Patents

Literature

35results about How to "Improve the problem of easy falling off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

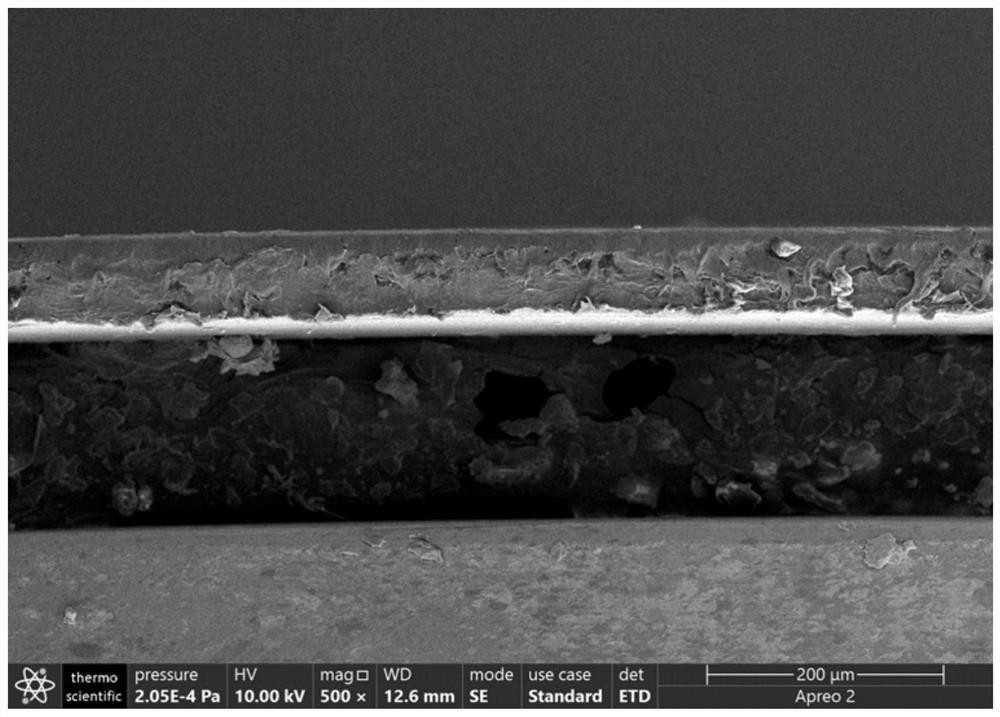

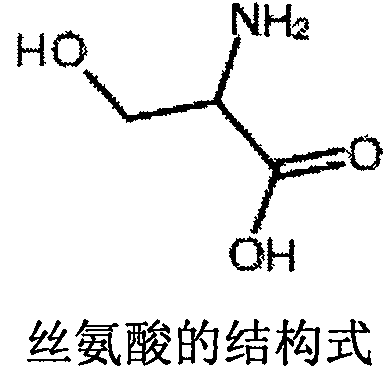

Preparation method of reverse osmosis membrane modified by oxidized graphene/polyvinyl alcohol coating

ActiveCN107638805AImprove the problem of easy falling offOrderly rowsWater/sewage treatment bu osmosis/dialysisReverse osmosisReverse osmosisGraphene

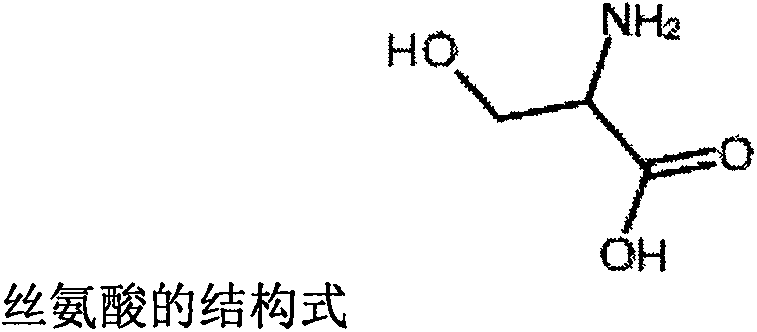

The invention discloses a preparation method of a reverse osmosis membrane modified by an oxidized graphene / polyvinyl alcohol coating. The preparation method comprises the following steps of: preparing a nascent reverse osmosis membrane in advance, then coating polyvinyl-alcohol crosslinking reaction liquid containing oxidized graphene on the nascent reverse osmosis membrane, and finally obtainingthe reverse osmosis membrane modified by the oxidized graphene / polyvinyl alcohol coating. The preparation method disclosed by the invention has the advantages that the oxidized graphene and serine are introduced into the polyvinyl alcohol coating to carry out modification on the polyvinyl alcohol coating, so that the problems of reduction of water flux and easy dropping of the polyvinyl alcohol coating of the reverse osmosis membrane modified by the polyvinyl alcohol coating can be improved.

Owner:宁波日新恒力科技有限公司

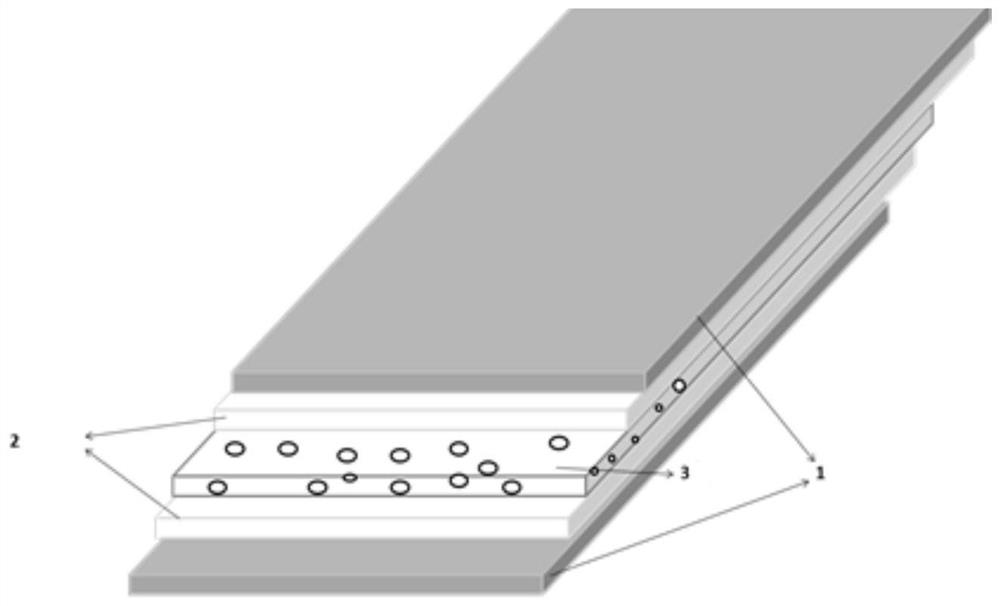

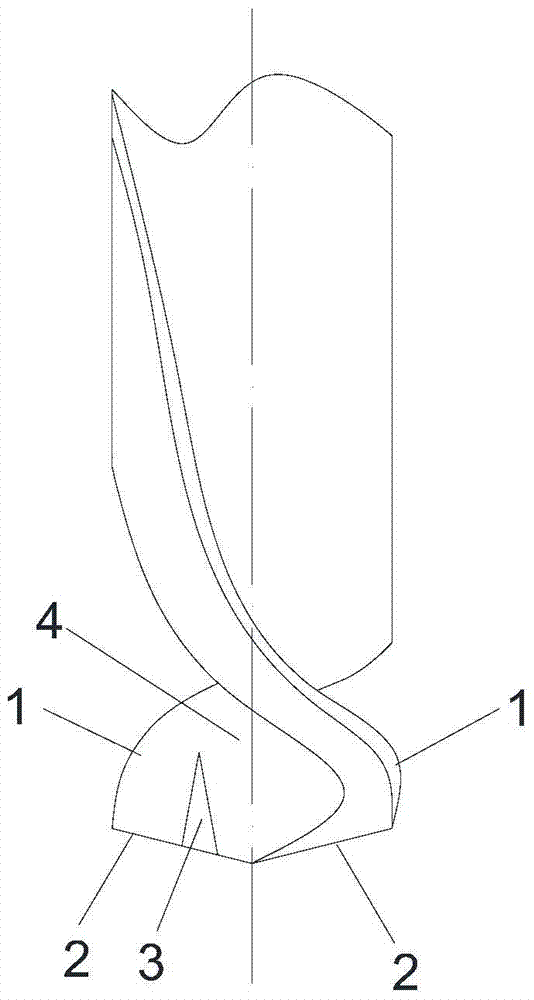

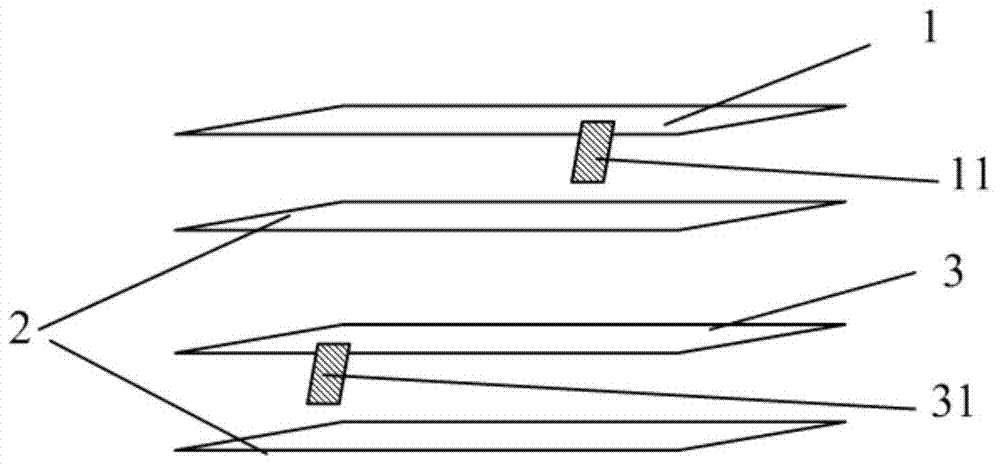

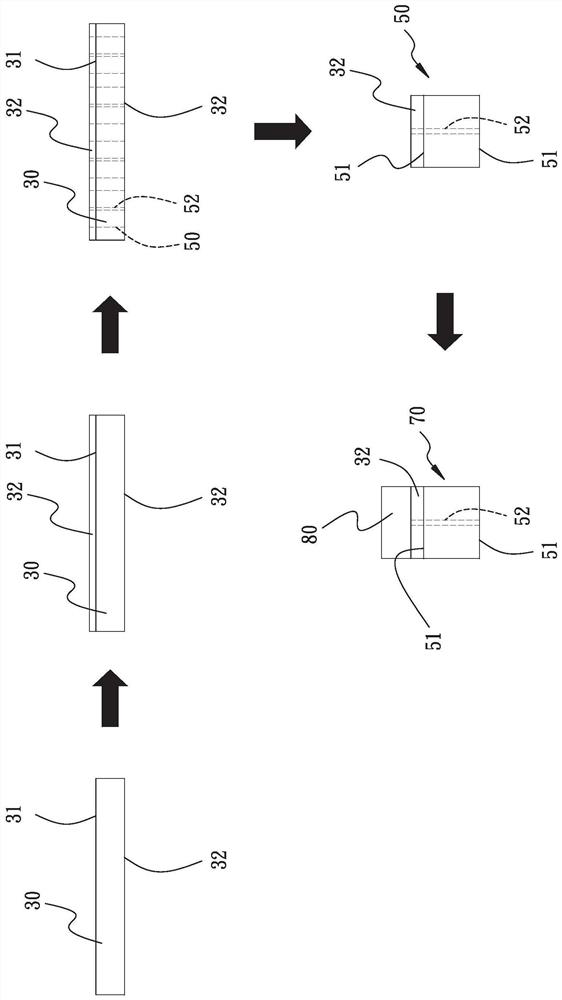

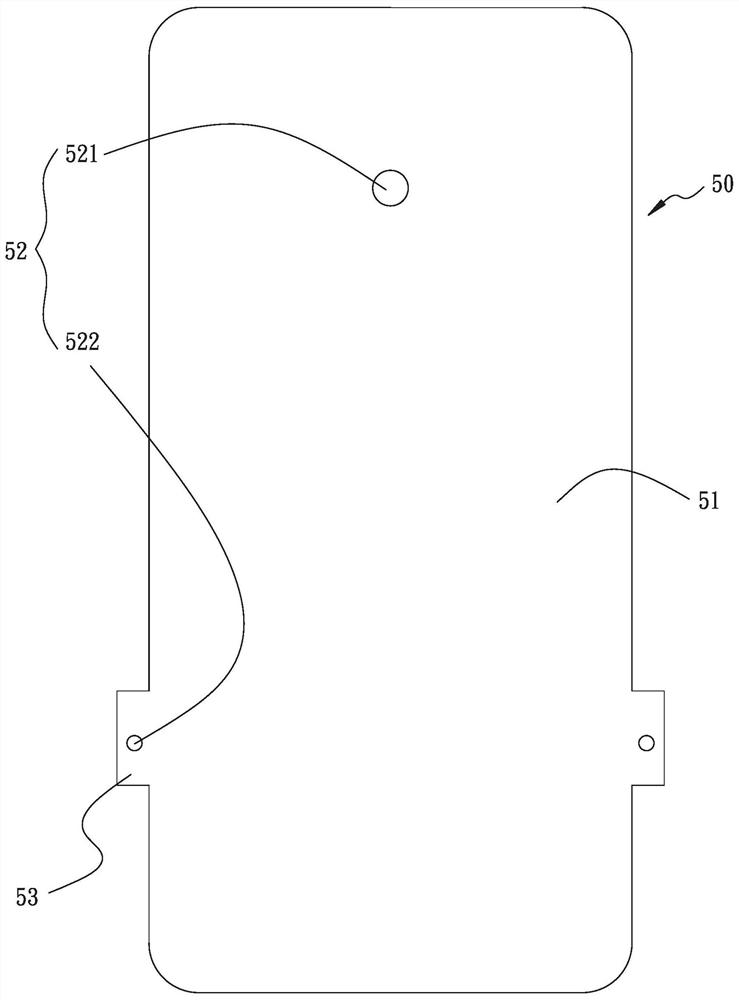

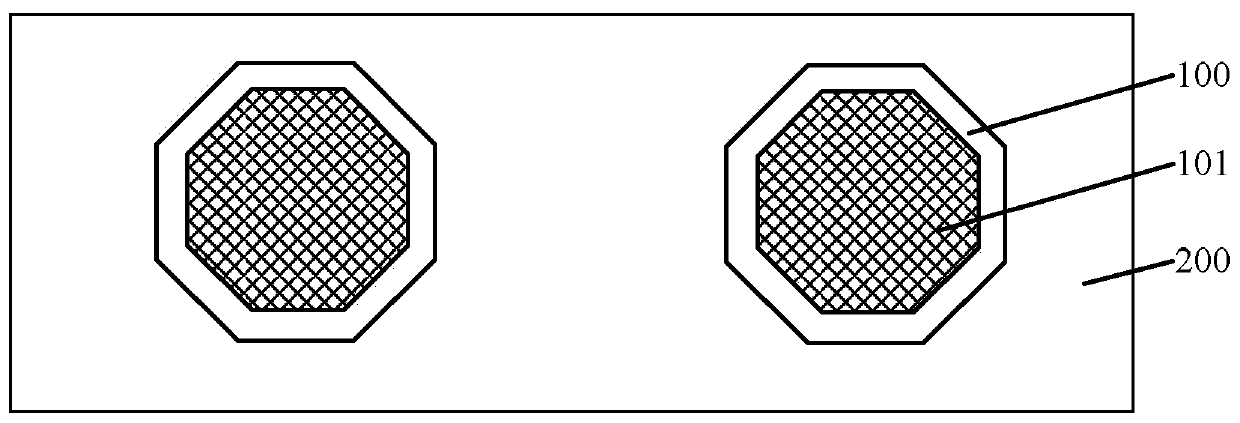

Square lithium ion battery winding cell and manufacturing method for same

ActiveCN104966852ASolve the deformationReduce deformation and wrinkleFinal product manufactureSecondary cellsPower batteryElectrical battery

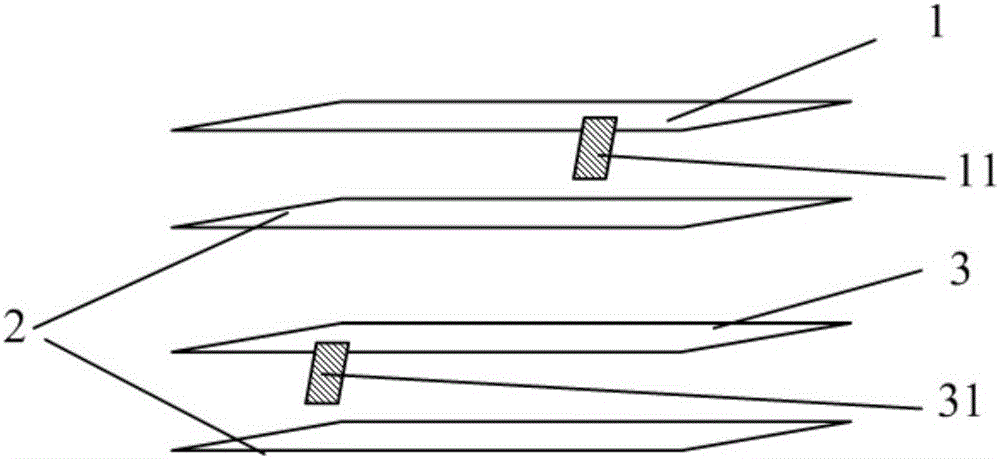

The invention provides a square lithium ion battery winding cell and a manufacturing method for the same. The square lithium ion battery winding cell comprises a positive pole piece, a diaphragm and a negative pole piece, wherein the positive pole piece is provided with a positive tab; the negative pole piece is provided with a negative tab; an internal supporting frame is arranged in the center of the square lithium ion battery winding cell. By the adoption of the technical scheme, the problems of easy deformation of pole pieces of a conventional square winding cell in charge-discharge cycles and easy disengagement of materials at semicircular positions of the bent pole pieces are solved, the consistency of a square lithium ion battery in a static state and a charge-discharge cycle dynamic state is maintained to the greatest extent, the production qualification rate of winding cells and the safety of the square lithium ion battery are improved, and conditions are created for reliable application of the square winding cell to the field of power batteries.

