A reaction tank and a method for treating printing and dyeing wastewater using the reaction tank

A technology of printing and dyeing wastewater and reaction tank, applied in chemical instruments and methods, textile industry wastewater treatment, filtration treatment, etc., can solve the problems of accelerating acid-base neutralization reaction in an orderly manner, poor effect of auxiliary agents, single effect, etc. Achieve the effect of accelerating the rate of acid-base neutralization reaction, increasing vibration and reducing the content of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

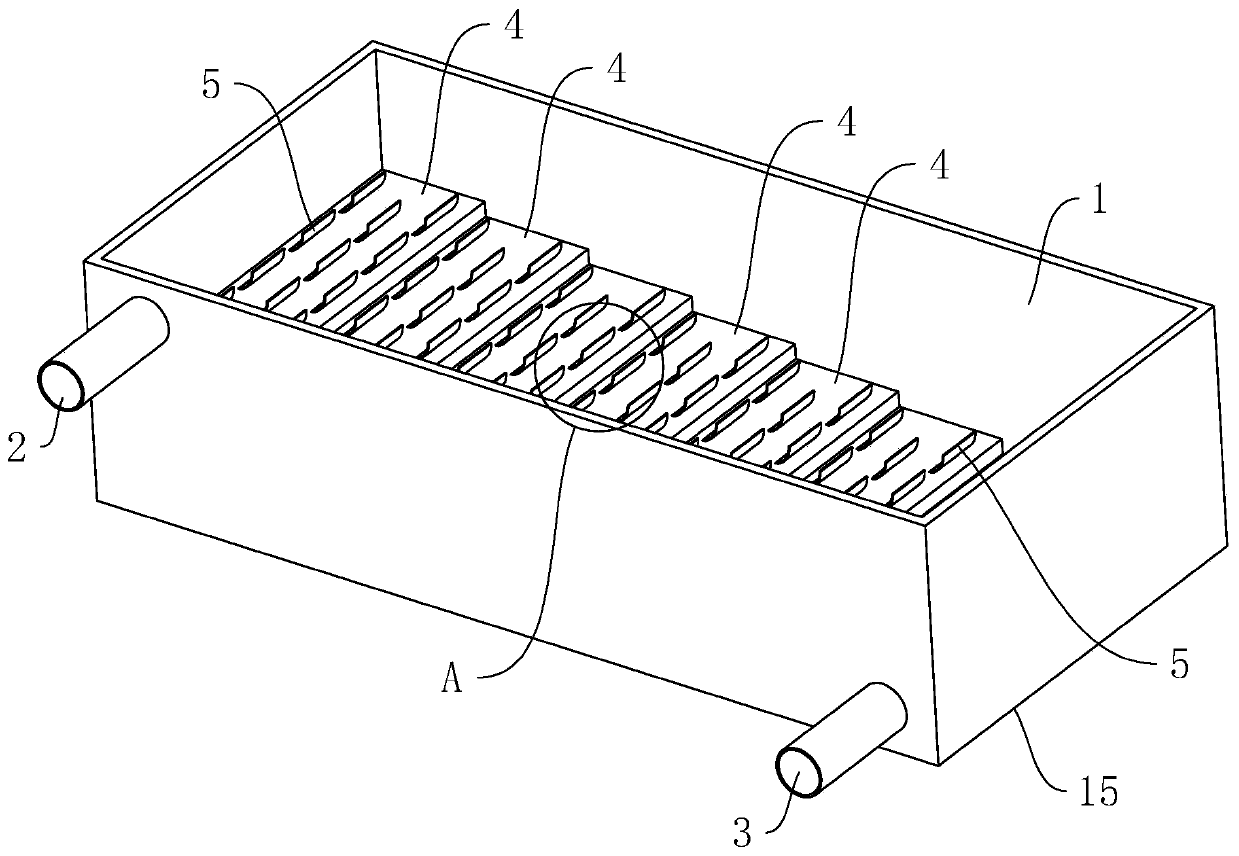

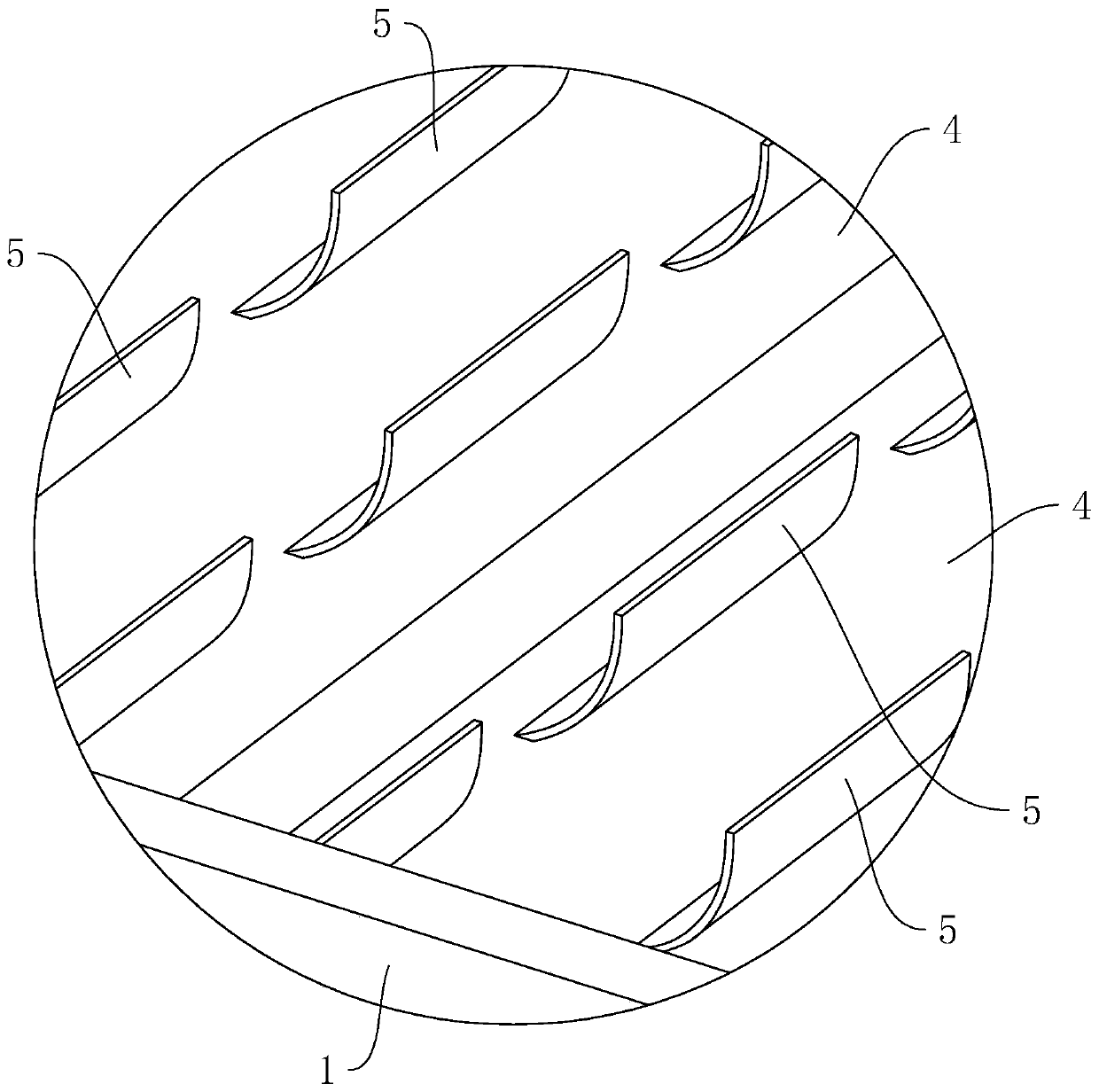

[0053] Embodiment 1: a kind of reaction tank 15, such as figure 1 and figure 2 As shown, it includes a pool body 1 , a water inlet pipe 2 and a drain pipe 3 arranged on both sides of the pool body 1 . Among them, the pool body 1 is inclined downward from the water inlet pipe 2 to the drain pipe 3 and is provided with seven steps 4, each step 4 is bent upwards and installed with a number of arc-shaped stainless steel baffles 5, wherein the arc-shaped stainless steel baffles 5 The cross-section is arc-shaped (see Figure 4 ). And the above-mentioned arc-shaped stainless steel baffles 5 are alternately arranged on the same level of steps 4 . Therefore, the water body (that is, the printing and dyeing wastewater) will flow from the direction of the inlet pipe 2 to the drain pipe 3, and the water body will increase the flow rate after the water body overcomes the height difference when it flows down. Sheet 5, the existence of arc-shaped stainless steel baffle 5 can block the n...

Embodiment 2

[0055] Embodiment 2: a kind of reaction tank 15, the difference with embodiment 1 is: as Figure 5 and Figure 6 As shown, in order to speed up the acid-base neutralization reaction in the water body, the lower end of the arc-shaped stainless steel baffle 5 is hinged at the turning point of the step 4 through the rotating shaft 6, and the rotating shaft 6 is sleeved for driving the arc-shaped stainless steel baffle 5 toward Follow the torsion spring 7 that water inlet pipe 2 direction moves. On the one hand, it has the blocking effect of other arc-shaped stainless steel baffles 5; The baffle plate 8 can be turned down around the rotating shaft 6 to drain excess water, and then reversely turned under the action of the torsion spring 7, and during the above-mentioned turning process, the arc-shaped stainless steel baffle plate 8 will generate lateral vibrations, thereby It will produce shocks in the flow direction of the water body, which will help to accelerate the acid-base ...

