Method for treating coking wastewater by using industrial pulverized coke instead of active carbon

A technology of coking wastewater and activated carbon, which is applied in the direction of adsorption water/sewage treatment, etc., can solve the problems of no harmless degradation, high cost, large consumption of chemicals, etc., and achieves significant wastewater treatment effect, low maintenance cost, no two The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific implementation mode 1 - static batch processing:

[0013] Take 3000mL of secondary coking waste water after coking biological dephenolization, acidify with 5%-10%wt sulfuric acid or industrial waste sulfuric acid, adjust its pH value to 2.0, and add 300g of coke powder tank with a particle size of 10-80 mesh , after stirring for 2 hours, let stand for 1.5-2.0 hours, draw out the supernatant after the precipitation is completed, and obtain qualified effluent that meets the national first-level discharge standard (GB8978-96) or industrial reuse water quality indicators.

[0014] Put the above-mentioned wet industrial coke powder adsorbed with waste water pollutants in a muffle furnace or tube furnace under the protection of vacuum or nitrogen atmosphere, under continuous vacuum (vacuum degree is 720-750mmHg) or flowing nitrogen (20-40L N 2 / h·kg wet coke powder) environment, the temperature is raised to 300-450°C under oxygen barrier, heated for 4-8 hours, and th...

specific Embodiment approach 2—

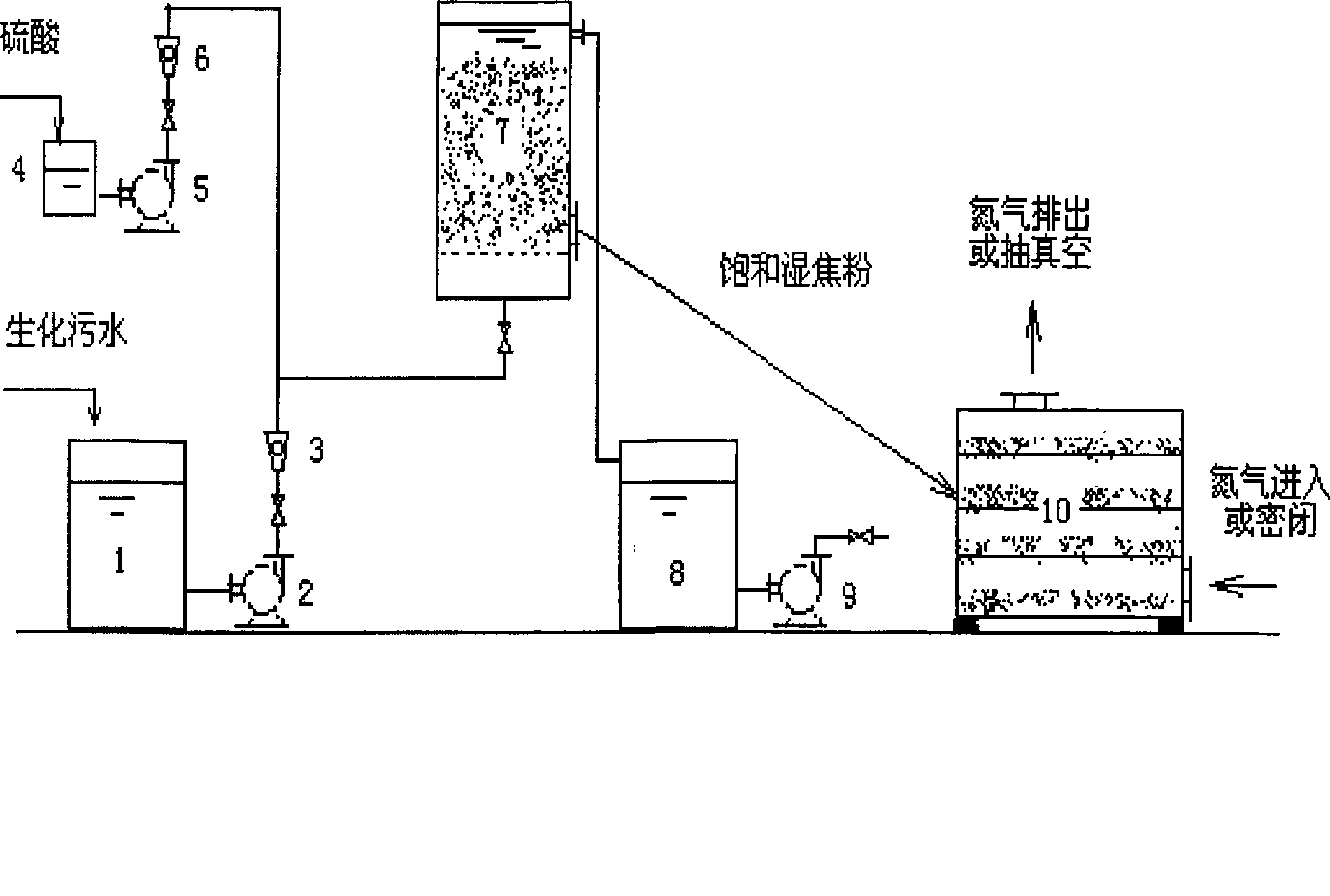

[0016] Embodiment 2——continuous dynamic processing:

[0017] As shown in the accompanying drawing, in the wastewater pool (1) is secondary coking wastewater after coking biological dephenolization, which is continuously acidified by using 5% to 10% dilute sulfuric acid or industrial waste sulfuric acid to adjust the pH of the wastewater to 3.0, and pump ( 2) After being lifted and pressurized and measured by the flow meter (3), it is sent to the bottom of the industrial coke powder adsorption tower (4) for adsorption treatment. The apparent residence time of the wastewater in the adsorption tower is 4 to 6 hours. The waste water is collected from the upper part of the adsorption tower and flows into the clear water pool (5). Wherein the flow after flow meter (3) metering is 500L / h, and the fresh coke powder about 1000Kg that comes by coking plant is housed in the industrial coke powder adsorption tower (4).

[0018] Adsorbed saturated wet industrial coke powder is regenerated...

specific Embodiment approach 3—

[0019] Specific embodiment 3——continuous dynamic processing:

[0020] This embodiment is basically the same as the second embodiment. The difference is: in the process, polyferric sulfate (PFS) or polyaluminum chloride (PAC) or polyaluminum sulfate (PAS) or their compound formula is used instead of sulfuric acid or industrial waste sulfuric acid for continuous acidification of wastewater, and the use of polymer agents The addition amount is 0.15%-0.30‰wt of the total waste water. Other steps are the same as the description of the second embodiment.

[0021] The particle size range of the coke powder used in the present invention is 10-80 mesh.

[0022] The amount of industrial coke powder in the three specific embodiments can be increased or decreased according to the specific conditions of the influent water quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com