High-power LED lamp using ceramic for heat dissipation

An LED lamp, high-power technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problem of affecting the luminous efficiency of LED chips, uneven lighting in the chip light-emitting area, and N-level solder layer 38 is too long. and other problems, to achieve the effect of improving LED luminous efficiency, increasing the area of light penetration layer, and optimal luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Combine below Figure 1 to Figure 34 , the present invention is further described:

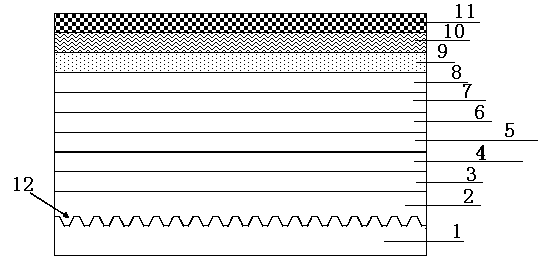

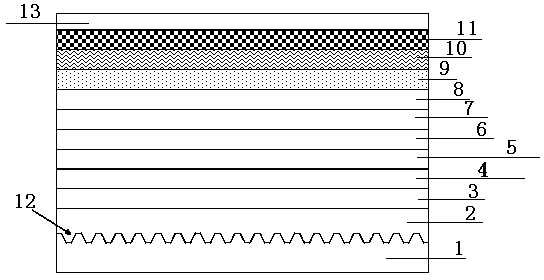

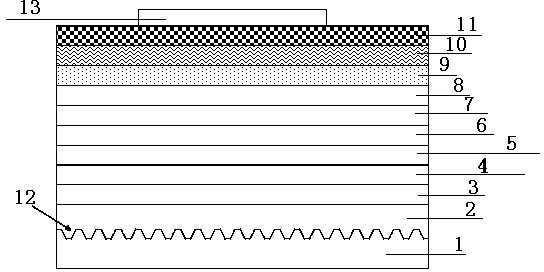

[0080] Such as figure 1 As shown, the substrate 1 is a carrier, generally made of materials such as sapphire, silicon carbide, silicon, GaAs, AlN, ZnO or GaN.

[0081] On the substrate 1, a layer of concave-convex surface 12 is firstly formed by etching. The concave-convex surface 12 can reduce the total reflection of light in the chip and increase the light extraction rate.

[0082] The buffer layer 2 is a transition layer on which high-quality N, P, quantum wells and other materials are grown.

[0083] LED is composed of pn structure, buffer layer 2, N-type layer 3, N-type confinement layer 4, P-type confinement layer 6 and P-type layer 7 are to form P and N-type materials required for making LED. The light-emitting area layer 5 is the light-emitting area of the LED, and the color of the light is determined by the material of the active area.

[0084] P-type ohmic contact layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com