Automatic forming machine for auto parts

A technology for automatic molding machines and auto parts, which is applied to vehicle parts, feeding devices, positioning devices, etc., which can solve problems such as poor machine continuity, high labor intensity for workers, and unsatisfactory results, and achieve high production efficiency and stable and continuous operation , conducive to the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

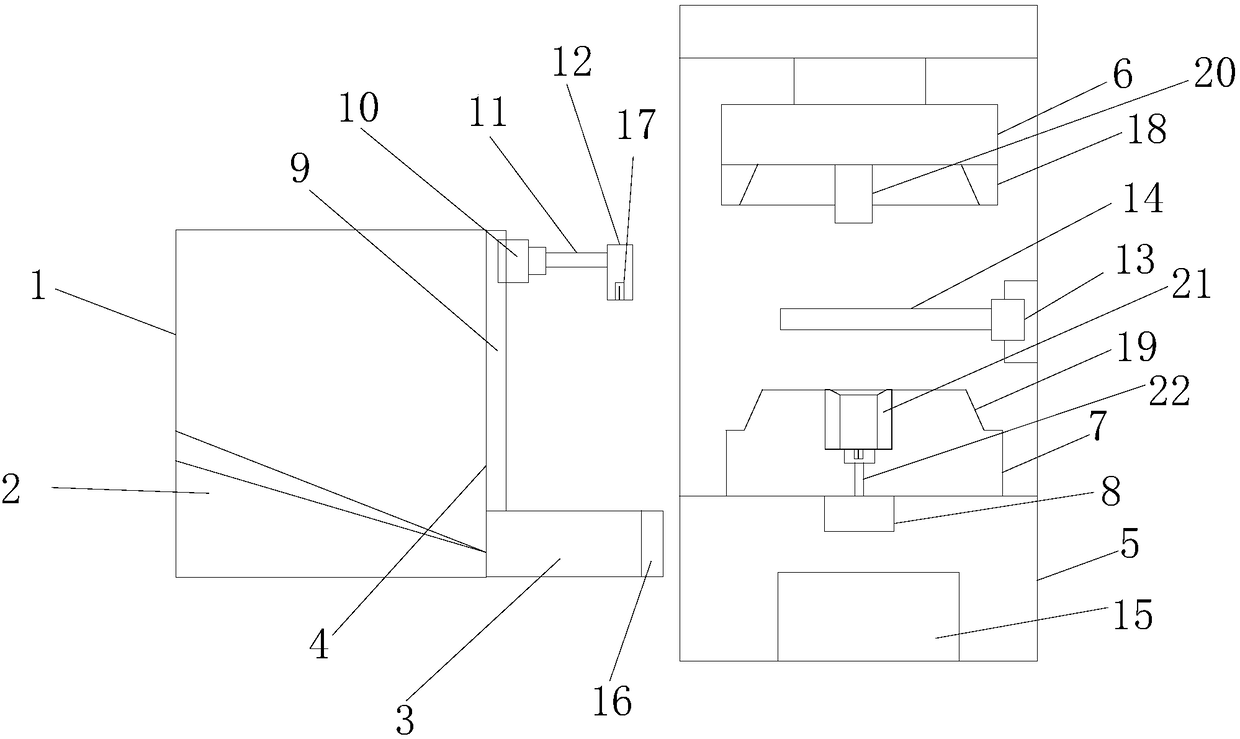

[0014] refer to figure 1 , an automatic molding machine for auto parts of the present invention, comprising a lower hopper 1, a monolithic bottom plate 2, a discharge trough 3, a feeder 4, a frame 5, an upper die 6, a lower die 7, and a discharger 8, The bottom of the lower bin 1 is provided with a monolithic bottom plate 2, the right side of the monolithic bottom plate 2 is connected with a discharge groove 3, and the right side of the lower bin 1 is provided with a feeder 4. Feeder 4 comprises lifting guide rail 9, lifting slide block 10, telescopic cylinder arm 11, suction block 12, and described lifting guide rail 9 is vertically arranged, and described lifting slide block 10 is installed on lifting guide rail 9, and described telescopic cylinder The arm 11 is horizontally arranged on the lifting slider 10 to the right, the rightmost end of the telescopic cylinder is provided with a suction block 12, the right side of the lower bin 1 is provided with a frame 5, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com