Plastic particle screening device

A screening device and technology for plastic granules, applied in the field of plastic processing, can solve the problems of short adhesion time, influence on the quality of plastic products, incomplete screening, etc., and achieve the effect of thorough screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

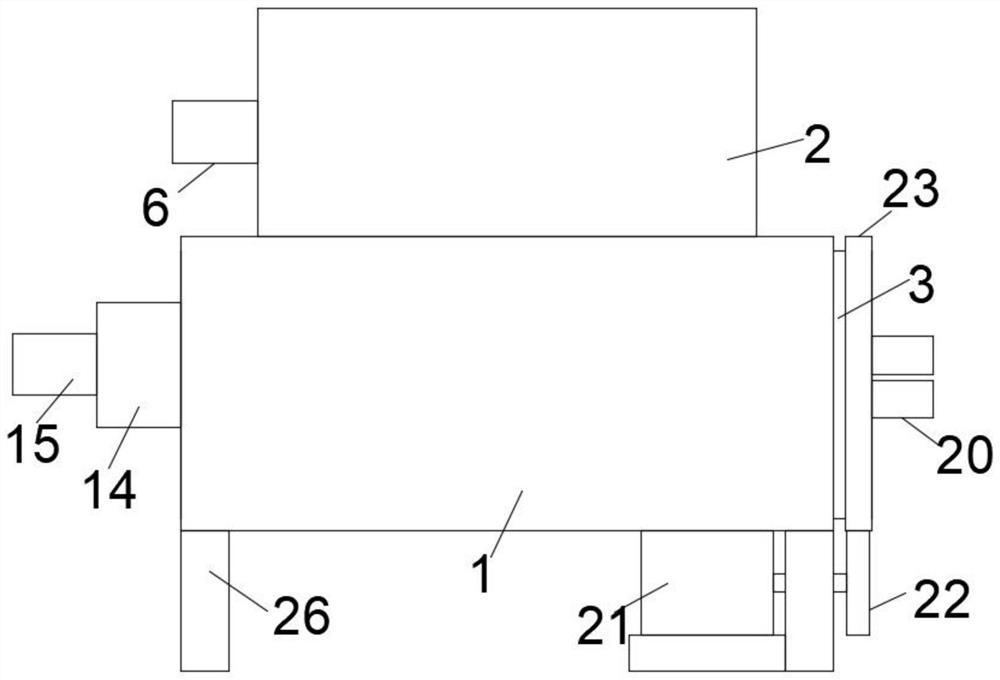

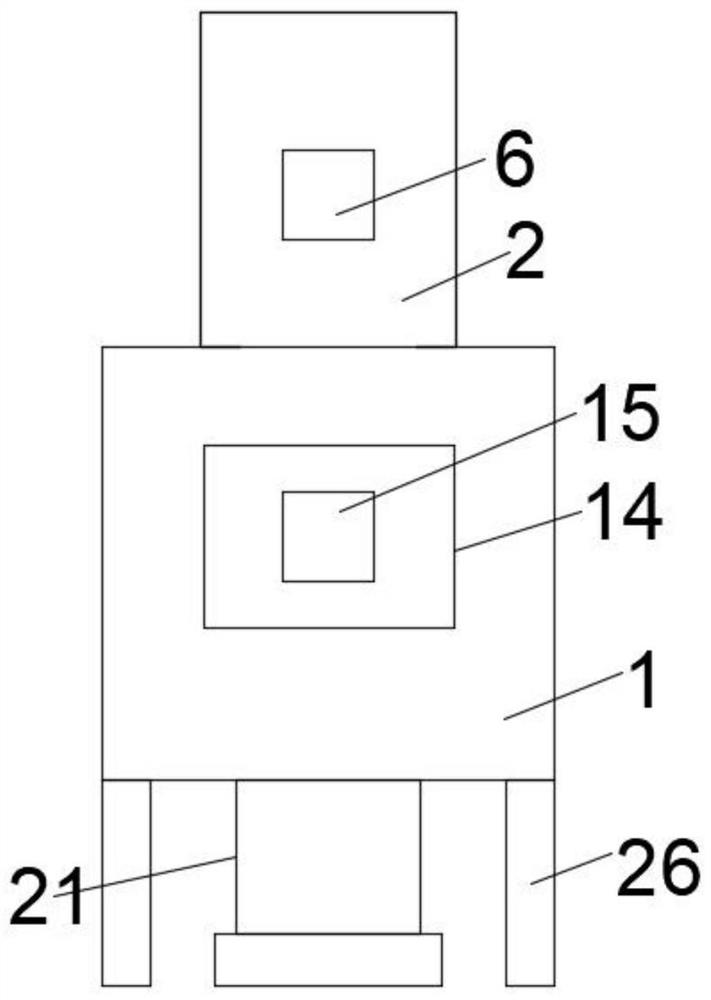

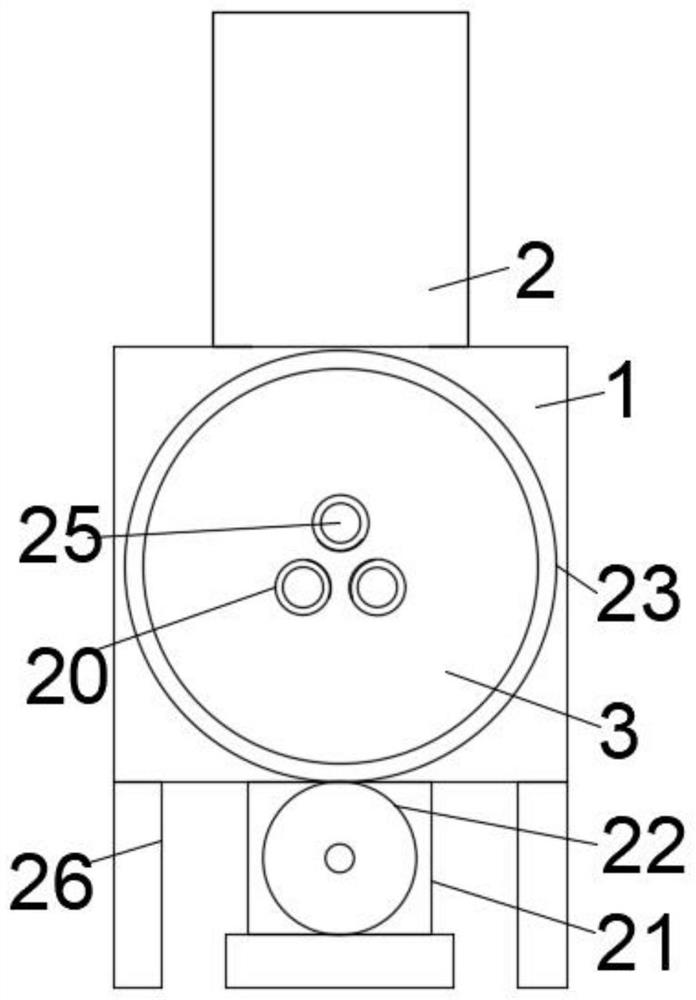

[0026] Embodiment: Pour the plastic granules into the feeding box 2, and pour the first batch of plastic granules in the feeding box 2 into the first screen part 11 through the feeding baffle plate 9 through the segmental feeding device, and pass through the second batch of plastic granules in the feeding box 2 A sieve part 11 filters small plastic particles, and at this time, the small plastic particles sieved into the first sieve part 11 are conveyed to the discharge pipe 20 corresponding to the first sieve part 11 through the conveying device for discharge Collecting, the cylinder 3 is driven to rotate through the transmission device, the first screen part 11 is rotated out directly below the blanking baffle 9, so that the second screen part 12 is located directly below the blanking baffle 9, and the plastic particles at this time enter The upper end of the second screen part 12, through the second screen part 12, the plastic particles are screened again, and the large plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com