Automobile battery shell rubber coating material, and preparation method

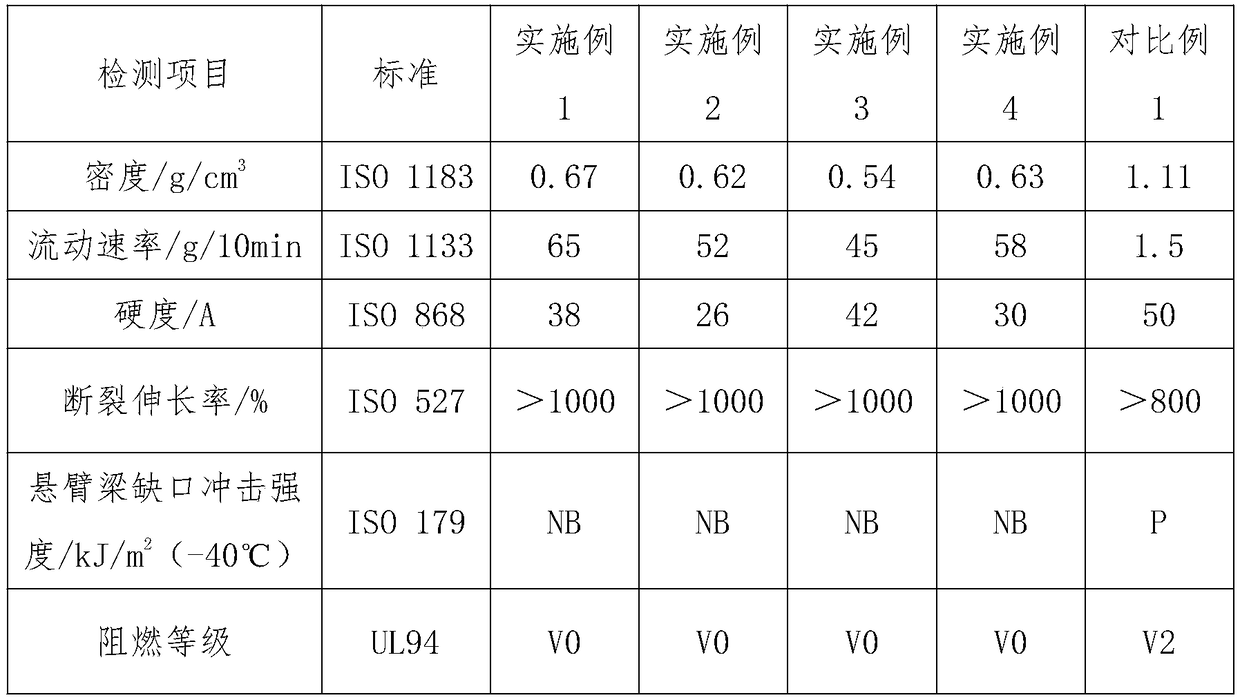

An automotive battery and encapsulation technology, applied in the field of materials, can solve the problems of poor low temperature impact performance and poor shock resistance, and achieve the effects of high fluidity, low manufacturing cost, and excellent low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