Owner:李震祺 +1

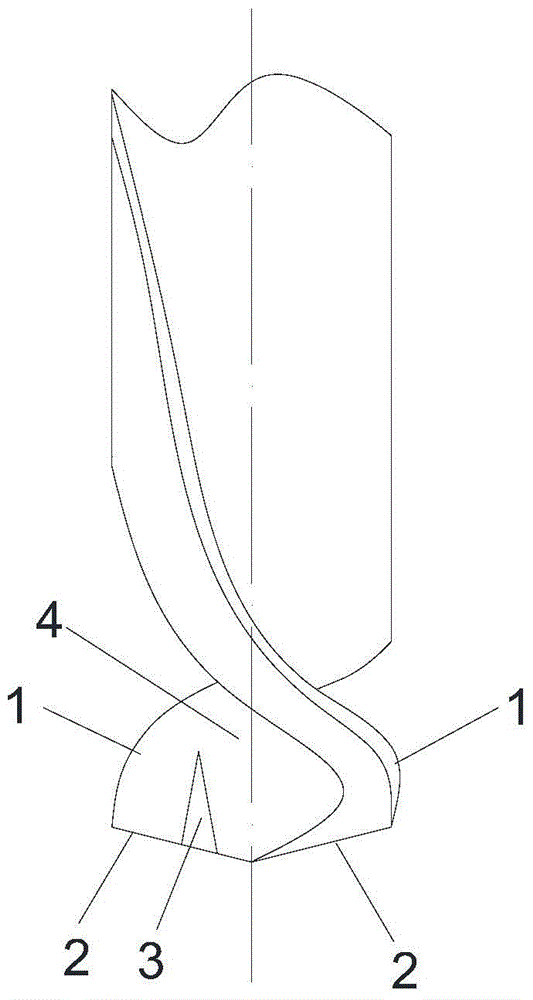

Drilling method of thick copper circuit board

InactiveCN104874826AEasy dischargeDischarge in timeTransportation and packagingTrepanning drillsCopper wirePetroleum engineering

The invention discloses a drilling method of a thick copper circuit board and relates to the technical field of circuit board manufacturing. The drilling method uses a drill with the rotation speed of 20-30krmp, tool feeding speed of 20-30mm / s and tool retracting speed of 220-300mm / s to drill holes. The drill comprises a drill stem and a drill bit. The drill bit comprises a cutting blade and a chip groove. The chip groove is axially provided with a groove at the drilling end of the drill bit. The thickness of copper of the inner circuit of the circuit board is not smaller than 3OZ. The method has the advantages that the drill with the groove notch is used, the groove notch in the drilling end of the3 drill bit can cut off a drilling copper wire, the cut-off copper wire can be discharge timely through the groove during drilling, and problems such as hole blocking and drilling copper wire drawing are avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

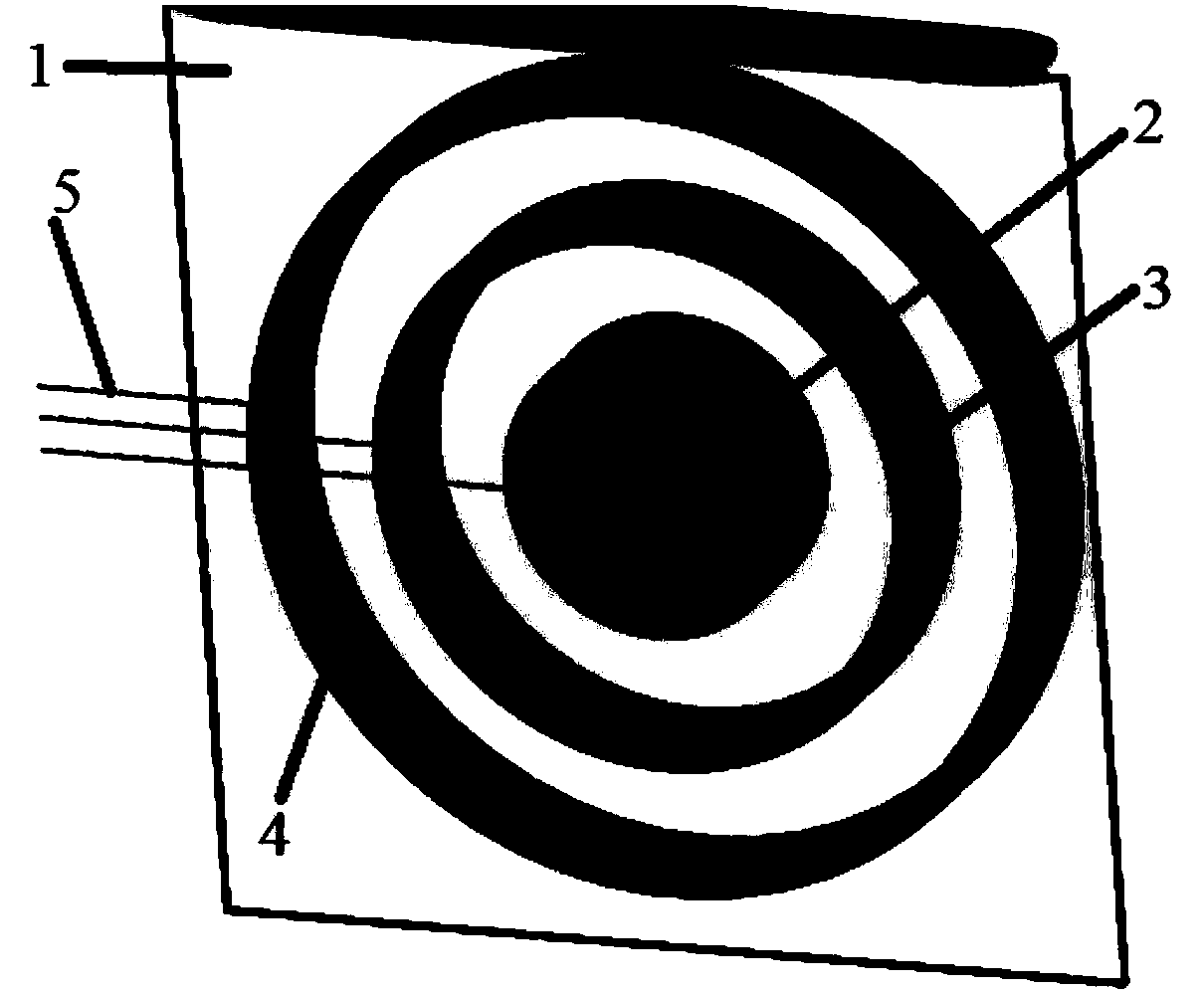

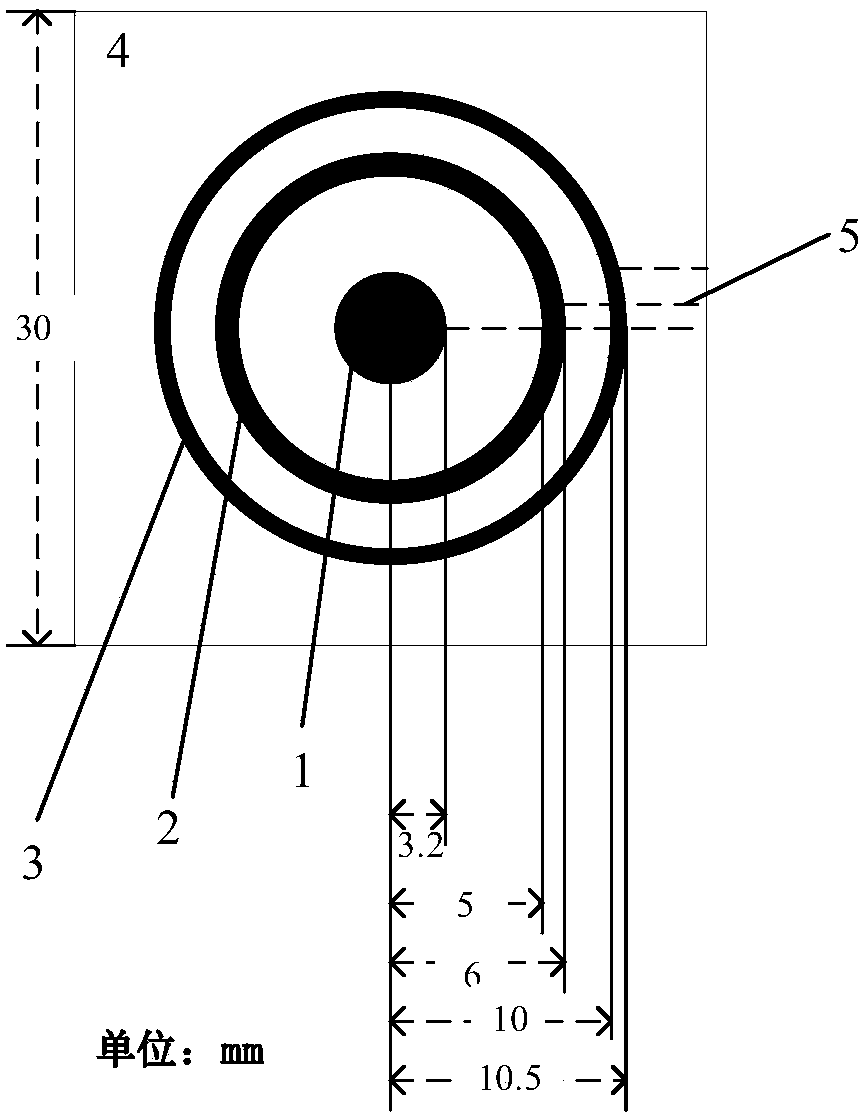

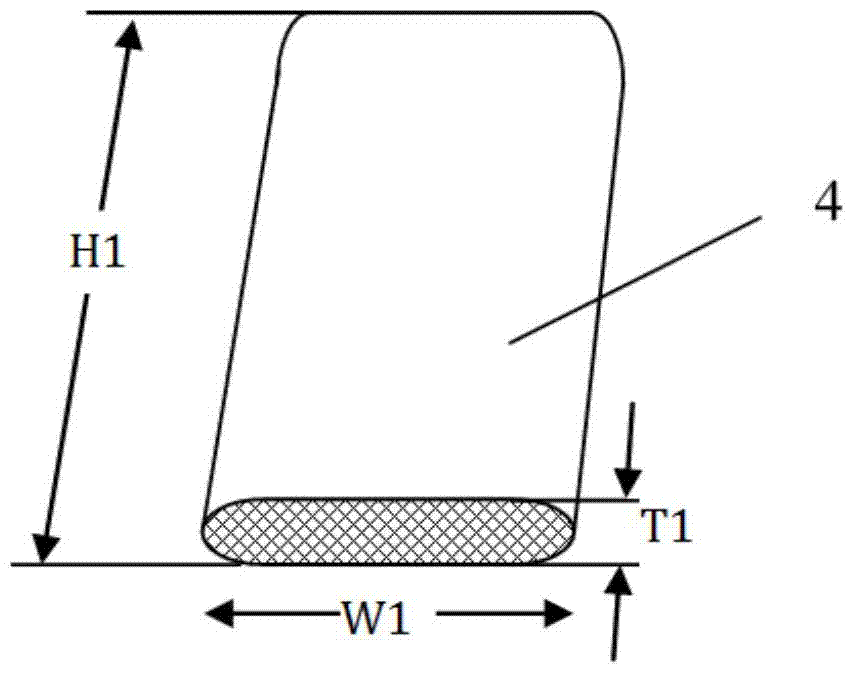

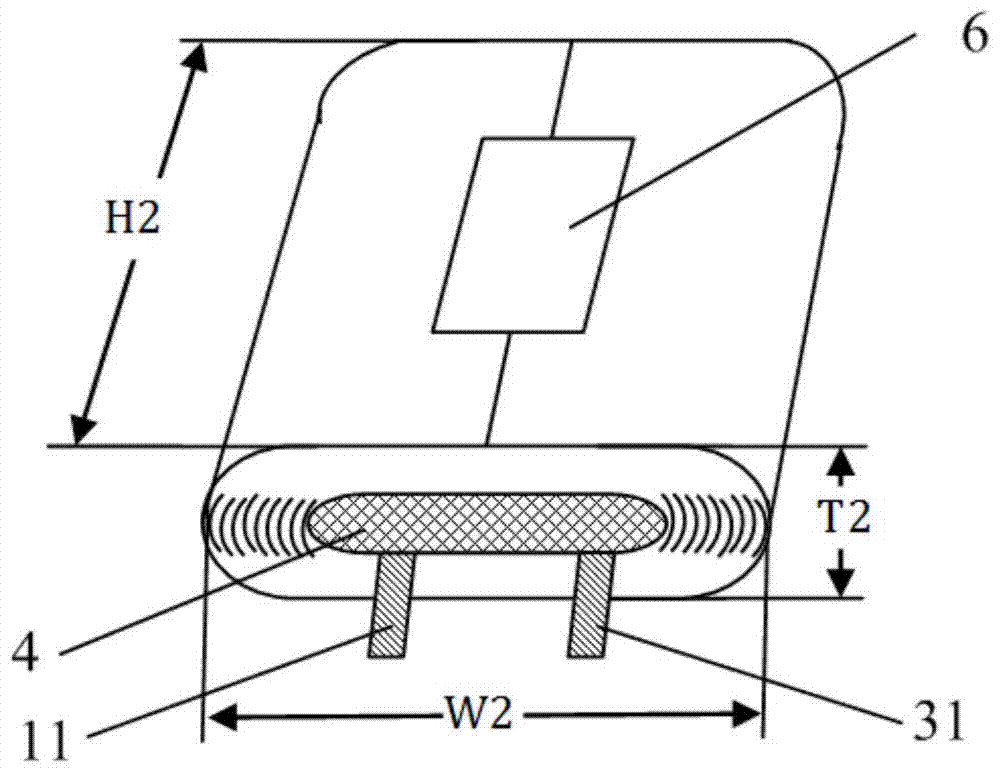

Flexible Laplacian electrode for detecting physiological electric signal

InactiveCN108209901AImprove fitImprove the problem of easy falling offDiagnostic recording/measuringSensorsSkin surfaceFlexible circuits

The invention provides a flexible Laplacian electrode for detecting a physiological electric signal, and belongs to the technical field of medical apparatuses. A flexible circuit is designed, a Laplacian electrode structure is embedded to a flexible substrate, and the Laplacian electrode is mainly composed of the flexible substrate, the Laplacian electrode structure and a connecting line. The physiological signal acquisition electrode can be randomly folded and bent, is of the Laplacian structure, is flexibly attached to the skin without gaps and does not easily fall.

Owner:BEIJING UNIV OF TECH

Conductive film replacing aluminum foil, and preparation method thereof

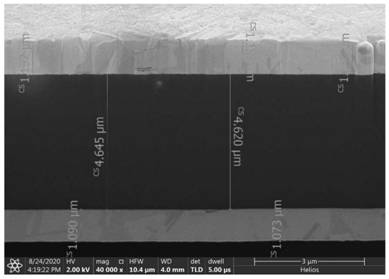

ActiveCN112201389AStable chemical propertiesStable temperature resistanceConductive layers on insulating-supportsVacuum evaporation coatingPolymer scienceOptical thin film

The invention discloses a conductive film replacing aluminum foil, and a preparation method thereof. The conductive film replacing aluminum foil comprises metal layers, middle reinforcing layers and apolymer film layer, wherein the middle reinforcing layers are arranged on the two sides of the polymer film layer, the metal layers are arranged on the outer sides of the middle reinforcing layers, the surface sheet resistance of the conductive film is 10-80 m omega, the tensile strength is 150-350 Mpa, the elongation at break is 75-150%, the elastic modulus is 3500-5500, the binding force between the middle reinforcing layer and the metal layer is greater than 2 N / 15 mm, the binding force between the polymer film layer and the middle reinforcing layer is 2-4 N / 15 mm, the water vapor transmission rate is less than 0.2 g / (m<2>.24 h), and the oxygen transmission rate is less than 0.005 cm <3> / (m<2>.24 h). According to the invention, the conductive film replacing the aluminum foil can be made to be very light and thin, the thickness is 3-20 microns, meanwhile, a plating layer is high in binding force, not prone to oxidation and falling, high in barrier property and good in conductivity,the conductive film has the advantages of being light, thin, high in strength and good in toughness, and the problems that pure aluminum foil is large in hardness and tension strength, small in tearing strength, extremely easy to tear, high in cost, large in weight and the like are effectively solved; and the conductive film can be used for replacing the traditional aluminum foil to be applied tothe fields of optical films, thermal protection coatings, shielding films, high-end food / medicine / cosmetic packaging with better barrier property requirements, electronic devices, batteries and the like.

Owner:浙江柔震科技有限公司

Aluminum substrate resistance welding screen making method for preventing photosensitive slurry from falling off

ActiveCN105517366AImprove the problem of easy falling offAvoid abnormal qualityNon-metallic protective coating applicationDirectly printed exposure masksSpray coatingPulp and paper industry

An aluminum substrate resistance welding screen making method for preventing photosensitive slurry from falling off comprises the following steps: (1) using double-sided adhesive to paste a PET protective film to each of the positions, corresponding to the running tracks at the two ends of a scraper, on the front of a screen mesh; (2) applying glue water to the positions, corresponding to the PET protective films, on the back of the screen mesh, and naturally drying the glue water for a period of time after glue water applying to make the PET protective films cured on the screen mesh; (3) before photosensitive slurry is applied, adding boiling oil water to the photosensitive slurry according to the ratio of 30ml boiling oil water to 1kg photosensitive slurry, manually stirring the boiling oil water and the photosensitive slurry, and letting the mixture stand for a period of time; (4) spray-coating a given photosensitive slurry applying position of the screen mesh with the photosensitive slurry added with boiling oil water; and (5) after the photosensitive slurry is applied, baking the screen in an oven for a period of time to make the photosensitive slurry cured on the screen mesh. By using the method, the problem that the photosensitive slurry on the mesh in the positions of the two ends of the scraper is easy to fall off is improved effectively, the product quality is improved, and the service life of the screen is increased.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

