Film evaporator

A thin-film evaporator and evaporation cylinder technology, which is applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of affecting the separation effect of organic solvents, reducing the quality of final products, and being difficult to form films, so as to achieve convenient film formation. , Prevent a lot of foaming, and ensure the effect of sufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

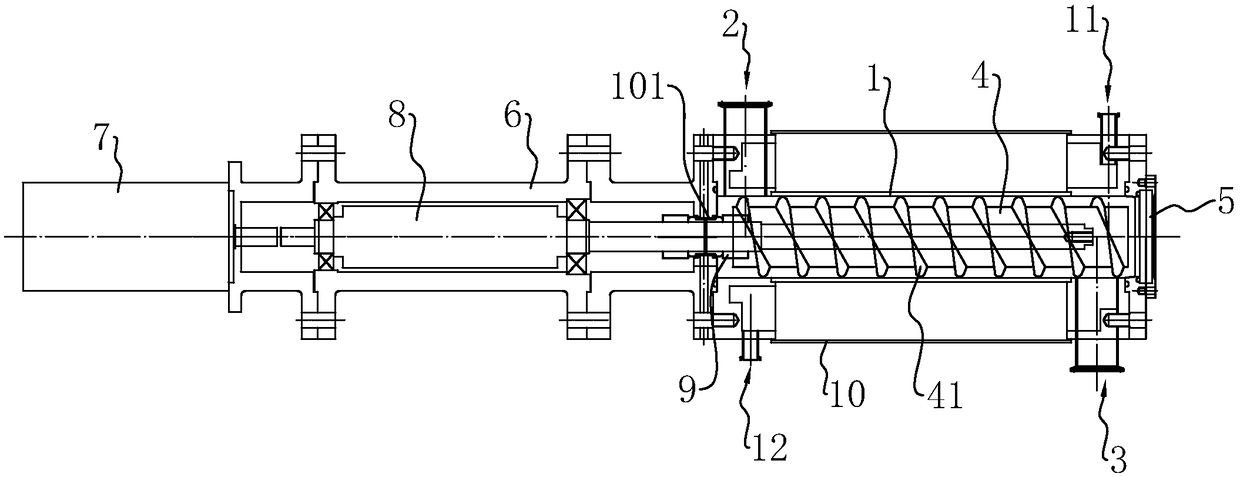

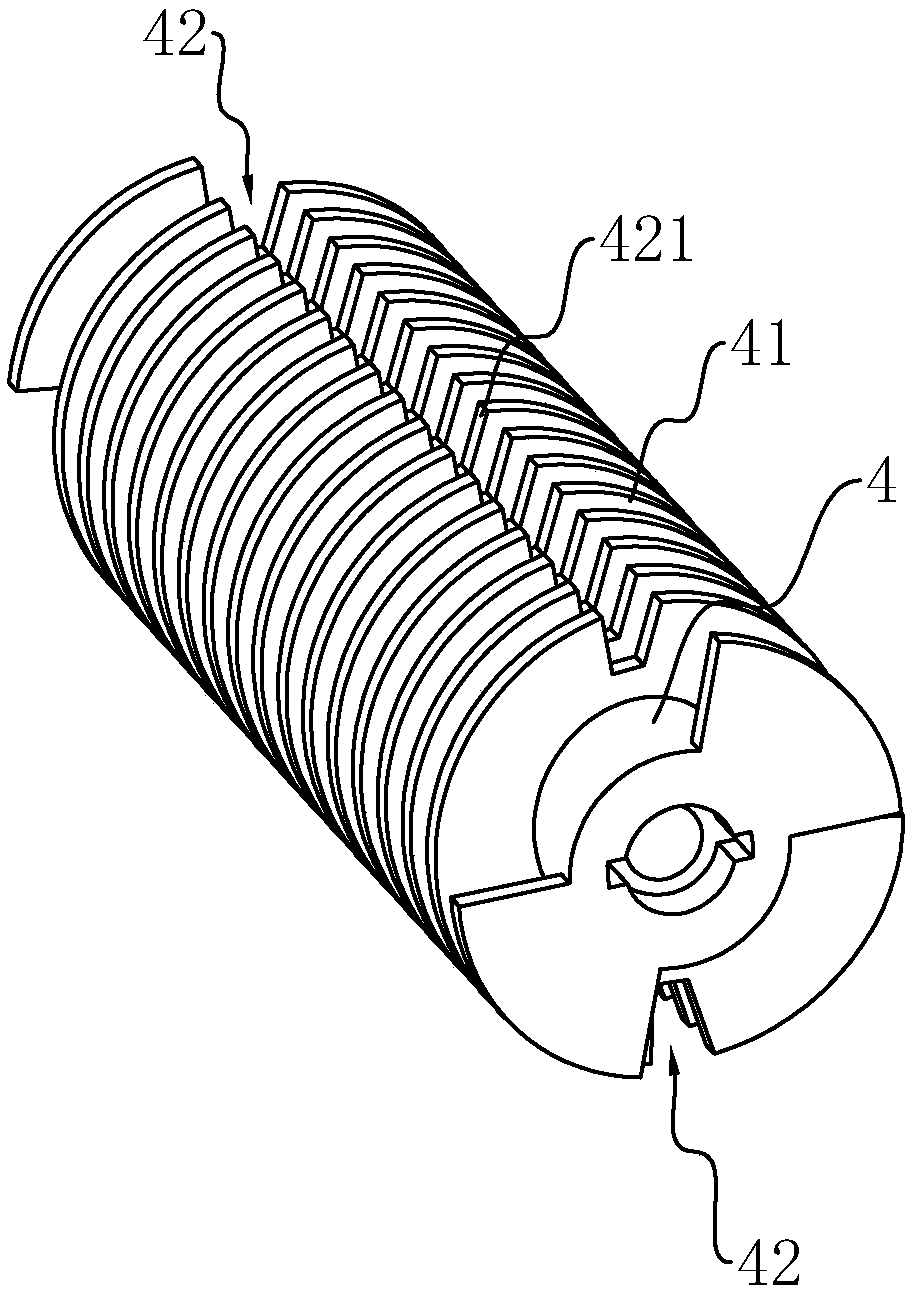

[0028] See attached figure 1 , a thin film evaporator, comprising an evaporation cylinder 1, the evaporation cylinder 1 is horizontally arranged, and the upper and lower sides of the evaporation cylinder 1 are respectively provided with a material inlet 2 and a material outlet 3; at the same time, the evaporation cylinder 1 is horizontally erected There is a push screw 4, and the push screw 4 is rotated and installed in the evaporation cylinder 1, and one side of the evaporation cylinder 1 in the length direction is provided with a driving assembly for driving the push screw 4 to rotate; A heating device for heating the evaporation cylinder 1.

[0029] In actual work, the material liquid enters the evaporation cylinder 1 through the material inlet 2; the drive assembly can drive the push screw 4 to rotate, and push the feed liquid to the side where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com