Embodiment 3

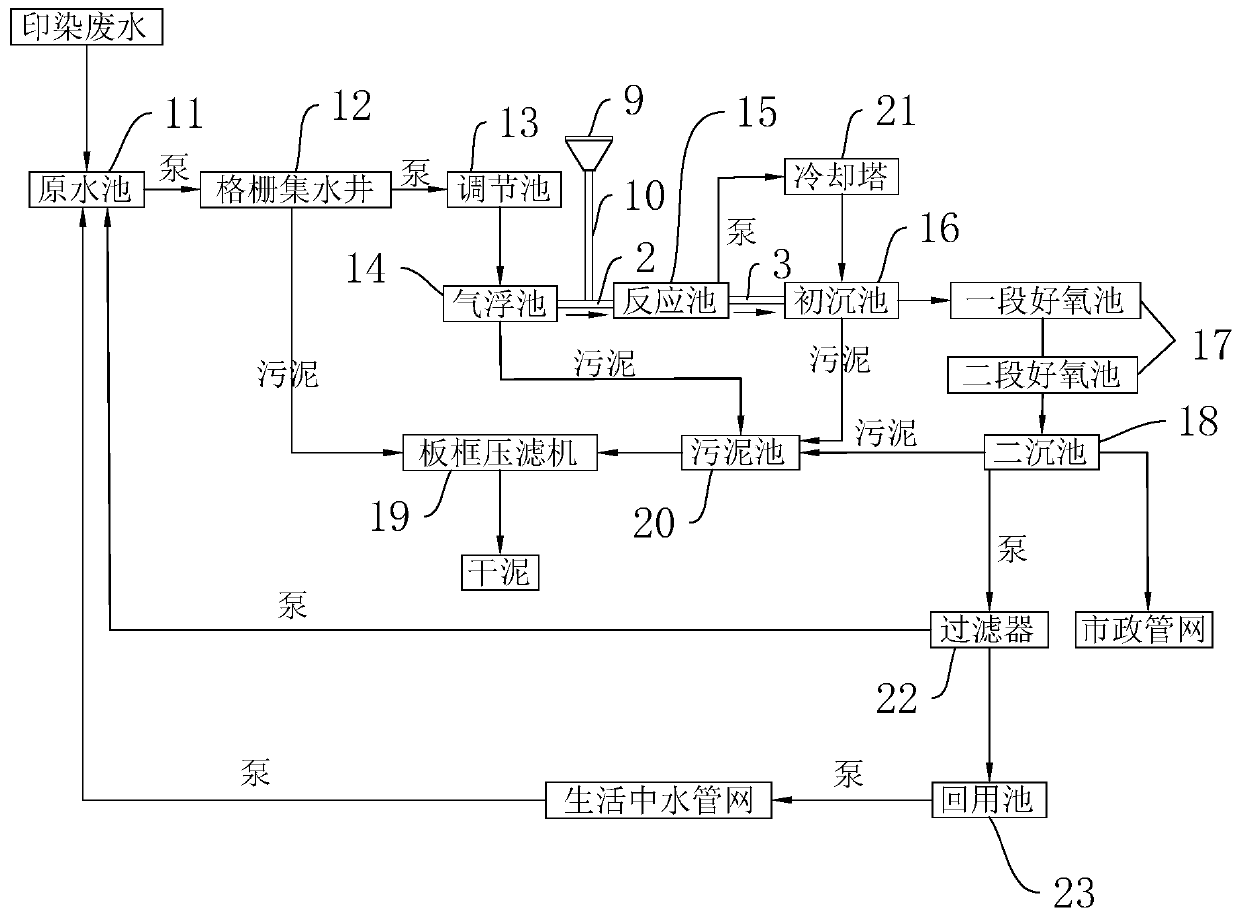

[0057] Embodiment 3: a kind of method that adopts this reaction tank 15 to control printing and dyeing wastewater, such as figure 1 shown, including the following steps,

[0058] Step S1, the printing and dyeing wastewater is discharged into the raw water pool 11 through the dyeing vat sewage pipe for preliminary heat dissipation, and the pH value of the raw water is detected and recorded at the same time.

[0059] Step S2: Drain the water body after preliminary heat dissipation in the raw water pool 11 into the grid water collection well 12, and drain the water body after removing suspended matter into the regulating pool 13 for temporary storage.

[0060] Step S3: Lift the water in the adjustment tank 13 into the air flotation tank 14 through a water pump, add polyferric flocculant and dilute sulfuric acid, adjust the pH to 5-6.5, and remove the suspended matter on the surface with a mud scraper after sufficient aeration.

[0061] Step S4, the lower clear liquid obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com