Welding machine

A technology for welding machines and welding racks, which is applied in welding accessories, welding protection devices, mechanical equipment, etc. It can solve problems such as solder easily adhering to the welding rack, uneven welded parts, and affecting the quality of welded parts, so as to protect the body Effects of health, increased vibration, and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

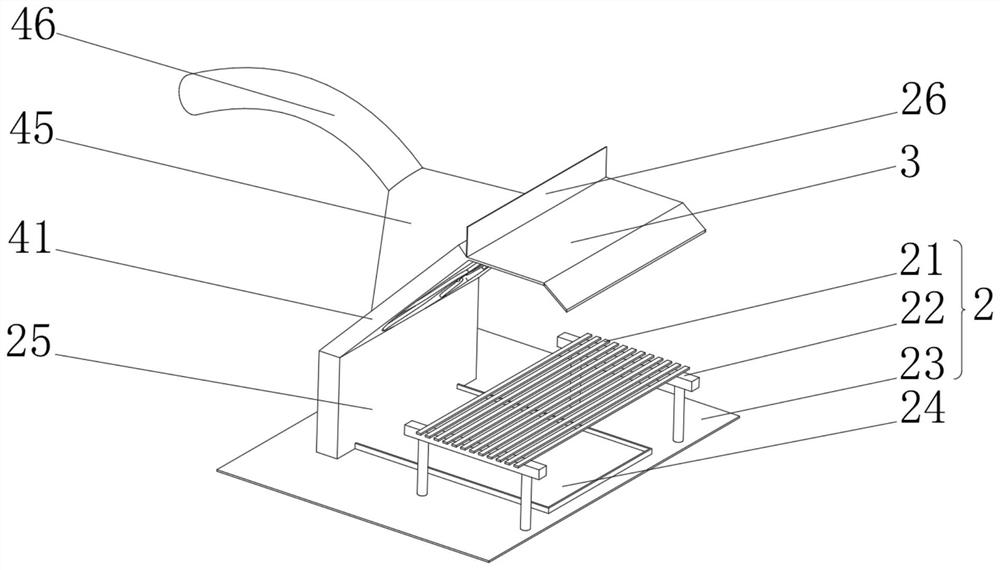

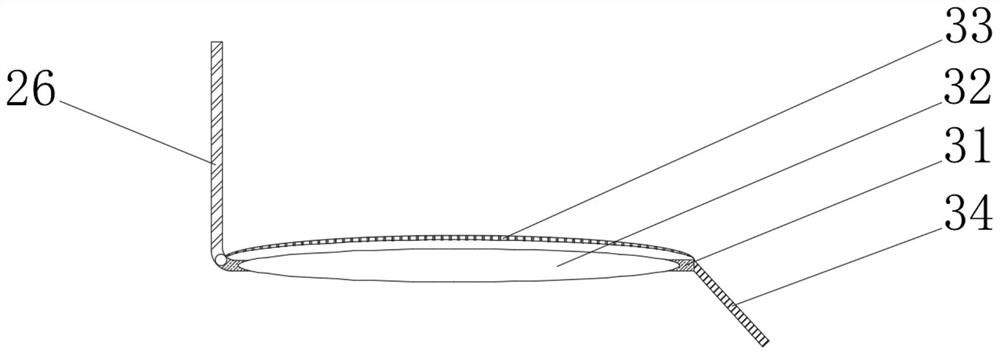

[0041] See Figure 1-2 The present invention provides a technical solution: a welding machine, a welding body 1 comprising a welding frame 2, a protective mechanism 3, and a diaaching mechanism 4, and the welding frame 2 includes a slider 21, a bottom fixed connection of the slider 21. The support frame 22, the bottom of the support frame 22 is fixedly connected to the base 23, and the top sliding of the base 23 is slidably connected to the scrap cartridge 24, and the top of the base 23 is fixedly connected to the waste passage 25, the top of the waste passage 25 fixes the connection. Institution 4, the top of the right side of the vacuum cleaner 4 fixedly connected to the receiving plate 26, and the bottom right side of the underside plate 26 is rotated by the damper shaft, the left side of the waste cassette 24 penetrates the waste passage 25 and extended to the waste The outside of the pass plate 25, the bottom of the waste passage 25 is connected to each other with the inside ...

