Method and device for structuring tunnel by propulsion of underground box

A box and tunnel technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as rising construction costs, and achieve the effects of simple construction, high safety factor, and low noise and vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

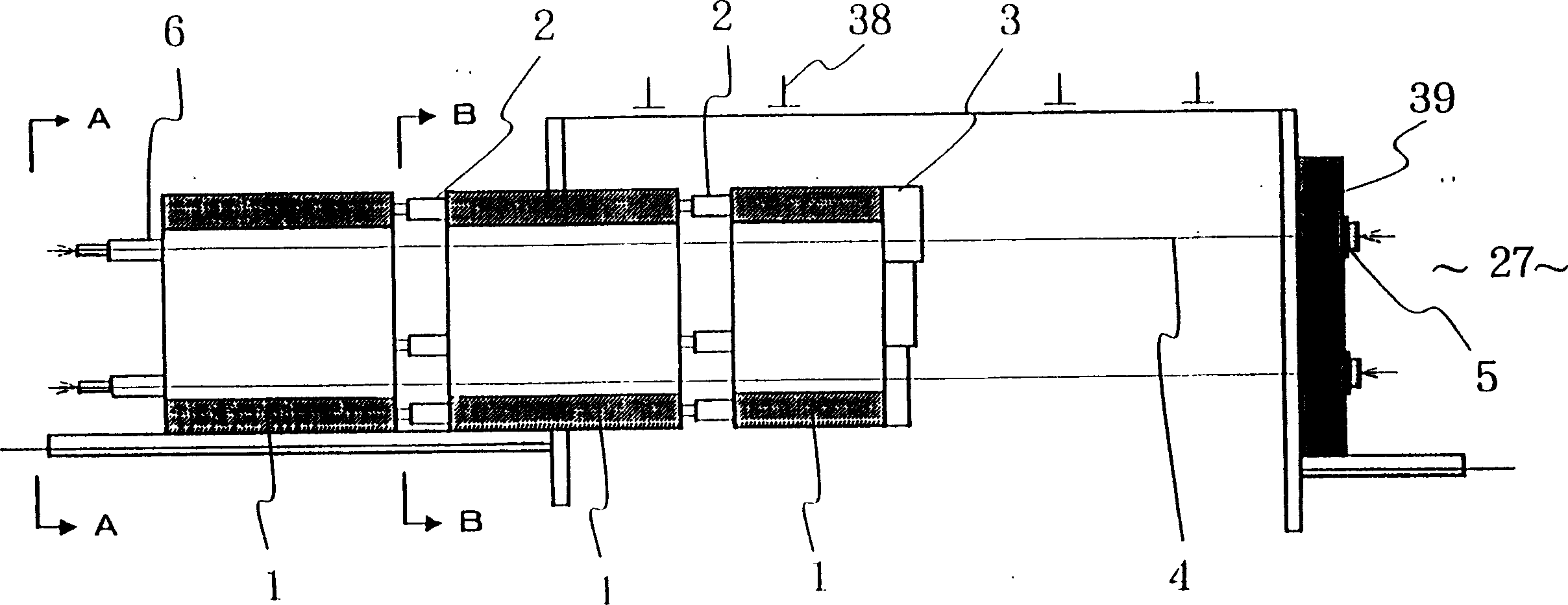

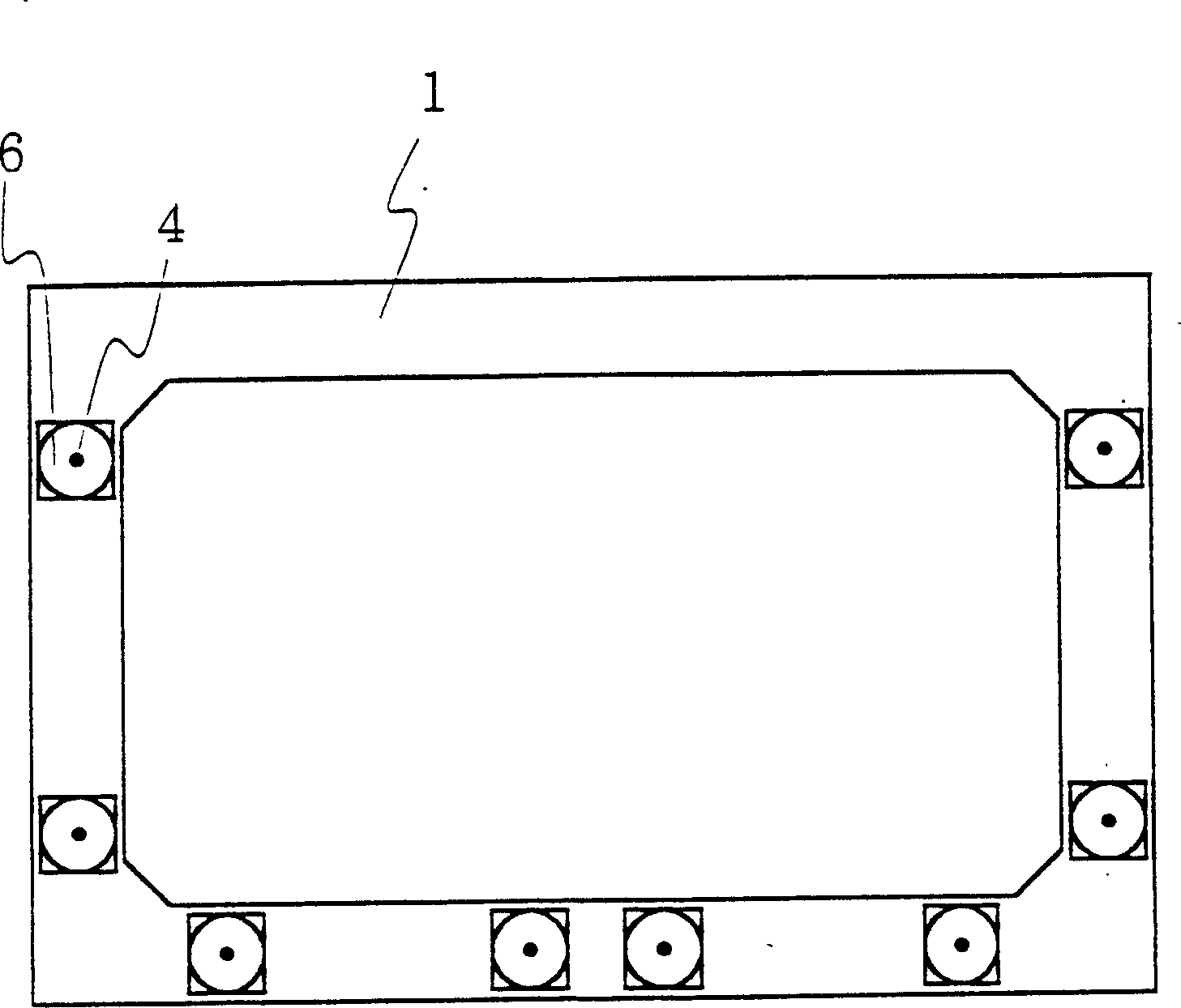

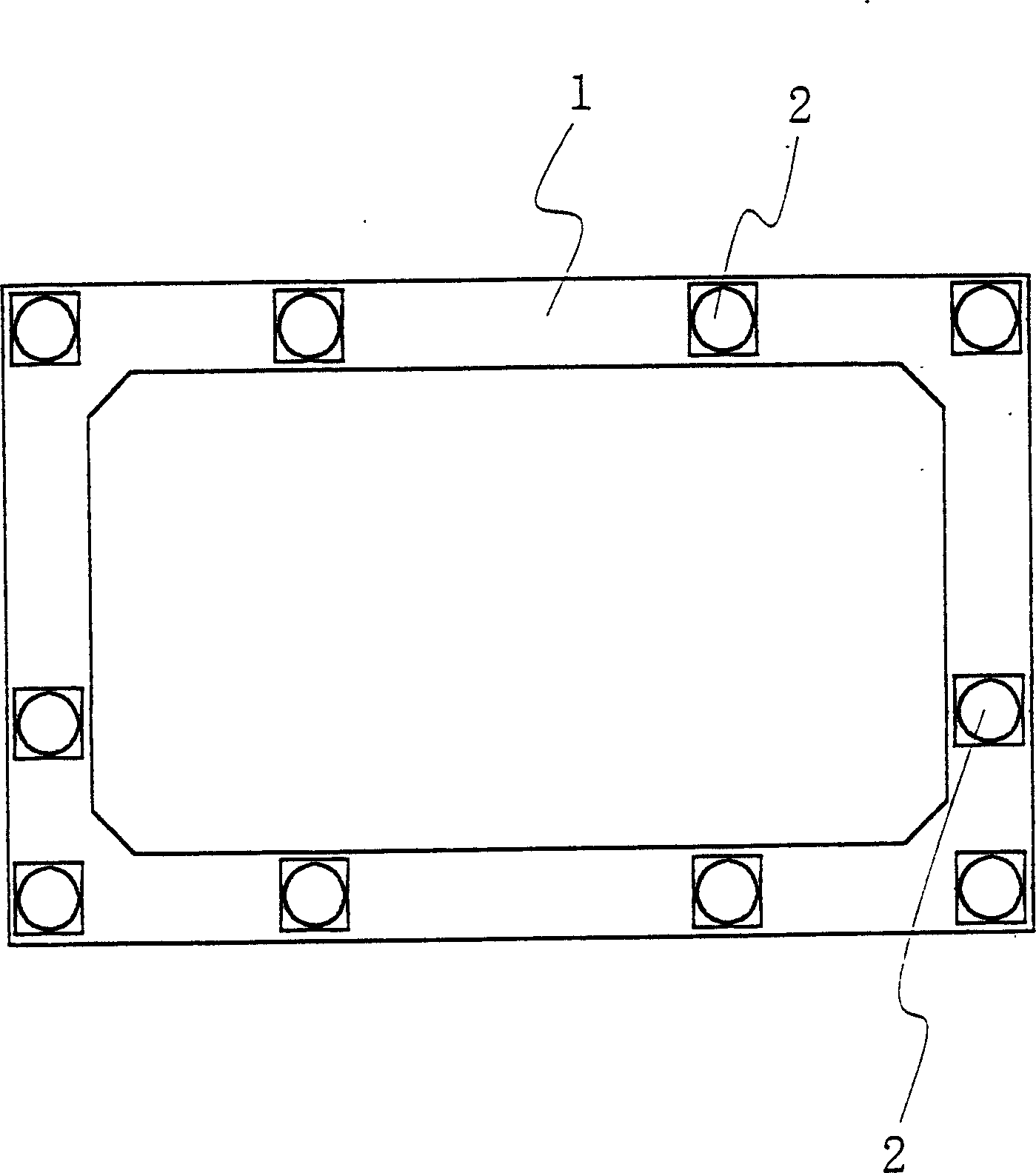

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a longitudinal sectional view showing the first embodiment of the method of constructing a tunnel by pushing an underground box body according to the present invention, figure 2 yes figure 1 Sectional view of midline A-A, image 3 yes figure 1 Sectional view of midline B-B.

[0046] The present invention is an infinite self-advancement method, suitable for constructing tunnel-like underground buildings across these roads at positions where the cover soil layer thickness is relatively shallow, such as directly below roads or railway lines 38 .

[0047] Multiple (more than 3) concrete boxes 1 are arranged side by side, and intermediate jacks 2 are arranged between the boxes 1 .

[0048] And the front end of the box body 1 in front is equipped with cover shape knife edge 3, is provided with PC steel rope 4 as traction part to run through whole b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com