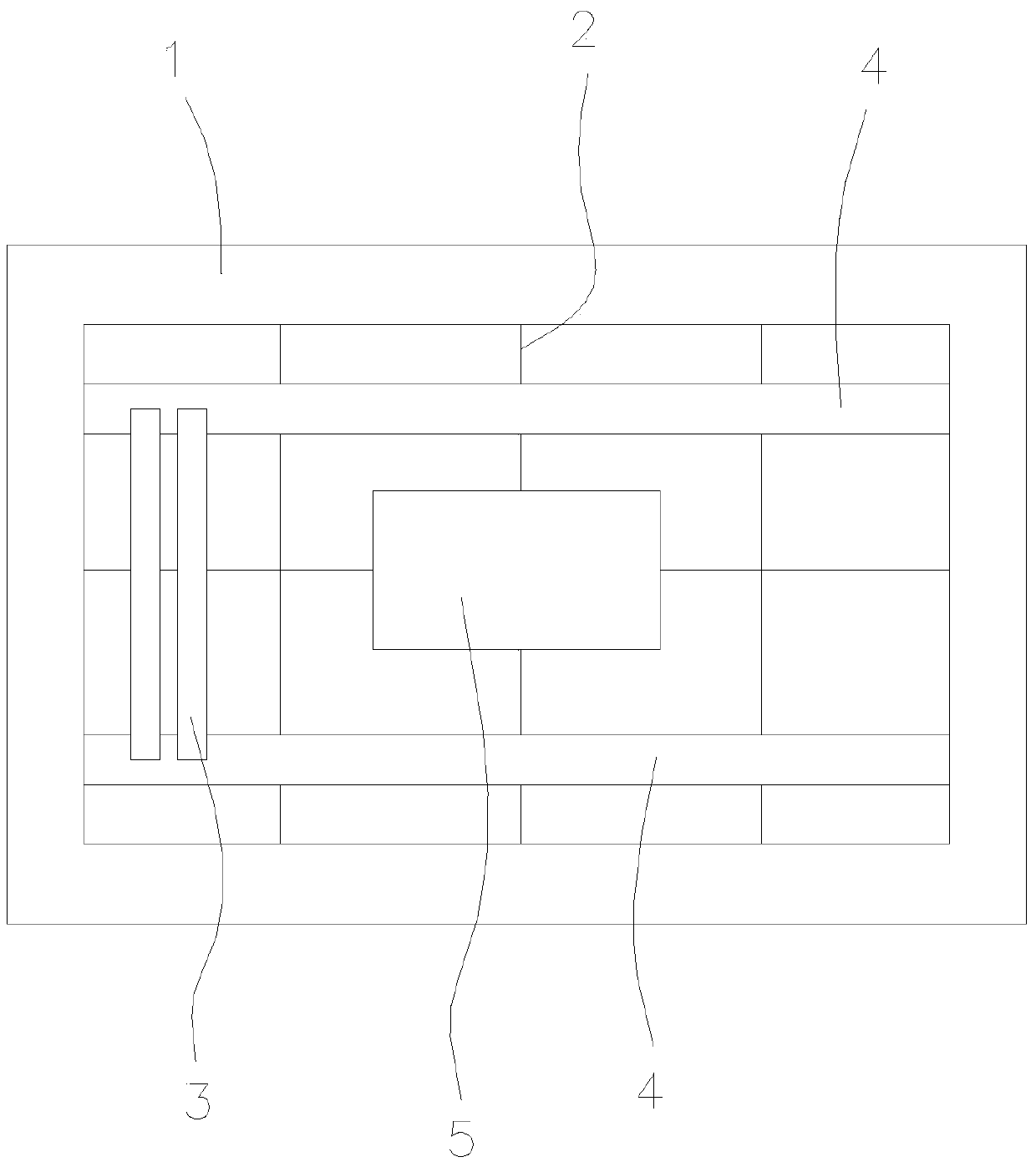

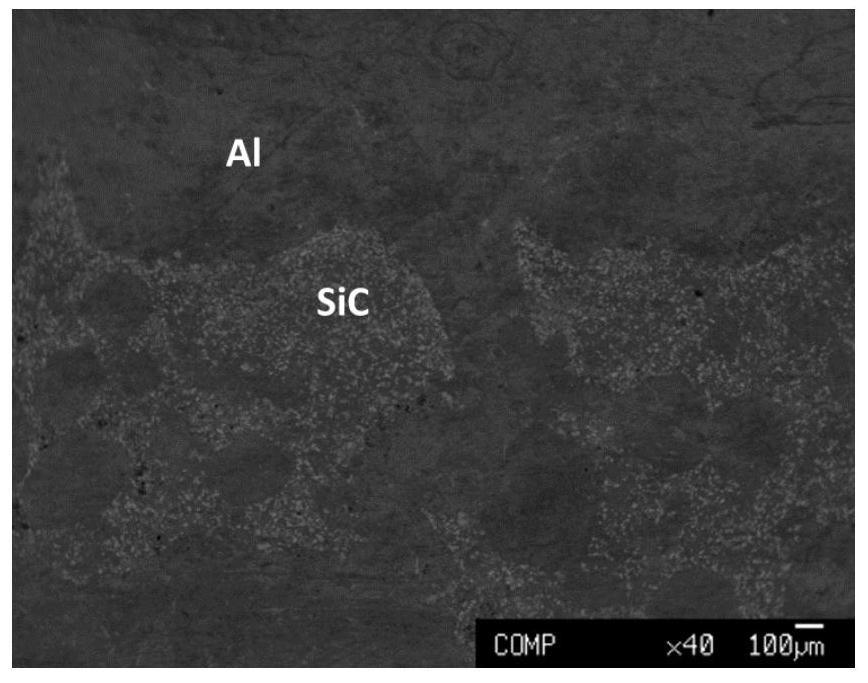

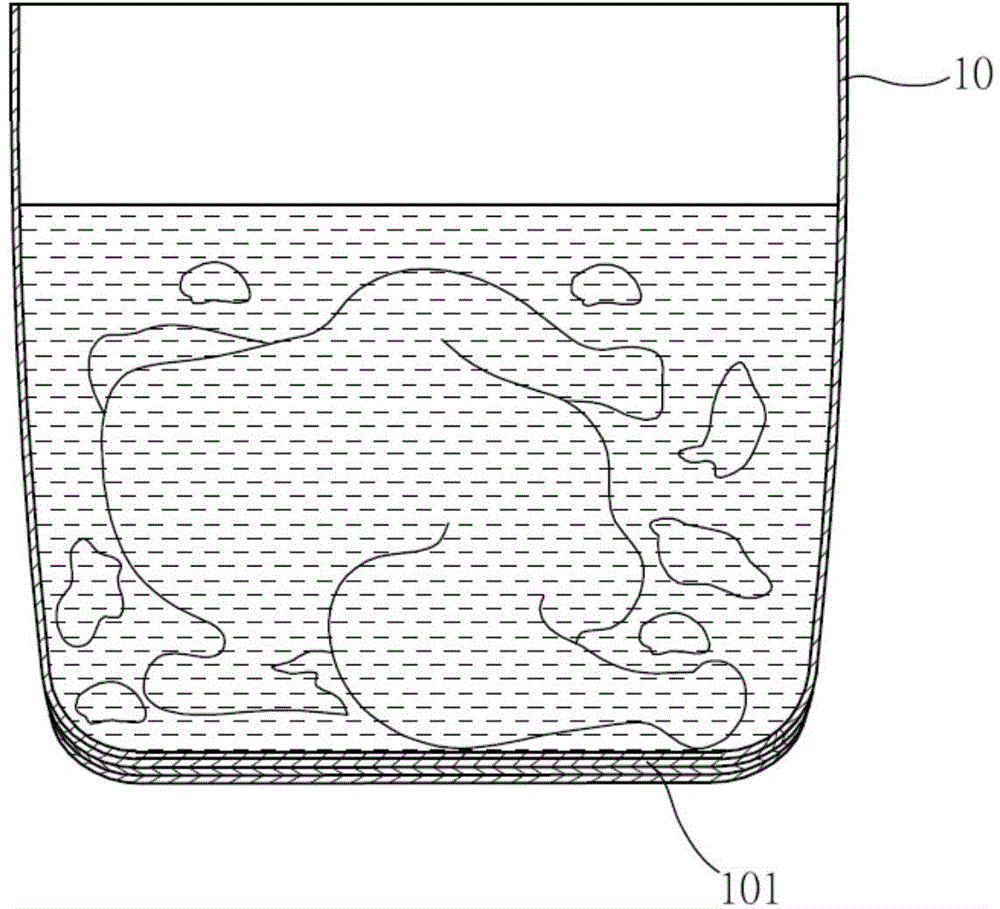

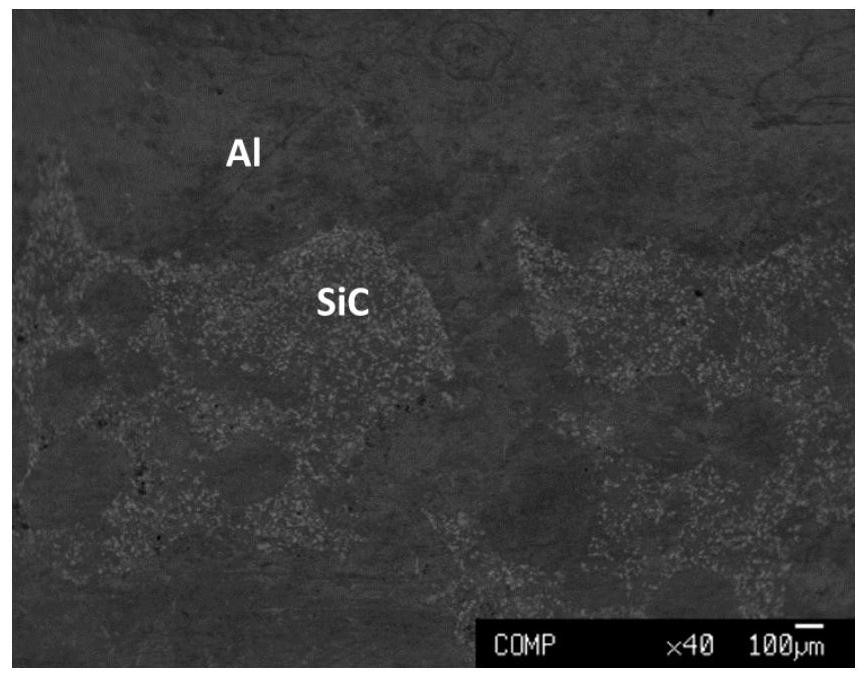

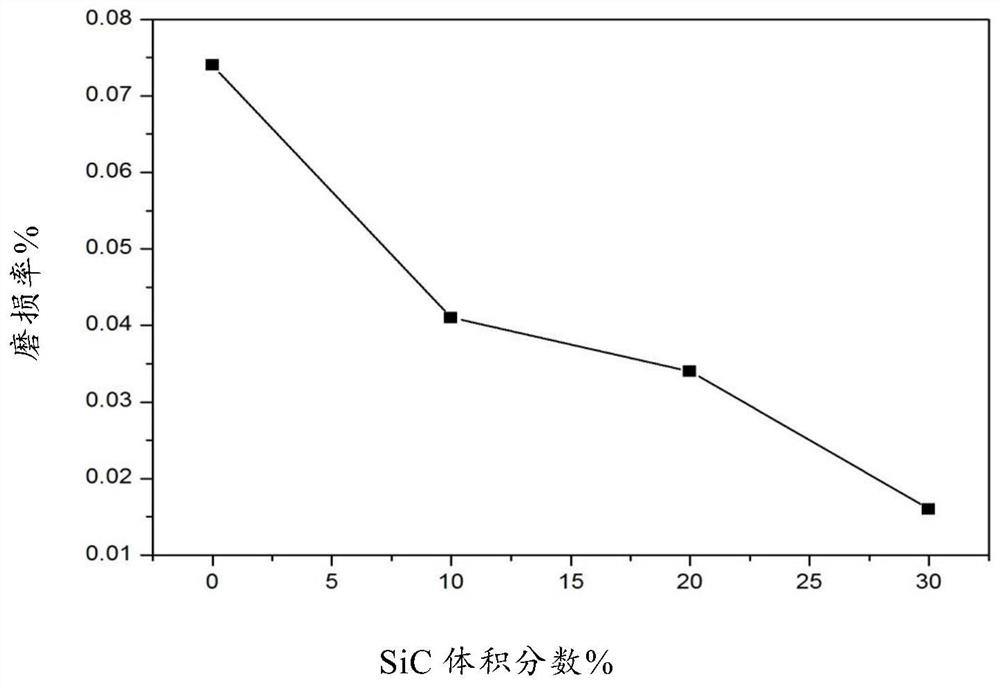

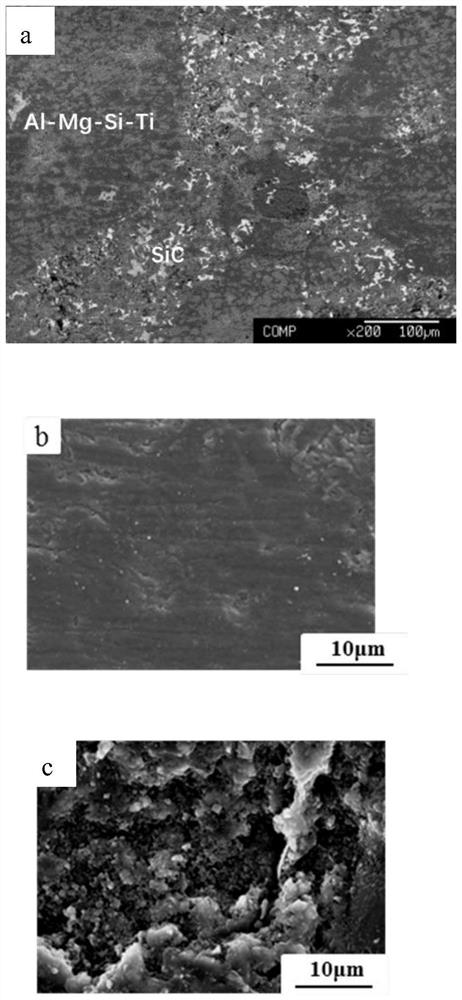

Preparation method of metal ceramic composite material

The invention discloses a preparation method of a metal ceramic composite material. The method comprises the following steps: (1) sequentially carrying out crushing, ultrasonic cleaning and drying onfoamed SiC ceramic according to the procedures of primary crushing, secondary crushing and tertiary crushing to obtain an ellipsoidal SiC ceramic block with the size of 2 mm to 15 mm; (2) carrying outpre-oxidation, pre-corrosion and cleaning on the ellipsoidal SiC ceramic block obtained in the step (1) to obtain a foamed SiC ceramic reinforcement; and (3) mixing the foamed SiC ceramic reinforcement obtained in the step (2) with metal, putting the mixture into a mold, performing heating and applying pressure in a nitrogen atmosphere, performing cooling, solidifying, demolding and polishing toobtain the metal ceramic composite material.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

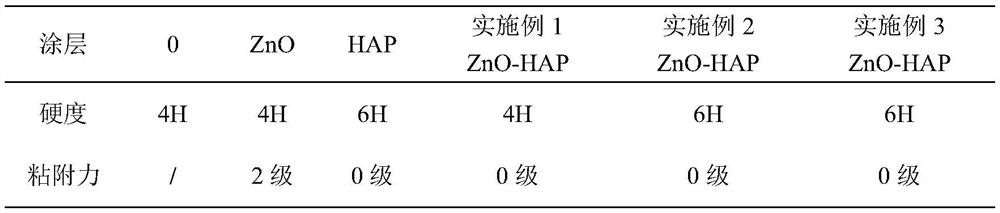

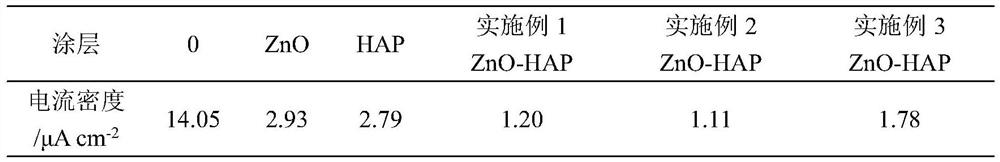

Preparation method of zinc oxide-hydroxyapatite composite anticorrosive pigment

ActiveCN114163859AImprove the problem of easy falling offImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsZinc Acetate DihydrateOxide coating

The invention relates to a preparation method of a zinc oxide-hydroxyapatite composite anticorrosive pigment, which comprises the following steps: adding calcium chloride powder and urea into a disodium hydrogen phosphate dodecahydrate solution, ultrasonically mixing uniformly, carrying out hydrothermal reaction in a reaction kettle, washing and drying to obtain flaky hydroxyapatite powder; the preparation method comprises the following steps: uniformly stirring hydroxyapatite powder in deionized water, sequentially adding zinc acetate dihydrate and sodium hydroxide, ultrasonically mixing uniformly, carrying out hydrothermal reaction in a reaction kettle, washing and drying to obtain the zinc oxide-hydroxyapatite composite anticorrosive pigment. According to the invention, nano-zinc oxide and hydroxyapatite are compounded into the anti-corrosion pigment, so that the problems that a nano-zinc oxide coating is easy to fall off and a hydroxyapatite coating is poor in anti-corrosion performance are solved, the adhesion performance of the coating and metal is improved, the porosity of the coating is reduced, chloride ions are cured, and synergistic corrosion prevention is realized.

Owner:WUHAN UNIV OF TECH

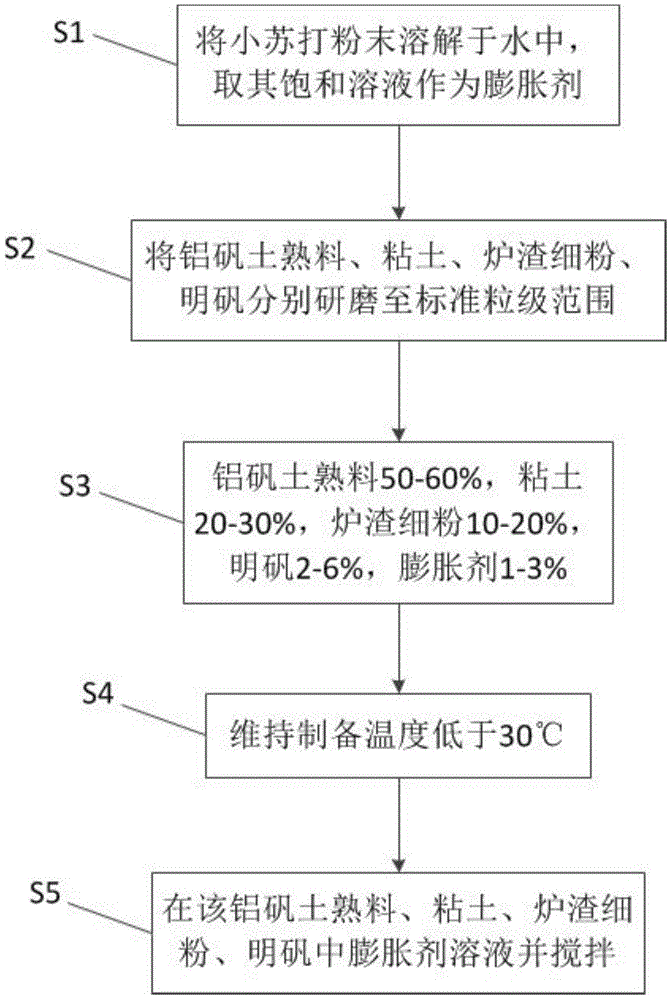

High temperature-resistant micro-expansive caulking mud and preparation method thereof

InactiveCN104788064AImprove secondary pollutionImprove the problem of easy falling offSolid waste managementSlagAlum

The invention discloses a high temperature-resistant micro-expansive caulking mud and a preparation method thereof. The preparation method comprises the following steps: step 1, dissolving sodium bicarbonate powder in water and taking a saturated solution of the dissolved sodium bicarbonate as an expanding agent; step 2, separately grinding 50 to 60% of bauxitic clay clinker, 20 to 30% of clay, 10 to 20% of fine slag powder and 2 to 6% of alum to respective standard particle size ranges; and step 3, adding the expanding agent solution containing 1 to 3% of sodium bicarbonate into bauxitic clay clinker, clay, fine slag powder and alum and carrying out stirring. With such a technical scheme, defects of secondary pollution, easy falling and high cost of conventional stemming caulking technology are overcome, and the caulking mud provided by the invention has high strength and can meet requirements on caulking of joints of cover plates. The production cost of the caulking mud provided by the invention is 1 / 3 of the production cost of the stemming, so blast furnace production cost is reduced; moreover, the caulking mud does not cause secondary pollution, thereby substantially promoting environmental protection.

