Coal slurry sieving equipment

A coal slurry screening equipment and coal slurry technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of poor economy and slow screening speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

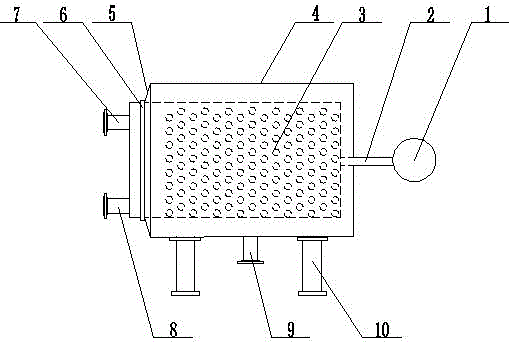

[0007] refer to figure 1 As follows: coal slurry screening equipment, the motor 1 is connected to the screen cylinder 3 through the transmission shaft 2, there is no screen hole on the left side of the outer surface of the screen cylinder 3, and the screen holes are evenly distributed on the rest of the outer surface of the screen cylinder 3, and the screen cylinder 3 is connected to the fine The central axis of the particle coal slurry collection cylinder 4 is on a straight line, the fine particle coal slurry collection cylinder 4 is set outside the screen cylinder 3, the left side of the fine particle coal slurry collection cylinder 4 sticks out of the screen cylinder 3, and the fine particle coal slurry collection cylinder 4. An anti-leakage plate 5 is arranged on the left side of the anti-leakage plate 5. A sealing ring 6 is arranged on the left side of the anti-leakage plate 5 to prevent the coal slurry from leaking. There is a fine-grained coal slurry outlet 9 at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com