Annular movement sieve

A kind of circular motion and screen technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of easy blocking of screen, low screening efficiency, intermittent feeding, etc., to reduce energy consumption, improve screening efficiency and Yield, the effect of reducing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In conjunction with the accompanying drawings and embodiments, the specific structure of the present invention to create a circular moving screen is further described.

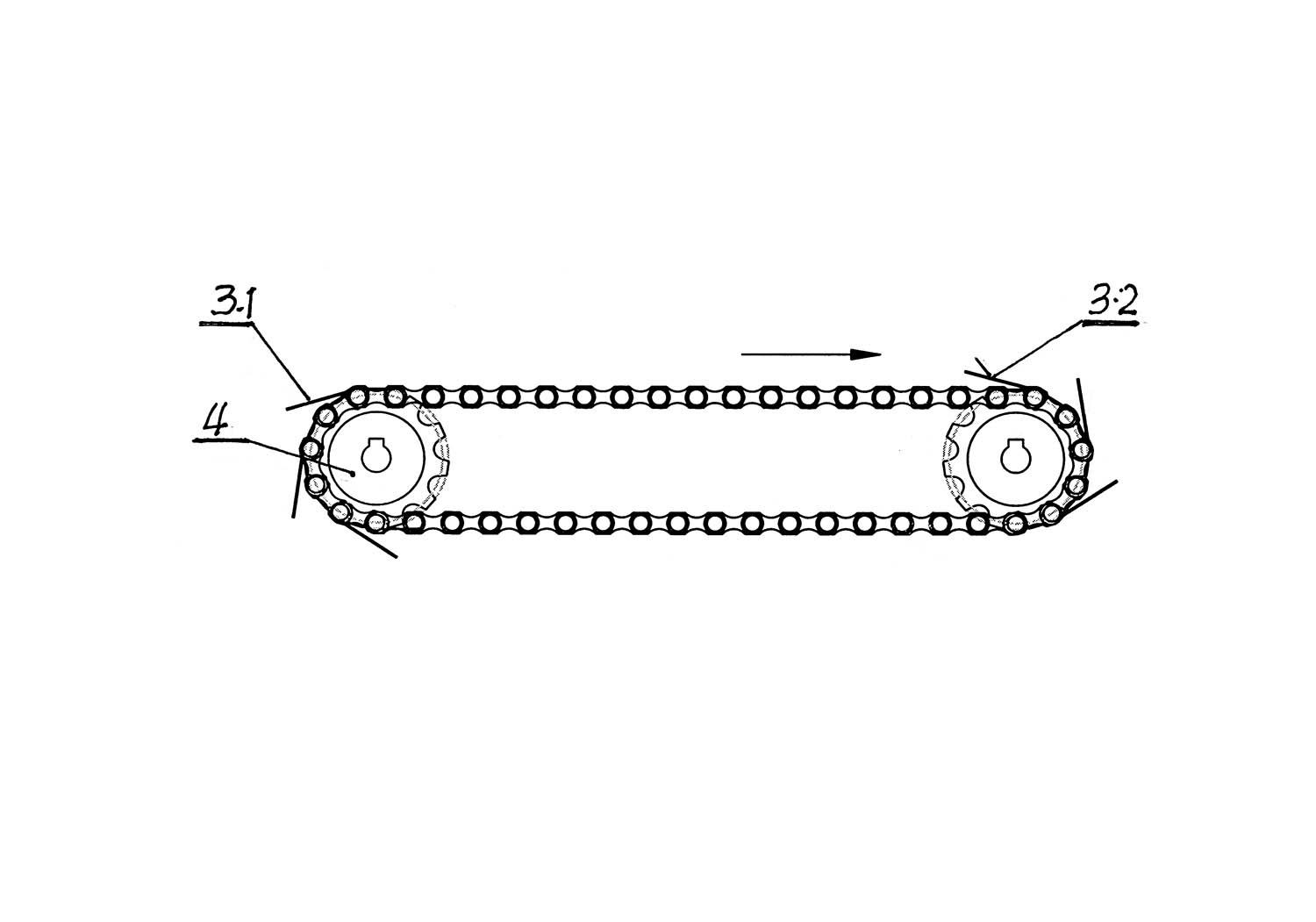

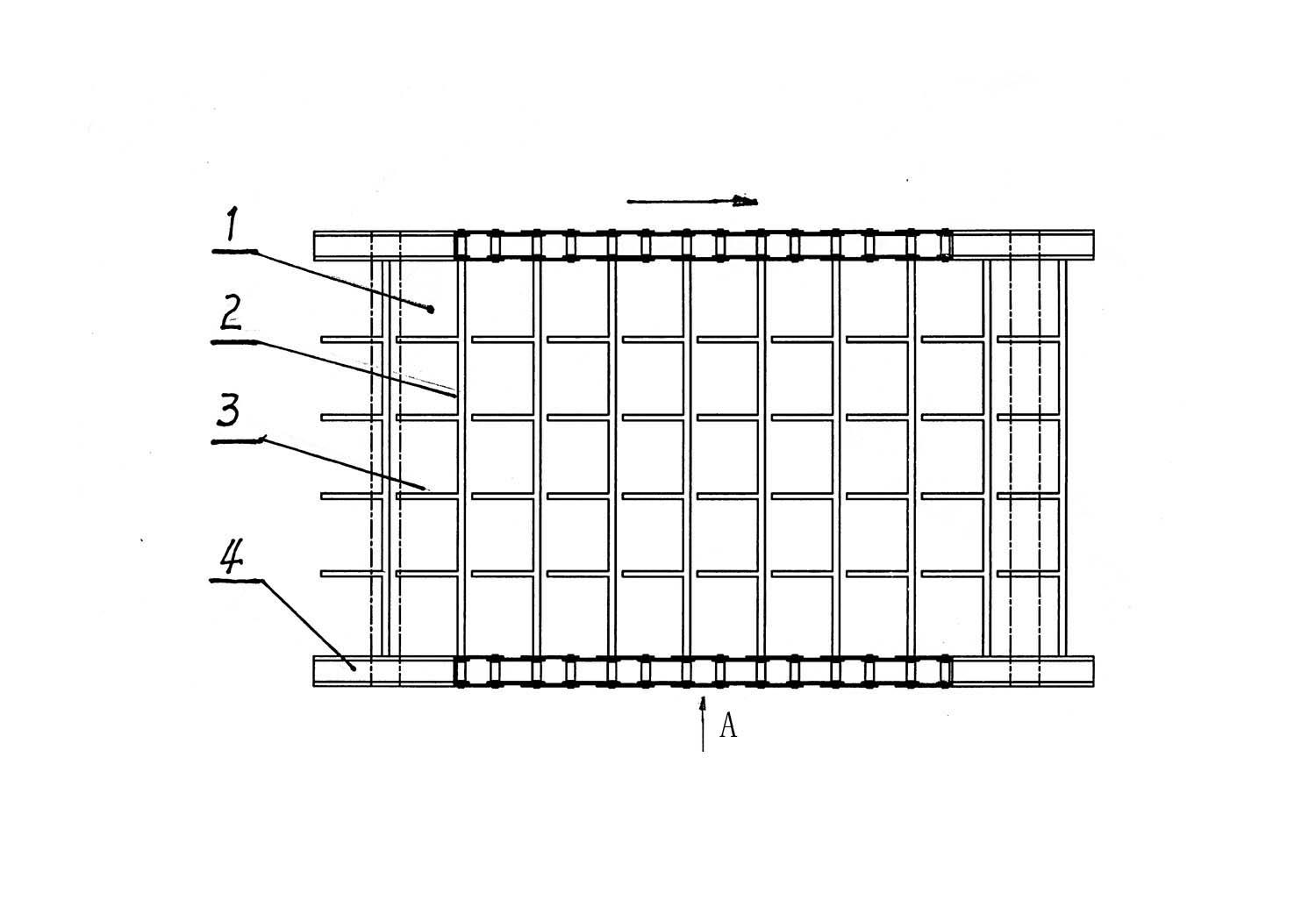

[0010] The present invention creates the embodiment 1 of ring moving sieve, refer to figure 1 , its structure includes: a screen 1, a horizontal grid 2 