Particle material sieving machine

A granular material and screening machine technology, which is applied in the direction of filtering, solid separation, grille, etc., can solve the problems of slow screening speed, unsatisfactory screening effect and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

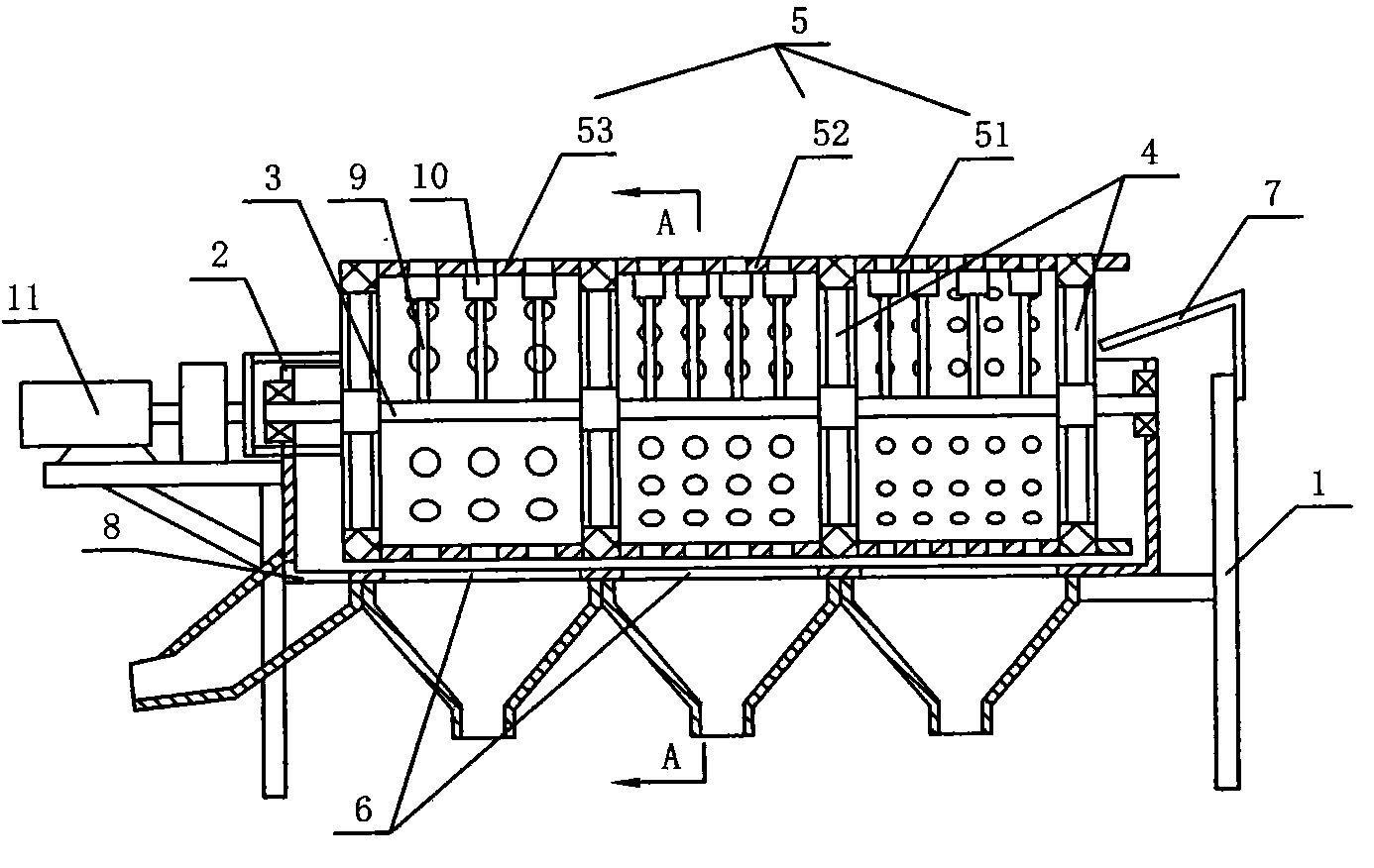

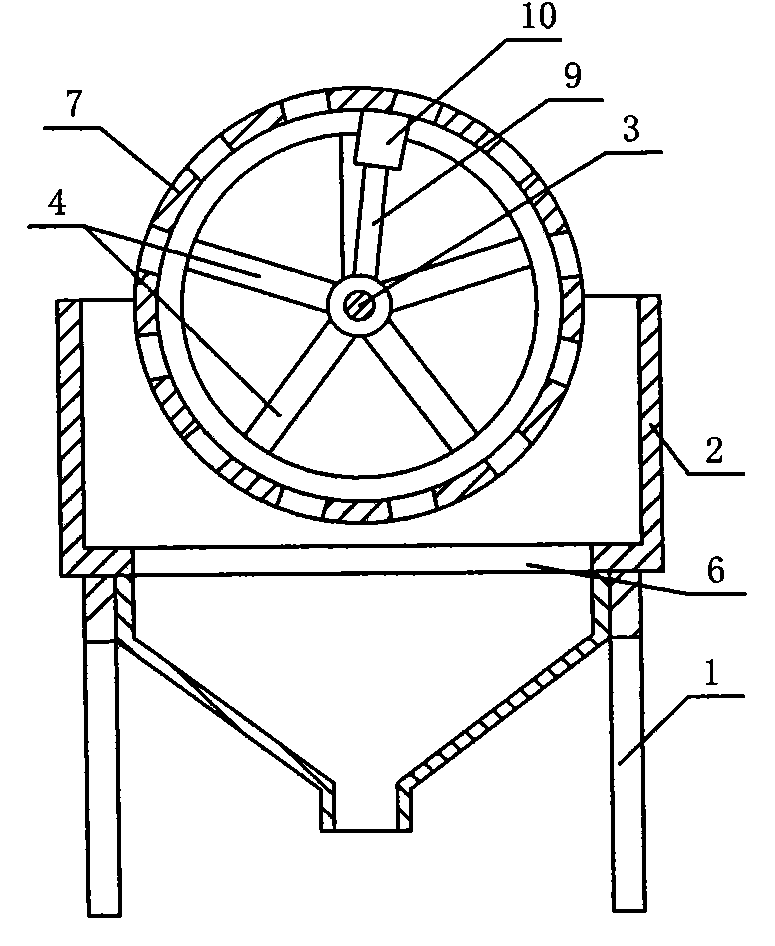

[0011] The present invention distinguishes the front and rear according to the direction of the granular material, with the feeding direction as the front and the discharging direction as the rear. Such as figure 1 and figure 2 As shown, it includes a frame 1, a material box 2 and a main shaft 3 connected to the material box 2 are housed on the frame 1, and the main shaft 3 is rotatably connected with a motor 11 driven by a rotating sleeve and a support arm 4 arranged in a divergent shape. And the sieve drum 5 with both ends open, the motor 10 is installed on the rear portion of the frame 1, the main shaft 3 and the sieve drum 5 are arranged obliquely downward from front to back, and the cylinder wall of the sieve drum 5 is provided with screen holes, and the screen drum 5 From front to back, it is divided into fine sieve section 51, middle sieve section 52 and coarse sieve section 53. The sieve hole on the fine sieve section 51 is smaller than the sieve hole of middle sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com