Syringe

A technology of syringes and syringes, applied in the field of syringes, can solve problems such as air embolism, achieve the effects of improving precision, improving precise control, and reducing propulsion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

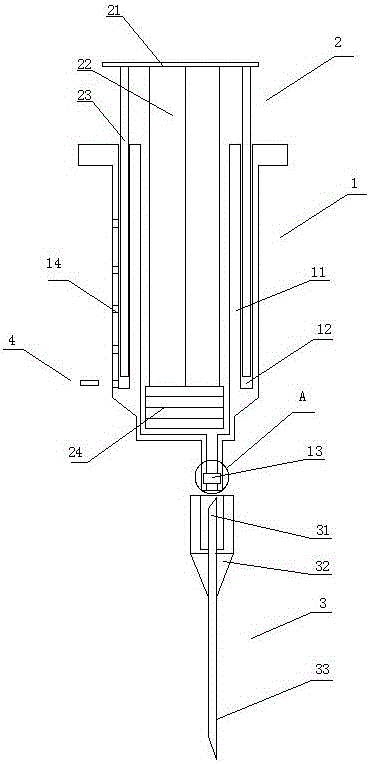

[0032] Such as figure 1 As shown, the present invention discloses a syringe, comprising a syringe 1, an injection plug 2, and an injection needle 3; to pierce the needle-like portion 31 of the sealing portion 13 .

[0033] The sealing part 13 is a thin film integrally formed with the syringe 1 . The film is integrally formed, has better sealing performance, lower cost, can be disposable, and is completely antibacterial. The injection needle 3 includes a connection portion and an injection portion 33 , the connection portion is located at the connection end of the injection needle 3 , and the connection portion includes a sleeve portion 32 and the needle portion 31 . The injection needle 3 can use its needle-like part 31 to pierce the sealing part 13 to ensure the normal use of the syringe. The design of the sleeve-like part 32 can improve the reliability of the connection between the needle and the syringe.

[0034] The syringe 1 includes a cylinder body 11, the injection p...

Embodiment 2

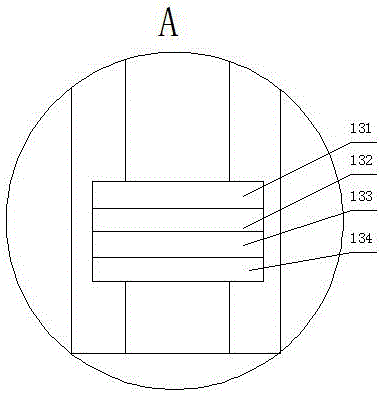

[0040] Such as figure 2 As shown, the sealing part 13 is cylindrical, and the sealing part 13 is composed of a silica gel layer 131, a braided layer 132, and a non-toxic rubber layer 133 from inside to outside, and the non-toxic rubber layer 133 is glued to the inner wall of the injection port of the injection cylinder 1; The braided layer 132 is braided by 5-12 parts of bamboo fiber, 8-16 parts of chopped glass fiber and 3-7 parts of activated carbon fiber. The structure of the sealing part 13 has a small stable structure, good elasticity, and strong resilience. After being punctured by the needle-like part 31, it can be quickly restored, thereby preventing bacteria from entering and causing pollution. Its elasticity is stronger than that used in existing medical equipment. Sterile rubber. The braided layer 132 can stabilize the silicone layer 131 and improve the integrity of the connection between the silicone layer 131 and the non-toxic rubber layer 133 . The silica gel ...

Embodiment 3

[0042] The making method of the sealing part 13 in embodiment 1 or 2 is:

[0043] Step 1: Heat the materials for making the silica gel layer 131 to 150-180°C and keep for 4-6 minutes to melt part of the materials into a gel, stir the materials for making the silica gel layer 131 evenly, and then put them into a mold to condense into a cylinder Shaped silicone rod;

[0044] Step 2: Weave a 0.5-0.7mm braided layer 132 on the outside of the silicone rod, and make the braided layer 132 have a mesh of 40-50 meshes, and then vulcanize the silicone rod with the braided layer 132 at a temperature of 91-102°C 4-7min, the braided layer 132 is fused with the silica gel rod;

[0045] Step 3: extruding semi-molten non-toxic rubber on the outer layer of the braided layer 132 with a pressure of 100-120kpa to form a non-toxic rubber layer 133 of 0.2-0.4mm, and making the first product of the sealing part 13;

[0046] Step 4: Put the initial product of the sealing part 13 into a zero-degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com