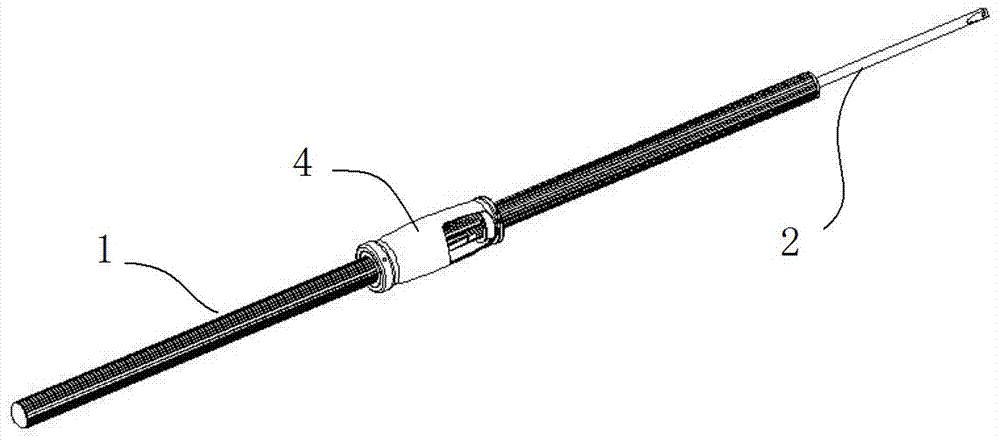

A kind of practice device for bow release

A practice device and bowstring technology, which is applied in the field of archery practice, can solve the problems of small scope of application and low degree of simulation training reduction, and achieve the effect of reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Use WIN&WIN recurve bow handle INNO CXT, assemble 40lbs WIN&WIN limbs, install aluminum alloy cylindrical casing, the casing is 880mm long, 24mm inner diameter, 1.2mm thick, with a 2mm diameter circular air hole at the end of the casing One, the spring is used as the cushioning part, the simulated arrow shaft is made of aluminum, the length is 850mm, the outer diameter is 9mm, and the piston head uses a rubber gasket. In the actual bow, the draw length is 710mm, and the release process is smooth. Under the double action of the slow-release compressed air and the buffer spring at the end of the sleeve, the simulated arrow shaft decelerates and shoots into the sleeve, and finally stops smoothly. The same stable performance results can be obtained by repeating the bow release process 1 to 500 times.

Embodiment 2

[0046] Use WIN&WIN recurve bow handle INNO MAX, assemble 20 lb WIN&WIN bow pieces, install aluminum alloy cylindrical sleeve, the sleeve length is 880mm, inner diameter is 24mm, thickness is 1.2mm, and the end of the sleeve has a circular air hole with a diameter of 2mm One, without using any cushioning parts, the simulated arrow shaft is made of aluminum, 850mm long, 9mm outer diameter, and the piston head uses a rubber gasket. In the actual bow, the draw length is 700mm, and the release process is smooth. Under the sole action of the slow-release compressed air, the simulated arrow shaft decelerates and shoots into the sleeve, and finally stops smoothly. The same stable performance results can be obtained by repeating the bow release process 1 to 500 times.

Embodiment 3

[0048] Use WIN&WIN recurve bow grip INNO CXT, assemble 36-pound WIN&WIN limbs, install carbon fiber cylindrical casing, the casing is 885mm long, 18mm inner diameter, 1.5mm thick, and the end of the casing has a 1mm diameter circular guide There are three air holes, springs are used as buffer components, the simulated arrow shaft is made of carbon material, the length is 860mm, the outer diameter is 6mm, and the piston head uses rubber gaskets. In the actual bow, the draw length is 710mm, and the release process is smooth. Under the double action of slow-release compressed air and buffer components, the simulated arrow shaft decelerates and shoots into the sleeve, and finally stops smoothly. The same stable performance results can be obtained by repeating the bow release process 1 to 500 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com