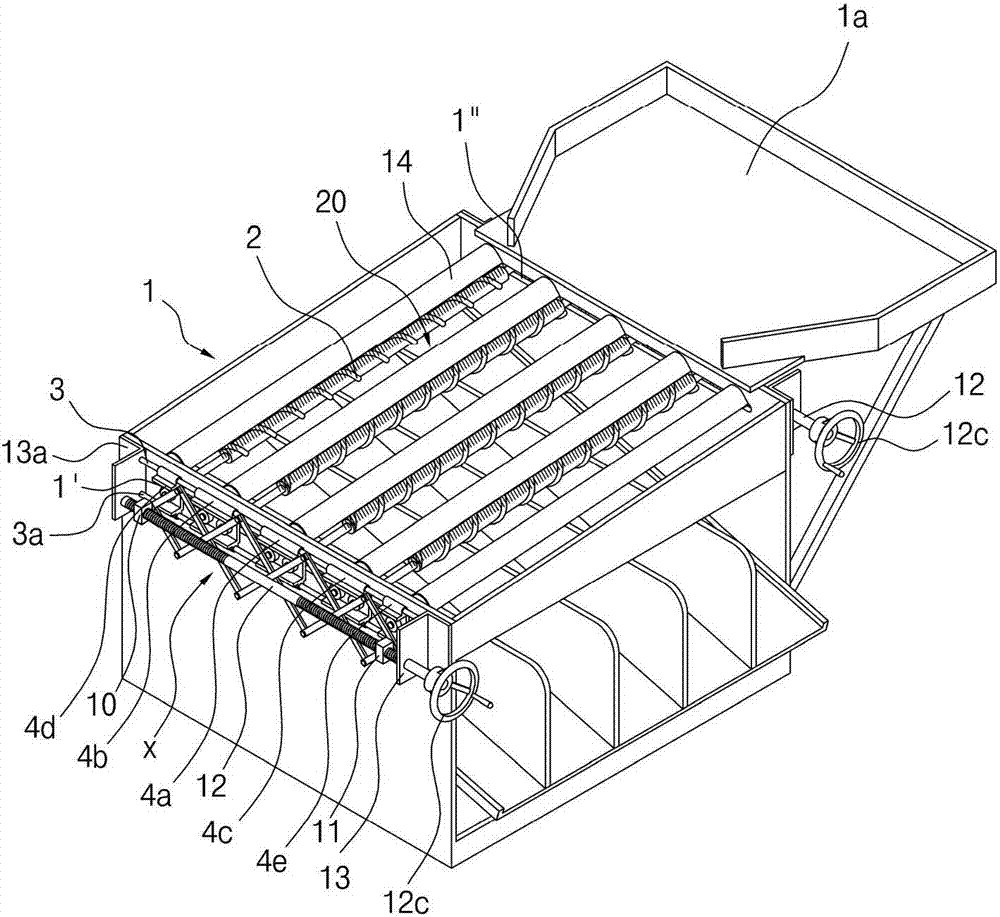

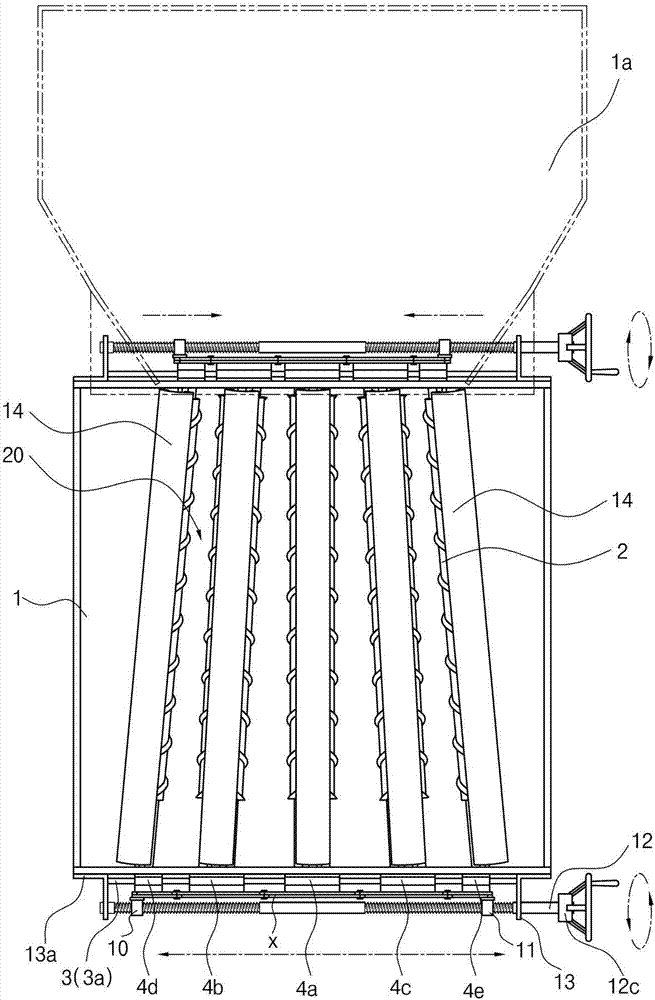

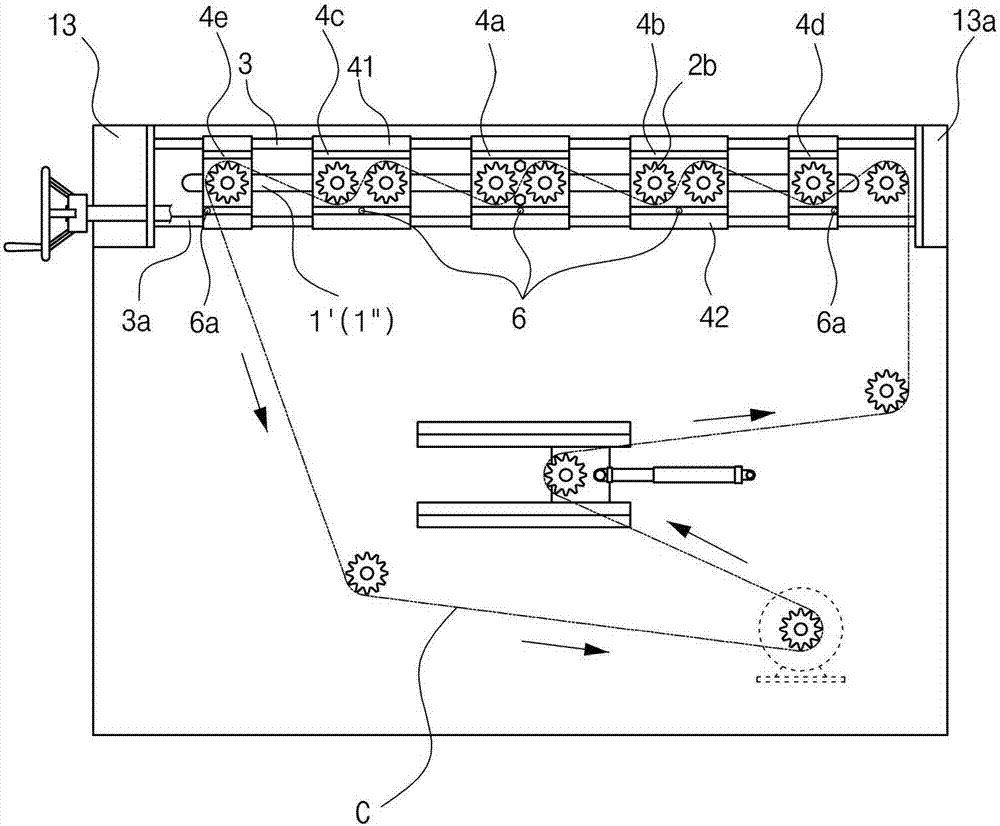

[0014] The present invention comprises: 8 screening rollers 2, arranged on the upper part of the screening machine body 1 facing the length direction, the above 8 screening rollers 2 are installed with a plurality of screening rollers in an inclined manner, so that the agricultural products used to supply the agricultural products to be screened The height on one side of the supply part 1a is high, and the height on the side opposite to the side of the agricultural product supply part 1a is low. The support holes of the outer support bodies 4d and 4e provided outside the guide horizontal hole of the main body are supported, and the screening rollers arranged on the inside of the above-mentioned 8 screening rollers 2 are arranged so that the supporting shafts of each screening roller are sealed in two groups. The end is supported by the support holes of the middle support body 4a, the first support body 4b and the support hole of the second support body 4c which are arranged sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com