Multiple grinding mechanism of silicon dioxide grinding barrel

A technology of silica and grinding mechanism, applied in chemical instruments and methods, cleaning methods and utensils, grain processing, etc., can solve problems such as inability to stir and clean, powder to stir, and silica to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Next, the technical solutions in the embodiments in the examples will be clearly and completely described, and it is intended to be described in the examples, not all of the embodiments of the embodiments. Based on the embodiments, all other embodiments obtained without making creative labor without making creative labor premises.

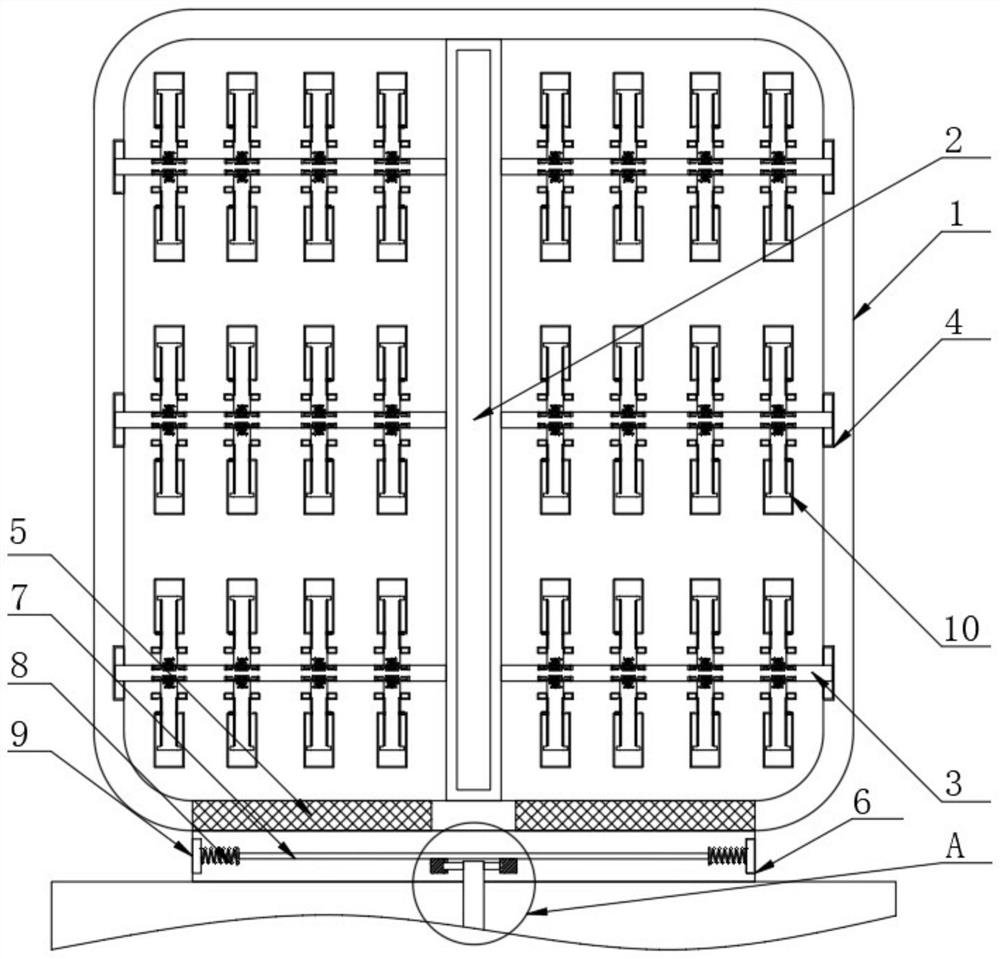

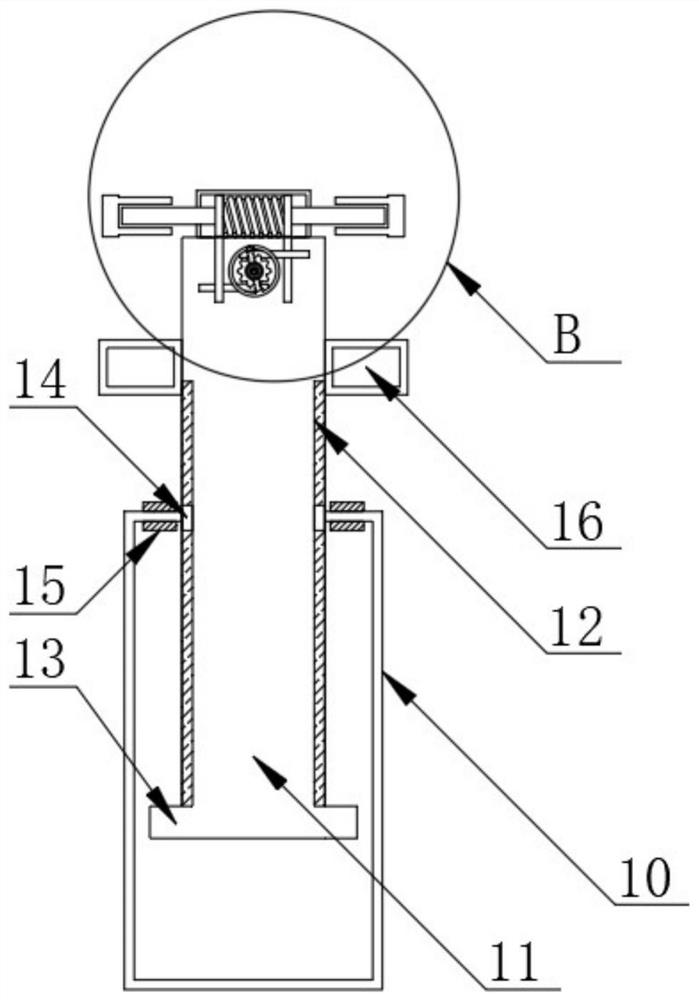