Owner:BAOSTEEL STAINLESS STEEL

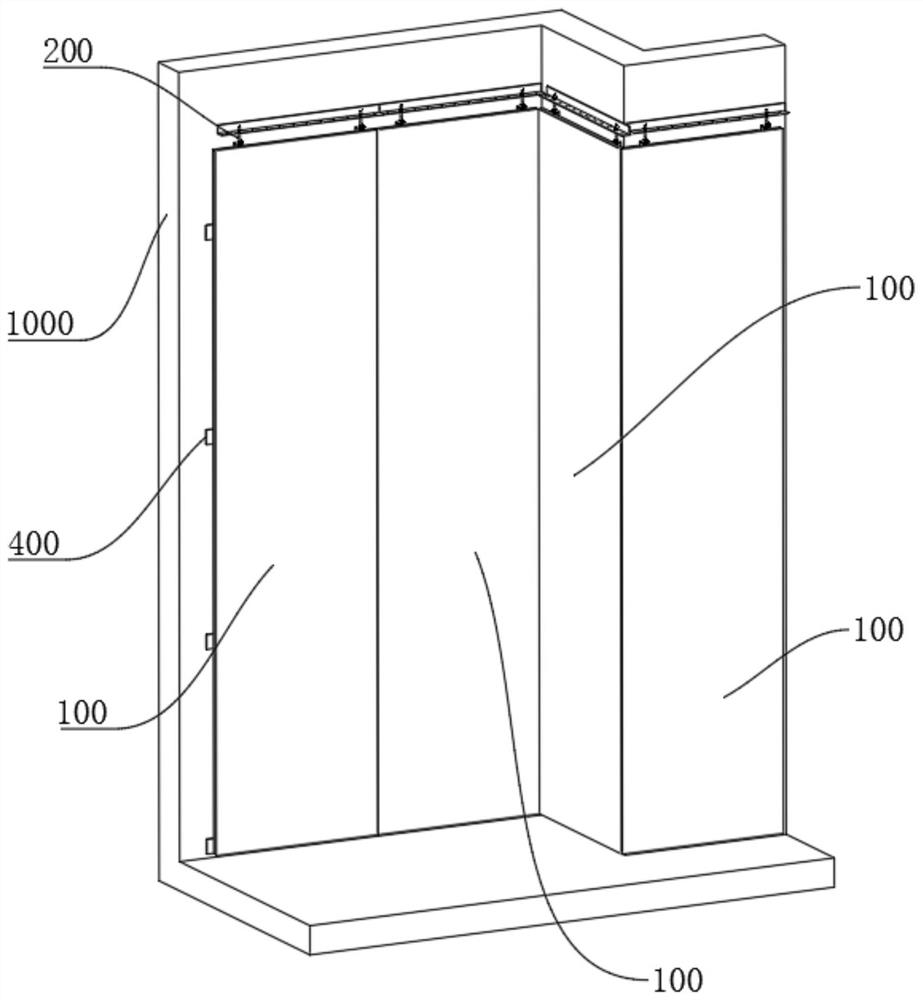

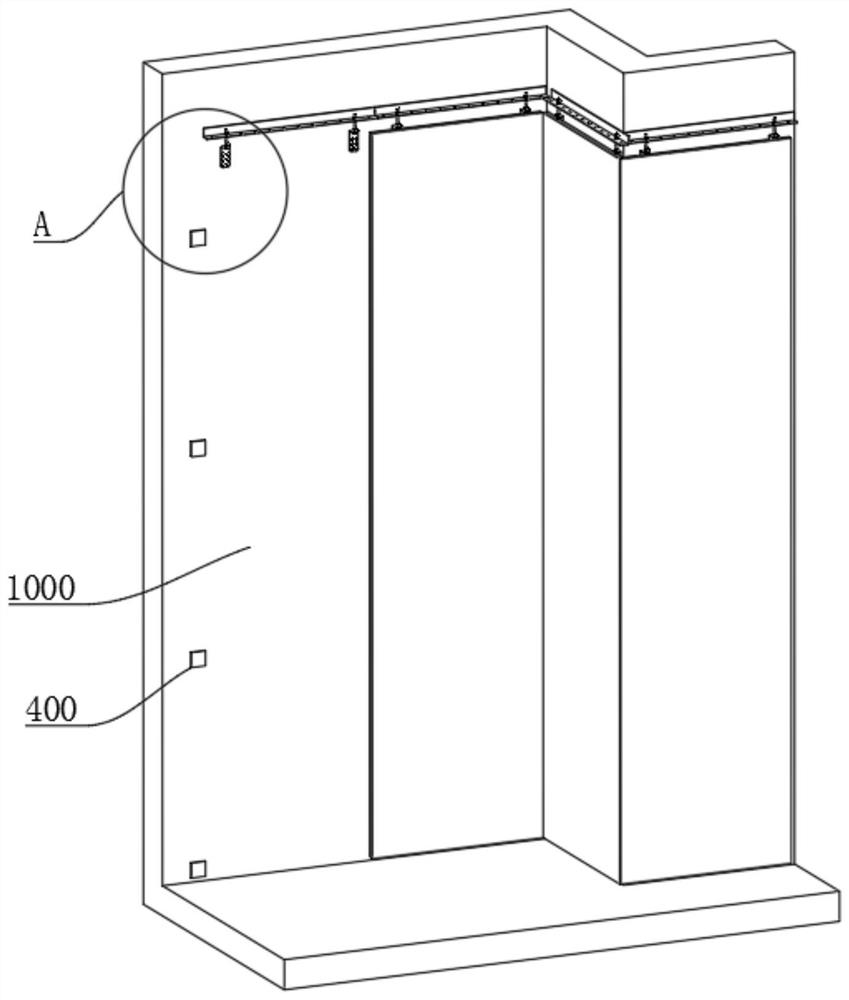

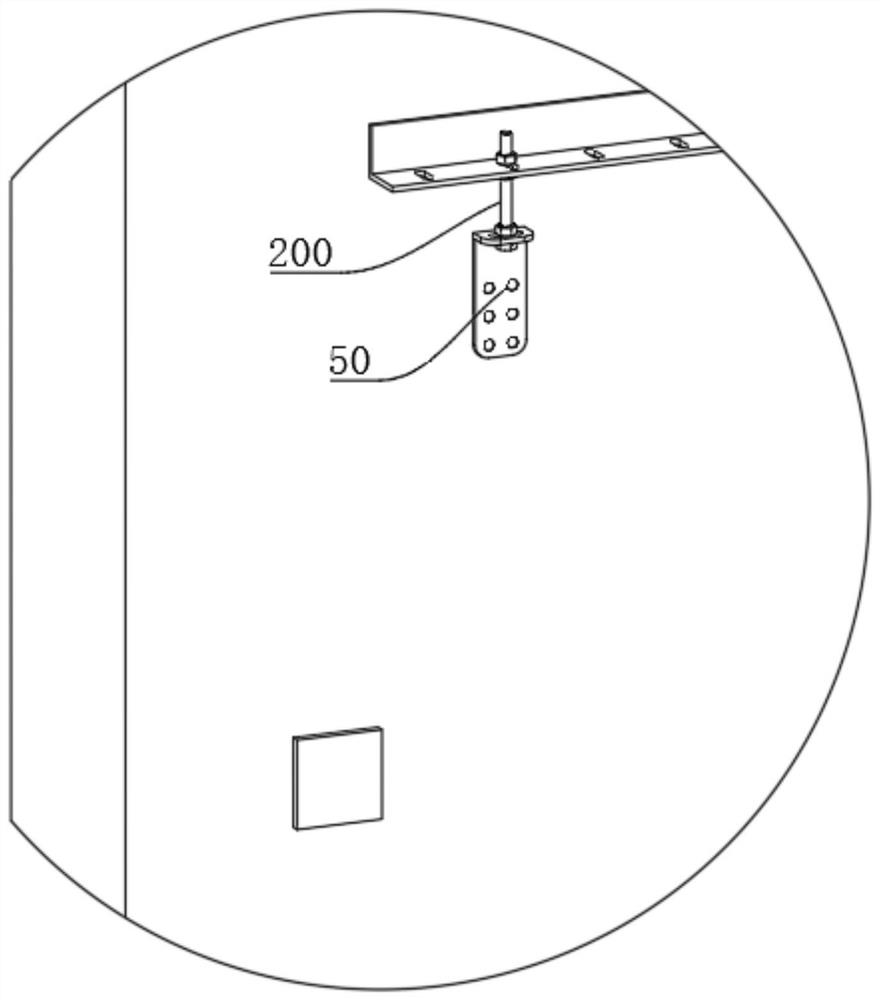

Crack resistance oil mahogany solid wood door

ActiveCN107120039BHigh glossLong-term use is firm and does not deformNoise insulation doors/windowsCoatingsVisibilitySolid wood

Owner:安徽舒柏阳门窗制造有限公司

Preparation method of tantalum 2.5 tungsten alloy

The invention provides a preparation method of a tantalum 2.5 tungsten alloy. The preparation method comprises the following steps: after preparing tantalum powder and tungsten powder in proportion, putting the powder into a drum mixer to be mixed for 24 hours; sieving the mixed powder with a 120-mesh sieve to obtain fine powder; pressing the fine powder into an alloy bar with a 500ton oil press; putting the alloy bar into a vacuum sintering furnace to be sintered to obtain a raw ingot blank; smelting the raw ingot blank at least twice with a vacuum electron beam furnace to prepare an alloy ingot blank; putting the alloy ingot blank into a high frequency furnace to be heated to 1400 DEG C, then taking out the alloy ingot blank and forging the alloy ingot blank for many times, thus obtaining a finished product of ingot blank. The preparation method has the beneficial effects that through full mixing of tantalum powder and tungsten powder and many times of smelting, the problem of nonuniformity of ingot blank tissues is solved and the problems that the blanks easily fall off and become brittle are improved.

Owner:陕西世纪创优金属材料有限公司

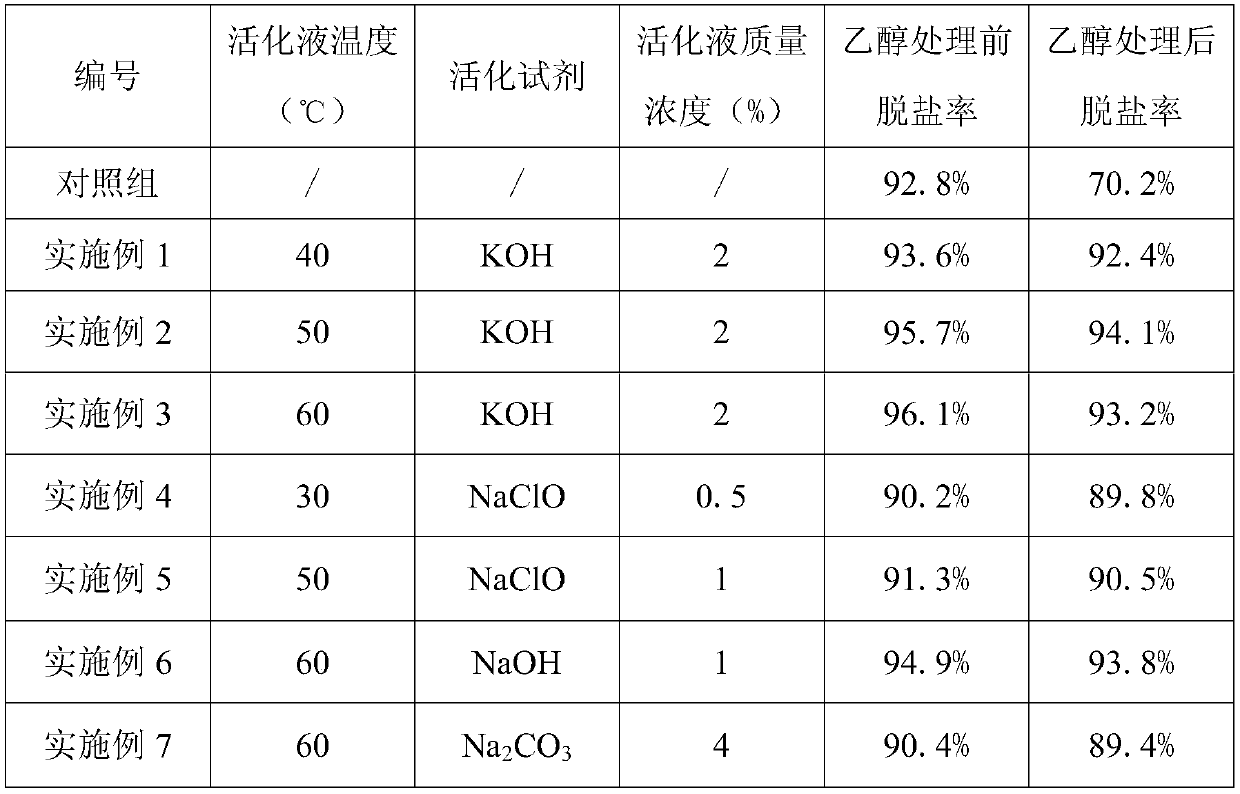

Polyamide hollow fiber nanofiltration composite membrane and preparation method thereof

The invention provides a polyamide hollow fiber nanofiltration composite membrane and a preparation method thereof. The preparation method comprises the following steps: 1, activating a polyamide hollow fiber ultrafiltration membrane to form carboxylic acid groups and amino groups on the surface of the polyamide hollow fiber ultrafiltration membrane; 2, putting the activated polyamide hollow fiberultrafiltration membrane into a polyamine aqueous solution; 3, taking out the polyamide hollow fiber ultrafiltration membrane from the polyamine aqueous solution, and putting the polyamide hollow fiber ultrafiltration membrane into a polyacyl chloride organic solution, wherein an interfacial polymerization reaction is generated on the surface of the polyamide hollow fiber ultrafiltration membraneto form a separation layer; and 4, taking out the polyamide hollow fiber ultrafiltration membrane with the separation layer from the polyacyl chloride organic solution, and carrying out heat treatment on the polyamide hollow fiber ultrafiltration membrane to obtain the polyamide hollow fiber nanofiltration composite membrane. By utilizing the method, the structural defects of the membrane separation layer can be effectively reduced, the connection tightness between the base membrane and the separation layer is enhanced, and the use performance of the membrane is improved.

Owner:OCHEMATE MATERIAL TECH CO LTD

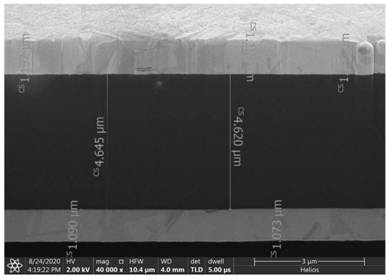

Conductive film replacing aluminum foil and preparation method thereof

ActiveCN112201389BStable chemical propertiesStable temperature resistanceConductive layers on insulating-supportsVacuum evaporation coatingThin membraneOptical thin film

The invention discloses a conductive film replacing aluminum foil and a preparation method thereof. The conductive film replacing aluminum foil includes a metal layer, an intermediate reinforcing layer and a polymer film layer, and the intermediate reinforcing layer is arranged on both sides of the polymer film layer. , the metal layer is arranged on the outside of the middle reinforcing layer, the surface resistance of the conductive film is 10-80mΩ, the tensile strength is 150-350Mpa, the elongation at break is 75-150%, and the elastic modulus is 3500- 5500, the bonding force between the middle reinforcement layer and the metal layer is greater than 2N / 15mm, the bonding force between the polymer film layer and the middle reinforcement layer is 2‑4N / 15mm, and the water vapor transmission rate is <0.2g / (m 2 .24h), oxygen transmission rate <0.005cm 3 / (m 2 .24h). This conductive film that replaces aluminum foil can be made very light and thin, with a thickness of 3-20 microns. At the same time, the coating has a strong bonding force, is not easy to oxidize and fall off, has high barrier properties, good conductivity, and has light, thin, high strength and good toughness. Features, effectively solve the problems of high hardness and high tensile strength of pure aluminum foil, but small tear strength, easy to tear, high cost and heavy weight. It can be used to replace traditional aluminum foil in the fields of optical film, thermal protective coating, shielding film, high-end food / drug / cosmetic packaging with better barrier properties, electronic devices and batteries.

Owner:浙江柔震科技有限公司

Drilling method for thick copper circuit board

InactiveCN104874826BEasy dischargeDischarge in timeTransportation and packagingTrepanning drillsCopper wireCopper-wiring

The invention discloses a drilling method of a thick copper circuit board and relates to the technical field of circuit board manufacturing. The drilling method uses a drill with the rotation speed of 20-30krmp, tool feeding speed of 20-30mm / s and tool retracting speed of 220-300mm / s to drill holes. The drill comprises a drill stem and a drill bit. The drill bit comprises a cutting blade and a chip groove. The chip groove is axially provided with a groove at the drilling end of the drill bit. The thickness of copper of the inner circuit of the circuit board is not smaller than 3OZ. The method has the advantages that the drill with the groove notch is used, the groove notch in the drilling end of the3 drill bit can cut off a drilling copper wire, the cut-off copper wire can be discharge timely through the groove during drilling, and problems such as hole blocking and drilling copper wire drawing are avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

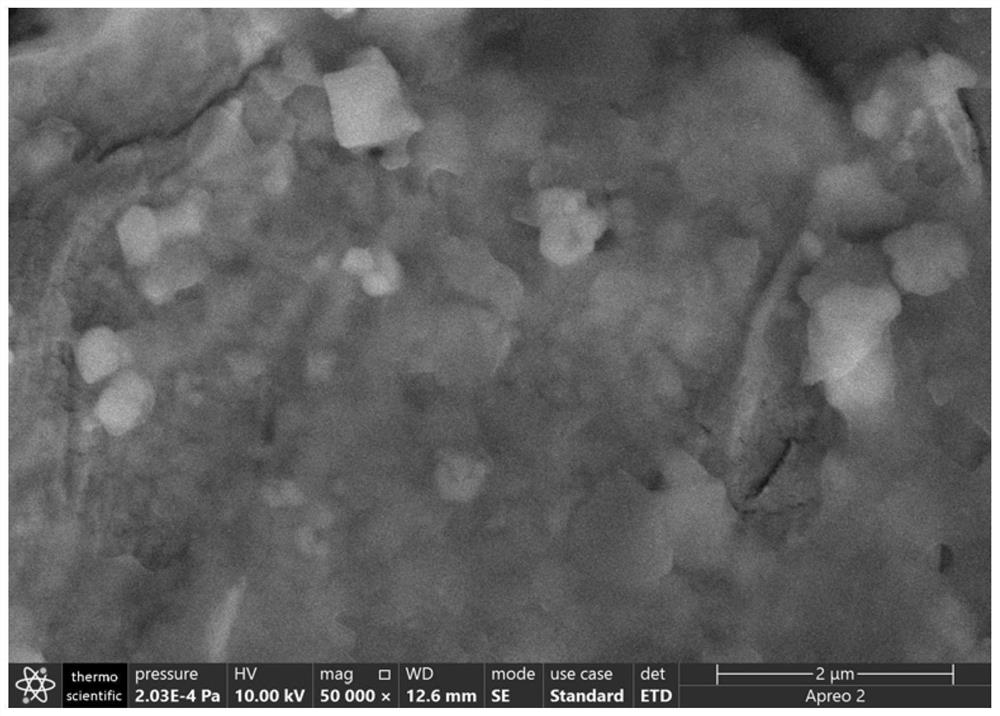

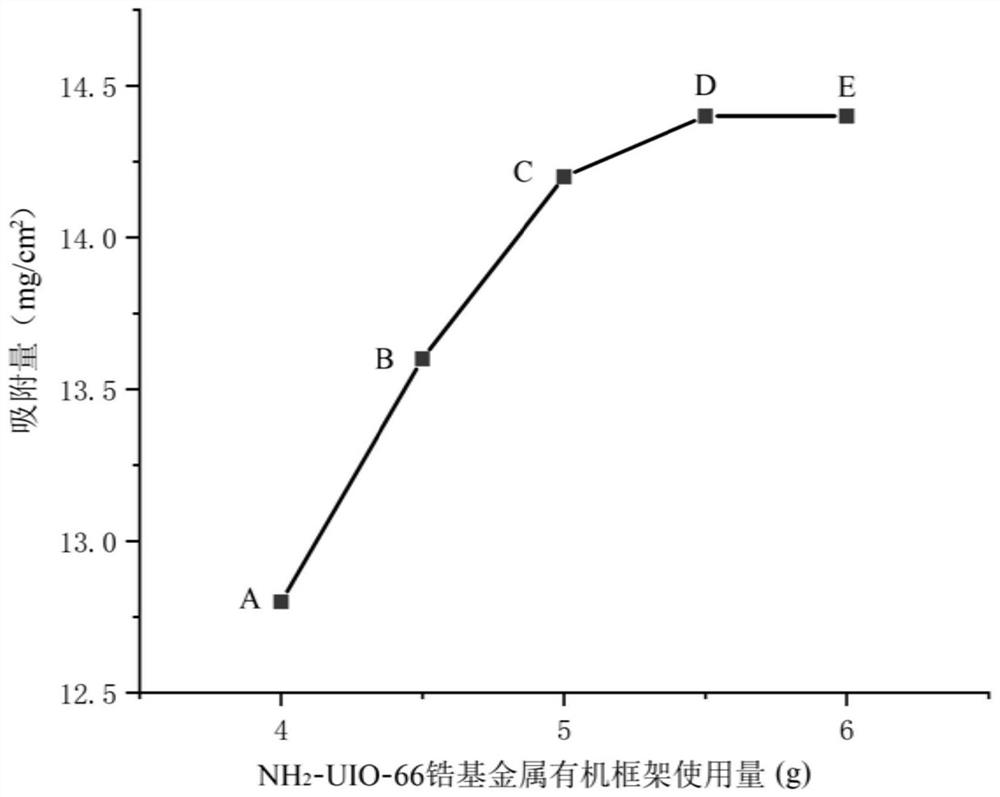

Preparation method of lithium ion imprinted composite nanofiber membrane based on MOFs (Metal-Organic Frameworks)

ActiveCN114797799AAvoid the problem of dissolving in DMFReduce usageOther chemical processesAlkali metal oxides/hydroxidesComposite nanofibersOrganic solvent

The invention discloses a preparation method of a lithium ion imprinting composite nanofiber membrane based on MOFs (Metal-Organic Frameworks), relates to the field of ion imprinting membrane preparation methods, and in particular relates to a method for combining MOFs and an ion imprinting technology. The invention aims to solve the problems that a large amount of dangerous organic solvents are used, the cost is high, the influence on the environment is great, the adsorption effect is poor, and high-selectivity removal of target pollutants in a complex system cannot be realized in the conventional method for loading MOFs on nanofibers. The method comprises the following steps: 1, preparing a high-selectivity Li < + > imprinted polymer; 2, preparing a polyacrylonitrile nanofiber membrane; and 3, preparing the MOFs-Li < II > Ps (at) PAN by a hydrothermal method, so as to obtain the lithium ion imprinted composite nanofiber membrane based on the MOFs. The lithium ion imprinted composite nanofiber membrane based on the MOFs prepared by the preparation method disclosed by the invention has the advantage that the adsorption capacity of the lithium ion is as high as 99.99%. The lithium ion imprinted composite nanofiber membrane based on the MOFs can be obtained by the preparation method disclosed by the invention.

