Protective film manufacturing method

A manufacturing method and technology of protective film, applied in the direction of manufacturing tools, glass manufacturing equipment, chemical instruments and methods, etc., can solve the problems of losing effect, reducing the service life of glass protective stickers, easy to detach from glass, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to illustrate the central idea of the present invention in the column of the above-mentioned content of the invention, it is now expressed in specific embodiments. Various objects in the embodiments are drawn according to proportions, sizes, deformations or displacements suitable for illustration, rather than drawn according to the proportions of actual components, and are described first.

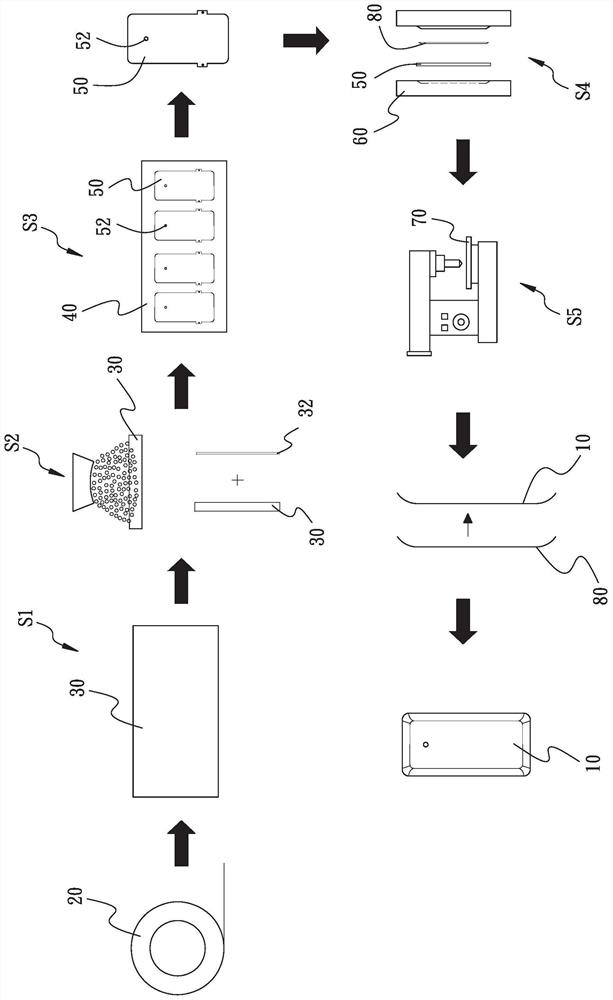

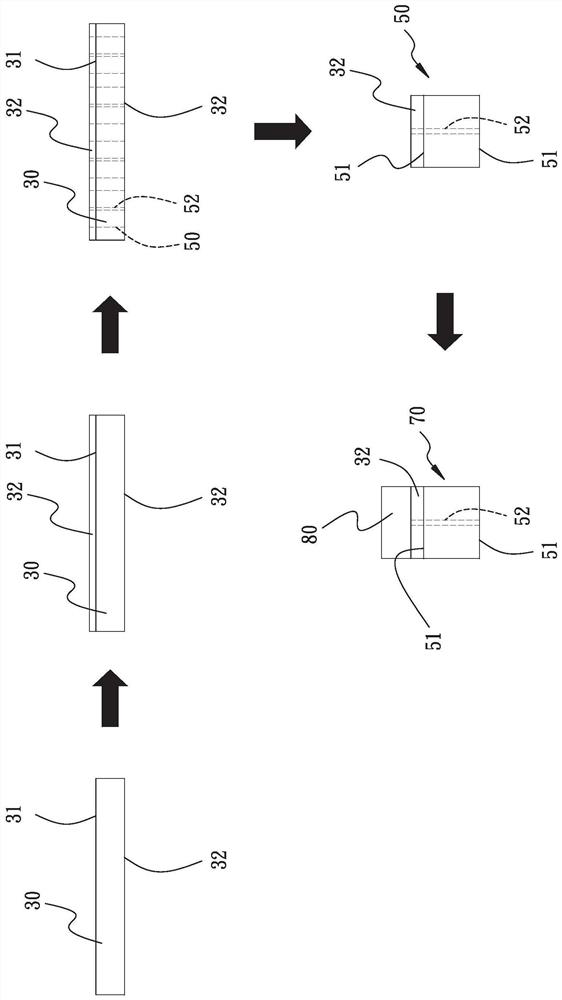

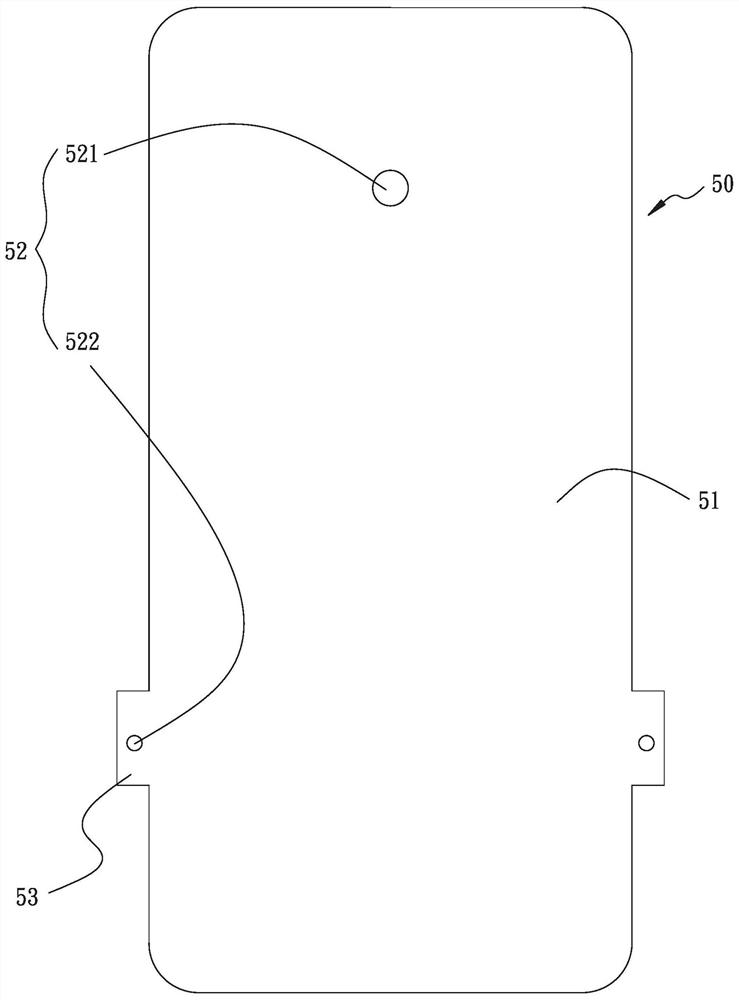

[0047] see Figure 1 to Figure 4 , the present invention provides a protective film manufacturing method for obtaining a protective film finished product 10 through the following steps. The protective film finished product 10 is used to be arranged on the screen or the back of an electronic device.

[0048] The manufacturing method of protective film of the present invention comprises the following steps:

[0049] The first cutting step S1: cutting a roll material 20 into a sheet 30, the sheet 30 has two opposite surfaces 31; wherein, the roll material 20 is made of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com