Fertilizer sampling and screening device

A screening device and fertilizer technology, which is applied in the direction of sampling device, filter screen, solid separation, etc., can solve the problems affecting the detection accuracy and the uneven screening of fertilizers, etc., and achieve the effect of convenient use of equipment and uniform screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

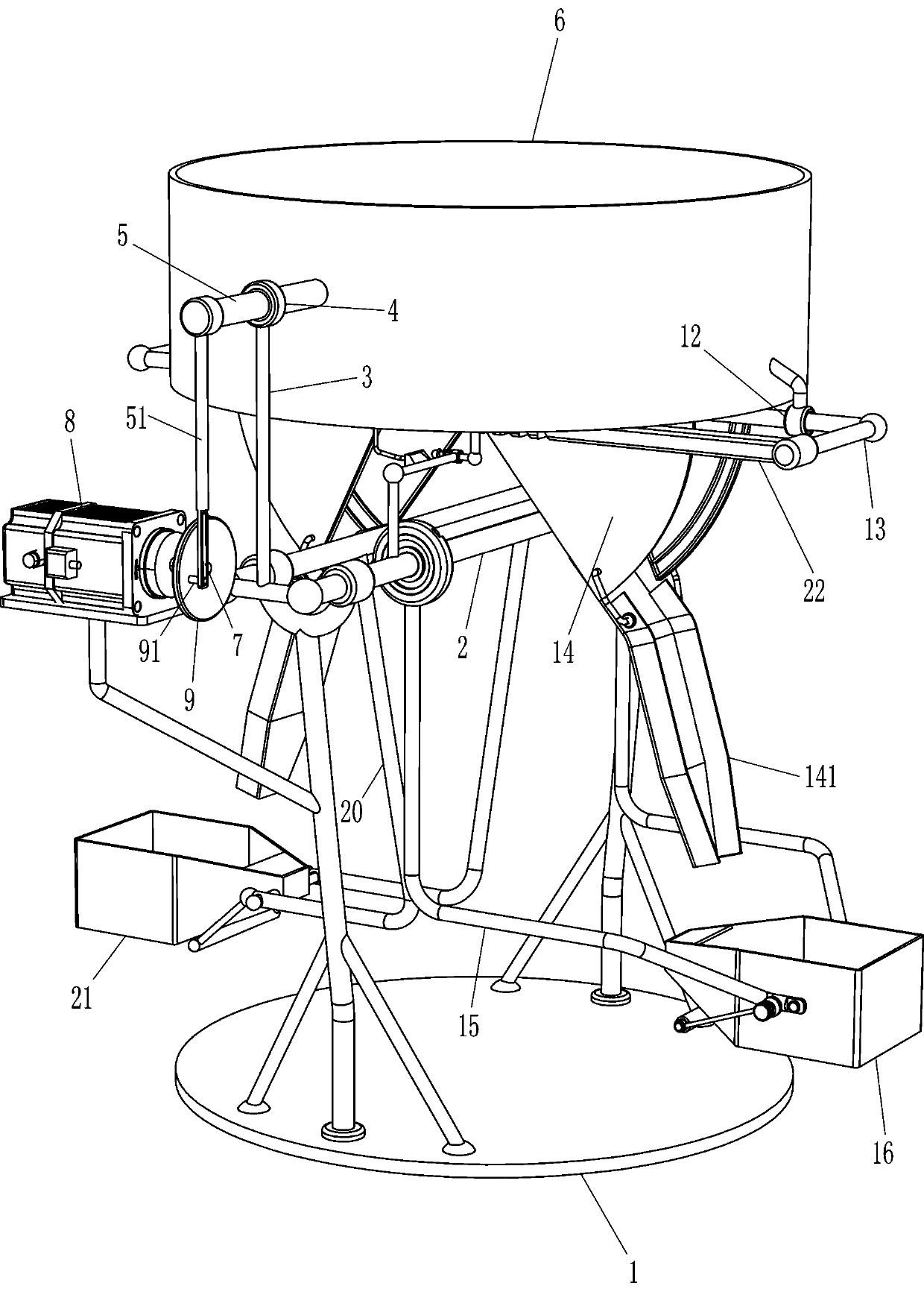

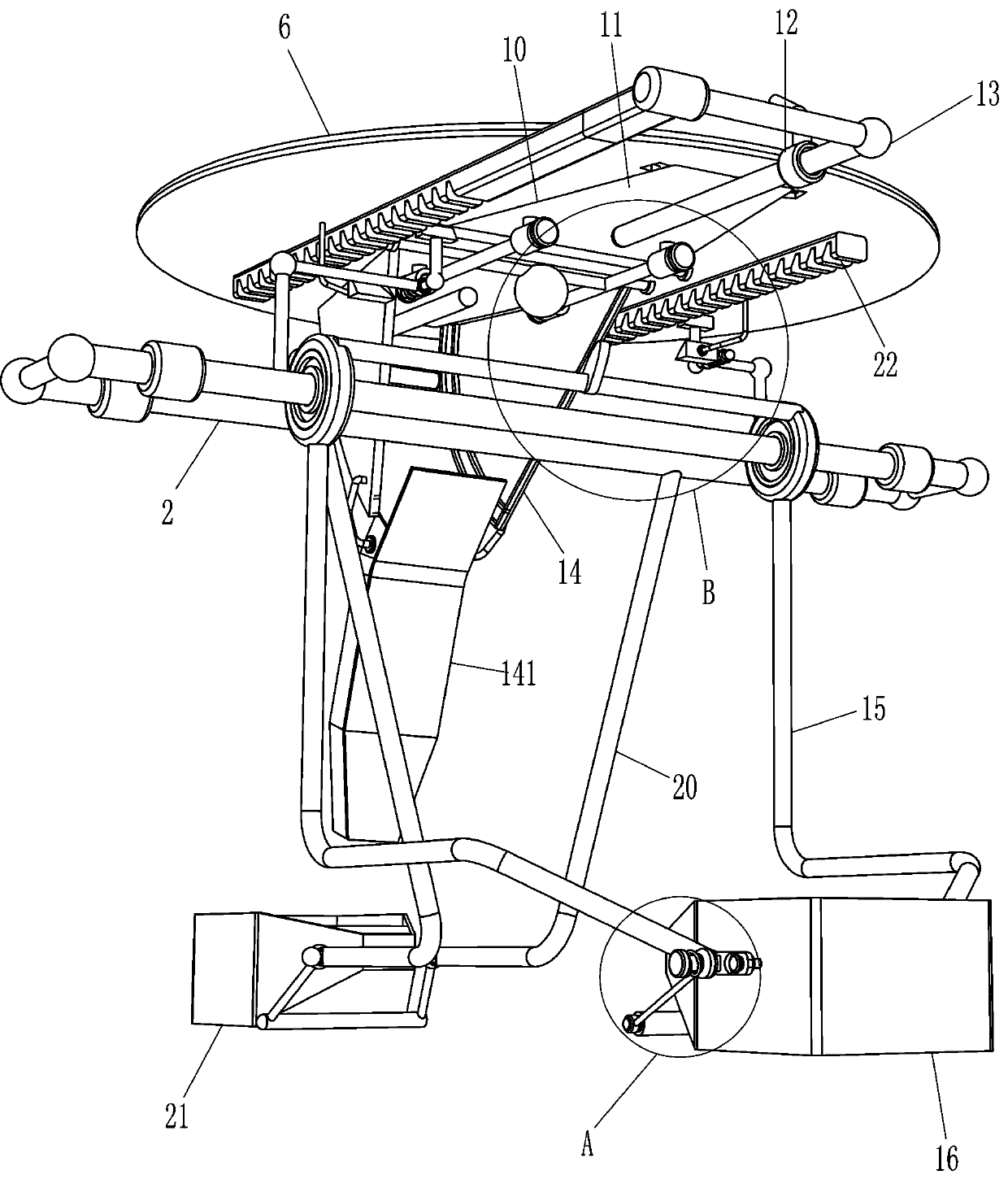

[0020] A fertilizer sampling and screening device, such as Figure 1-3 As shown, it includes a mounting frame 1, a square rod 2, a vertical rod 3, a shaking assembly, a blanking assembly and a collecting assembly. The vertical rods 3 on the front and rear sides are equipped with a rocking assembly that shakes by moving back and forth. The bottom of the rocking assembly is equipped with a blanking assembly that is loaded by rotating. Collect components.

[0021] Such as figure 1 As shown, the rocking assembly includes a first guide sleeve 4, a first slide bar 5, a connecting rod 51, a storage hopper 6, a motor 8, a turntable 9 and a slider 91, and the top ends of the vertical bars 3 are fixed with the first guide by screws. The sleeve 4 and the first guide sleeve 4 are all slidably installed with a first slide bar 5, the inner end of the first slide bar 5 is fixedly connected with a storage hopper 6 through bolts, and a connecting rod 51 is installed at the front end of the f...