Owner:NORTHEAST DIANLI UNIVERSITY

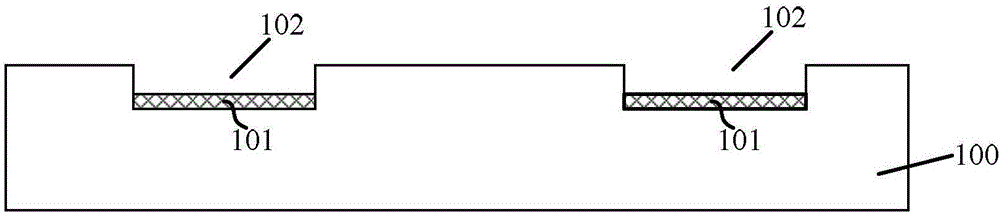

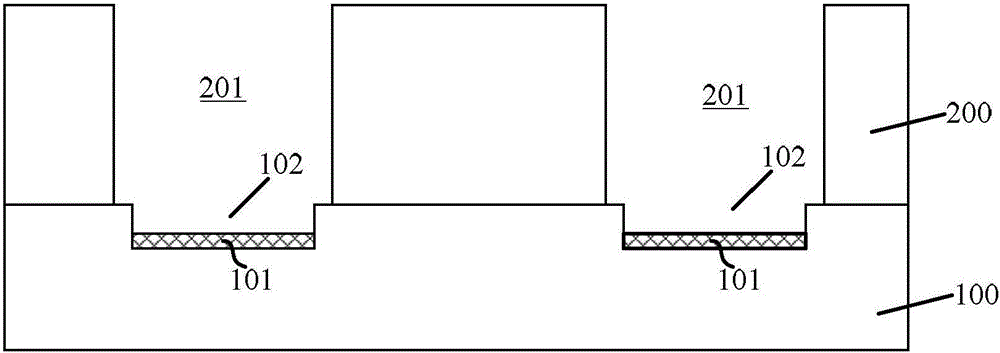

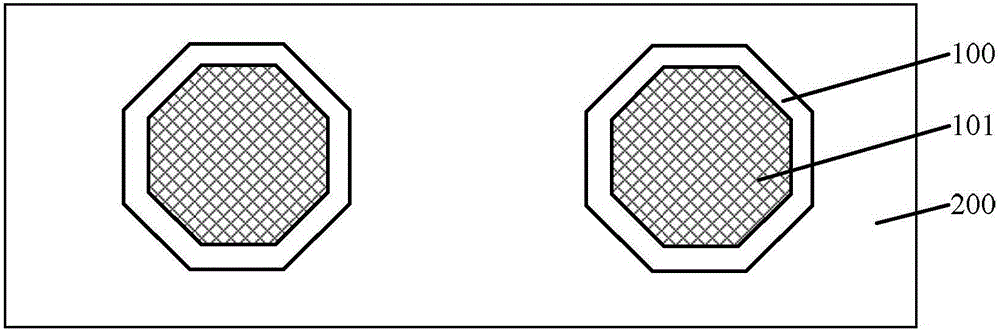

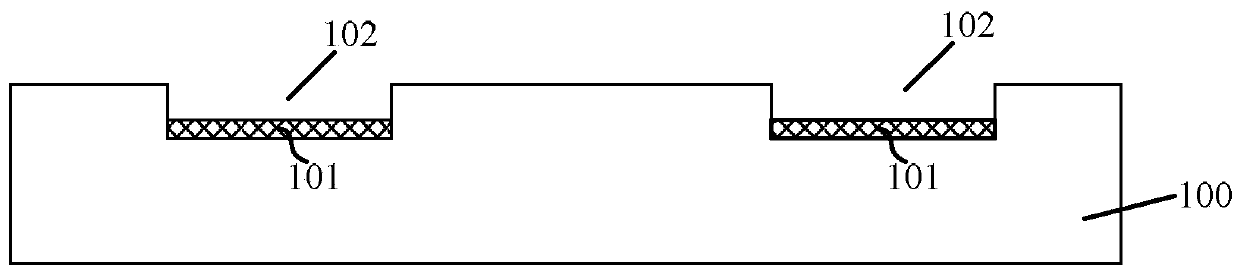

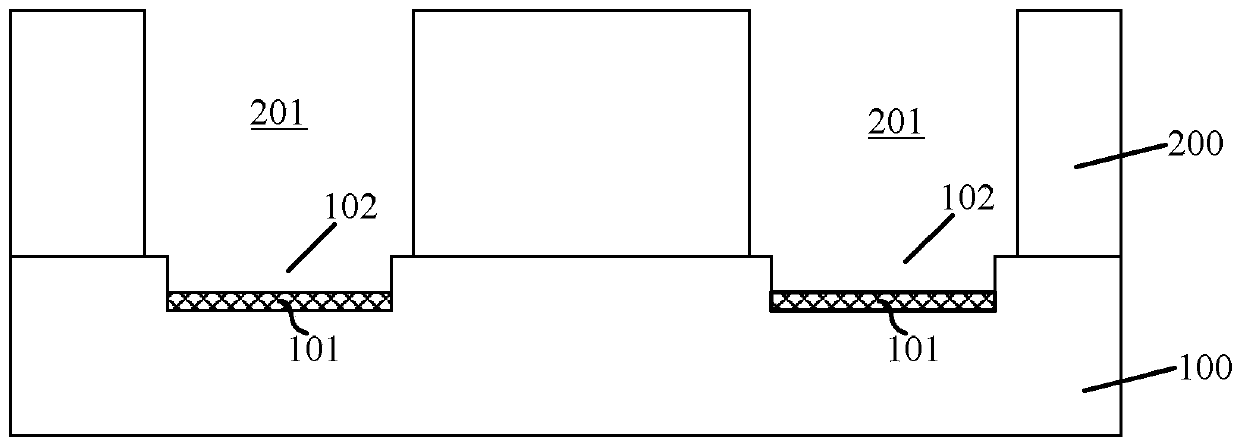

Semiconductor structure and forming method thereof

ActiveCN106252247AUniform stress distributionNot easy to fall off or breakSemiconductor/solid-state device detailsSolid-state devicesVertical distanceSemiconductor structure

The invention discloses a semiconductor structure and a forming method thereof. The semiconductor structure comprises a substrate, wherein the surface of the substrate is provided with a groove. The groove is exposed out of the surface of a metal layer. A metal bump is positioned on the surface of the metal layer and on the partial surface of the substrate. The shape of the cross section of the metal bump is the same as the shape of the cross section of the groove. The vertical distances between the sidewalls of the metal bump and the sidewalls of the groove are the same. The metal bump in the semiconductor structure is not easy to break or fall off.

Owner:JIANGSU NEPES SEMICON

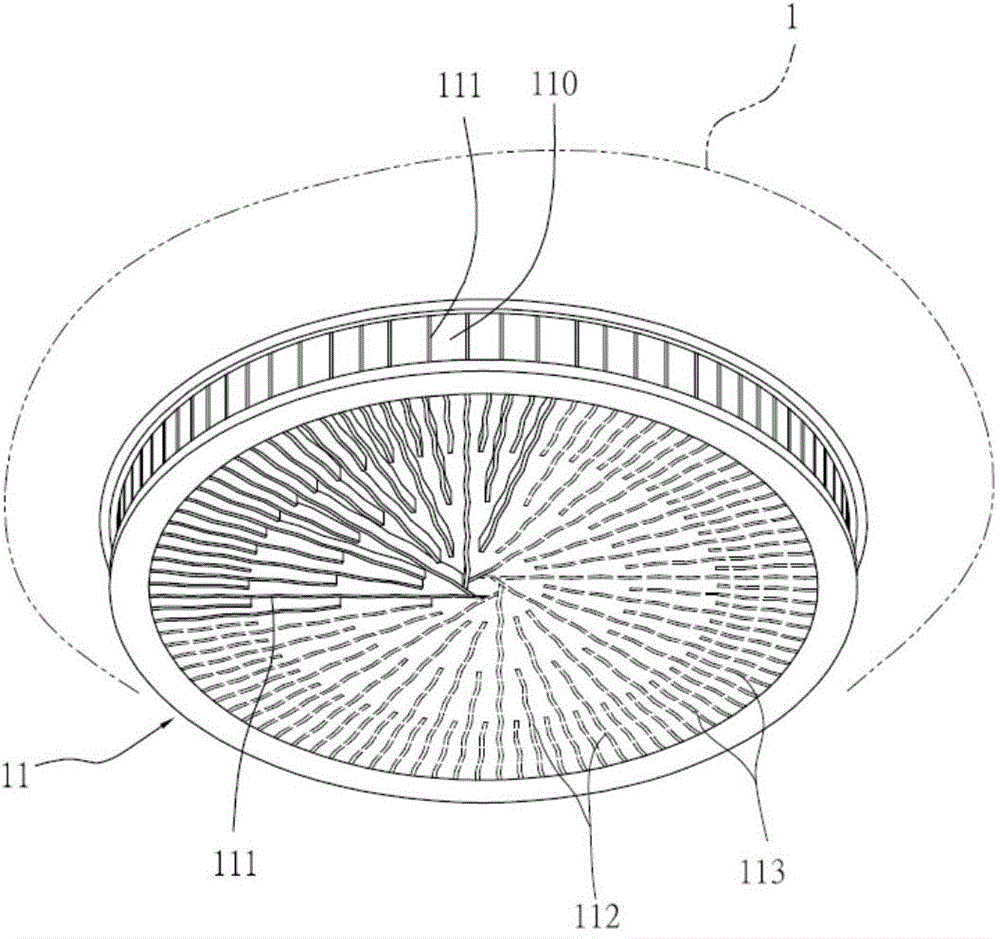

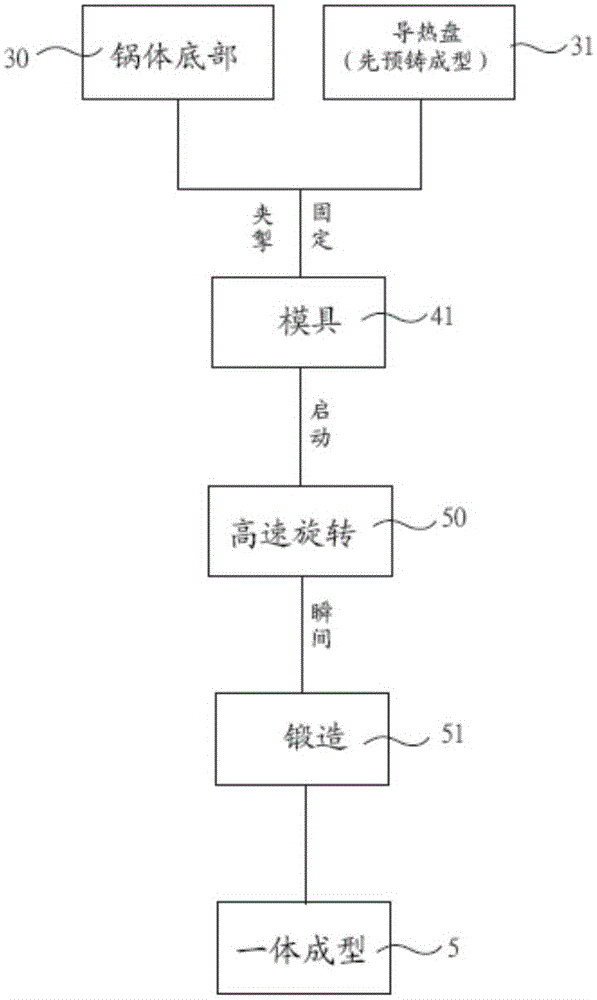

Method for manufacturing quick heat conduction pot

InactiveCN104625596AImprove the problem of easy falling offHigh strengthWelding/soldering/cutting articlesNon-electric welding apparatusPunch pressEngineering

The invention relates to a method for manufacturing a quick heat conduction pot. The method is mainly characterized in that a heat conduction disc is combined with the bottom of the metal (stainless steel) pot, the heat conduction disc and the pot are combined through friction fusion or a friction punch press, the heat conduction disc which is in a non-planar shape or with shapes is formed, the manufacturing speed is high, disengagement never happens, multiple defects of a traditional bonding mode can be overcome, multiple machining procedures are simplified, cost is reduced, the rejection rate is avoided, and the method has the advantages of being advanced and practical.

Owner:高耀宗

A method for constructing an immobilized multi-enzyme system based on the interaction between DNA, graphene oxide and metal-organic framework materials

ActiveCN112980807BGood mechanical rigidityGood biocompatibilityOxidoreductasesOn/in organic carrierBase JMetal-organic framework

Owner:BEIJING UNIV OF CHEM TECH

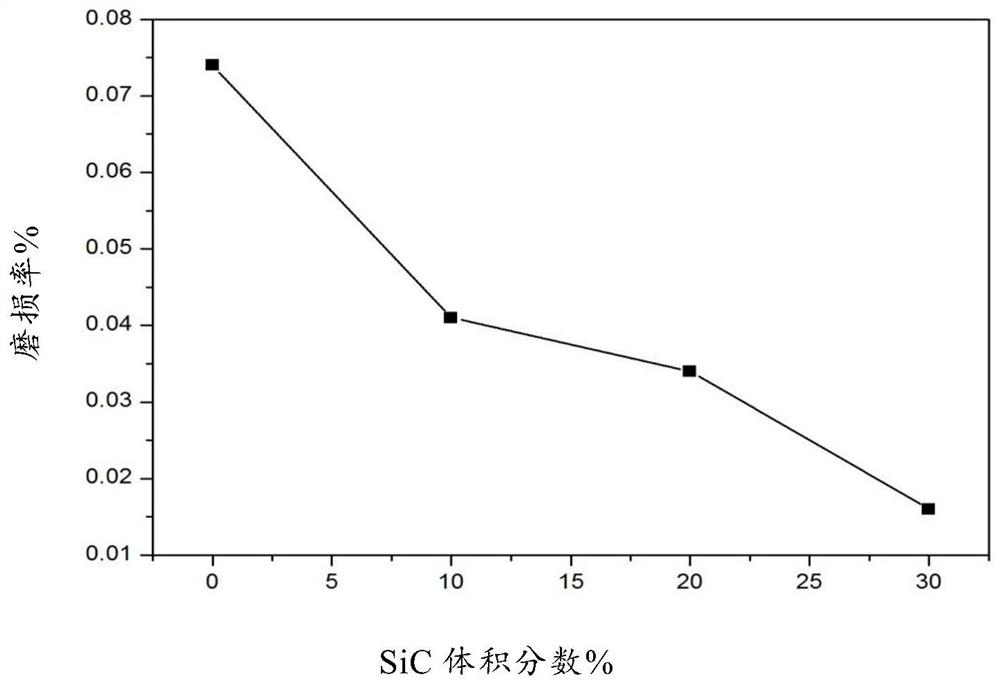

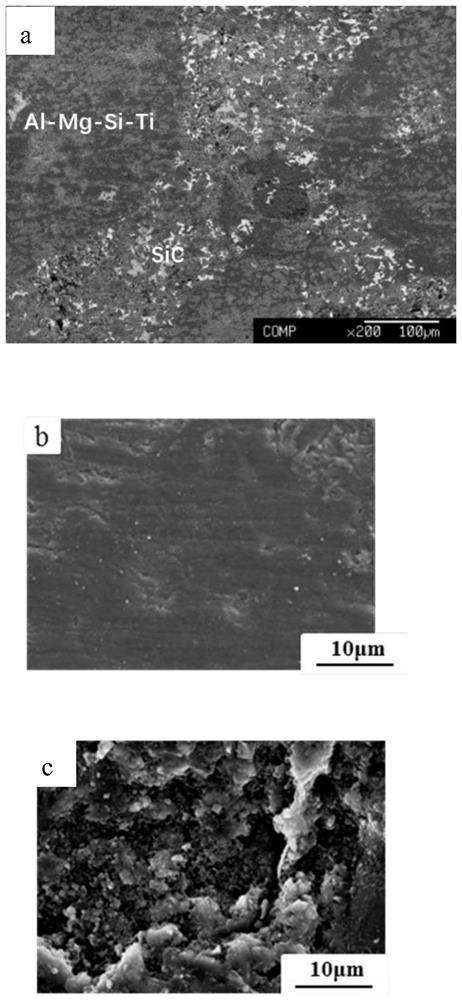

A kind of preparation method of metal-ceramic composite material

The invention discloses a preparation method of a cermet composite material. The method includes: (1) sequentially crushing the foamed SiC ceramics according to the procedures of primary crushing, secondary crushing and tertiary crushing, ultrasonic cleaning, and drying to obtain an ellipsoidal SiC ceramic block with a size of 2 mm-15 mm; (2) Pre-oxidize and pre-corrode the ellipsoidal SiC ceramic block obtained in step (1), and obtain a foamed SiC ceramic reinforcement after cleaning, (3) mix the foamed SiC ceramic reinforcement obtained in step (2) with metal, and put it into a mold , under nitrogen atmosphere, heating and applying pressure, lowering the temperature, solidifying, demolding, and polishing to obtain the metal-ceramic composite material.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

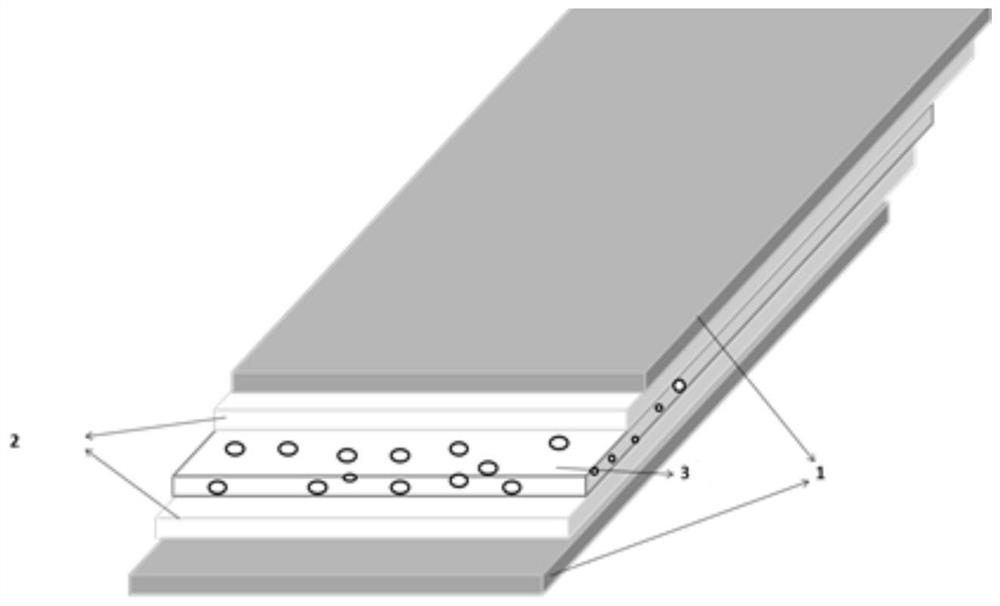

A kind of square lithium-ion battery wound electric core and manufacturing method thereof

ActiveCN104966852BImprove deformationImprove the problem of easy falling offFinal product manufactureSecondary cellsProduction ratePower battery

The invention provides a square lithium-ion battery winding cell and a manufacturing method thereof. The square lithium-ion battery winding cell includes a positive electrode sheet, a separator and a negative electrode sheet, and the positive electrode sheet is provided with a positive electrode lug. The negative electrode sheet is provided with a negative electrode tab, and the center of the coiled cell of the square lithium ion battery is provided with an internal support frame. Adopting the technical solution of this invention, the problem of easy deformation of the pole piece in the charge-discharge cycle of the traditional square winding battery cell and the problem that the material is easy to fall off at the semicircular position of the pole piece bending are improved, and the square lithium ion is kept to the maximum extent. The consistency of the battery under static and charge-discharge cycle dynamics improves the production pass rate of winding cells and the safety of square lithium-ion batteries, creating conditions for the reliable application of square winding cells in the field of power batteries .

