Discharging device for screening bright firework beads

A technology of screening and bright beads, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of inability to realize man-machine separation, hidden safety hazards of fireworks bright beads, material extrusion, etc., achieving a high degree of mechatronics, The effect of bright beads sieving evenly and sieving evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

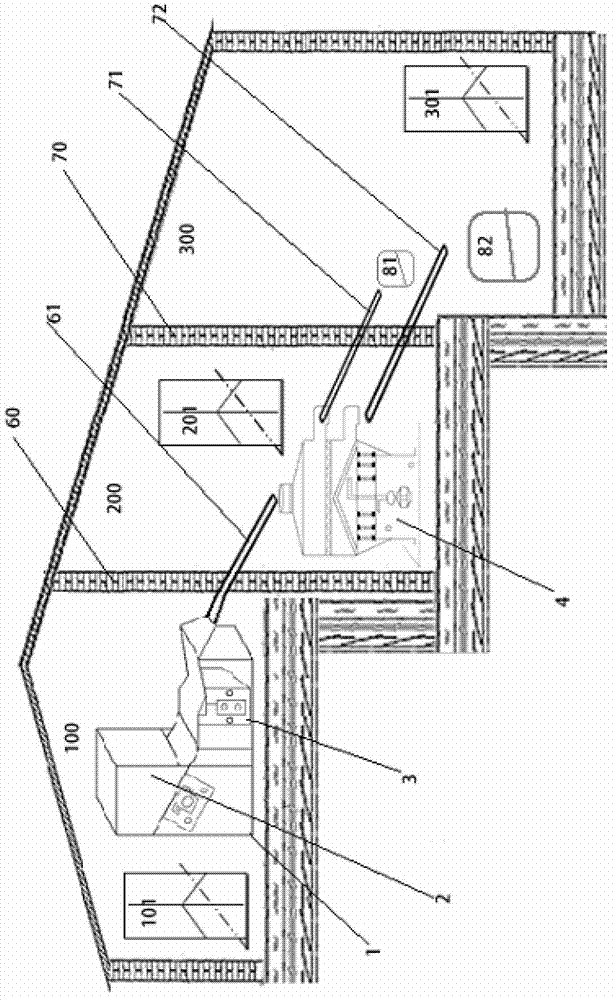

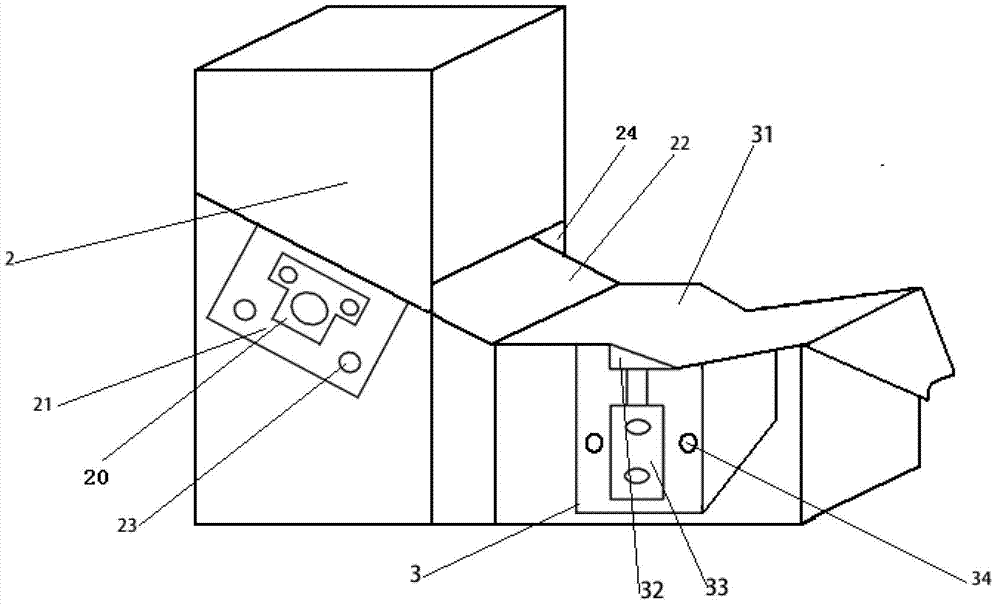

[0032] Referring to accompanying drawing, reflect a kind of specific structure of the present invention, feeding workshop 100 is provided with automatic control door 101 and is provided with explosion-proof separation wall 60 between feeding workshop 100 and explosion-proof screening workshop 200, for the convenience of equipment installation and operation, described There is a drop of more than 1.3 meters between the feeding workshop 100 and the explosion-proof screening workshop 200, and the explosion-proof wall 60 is provided with a material guide trough 61 .

[0033]The feeding workshop 100 is provided with a frame 1, a hopper 2 is arranged above the frame 1, and a shaking cylinder 20 is arranged below the bottom plate 22 of the hopper, and the electromagnetic valve 51 driven by the PLC controller 5 controls the operation of the shaking cylinder 20. The controller 5 controls the blower to start, and opens the solenoid valve 52 of the first ventilation hole 23, and the fan p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com