Efficient tea screening device

A screening device and high-efficiency technology, applied in the field of high-efficiency tea screening devices, can solve the problems of uneven distribution of tea screening size, poor tea separation effect, low screening efficiency, etc. Small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

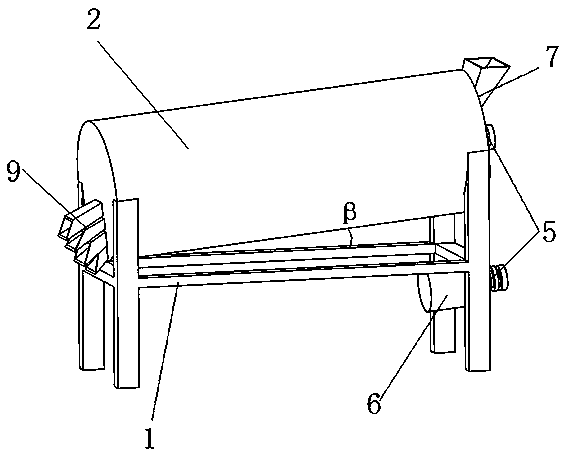

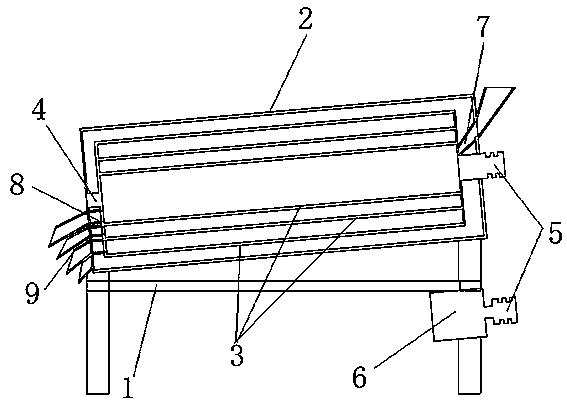

[0028] Such as Figure 1~2 As shown, a high-efficiency tea screening device includes a frame 1, an inclined screening cylinder 2, and a plurality of screen cylinders 3 that are installed in the screening cylinder 2 and coaxially arranged in sequence, and are connected inside and outside. The screening cylinder 2 is fixedly mounted on the frame 1, and one end of the screen cylinder 3 is rotatably mounted on the frame 1 through a rotating shaft 4, and the rotating shaft 4 is rotatably mounted in the center of the screening cylinder 2. At the axis, the other end is connected with a drive motor 6 through a belt (not shown in the figure) and a pulley 5. The drive motor 6 is installed on the frame 1, and the multi-layered screen cylinder 3 has a mesh aperture from the inside to the outside. Decrease in turn, the upper end of the innermost screen cylinder 3 is provided with a feed port 7 leading to the outside of the screen cylinder 2, and the bottom of the screen cylinder 2 and each...

Embodiment 2

[0036] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0037] In this embodiment, at one end of the screen cylinder 3 , only the innermost screen cylinder 3 is fixedly connected to the rotating shaft 4 .

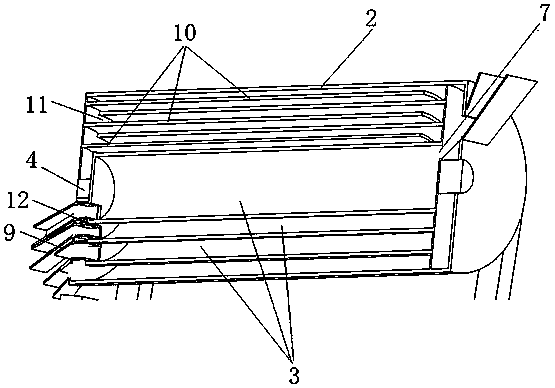

[0038] Such as image 3 As shown, each sieve cylinder 3 is provided with a baffle 10 fixedly connected to the sieve cylinder 2 to prevent the tea leaves from falling back into the relatively inner sieve cylinder 3 when they are turned over in the sieve cylinder 3. Screening efficiency.

[0039] Such as Figure 3~4 As shown, in order to facilitate the installation of the baffle plate 10, one end of the screen cylinder 3 is all fixed on the rotating shaft 4, and the other end is a through-hole 11 extending along its axial direction except for the innermost screen cylinder 3. , the baffle plate 10 extends into the screen cylinder 3 along the through opening 11, one end of the baffle plate 10 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com