Owner:李震祺 +1

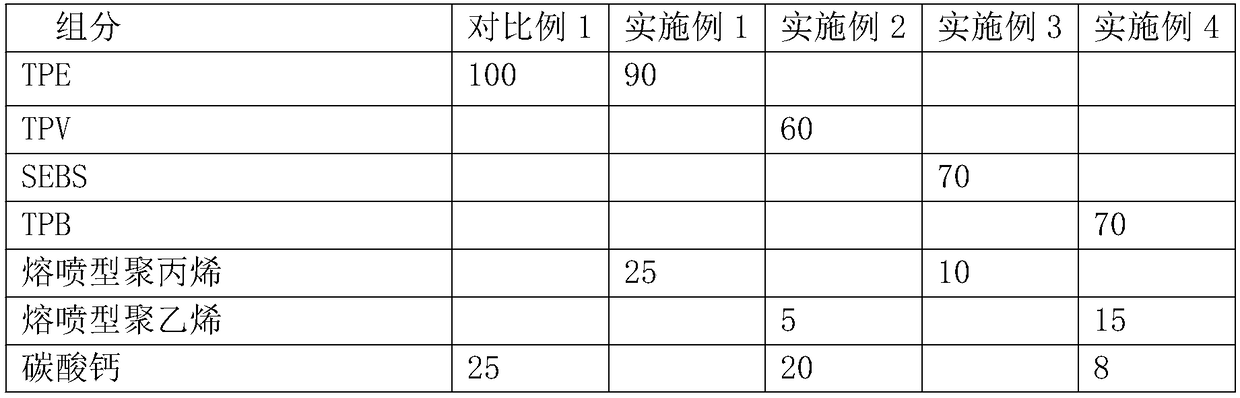

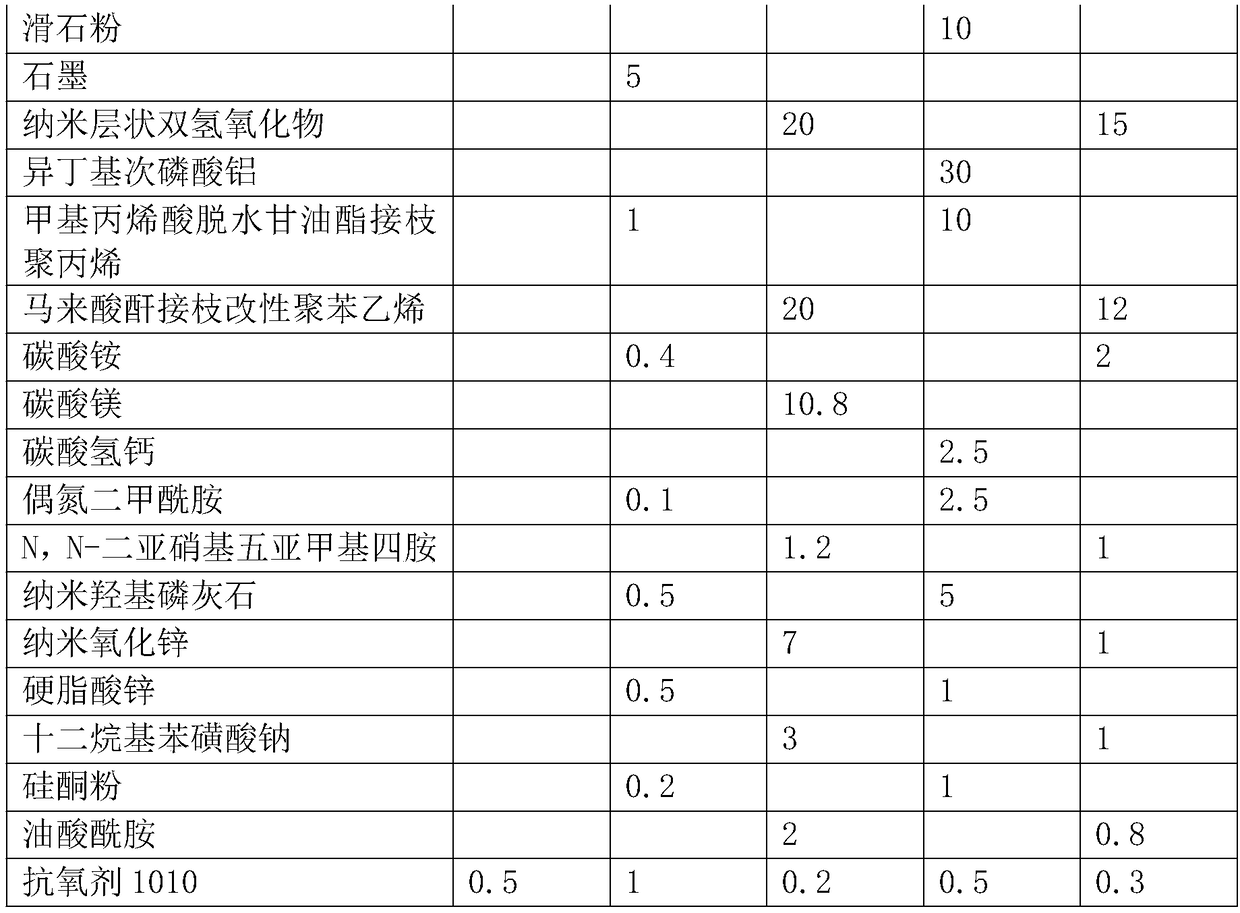

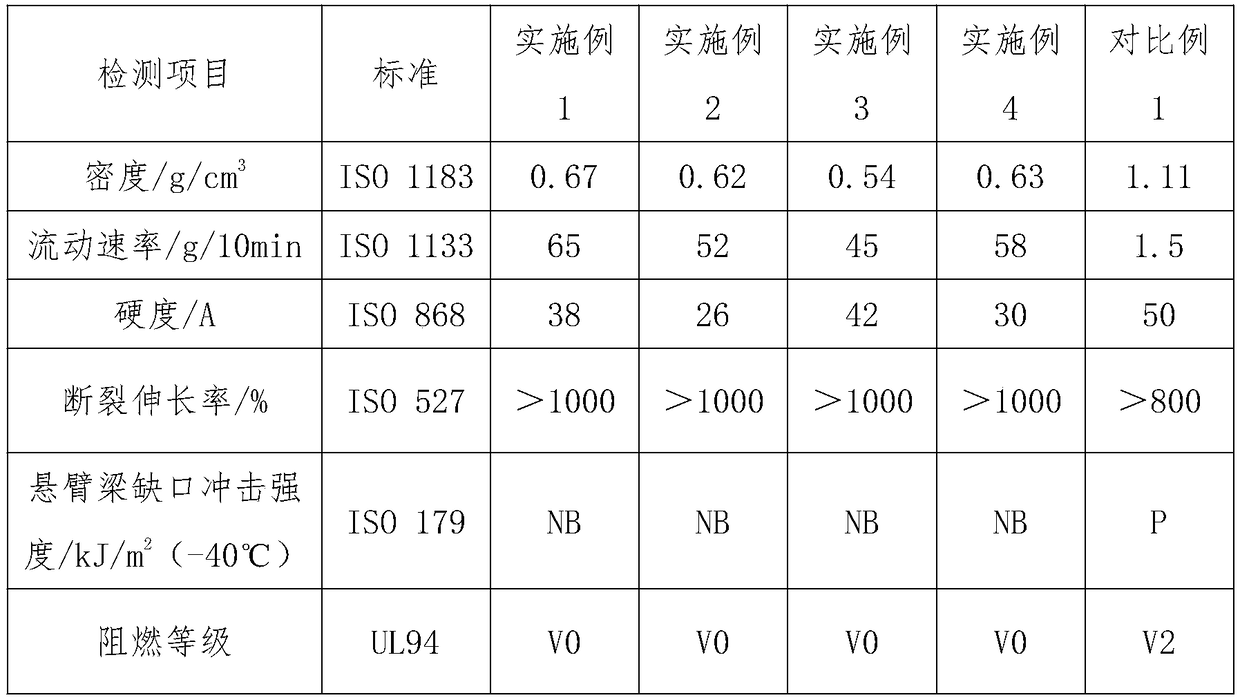

Automobile battery shell rubber coating material, and preparation method

PendingCN109337153AImprove liquidityGuaranteed exact copy and effective fitCell component detailsAntioxidantAutomotive battery

The invention relates to an automobile battery shell rubber coating material, and a preparation method thereof. The material comprises components with the following parts by weight: 60-90 parts of a thermoplastic elastomer, 5-25 parts of a melt-blown polymer, 5-30 parts of a flame retardant, 0-20 parts of a filler, 1-20 parts of an interface modifier, 0.5-12 parts of a foamer, 1-10 parts of a foaming synergist, 0.5-2 parts of a lubricant, and 0.2-1 part of an antioxidant. The invention further discloses the preparation method of the automobile battery shell rubber coating material. The automobile battery shell rubber coating material and the preparation method thereof have the advantages that through high fluidity and extremely high machining formability, a complex battery shell structurecan be accurately replicated, the material can be effectively adhered to the battery shell structure, and the product wall thickness can be optimally reduced, so that high product portability is achieved; the material can be effectively bonded with a metal or engineering plastic shell, so that the problem of high dropping possibility of the conventional market product is effectively solved, and better buffering protection effects for a battery are achieved; and the material has excellent low-temperature-resistant, buffering and flame-retardant performances, so that such problems as unsatisfactory low-temperature falling ball impact performance and unsatisfactory shock-resistant performance of the conventional market product are solved.

Owner:NANJING JULONG SCI&TECH CO LTD

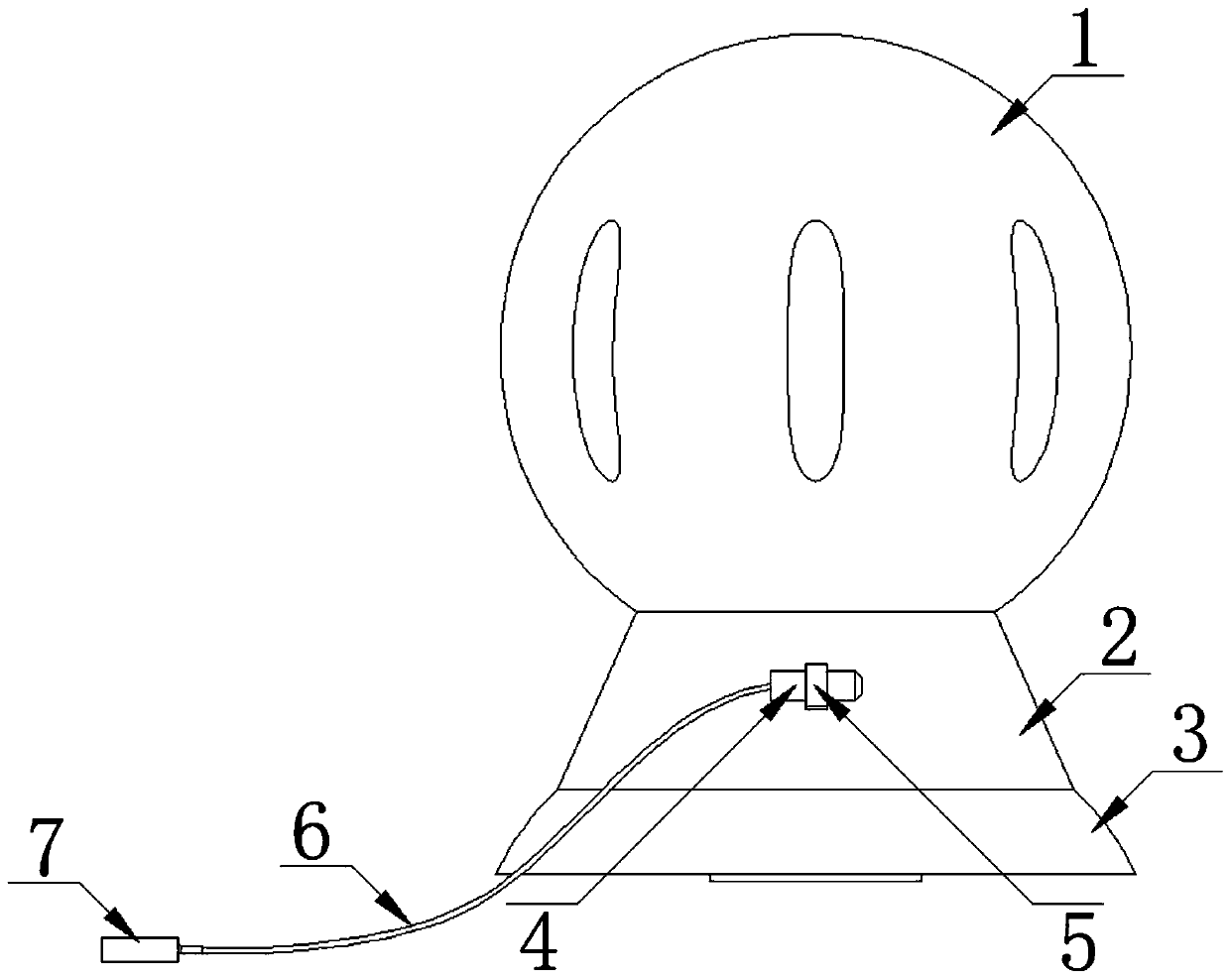

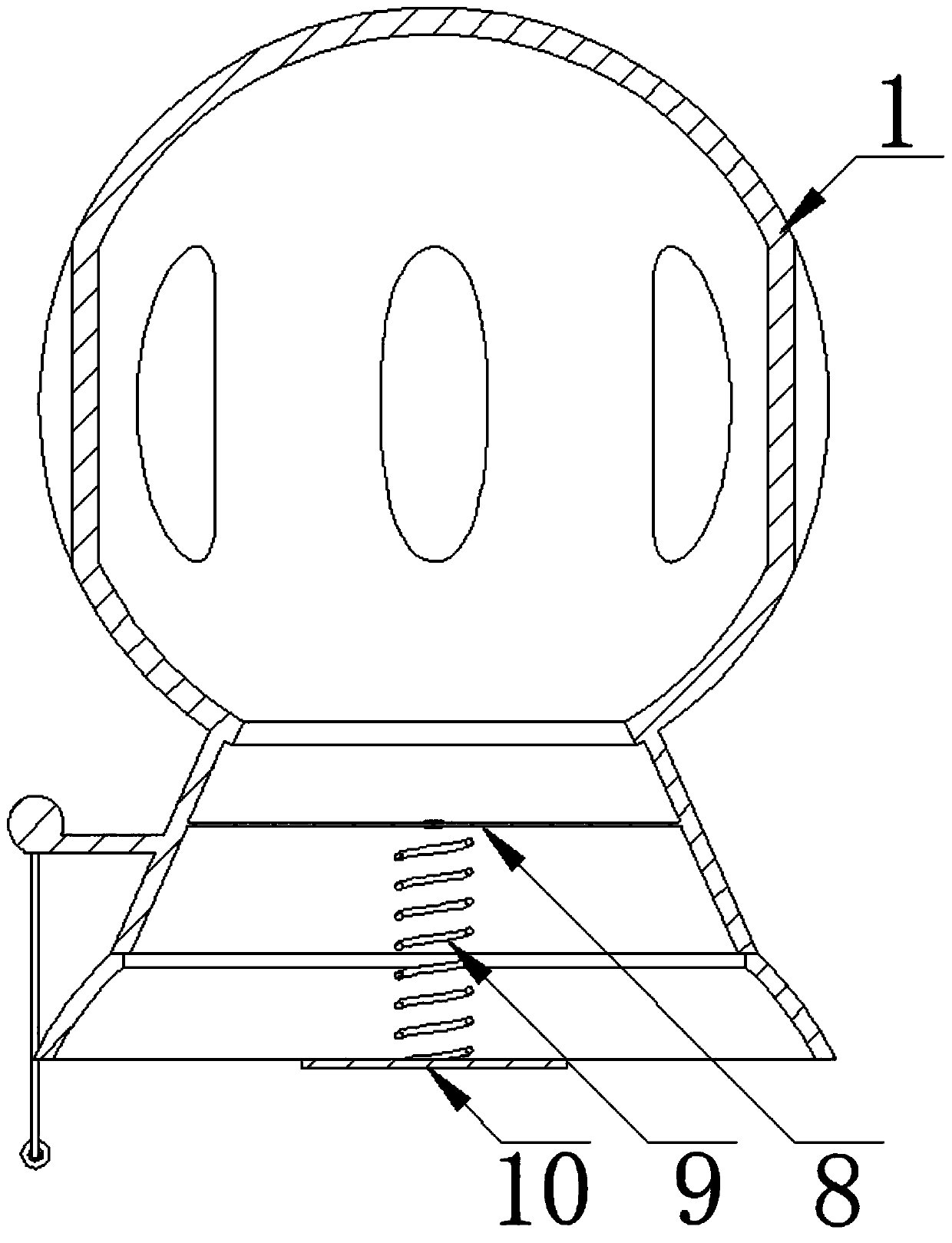

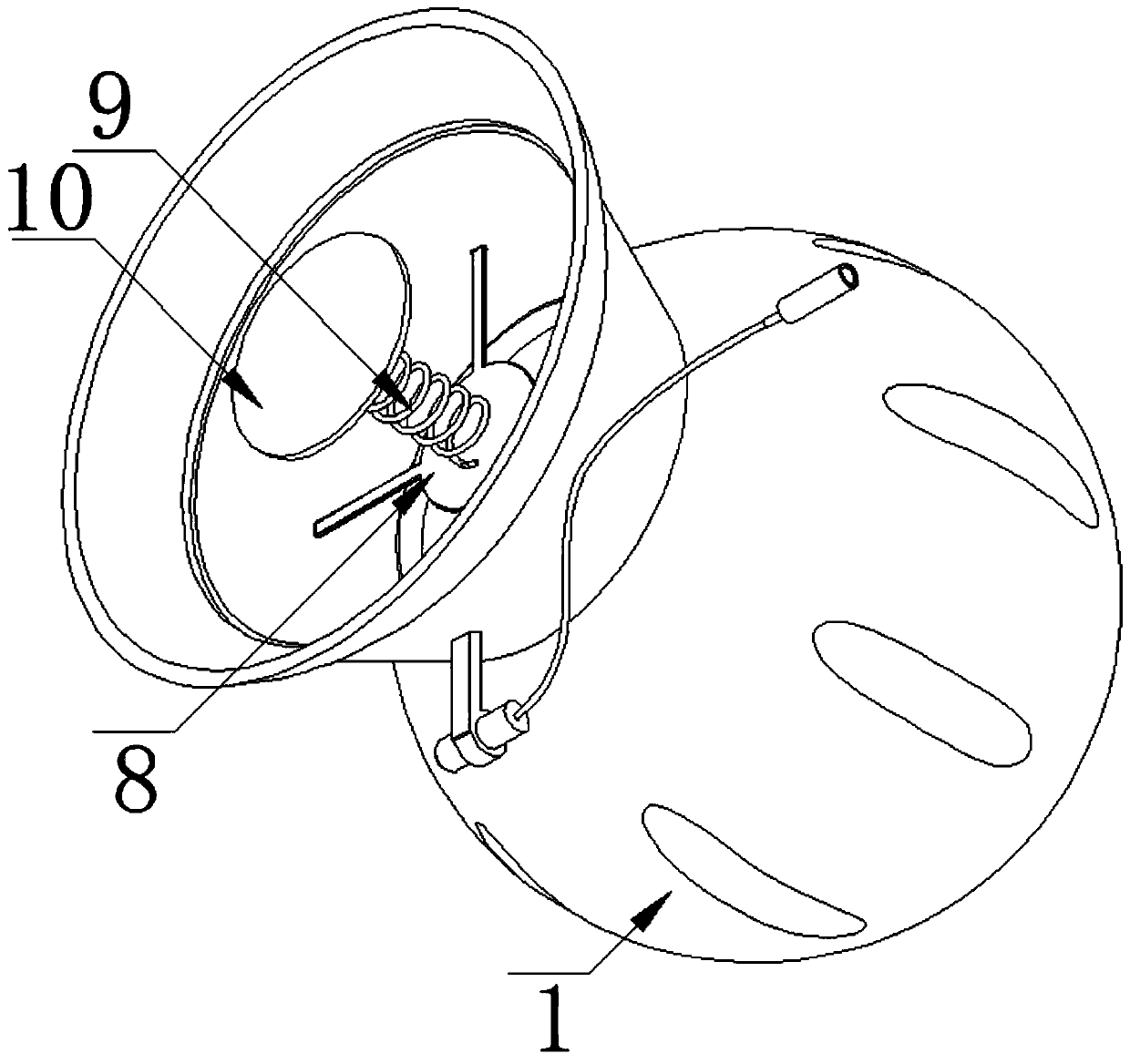

Matched signal collection suction ball of novel ECG machine

InactiveCN111387971ASolve the problem of excessive hardnessImprove sealingDiagnostic recording/measuringSensorsSuction forceWhole body

The invention discloses a matched signal collection suction ball of a novel ECG machine and belongs to the technical field of medical appliances. The signal collection suction ball comprises a soft ball, wherein a metal side skirt is fixedly connected to the bottom of the soft ball, the soft ball communicates with inside of the metal side skirt, a rubber side skirt is fixedly connected to the outer edge of the bottom of the metal side skirt, a fixation ring is fixedly connected on the outer side wall of the metal side skirt and a metal interface is inserted in the fixation ring, and the metalinterface is fixedly connected to one end of a wire. An internal metal patch can get close to skin under effects of a spring on a metal side skirt support, elastic force of the spring is very small and only applied to fitting with the surface of a patient, the elastic force of the spring is smaller than suction force of the soft ball, the whole body is prevented from being ejected by the spring and then falling down, the rubber side skirt is used for improving problems in easy stripping, red marks and plaques, the spring is used for solving the problem that electric signal collection is unstable, and the wire and the external interface are used for solving the problem that existing wires are too hard.