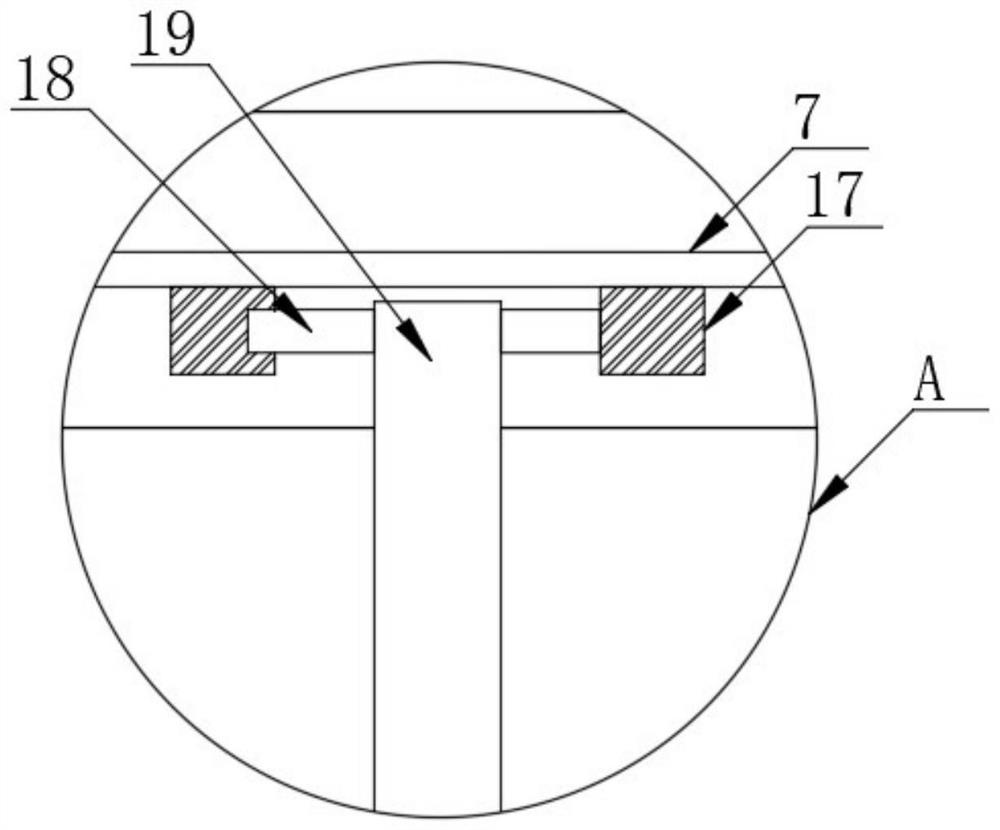

[0025]SeeFigure 1-4The multi-grinding mechanism of the silica grinding bucket includes a device body 1, a stirring mechanism, a protective mechanism, and a stirring mechanism comprising a drive shaft 2, and the drive shaft 2 is connected to the inside of the apparatus body 1, and the interior of the drive shaft 2 is continuously connected to stirring The rod 3, both ends of the stirring rod 3 are joined to the finite spots 4, and both sides of the stirring rod 3 are active and the active stirring plate 10 is attached, and the internal sleeve of the movable mixing plate 10 has a fixed stirring rod 11, and the mixing rod 11 is fixed. Sliding grooves 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com