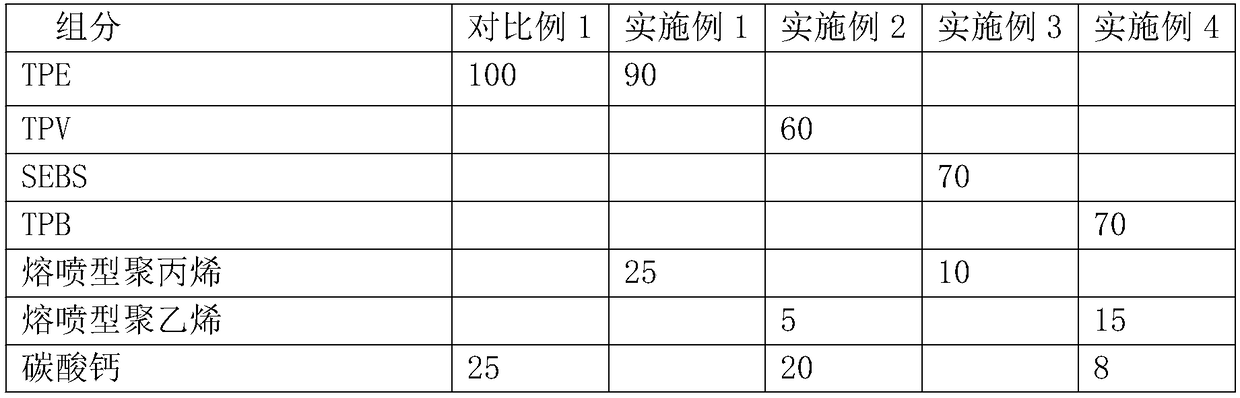

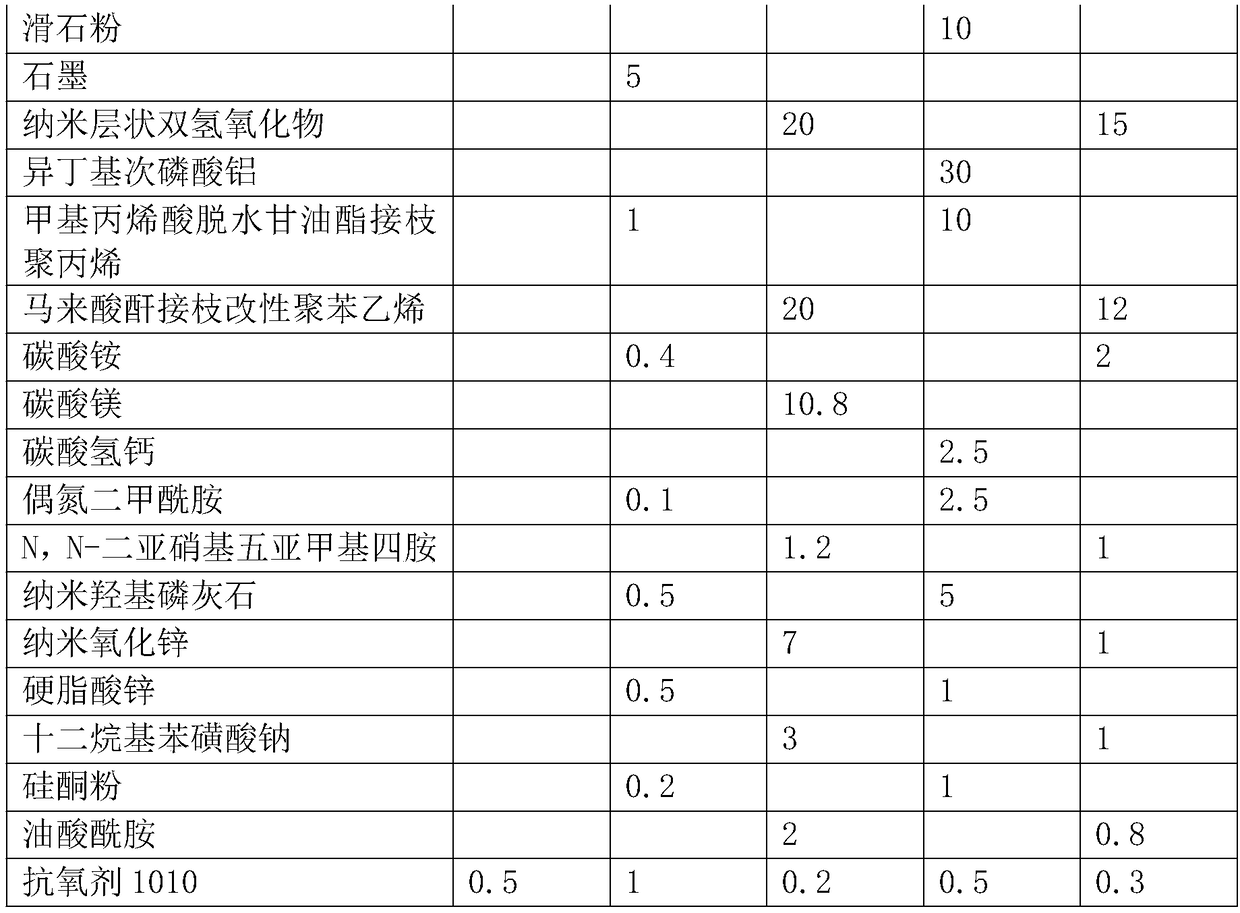

Embodiment 1

[0029] A preparation method of an automotive battery housing rubber covering material, comprising the following steps:

[0030] Step 1: 90 parts of thermoplastic elastomer olefin-based elastomer TPE, 25 parts of melt-blown polypropylene, 5 parts of graphite, 1 part of dehydrated glyceryl methacrylate grafted polypropylene, 0.5 parts of nano-hydroxyapatite, stearin 0.5 parts of zinc acid, 0.2 parts of silicone powder, 1 part of antioxidant 1010 parts by weight, mixed in a mixer for 1 min, added to a twin-screw extruder through a hopper, granulated at a temperature of 140-190 ° C, the screw speed 200r / min, to obtain the composite material used for battery casing rubber wrapping;

[0031] Step 2: Add foaming agent (0.4 part of ammonium carbonate, 0.1 part of azodicarbonamide) and the encapsulation composite material obtained in step 1 to the barrel of the injection molding machine in parts by weight; Plastic-coating injection molding to obtain a battery case with rubber-coating....

Embodiment 2

[0034] A preparation method of an automotive battery housing rubber covering material, comprising the following steps:

[0035] Step 1: 60 parts of thermoplastic elastomer olefin-based elastomer TPV, 5 parts of melt-blown polyethylene, 20 parts of calcium carbonate, 20 parts of nano-layered double hydroxide, 20 parts of maleic anhydride grafted modified polystyrene, 7 parts of nano-zinc oxide, 3 parts of sodium dodecylbenzenesulfonate, 2 parts of oleic acid amide, 