Process for producing (meth) acrylic acids

一种甲基、制造设备的技术,应用在丙烯酸类的制造领域,能够解决妨碍有用物高回收率、压差上升、气液接触状态恶化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach b

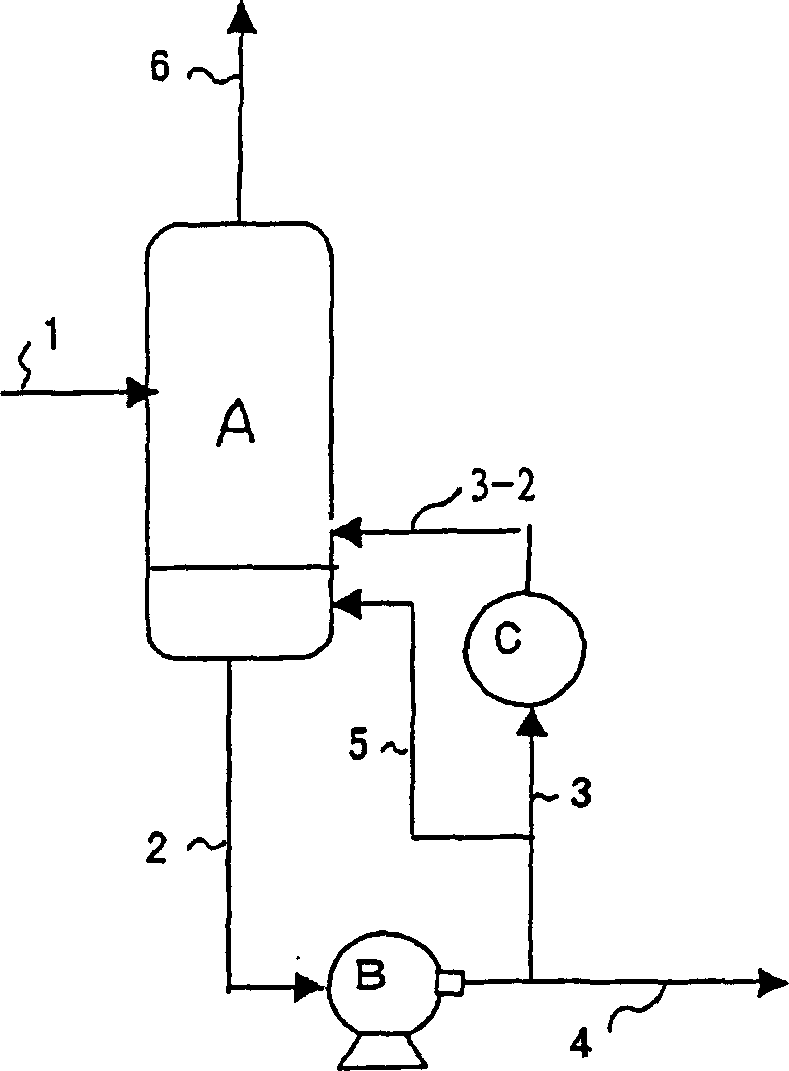

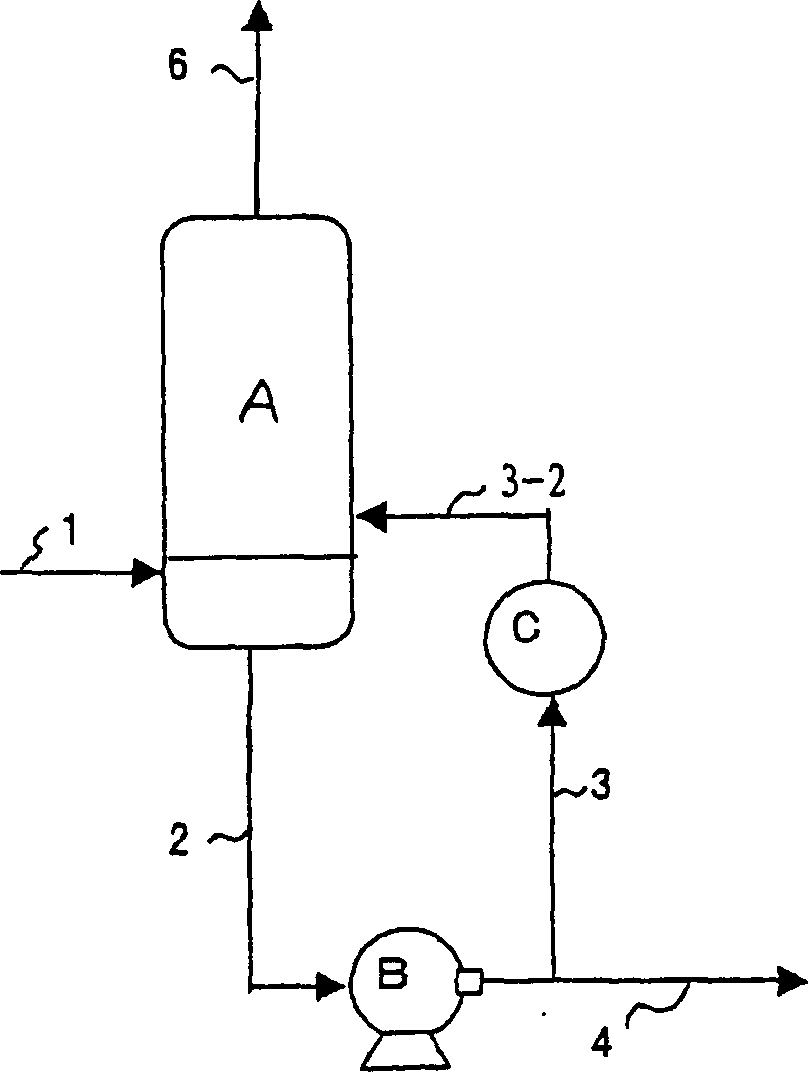

[0177] In this embodiment b, when implementing the decomposition reaction of (meth)acrylic-type Mikkel adducts, it is found that the tower bottom liquid is not continuously drawn out from the bottom of the reactor, but sent out by pulsation, that is, intermittently drawn out, which can be achieved without clogging for a long time. implemented to achieve the purpose. The reason why clogging is prevented well is not clear, but the present inventors infer from the experimental facts that clogging in the pipe under normal flow makes the flow of fluid more turbulent due to intermittent flow, although the flow of fluid has nothing to do with temporary stop, but the The disorder effect is due to extremely effective suppression of clogging.

[0178] and are the same as in the case of embodiment a.

[0179]

[0180] Figure 6 It is an example of the production pipeline of the thermal decomposition reaction of the present invention, except for C: heat exchanger for heating, F: in...

Embodiment approach C

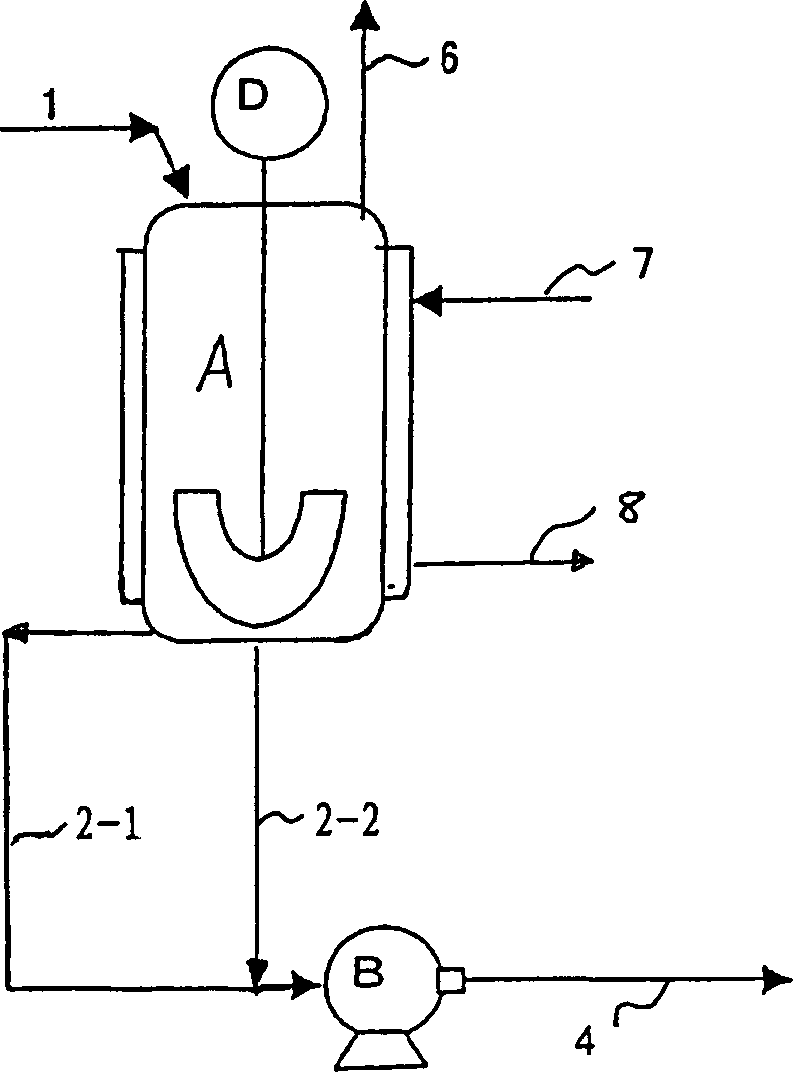

[0186] Embodiment C solves the problems of attachment, accumulation and accumulation of solids by using overflow plate discs and ring-shaped trays as the trays of the distillation tower. That is, the disc and ring-shaped trays are trays in which disc-shaped trays and ring-shaped trays are alternately arranged at appropriate intervals, as will be shown later. Figure 7 , Figure 8 As shown, because the structure is extremely simple and the opening is very large, it is difficult for solids to settle and accumulate, so the problems of adhesion, accumulation and accumulation of solids can be solved.

[0187] Therefore, the decomposition of by-products and the recovery of useful substances during (meth)acrylic acid production can be stably performed by using a distillation column having discs and ring-type trays, which are extremely structurally It is simple, and has an advantage that construction costs such as manufacturing costs and installation costs of the distillation tower a...

Embodiment approach d

[0212]Embodiment d is an invention in which oxygen or an oxygen-containing gas is directly supplied to the distillate containing the decomposition product produced by the decomposition reaction of the above-mentioned by-product, and uses the action of this oxygen to suppress the polymerization of the easily polymerizable compound in the decomposition product. method. As a result of various studies, it has been found that the addition of such oxygen or oxygen-containing gas sufficiently suppresses the polymerization of the easily polymerizable compound in the decomposition product. This is presumably because the added oxygen increases the polymerization inhibitor effect of the polymerization inhibitor normally contained in the decomposition reaction raw material.

[0213] The (meth)acrylate in embodiment d is not particularly limited, and the same examples as those described in embodiment c can be cited. In addition, the same contents as those described in the embodiment c can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com