Process for producing (meth)acrylic acid or (meth)acrylic ester

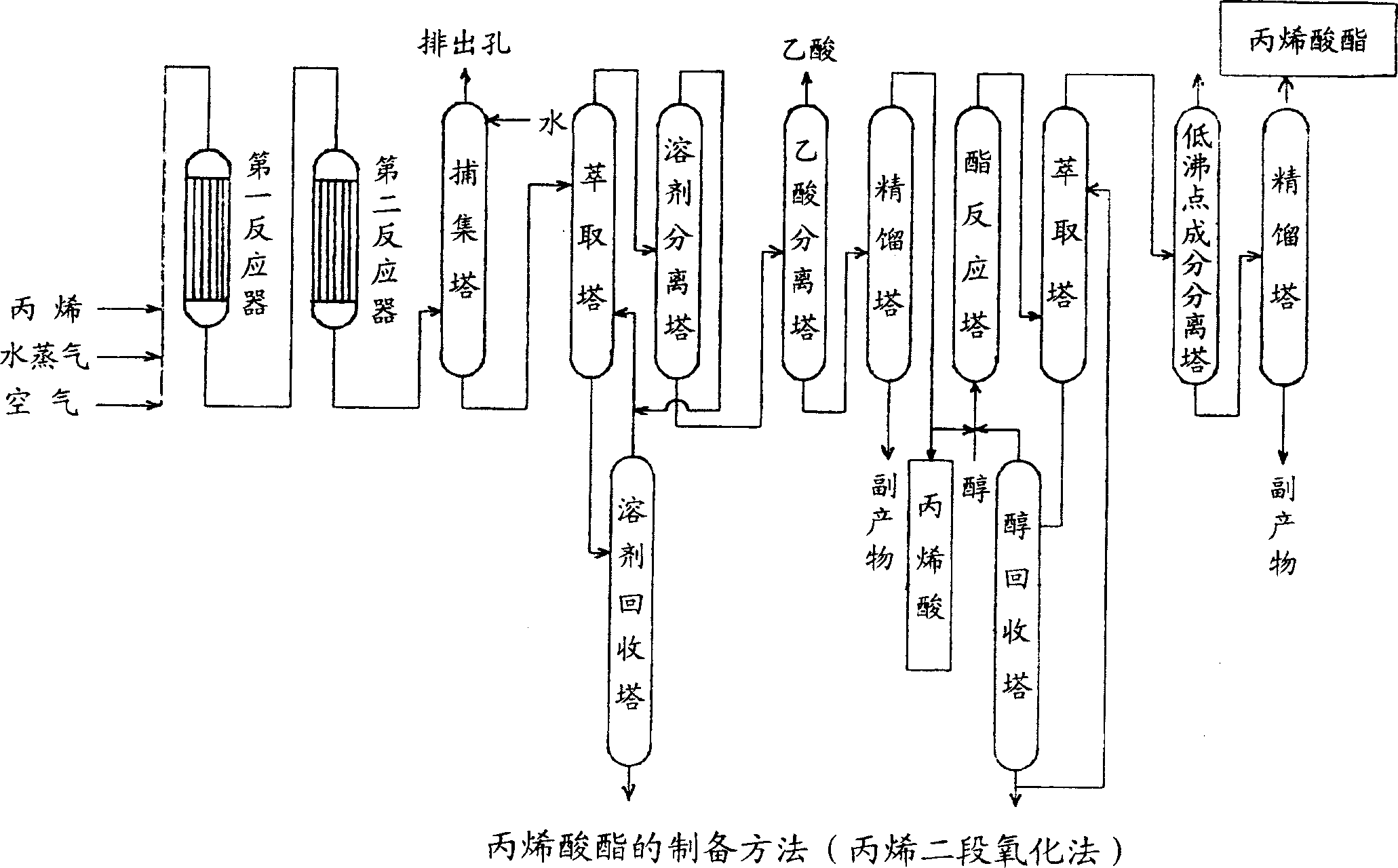

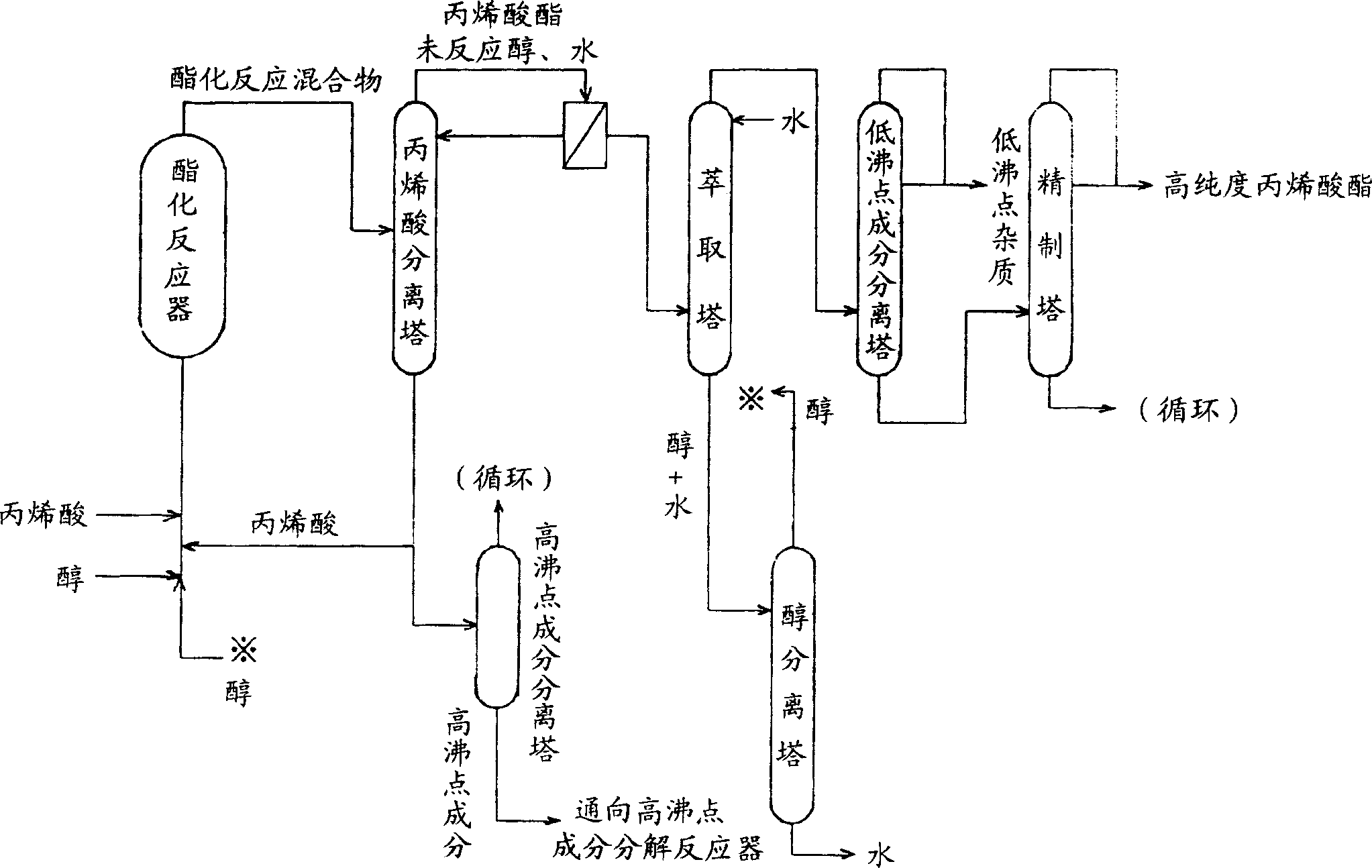

A technology for acrylate and acrylic acid, applied in the field of distillation and purification, can solve the problems of deterioration of gas-liquid contact state, reduction of the recovery rate of target products, hindering continuous operation of distillation towers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

