A kind of cornus officinale fully automatic meat core peeling machine

A fully automatic, dogwood technology, applied in fruit pitting devices, food science, applications, etc., can solve problems such as low work efficiency and uneven feeding, achieve the effects of reducing labor intensity, uniform feeding, and improving peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

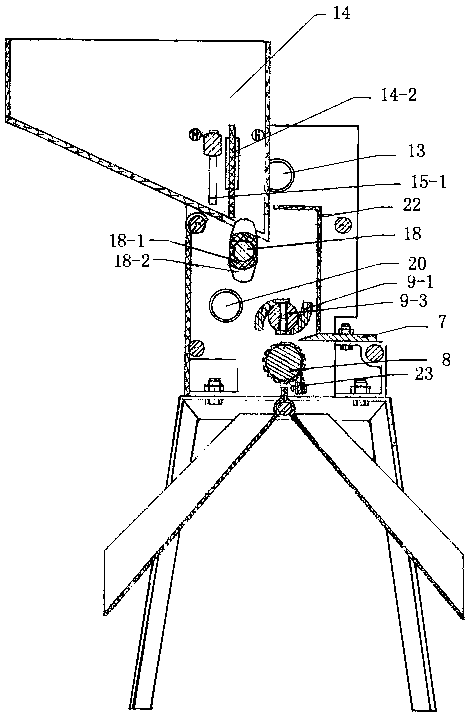

[0030] A full-automatic cornel core peeling machine comprises a frame 1 on which a feeding mechanism, a core core peeling mechanism and a motor 2 are sequentially arranged from top to bottom.

[0031] The feeding mechanism includes a hopper 14 and a feeding adjustment shaft 18. The lower part of the hopper 14 has a feeding opening 14-1 arranged at intervals in the axial direction, and the feeding adjustment shaft 18 is located at the lower part of the feeding opening 14-1.

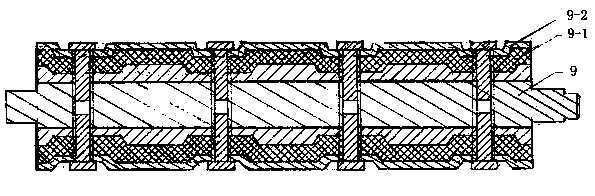

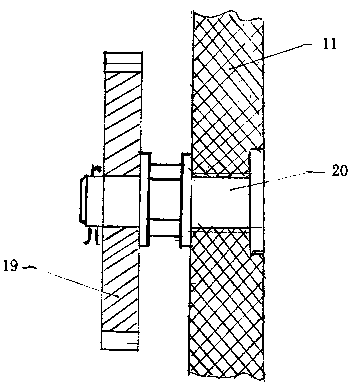

[0032]The meat core stripping mechanism is located at the bottom of the blanking adjustment shaft 18, and includes a paddle shaft 9, a stripping knife 7, a material retaining plate 22 and a toothed roller shaft 8, and the axial symmetry of the paddle shaft 9 is provided with two flexible paddles 9- 1, the bottom of the paddle shaft 9 is provided with a stripping roller shaft 8, and the stripping knife 7 is installed on the frame 1, and the blade of the stripping knife 7 faces between the paddle shaft 9 and ...

Embodiment 2

[0035] A full-automatic cornel core peeling machine comprises a frame 1 on which a feeding mechanism, a core core peeling mechanism and a motor 2 are sequentially arranged from top to bottom.

[0036] The feeding mechanism includes a hopper 14 and a feeding adjustment shaft 18. The lower part of the hopper 14 has a feeding opening 14-1 arranged at intervals in the axial direction, and the feeding adjustment shaft 18 is located at the lower part of the feeding opening 14-1.

[0037] The meat core stripping mechanism is located at the bottom of the blanking adjustment shaft 18, and includes a paddle shaft 9, a stripping knife 7, a material retaining plate 22 and a toothed roller shaft 8, and the axial symmetry of the paddle shaft 9 is provided with two flexible paddles 9- 1, the bottom of the paddle shaft 9 is provided with a stripping roller shaft 8, and the stripping knife 7 is installed on the frame 1, and the blade of the stripping knife 7 faces between the paddle shaft 9 and...

Embodiment 3

[0041] A full-automatic cornel core peeling machine comprises a frame 1 on which a feeding mechanism, a core core peeling mechanism and a motor 2 are sequentially arranged from top to bottom.

[0042] The feeding mechanism includes a hopper 14 and a feeding adjustment shaft 18. The lower part of the hopper 14 has a feeding opening 14-1 arranged at intervals in the axial direction, and the feeding adjustment shaft 18 is located at the lower part of the feeding opening 14-1.

[0043] The meat core stripping mechanism is located at the bottom of the blanking adjustment shaft 18, and includes a paddle shaft 9, a stripping knife 7, a material retaining plate 22 and a toothed roller shaft 8, and the axial symmetry of the paddle shaft 9 is provided with two flexible paddles 9- 1, the bottom of the paddle shaft 9 is provided with a stripping roller shaft 8, and the stripping knife 7 is installed on the frame 1, and the blade of the stripping knife 7 faces between the paddle shaft 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com