Centrifugal grinding device for obtaining survival single cells

A grinding device and single-cell technology, applied in centrifuges and other directions, can solve the problems of inconvenient preparation of single-cell suspension, inability to obtain more viable single cells, etc., and achieve improved function and practicability, short tissue refinement cycle, and disorder. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

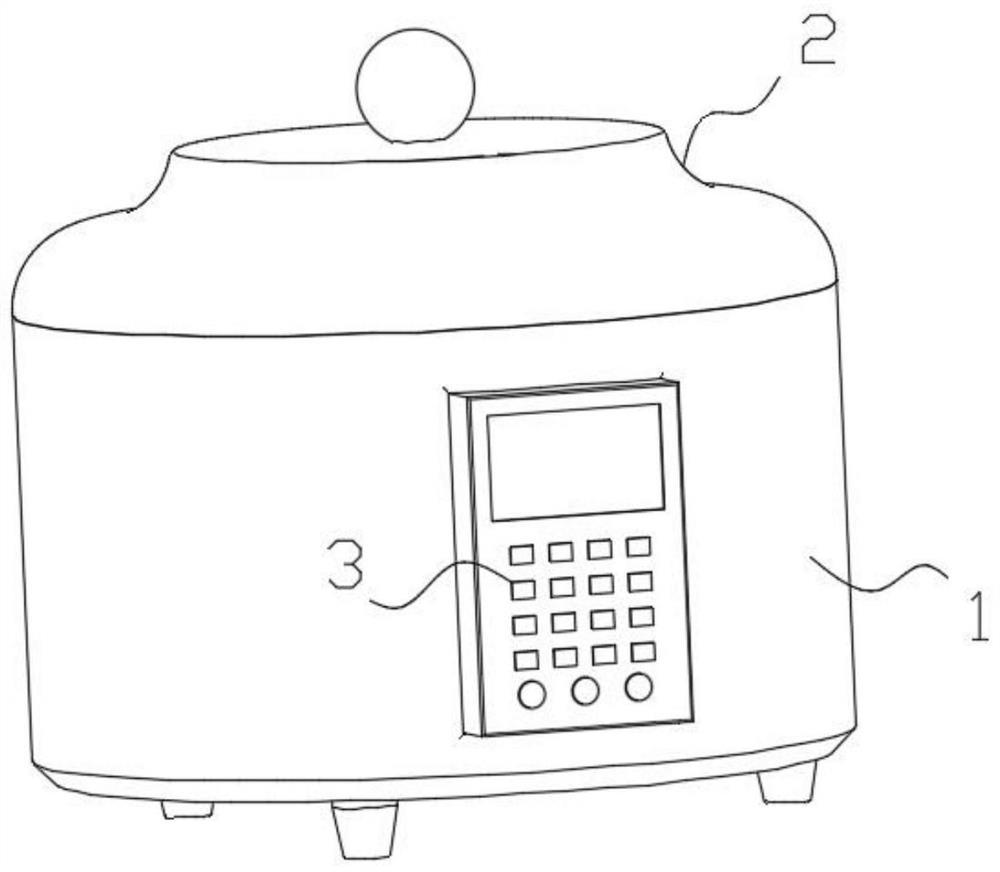

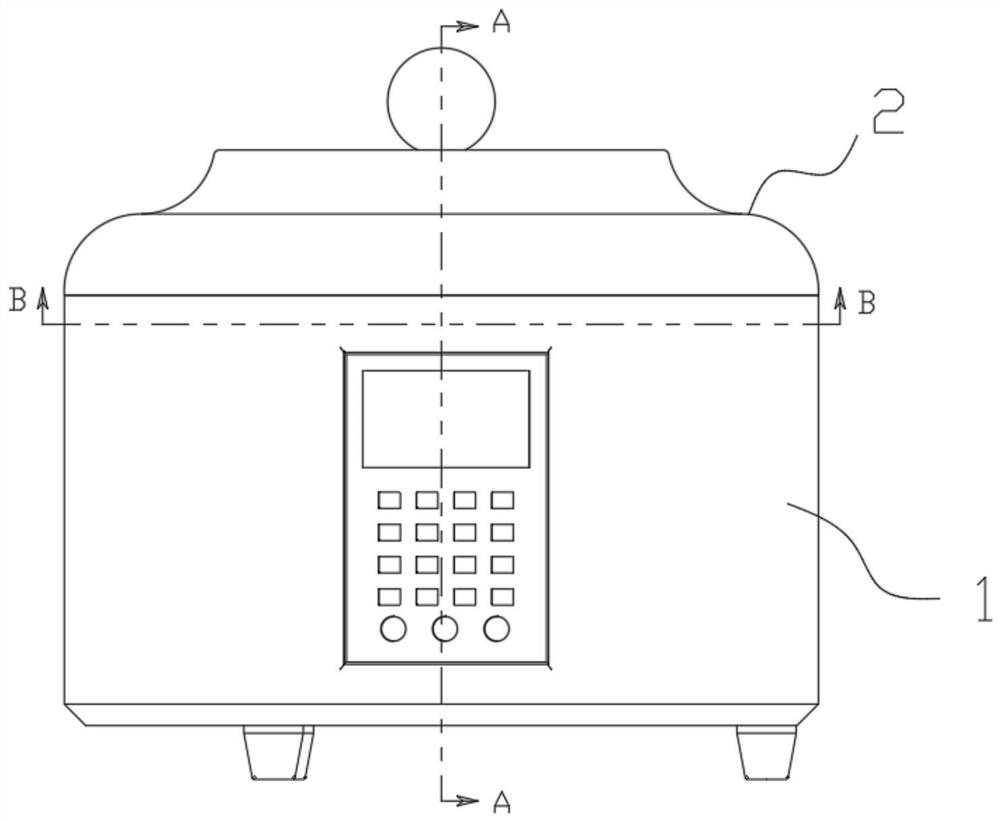

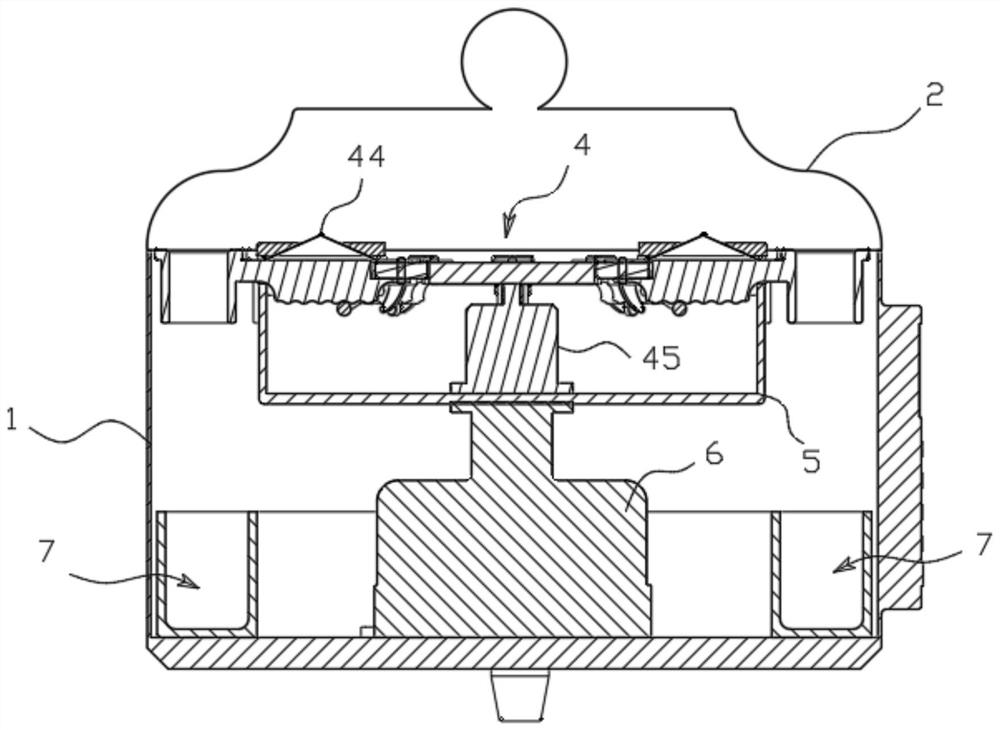

[0035] Attached to the manual Figure 1-Figure 5 The shown centrifugal grinding device for obtaining viable single cells includes a centrifugal unit and an oscillating grinding unit 4, the oscillating grinding unit 4 is rotatably arranged on the centrifugal unit, and the oscillating grinding unit 4 includes a turntable 41. The lower surface of the turntable 41 is uniformly provided with a plurality of chutes for accommodating the oscillating mechanism 42 along the diametrical center. One end of the center of the circle abuts on the outer side wall of the driving disk 43, and the outer side wall of the driving disk 43 is formed by a plurality of smoothly connected outer convex and inner concave arcs with equal or unequal diameters. The center of the lower surface of the disk 43 is in driving connection with the first driver 45 ; the lower surface of the turntable 41 is also provided with a return mechanism 46 that pushes the oscillating mechanism 42 to abut and contact the driv...

Embodiment 2

