Material jamming preventing rotary screen

A rotary sieve and material jam prevention technology, which is applied in the direction of filter screen, rotation vibration suppression, grille, etc., can solve the problems that fine materials cannot be screened out, the noise of screening operation is large, and the screening efficiency is reduced, so as to prevent jamming into the sieve hole, the screening speed is fast, and the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

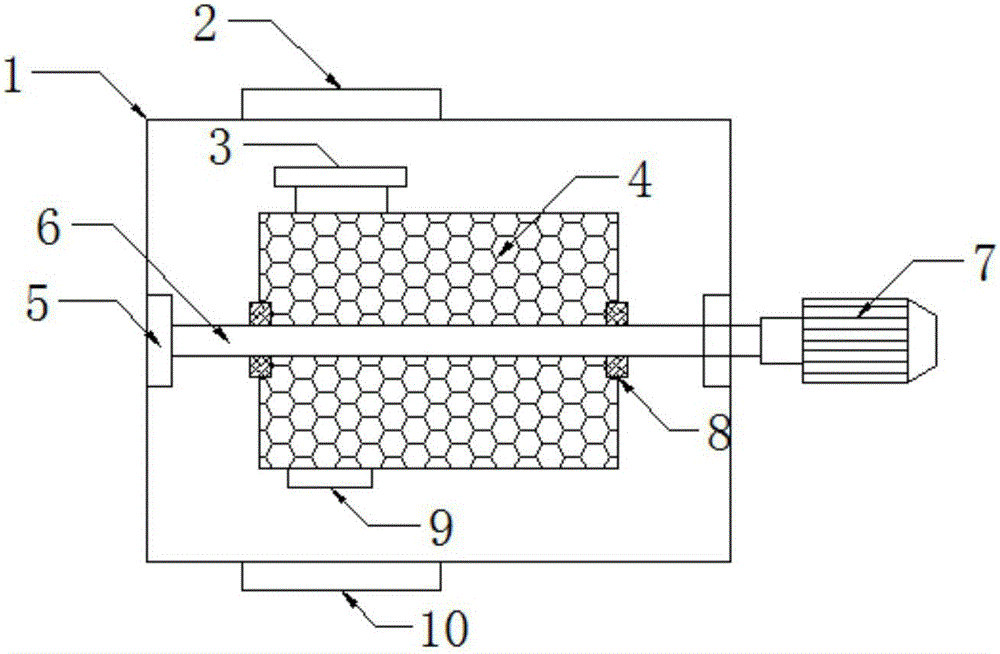

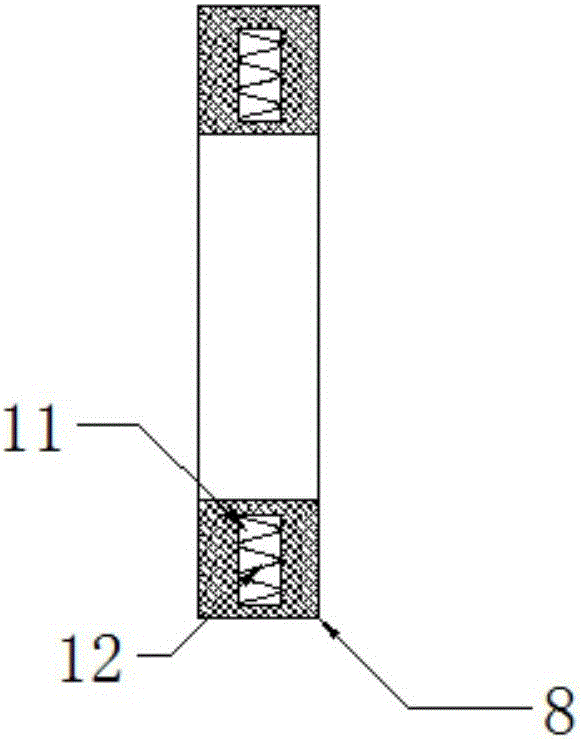

[0017] Such as Figure 1-2 As shown, an anti-jamming rotary screen of the present invention includes a casing 1, a feed port 2, a screen opening 3, a rotary screen cylinder 4, a shockproof bearing 5, a transmission shaft 6, a servo motor 7, a shock absorbing ring pad 8, Vibration generator 9, discharge port 10, shock absorbing cavity 11, shock absorbing spring 12;

[0018] The top of the shell 1 is provided with a feed port 2, and the bottom end is provided with a discharge port 10, and the shell 1 is provided with a coaxial drive shaft 6, which is assembled in the shell 1 through a shockproof bearing 5, and the end is passed through The shaft coupling is fixed on the output shaft of the servo motor 7;

[0019] The rotary screen cylinder 4 is fixed on the transmission shaft 6 and can rotate with the rotation of the transmission shaft 6. The rotary screen cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com