Elastic vibration sieving device

A vibrating sieve and elastic technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problem of insufficient screening, achieve good screening effect and enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

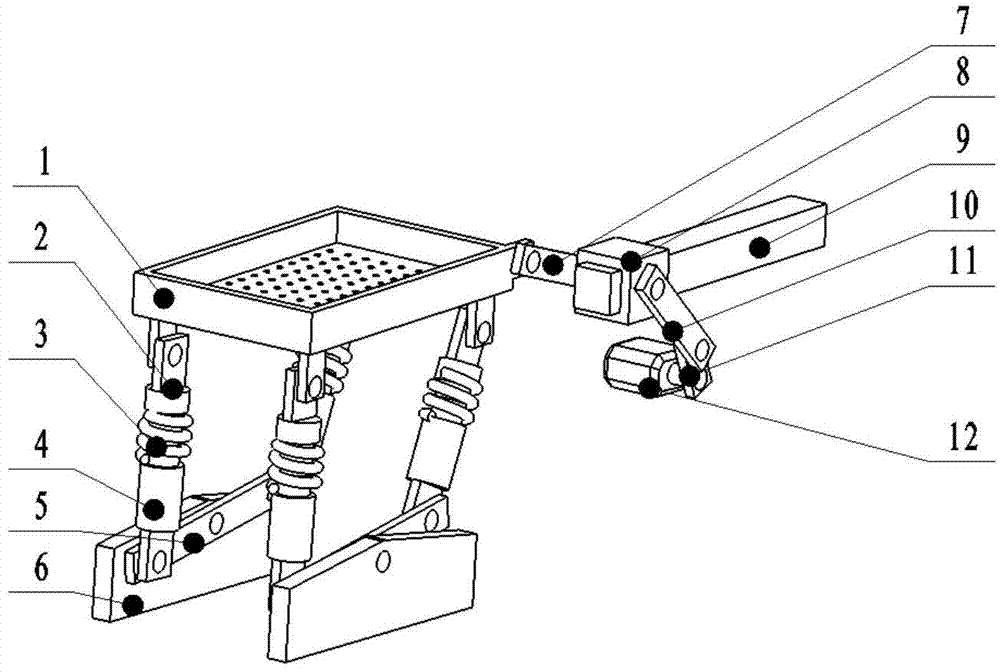

[0008] An elastic vibration screening device is composed of a stage, an upper support frame 2, a spring 3, a lower support frame 4, a swing rod 5, a fixed support 6, a crank rocker 7, a slider 8, a fixed guide rail 9, and a crank shaker. Rod 10, crank rocker 11, AC motor 12, AC motor 12 is fixed on the ground and connected with crank rocker 11, crank rocker 11 is connected with slider 8 through another crank rocker 10, slider 8 is installed on the fixed guide rail 9, the load screening table 1 is connected with the slider 8 through a crank rocker 7, and the four upper support frames 2 and the load screening table 1 are hinged under the load screening table 1, fixed Above the support 6, the four lower support frames 4 and the swing rods 5 are respectively hinged, the swing rod 5 is hinged on the fixed frame 6, and four springs 3 are connected between the four lower support frames 4 and the four upper support frames 2. , so that the upper support frame 2, the lower support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com