Owner:焦爱燕

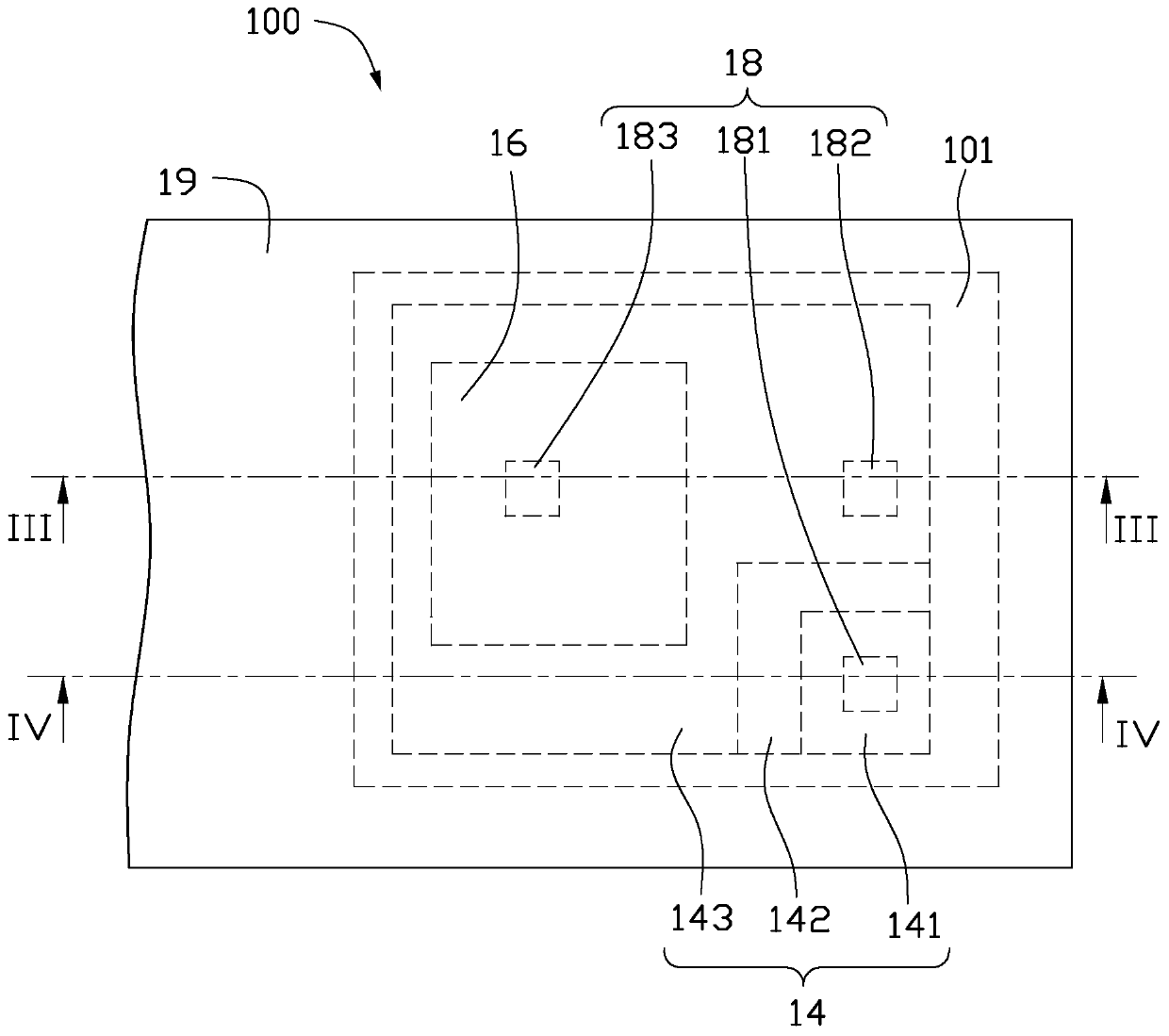

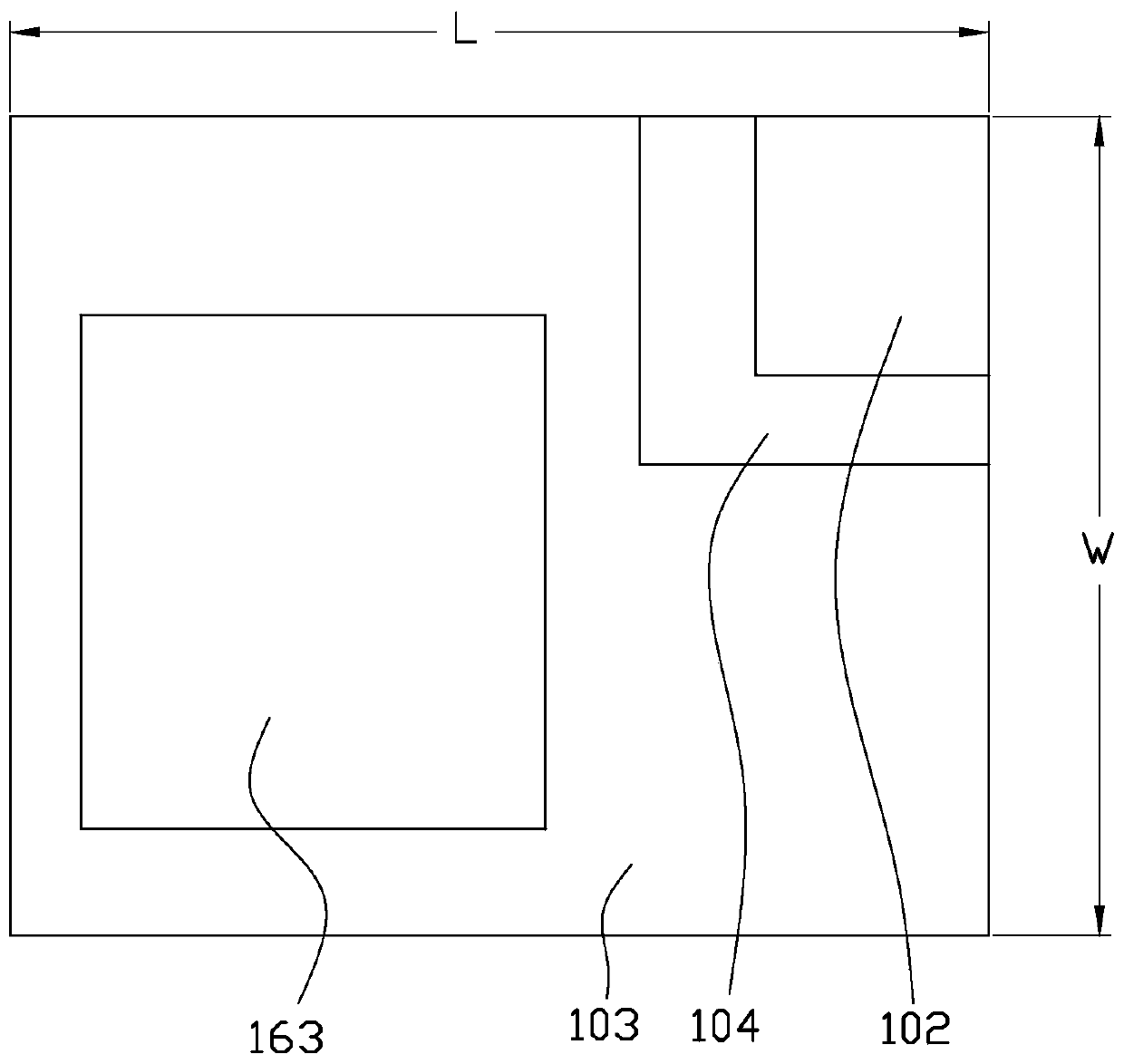

Sensing device

ActiveCN106886333BAvoid tidying upImprove the problem of easy falling offInput/output processes for data processingFlexible circuitsEngineering

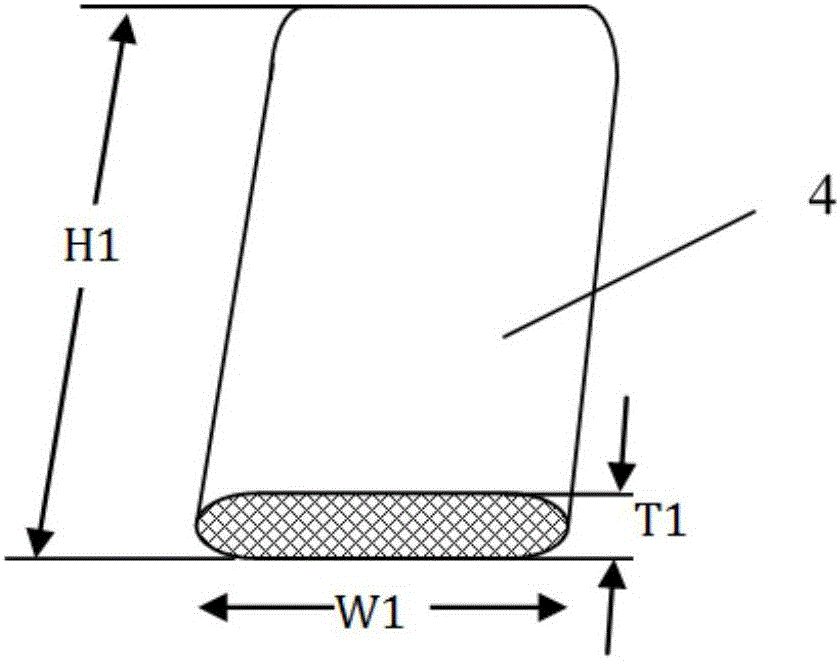

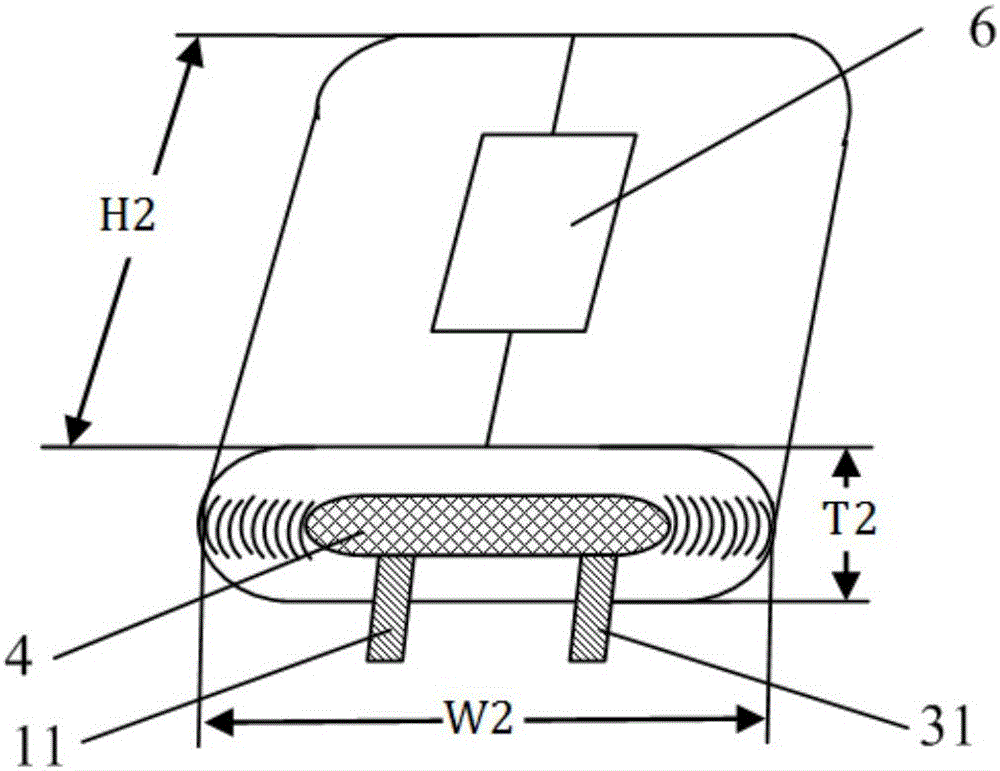

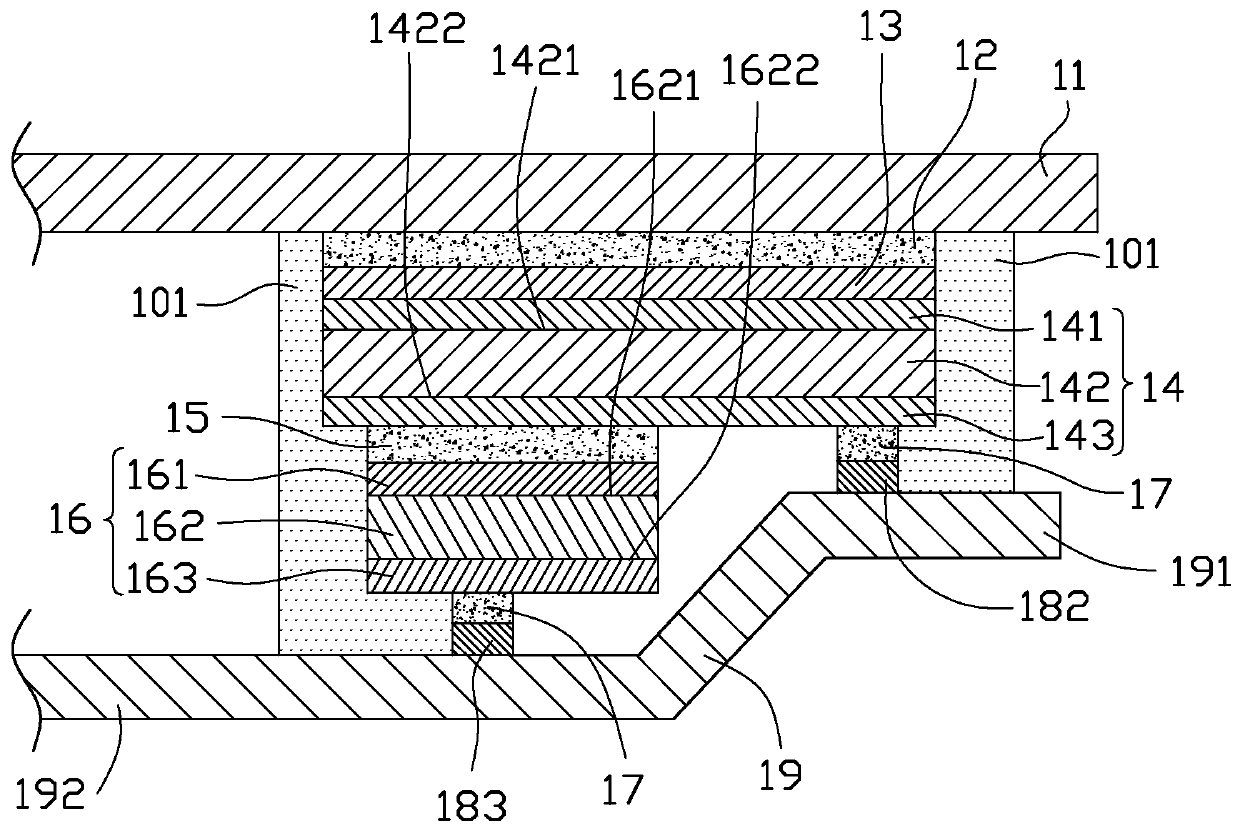

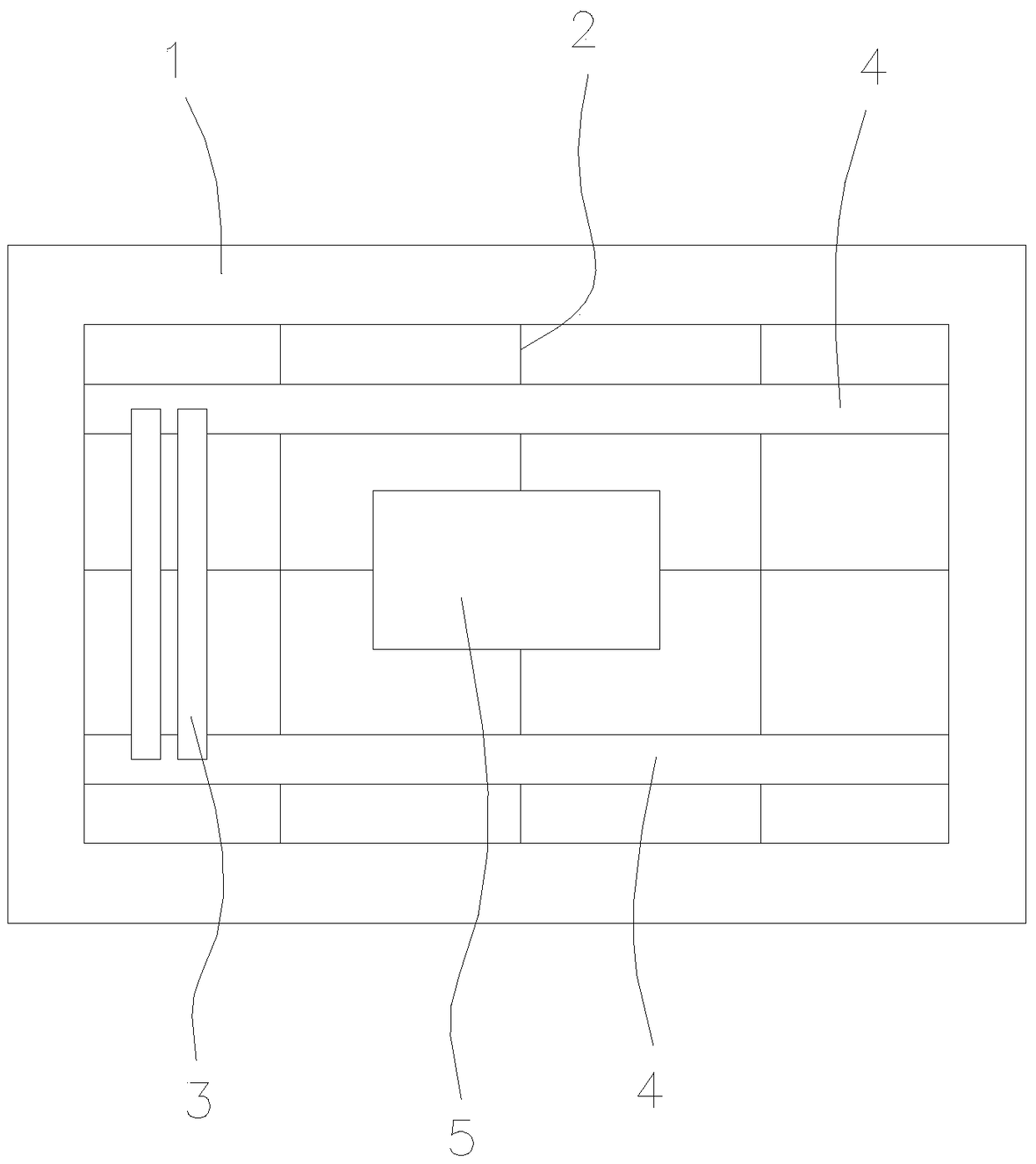

The invention provides a sensing apparatus. The sensing apparatus comprises a first signal sending / receiving layer, a second signal sending / receiving layer and a flexible circuit board. One end of the flexible circuit board is fixed to the lower part of the first signal sending / receiving layer and the second signal sending / receiving layer. The first signal sending / receiving layer comprises a first electrode and a second electrode which are arranged oppositely, and a first spacing layer located between the first electrode and the second electrode. The first spacing layer comprises a first surface and a second surface which are arranged oppositely; and the first electrode has an extending part extending to the second surface from the first surface of the first spacing layer. The second signal sending / receiving layer comprises a third electrode, a fourth electrode and a second spacing layer sandwiched between the third electrode and the fourth electrode. The sensing apparatus realizes signal transmission with an external system through the flexible circuit board. The sensing apparatus performs signal transmission through the flexible circuit board without an external wire, so that the overall structural strength of the apparatus is improved.

