Material screening and collecting device based on sample preparation and detection

A collection device and material sieve technology, applied in measuring devices, sieves, sampling, etc., can solve the problems of taking up large space and not suitable for small-scale sample preparation and sieving, and achieve fast sieving speed, light weight and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

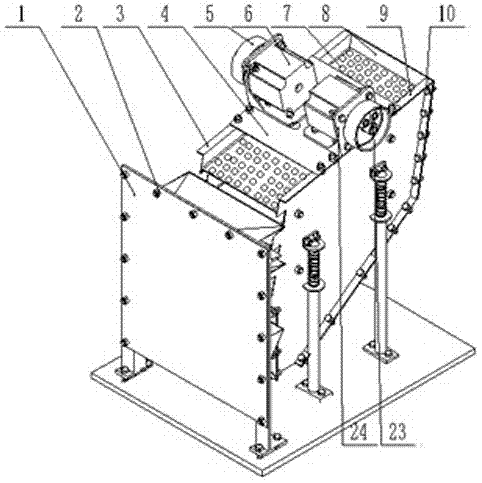

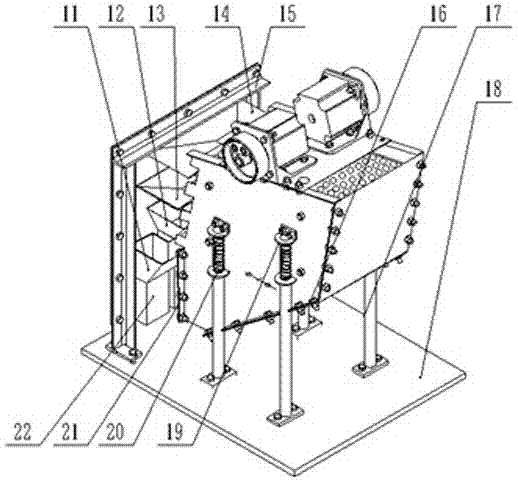

[0024] Such as figure 1 , figure 2 As shown, a material screening and collecting device based on sample preparation and detection in the present invention includes a linear vibrating screen mechanism and a sample collection mechanism, and the sample collection mechanism is arranged behind the linear vibrating The structure of the linear vibrating screen mechanism is as follows: including a right side plate 3, an upper plate 4, a polarizing wheel 5, a motor 6, a screen 7, a front side plate 8, a left side plate 9, a bottom plate 16, a support rod 17. Fixed seat 18, spring support 19, spring 20, rear plate 21, eccentric block 23 and motor seat plate 24, the right side plate 3, left side plate 9, front side plate 8 and rear plate 21 are matched and assembled with each other It forms a cylindrical structure with closed surroundings and open upper and lower ends. The bottom plate 16 is obliquely arranged at the bottom of the cylindrical structure. The lower end of 8 is correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com