Air flow screening device for micron-sized powder materials

A powder material and airflow sieve technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of poor exhaust, airflow screening cannot be carried out normally, and can not achieve good results, so as to improve the anti-airflow The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

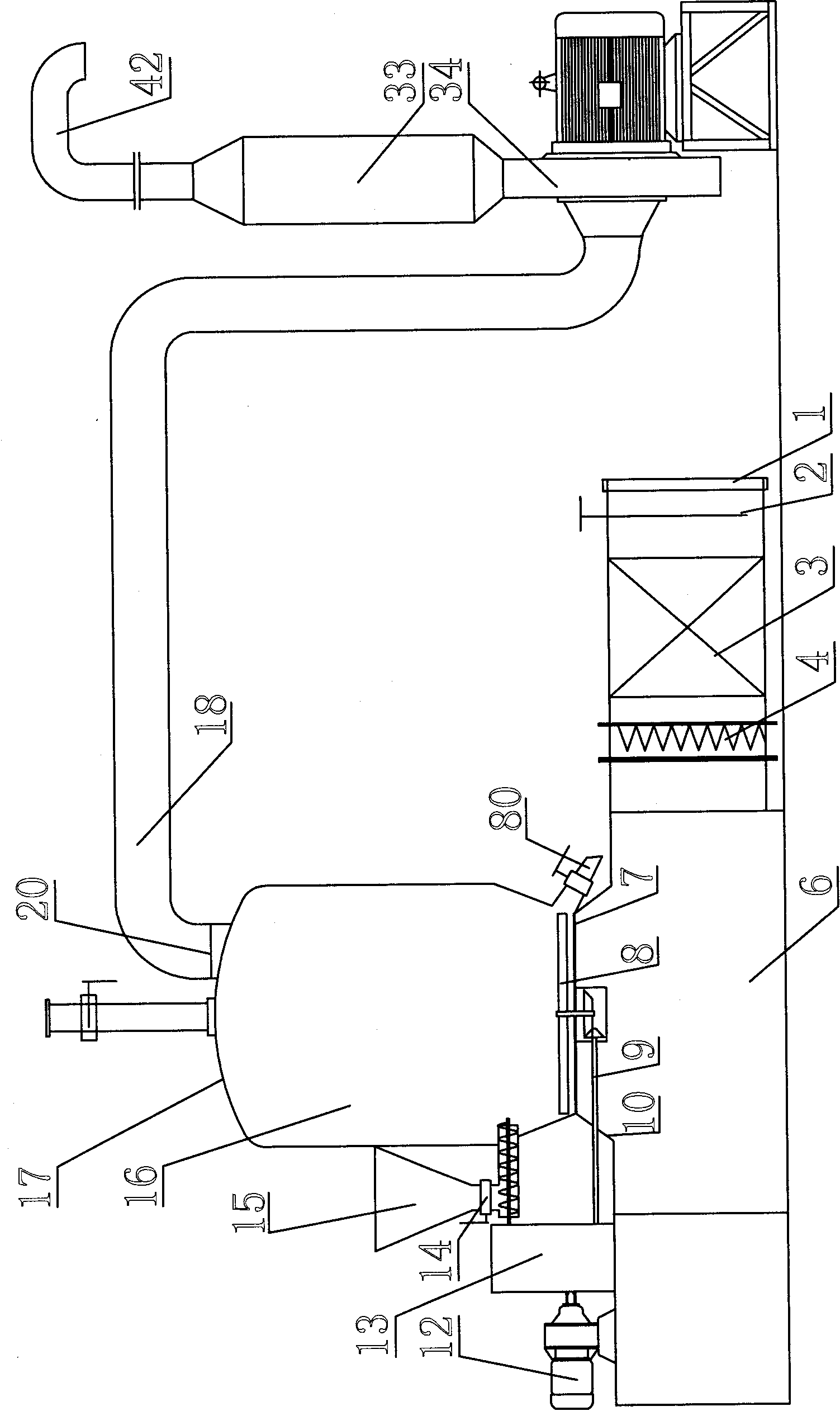

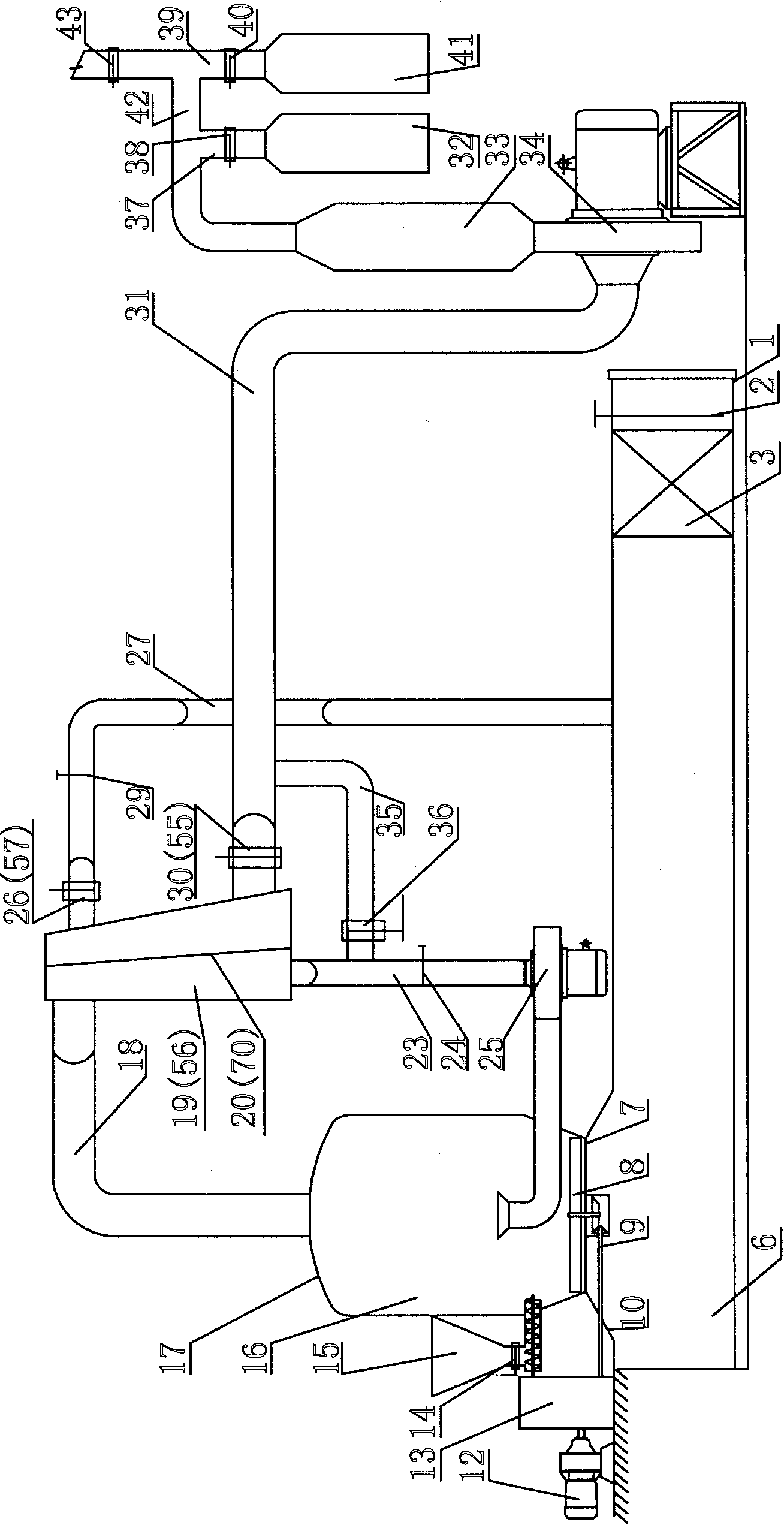

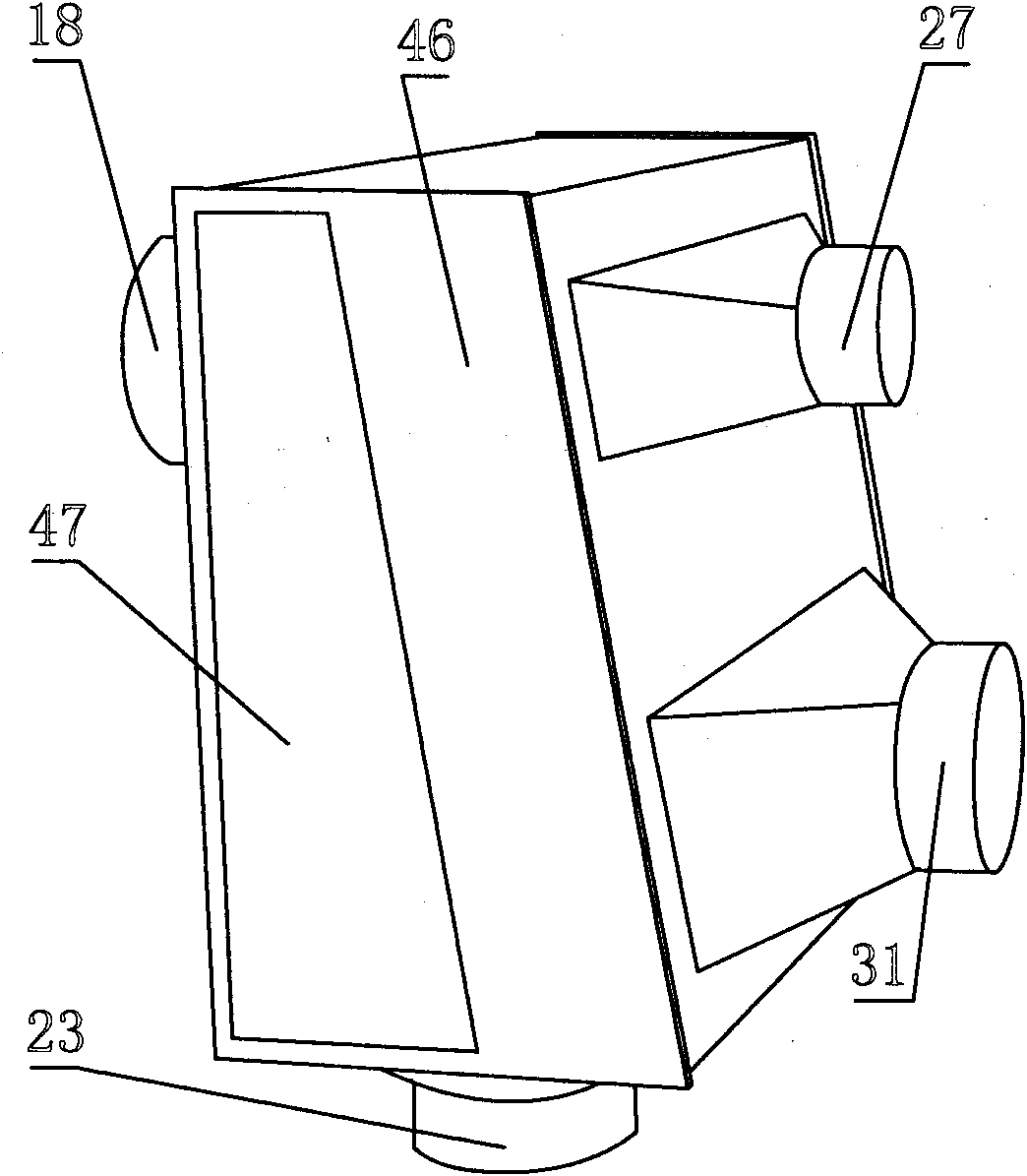

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments. In the embodiments, the sieve plate cage adopts a double sieve plate cage structure. The structure of this device is shown in the attached figure 2 , consisting of the following parts:

[0032] 1) Air intake system: The function of the air intake system is to provide air for the circulating airflow screening machine to make the material form a fluidized state. The bed bottom cavity 6 and the fluidized bed air inlet 10 are composed of the air intake volume, wind speed and the pressure in the screening machine are regulated by the general air regulating gate 2; the air filter 3 is used to purify the air entering the screening machine; the fluidized bed The air inlet 10 is connected with the fluidized bed and the air inlet system.

[0033] 2) Fluidized bed main body: including a fluidized bed main chamber 16, a fluidized bed shell 17, and a metal orifice pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com