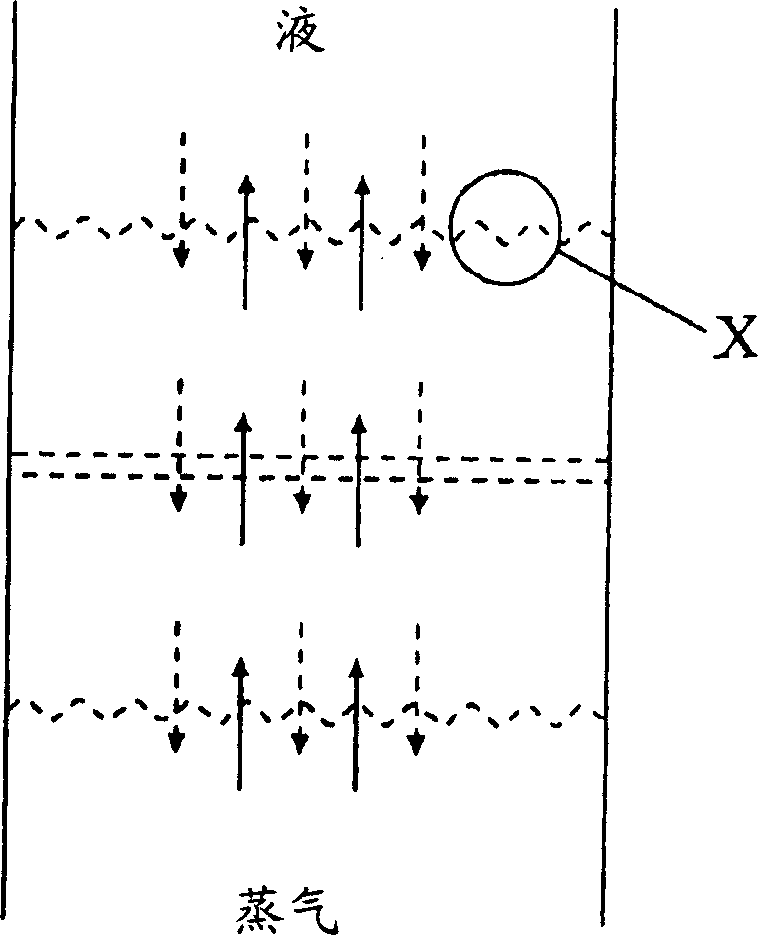

[0088] Acrylic acid was distilled using a vacuum distillation column with a diameter of 1,000 mm. This vacuum distillation column has a column tank for supplying a raw material liquid for distillation, a column body for passing the vapor of the heated liquid in the column tank, and a condenser for condensing the vapor discharged from the top of the column.

[0089]A reboiler for heating the supplied raw material liquid is installed in the column pot. The above-mentioned tower body is a plate tower. The tower body has a structure in which 30 arbitrary perforated plates can be arranged as trays.

[0090] In this example, a total of 30 corrugated plate-type perforated plates without weirs and flat plate-type perforated plates without weirs were installed as the above-mentioned trays. In this embodiment, the perforated plate group arranged from bottom to top according to the order of four corrugated plate-type non-weir perforated plates and one flat-type non-weir perforated plat...

Embodiment 2

[0105] In this embodiment, as shown in Table 1, the group of porous plates arranged from bottom to top in the order of 3 corrugated plate-type non-weir perforated plates and 2 flat-type non-weir perforated plates is regarded as a group. Six groups of plate groups are arranged in order from bottom to top, and are configured as perforated plates as trays. In addition, as a flat plate type non-weir perforated plate, a flat type non-weir perforated plate having a hole diameter of 30 mm and an opening ratio of 27% was used. Except for this, in this example, the experiment of dehydration distillation was performed similarly to Example 1. In operation, the composition of the raffinate extracted from the bottom of the tower is the same as in Example 1.

[0106] Similar to Example 1, the pressure difference between the top and the bottom of the distillation column was 5.5 kPa, and there was no rise, and the operation could be continued stably. After 3 months, the operation was stoppe...

Embodiment 3

[0111] As shown in Table 1, as the above-mentioned corrugated plate type non-weir porous plate, a corrugated plate type non-weir porous plate having a through hole with a diameter of 25 mm and an opening ratio of 24% is used. The height of the corrugated plate type non-weir perforated plate is 30 mm. As the above-mentioned flat type non-weir perforated plate, a flat type non-weir perforated plate with a hole diameter of 30 mm and a porosity of 24% is used. In addition, The experiment of dehydration distillation was performed similarly to Example 1. In operation, the composition of the raffinate extracted from the bottom of the tower is the same as in Example 1.

[0112] Similar to Example 1, the pressure difference between the top and the bottom of the distillation column was 5.5 kPa, and there was no rise, and the operation could be continued stably. After 3 months, the operation was stopped, and when the distillation column was checked from an open point, no polymer of acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com