[0038] On the basis of Embodiment 1, this embodiment further optimizes the oscillating mechanism 42. The oscillating mechanism 42 includes a guide rail 421 slidably arranged in the chute, and an end of the guide rail 421 close to the drive plate 43 is provided with a The other end of the first fixed pulley 422 and the guide rail 421 is fixedly connected with a centrifuge tube rack 423 for mounting the centrifuge tube 424 . The beneficial effect of adopting the above structure is that: the first fixed pulley 422 abuts against the driving disc 43 and rolls, which can greatly reduce the friction force during the oscillation process, reduce the internal resistance and friction loss, improve the stability, and can The service life is prolonged; in addition, the guide rail 421 is embedded with a chute and is arranged radially symmetrically with the center of the turntable 41 as the center point, which can realize the grinding and vibration treatment of multiple tissue blocks at the s...

Embodiment 3

[0040] In order to further improve the reliability of the operation of the oscillating mechanism 42 , in conjunction with the instructions attached Figure 6-Figure 8 As shown, the return mechanism 46 includes a first fixing base 461 fixedly connected to the lower surface of the turntable 41 , a second fixing base 464 fixedly connected to the guide rail 421 , and the second fixing base 464 is fixed on the upper An anti-roll bar 463 is connected, and a spring 462 is sleeved on the anti-roll bar 463 , and both ends of the spring 462 are fixedly connected to the first fixing seat 461 and the second fixing seat 464 respectively. Since the first fixing seat 461 and the second fixing seat 464 are respectively fixed on the turntable 41 and the guide rail 421 , the spring 462 in the pull-rope state pushes the guide rail 421 away from the center of the turntable 41 under the action of the driving disc 43 , and can withstand the pulling force of the spring 462 after pushing the guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com