Embodiment 2

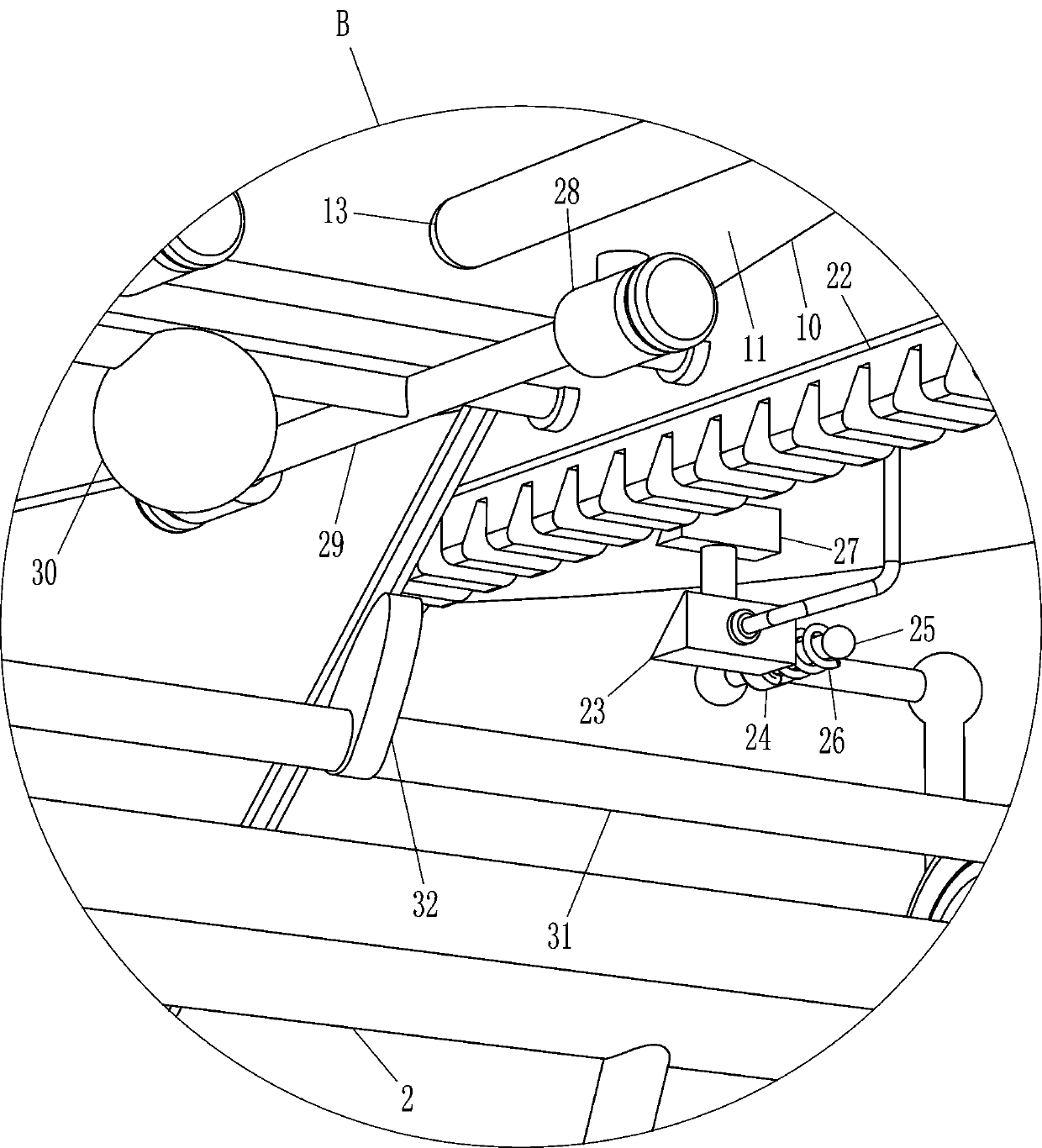

[0029] On the basis of Example 1, such as Figure 4 As shown, in order to better use the device, an automatic unloading assembly is also included. The automatic unloading assembly includes a ratchet 22, a first wedge block 23, a third guide sleeve 24, a second slide bar 25, and a compression spring 26. And the second wedge-shaped block 27, the L-shaped rod 13 outer ends are all connected with ratchet strips 22 by bolts, the left and right sides of the storage hopper 6 bottoms are all welded with the first wedge-shaped block 23, and the front and rear sides on the square bar 2 are all equipped with the first wedge-shaped block 23. Three guide sleeves 24, the second slide bar 25 is all slidably installed in the third guide sleeve 24, and the compression spring 26 is connected between the second slide bar 25 and the third guide sleeve 24, and the second slide bar 25 inner ends are A second wedge block 27 is installed.

[0030] Such as Figure 4 As shown, in order to use the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com