0.2 part of antioxidant 1010 parts by weight are mixed in mixer for 5min, are added in the twin-screw extruder by hopper, Granulate at a temperature of 140-190°C, with a screw speed of 600r / min, to obtain a composite material for battery case encapsulation;

[0036] Step 2: Add foaming agent (10.8 parts of magnesium carbonate, 1.2 parts of N,N-dinitrosopentamethylenetetramine) and the encapsulation composite material obtained in step 1 to the barrel of the injection molding machine in parts by weight; At a temperatu...

Embodiment 3

[0039] A preparation method of an automotive battery housing rubber covering material, comprising the following steps:

[0040] Step 1: Add 70 parts of thermoplastic elastomer olefin elastomer SEBS, 10 parts of melt-blown polypropylene, 10 parts of talcum powder, 30 parts of isobutyl aluminum hypophosphite, 10 parts of dehydrated glyceryl methacrylate grafted polypropylene, nano 5 parts of hydroxyapatite, 1 part of zinc stearate, 1 part of silicone powder, 0.5 parts by weight of 1010 parts of antioxidant are mixed in a mixer for 2 minutes, and added to a twin-screw extruder through a hopper, at 140- Granulating at a temperature of 190°C, with a screw speed of 500r / min, to obtain a composite material for battery case encapsulation;

[0041] Step 2: Add the foaming agent (2.5 parts of calcium bicarbonate, 2.5 parts of azodicarbonamide) and the encapsulation composite material obtained in step 1 to the barrel of the injection molding machine in parts by weight; at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com