Embodiment 2

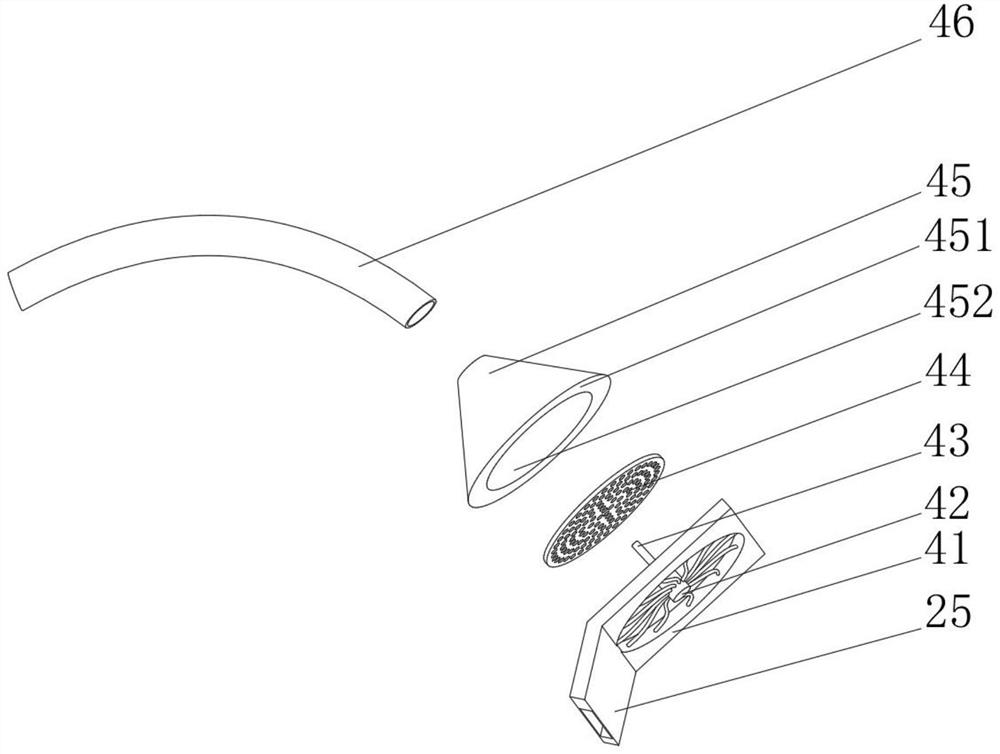

[0045] See Figure 1-5 Based on the first example, the present invention provides a technical solution: the diaaching mechanism 4 includes a vacuum-saving frame 41, and the inside of the vacuum cleaning frame 41 is fixedly connected to the microscope 42, and the left side fixed connection of the micro motor 42 is The receiving rod 43, the inner receptor 43 is fixed to one end of the micro motor 42 is fixedly coupled with the filter 44, and the top of the left side of the vacuum frame 41 is fixedly connected to a kit 45, and the top of the sleeve 45 has a vacuum tube 46, a filter The outer side of 44 is fixed to the right side wall of the sleeve frame 45, and the bottom end of the vacuum cleaner 41 is in communication with the top right side of the scrapper plate 25, and the top end of the waste passage 25 penetrates the dust frame 41 and extends to the kit 45. internal.

[0046] The first suction hole 451 and the second suction hole 452 are provided inside the sleeve 45.

[0047] ...

Embodiment 3

[0051] See Figure 1-8 On the basis of the first and embodiment 2, the present invention provides a technical solution: the outer sleeve of the slider 21 is provided with a slag-slag-slag, the inside of the slag mechanism B is slidable, divided by the outside of the slider 21, divided The left side of the slag mechanism B is fixedly connected to the hydraulic telescoping rod 211, and the outer side of the hydraulic telescopic rod 211 is fixed to the left side of the slider 21.

[0052] The slag mechanism B includes a slag frame B1, and the inner wall of the slag frame B1 is fixedly connected to the first electromagnetic block B2, and both sides of the first electromagnetic block B2 are fixedly connected to the active rod B3, and the bottom fixed connection of the movable rod B3 is slippery. The top of the knife B4, the top of the slipper B4 is fixedly connected to the second electromagnetic block B5, and the second electromagnetic block B5 is located directly below the first electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com