Owner:INTERFACE TECH CHENGDU CO LTD +1

A method for making an aluminum substrate solder resist screen plate to prevent photosensitive paste from falling off

ActiveCN105517366BImprove the problem of easy falling offAvoid abnormal qualityNon-metallic protective coating applicationDirectly printed exposure masksResistAdhesive

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

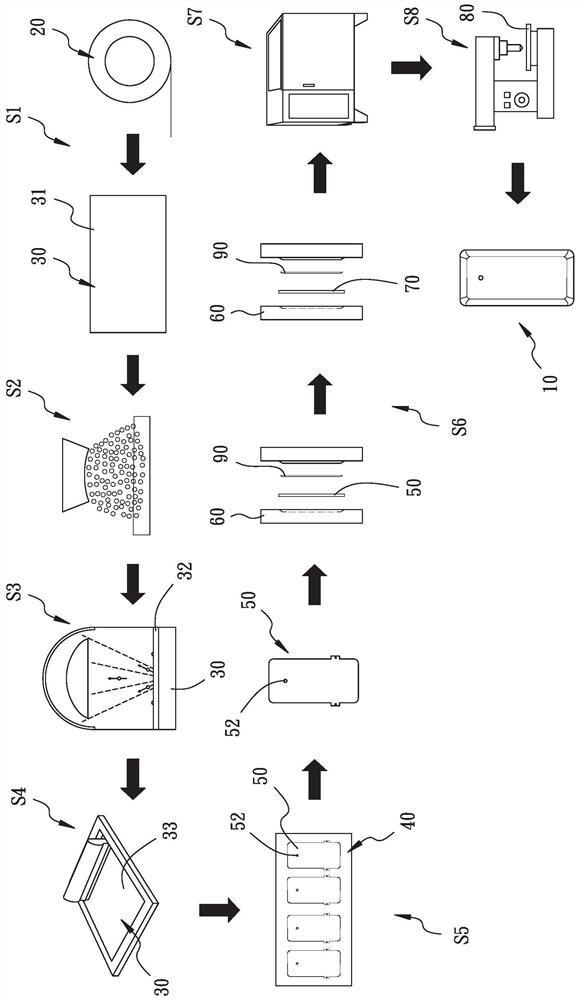

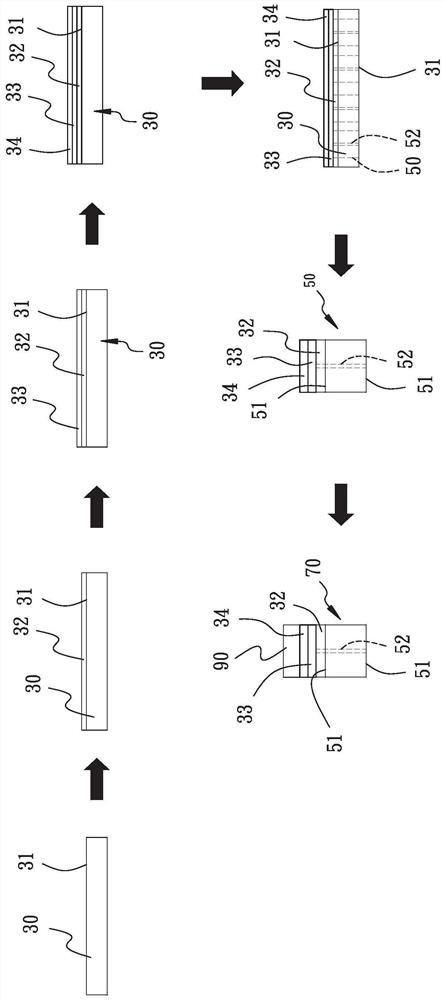

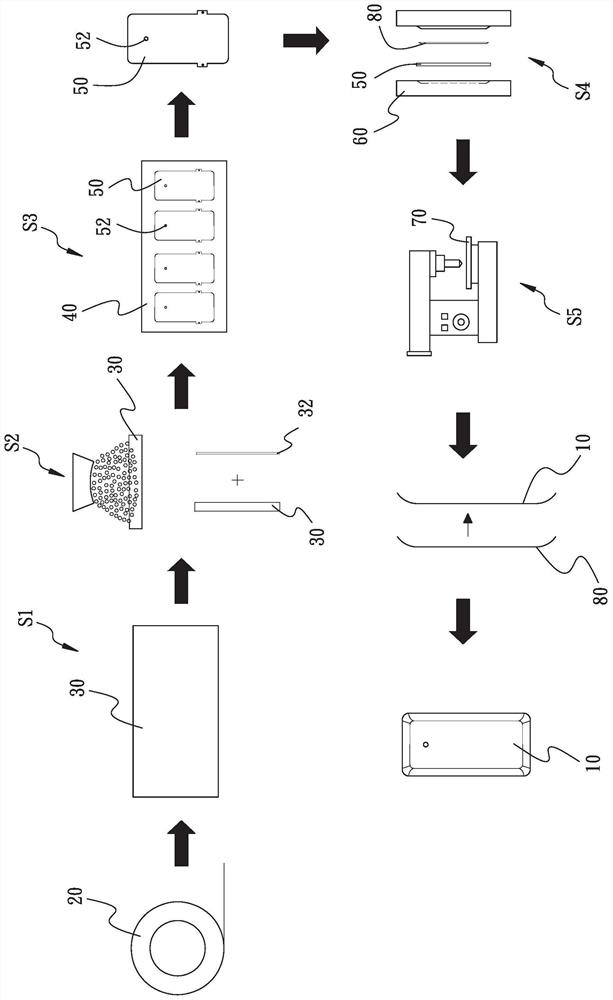

Glass-like protective film manufacturing method

InactiveCN111662645AImprove wear resistanceImprove the problem of easy falling offFilm/foil adhesivesOther printing apparatusTectorial membraneEngineering

The invention provides a manufacturing method of a glass-like protective film. The manufacturing method comprises the following steps: cutting a roll material into a sheet; coating the surface of thesheet with an adhesion layer by a first processing means; arranging a material layer on the adhesion layer by a second processing means; arranging a pattern layer on the material layer by a third processing means to form a processed sheet; forming a film sheet from the processed sheet by a cutting means; carrying out injection molding on the film sheet to form a semi-finished product; and performing a trimming means on the semi-finished product to obtain a protective film finished product, so that the protective film finished product with an imitation material effect is formed through the material layer and the pattern layer.

Owner:HEYU CAPITAL CO LTD

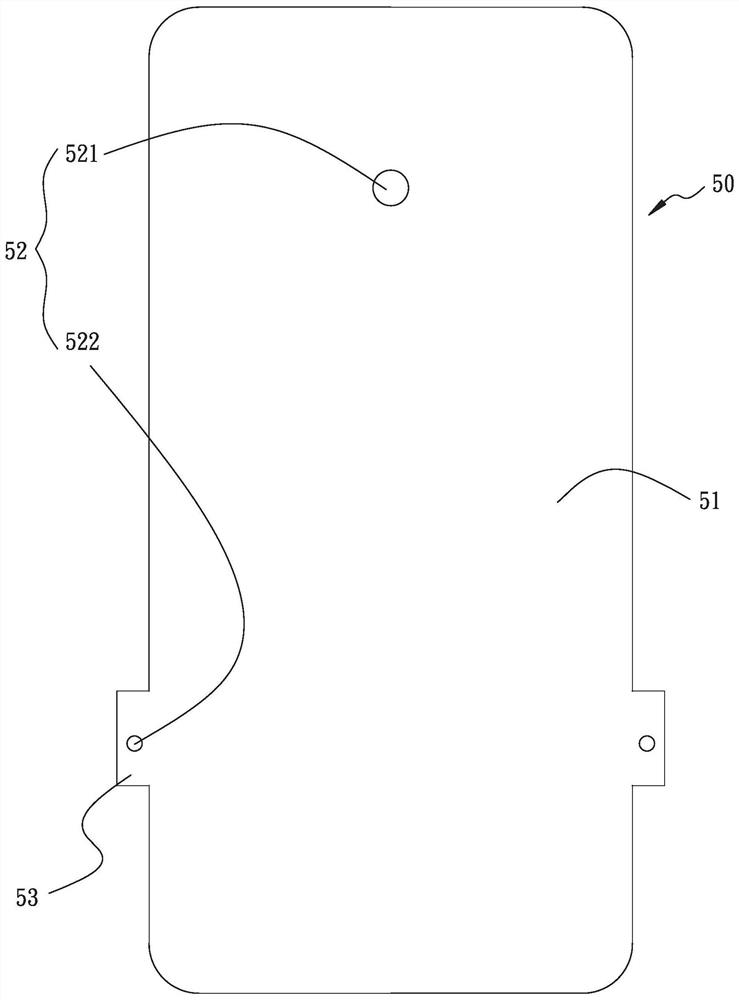

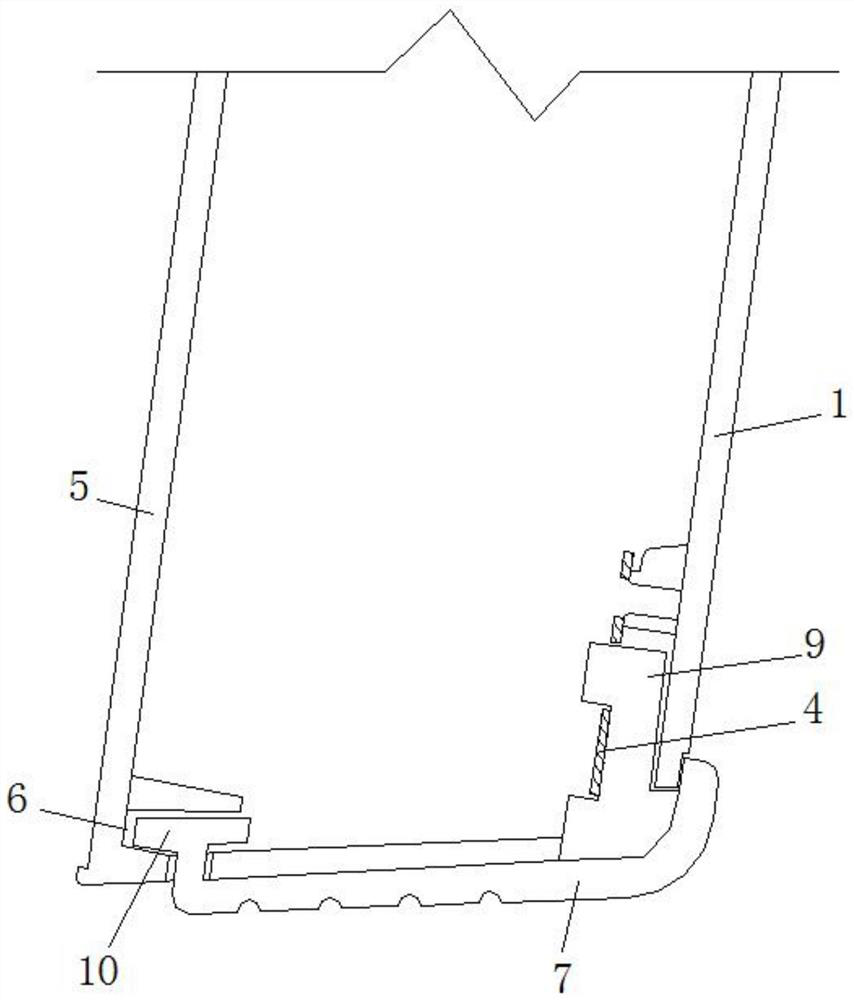

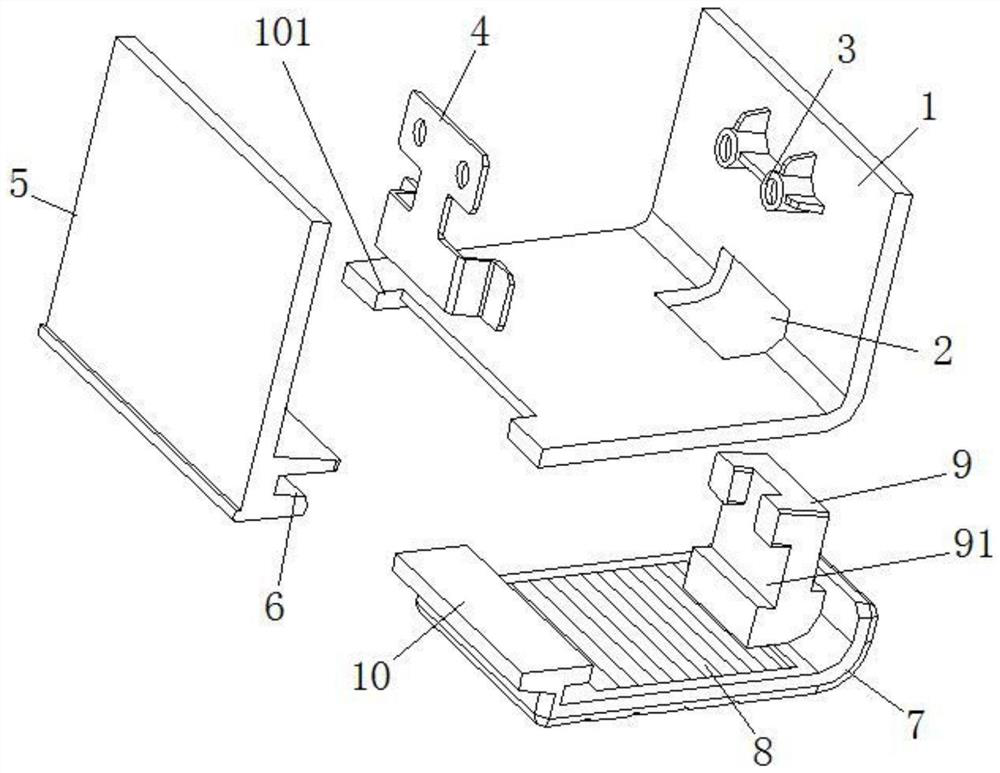

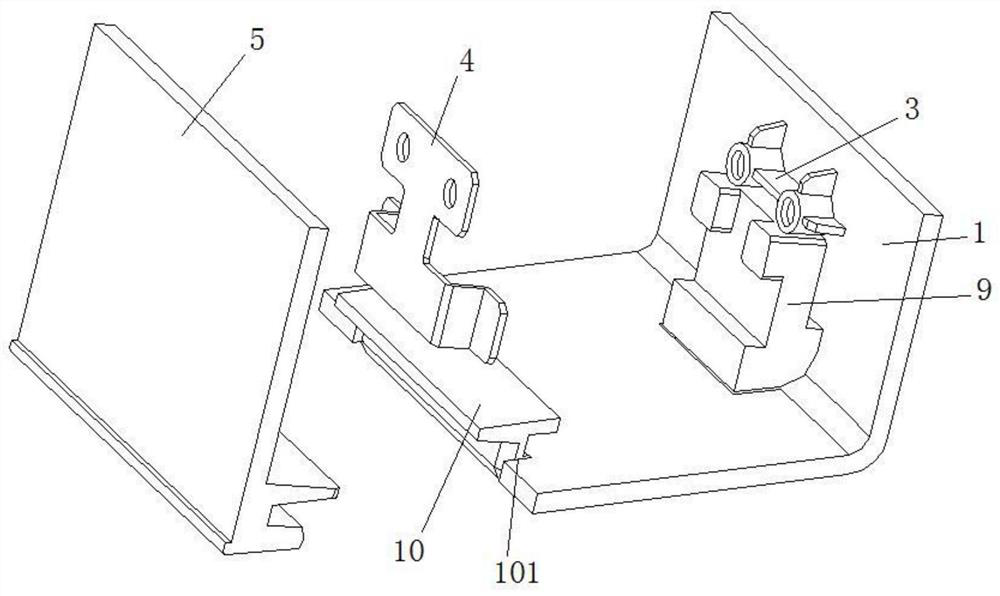

Foot pad anti-falling structure

PendingCN112097017AEasy to assembleImprove the problem of easy falling offMachine framesCasings/cabinets/drawers detailsPhysicsEngineering

Owner:广西世纪创新显示电子有限公司

Decorative wall panel and mounting method

InactiveCN113027060AIncrease wasteImprove the problem of easy falling offCovering/liningsBuilding material handlingMolding (decorative)Structural engineering

The invention provides a decorative wall panel and a mounting method, and relates to the technical field of building decoration. The decorative wall panel comprises a decorative surface layer and a structural layer. The structural layer is a high-performance cement-based material plate, serves as a base layer of the decorative surface layer, is arranged on the lower layer of the decorative surface layer and is relatively fixed to the decorative surface layer. According to the decorative wall panel, the decorative surface layer and the structural layer formed by the high-performance cement-based material plate are combined, and thus the decorative wall panel can be quickly formed; and dry construction can be conducted by combining the decorative wall panel with the corresponding mounting method, material waste is reduced, the construction efficiency is improved, and the flatness of a decorative surface can further be guaranteed. In addition, some traditional decorative sheets needing to depend on wet construction can be allowed to be subjected to dry construction, the using range is wide, later maintenance is also convenient, construction waste can further be reduced, and environmental protection is also facilitated.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Protective film manufacturing method

InactiveCN111660653AHigh precisionImprove vulnerability to external forceLamination ancillary operationsLaminationIndustrial engineeringComposite material

The invention provides a method for manufacturing a protective film. The method comprises the following steps of: cutting a roll material into a sheet; coating the surface of the sheet with a releaselayer through a processing means to form a processed sheet; forming a film sheet from the processed sheet by a cutting means; carrying out injection molding on the film sheet to form a semi-finished product; and performing a trimming means on the semi-finished product to obtain a protective film finished product. With the method, a high-precision protective film finished product is formed throughinjection molding.

Owner:HEYU CAPITAL CO LTD

Semiconductor structure and method of forming the same

ActiveCN106252247BAvoid breakingUniform stress distributionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureMetal

The invention discloses a semiconductor structure and a forming method thereof. The semiconductor structure comprises a substrate, wherein the surface of the substrate is provided with a groove. The groove is exposed out of the surface of a metal layer. A metal bump is positioned on the surface of the metal layer and on the partial surface of the substrate. The shape of the cross section of the metal bump is the same as the shape of the cross section of the groove. The vertical distances between the sidewalls of the metal bump and the sidewalls of the groove are the same. The metal bump in the semiconductor structure is not easy to break or fall off.

Owner:JIANGSU NEPES SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com