Method for precooling centrifugal pump used for transporting low temperature ethylene

A technology of low-temperature ethylene and centrifugal pumps, which is applied to parts of pumping devices for elastic fluids, pumps for special fluids, pumps, etc., and can solve heat damage to the mechanical seal of the pump body, increased production costs, and potential safety hazards, etc. problems, to achieve stable and continuous operation, reduce production costs, and ensure safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through embodiments and accompanying drawings. But it is not a limitation of the present invention.

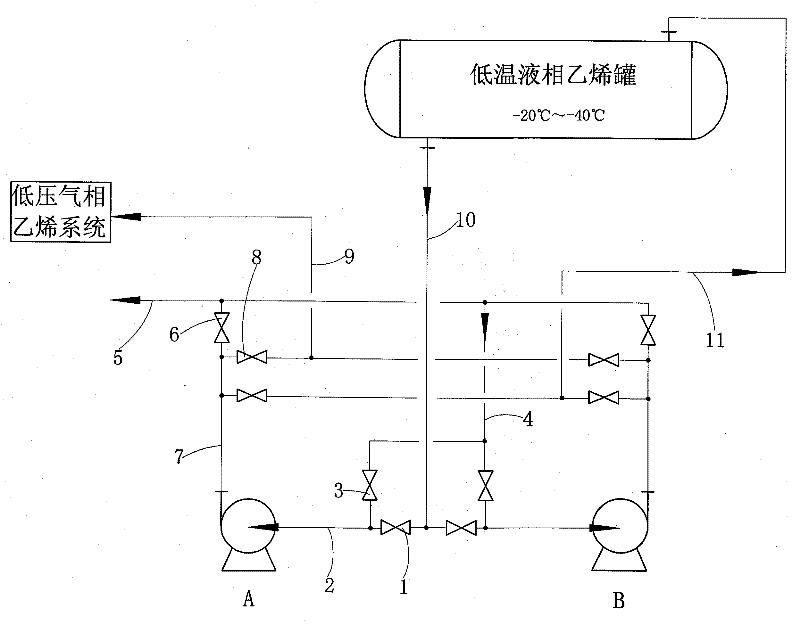

[0020] Referring to the accompanying drawings, the precooling method for the centrifugal pump used to transport low-temperature ethylene, the process steps are:

[0021] a. Set a liquid-phase ethylene inlet pipe 4 with a manual shut-off valve 3 on the inlet pipeline 2 between the standby centrifugal pump A and its manual shut-off valve 1 at the inlet end, and the liquid-phase ethylene inlet pipe 4 enters the inlet end of the pipe 4 Connected to the liquid-phase ethylene outlet main pipe 5 shared by the standby centrifugal pump A and the running centrifugal pump B, the liquid-phase ethylene inlet pipe 4 is close to the liquid-inlet end of the standby centrifugal pump A and the manual stop valve 1 is connected to the standby centrifugal pump A A gas-phase ethylene discharge pipe 9 with a manual shut-off valve 8 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com