Sand sieving machine for constructional engineering

A technology of construction engineering and sand screening machine, applied in the direction of screen, solid separation, grille, etc., can solve the problems of affecting work efficiency and project progress, reducing the service life of screen mesh, low sand screening efficiency, etc., and achieving high work efficiency , the effect of increasing the service life and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

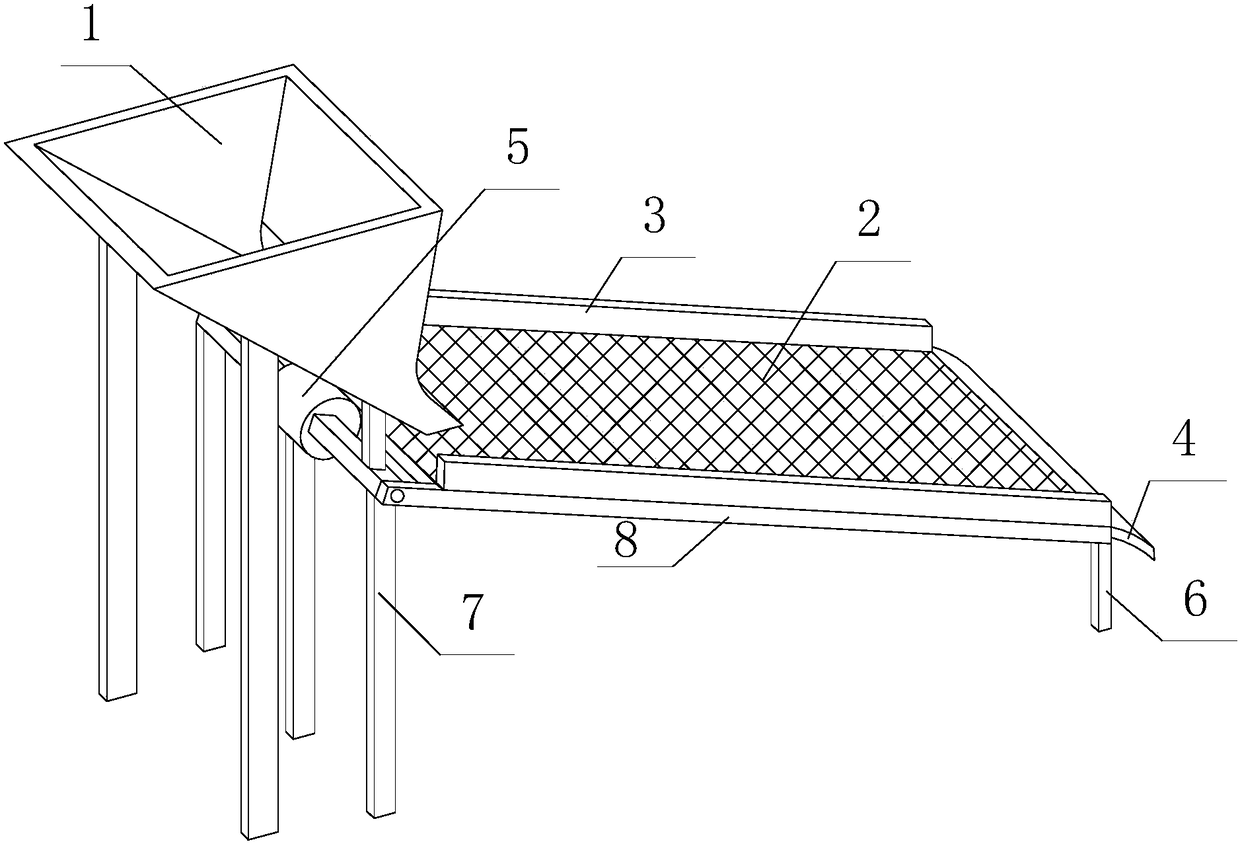

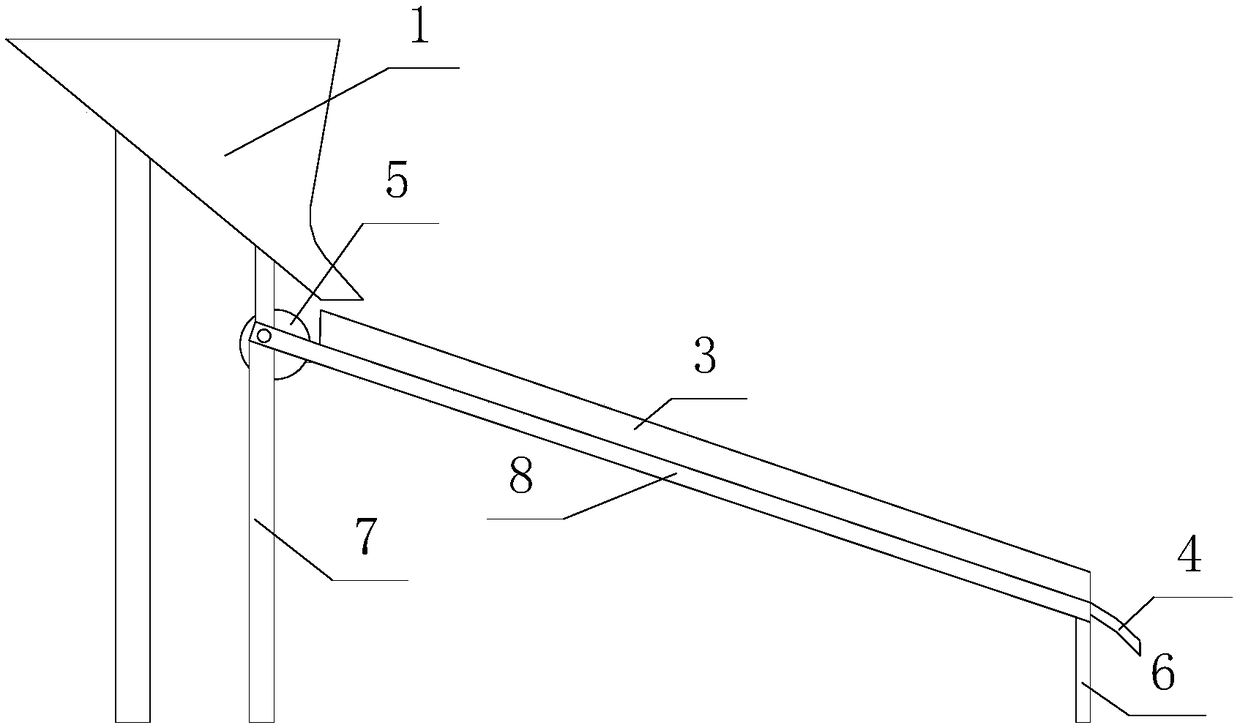

[0016] refer to Figure 1 to Figure 2 , the present invention provides a sand screening machine for construction engineering, which includes a telescopic rod 6, a frame 7 and a frame 8, the frame 8 is arranged obliquely, the surface of the frame 8 is provided with a screen 2, and the left end of the frame 8 is hinged on the frame 7 The upper end of the telescopic rod 6 is located on the lower side of the right end of the frame 8, the upper end of the frame 7 is provided with a feed hopper 1 and a vibration motor 5, the vibration motor 5 is located below the feed hopper 1, and the vibration motor 5 is located on the screen 2, the left and right end surfaces of the feed hopper 1 are inclined planes and curved surfaces respectively, and the discharge port of the feed hopper 1 is arranged obliquely, which can reduce the impact of sand and gravel materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com