Method for manufacturing quick heat conduction pot

A manufacturing method and pot body technology, which can be used in manufacturing tools, non-electric welding equipment, welding/welding/cutting items, etc., and can solve the problems of high strength and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are examples and test data thereof, etc., but the content of the present invention is not limited to the scope of these examples.

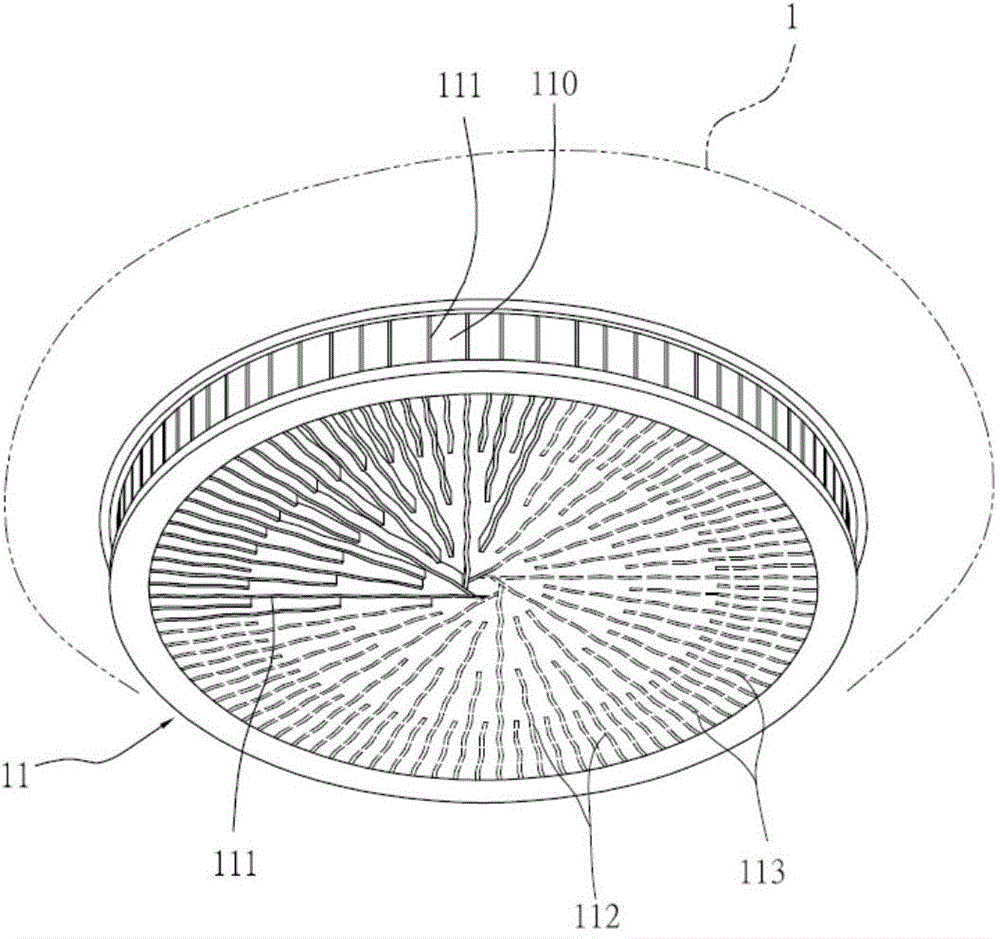

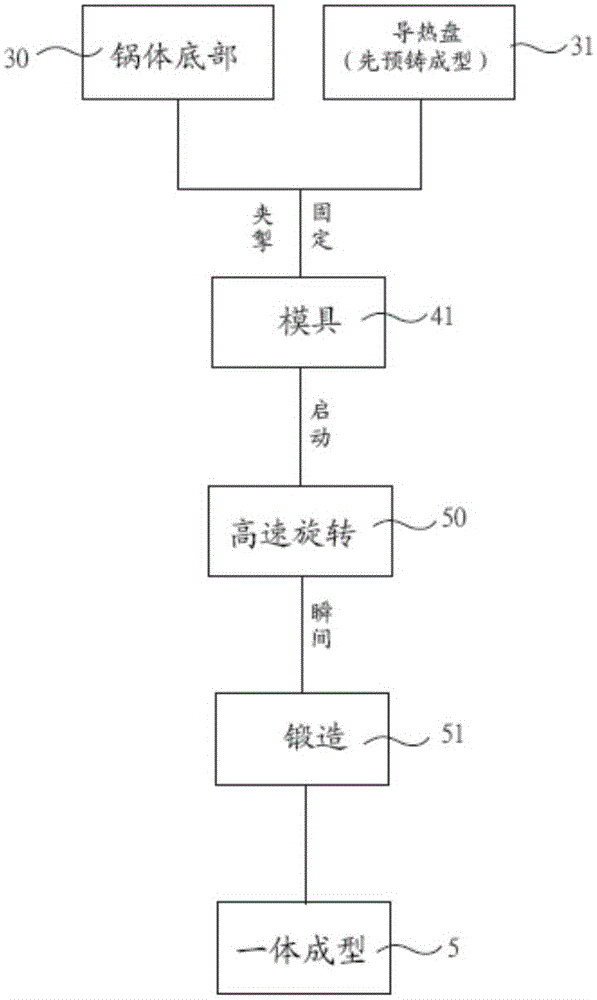

[0019] First, see image 3 As shown, it is a flow chart of the friction welding preparation process of the present invention. The pot body is a metal (stainless steel) frying pan, soup pot or teapot, and the heat conducting plate 31 is made of aluminum and pre-cast, so that the heat conducting plate 31 has several a convex line or a groove, and can be placed on the fire (gas stove) for rapid heating, effectively improving the heat conduction of the pot body. The heat conduction plate 31 is respectively clamped and fixed on the mold 41 of the friction welding machine, and the heat conduction plate 31 is pre-formed with several convex lines or grooves, which are non-planar and can firmly clamp the heat conduction plate 31 on the mold 41, and then Control the heat conduction plate 31 to rotate 50 at a high speed, and then push t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com