of the screen, a vertical grid 3, a chain drive mechanism 4, wherein the right end of the vertical grid 3 is in a "T" shape with the horizontal grid 2 adjacent to the right Connect, the other end is a free end, and the two ends of the horizontal grid bar 2 are connected with the inner chain plate of the chain drive mechanism 4.

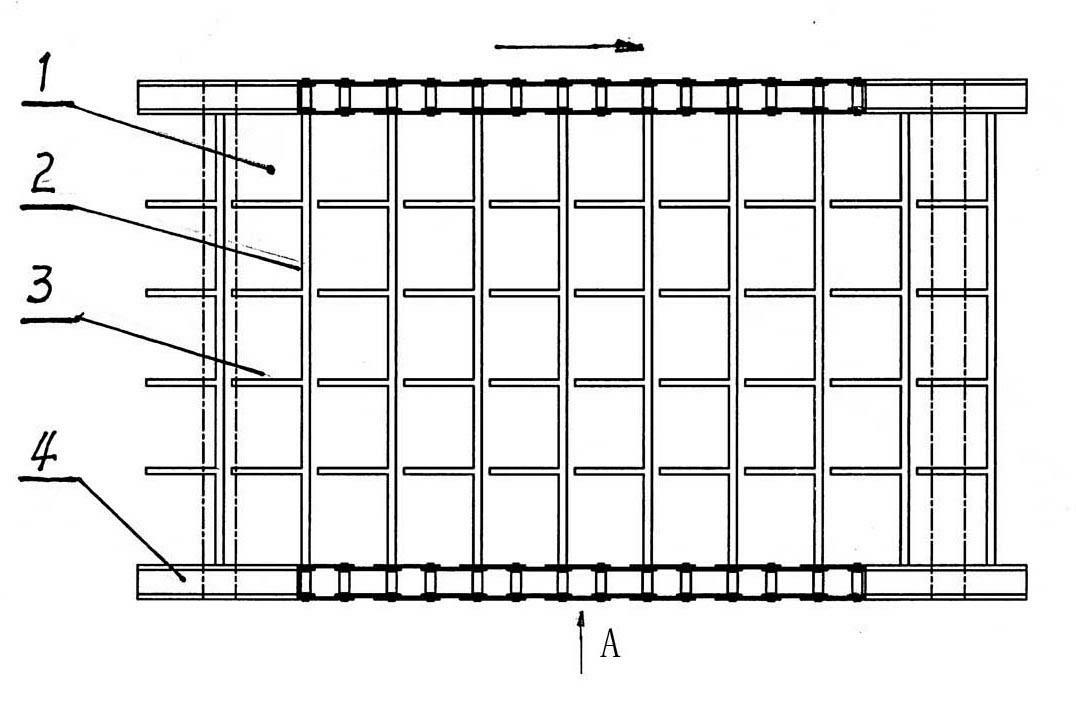

[0011] The present invention creates the embodiment 2 of ring moving sieve, see figure 2 , its structure includes: in the structure of embodiment 1, wherein the vertical grid bar 3 and the horizontal grid bar 2 are connected in an oblique "T" shape, and the free end corresponds to the top of the horizontal grid bar 2 and is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com