Preparation method of metal ceramic composite material

A technology of composite materials and cermets, applied in the field of materials, can solve problems such as difficulty in obtaining large and uniform products, and SiC particles are easy to fall off, and achieve the effects of reducing internal stress, increasing roughness, and reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

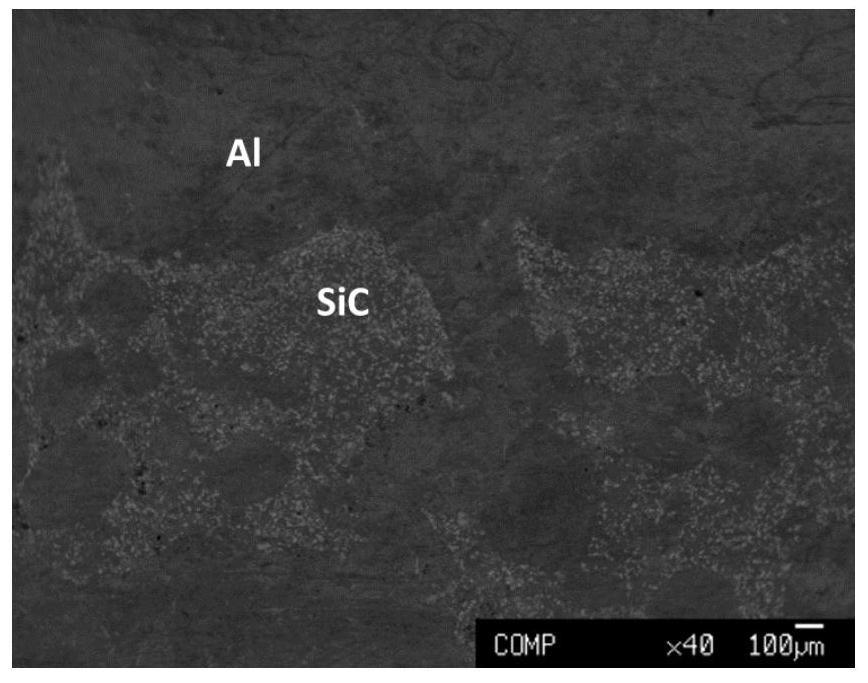

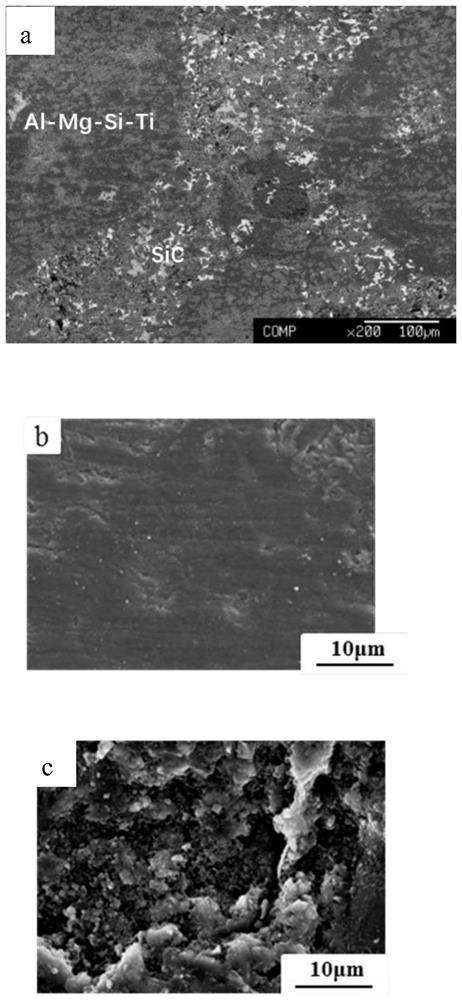

[0059] Example 1: Metal-ceramic composite material of the present invention

[0060] (1) Preparation of foamed SiC ceramics: 30 g of acrylamide, 2 g of N,N-methylenebisacrylamide, and 210 g of deionized water were put into a magnetic stirrer and stirred to dissolve to prepare a premix. Put 278.4g of SiC powder, 3.48g of strong tetramethylammonium oxide, 2.32g of polyvinyl alcohol, and 232g of the premix into a nylon resin ball mill jar, add alumina balls, and mill at a speed of 350r / min for 6 hours to obtain a slurry. Weigh 400g of the ball-milled slurry and pour it into a beaker, add 7.2g of sodium lauryl sulfate, 0.48g of ammonium persulfate and 0.24g of tetramethylethylenediamine in turn, and use a magnetic stirrer at a stirring speed of 240r / min Stir and foam, then stir at a stirring speed of 60r / min until the bubbles are uniform. Pour the uniformly foamed slurry into the mold, keep it warm in a water bath at 40°C for 0.5h, remove the mold after the gel solidifies, put ...

Embodiment 2

[0067] Example 2: Metal-ceramic composite material of the present invention

[0068] (1) Preparation of foamed SiC ceramics: put 24g of acrylamide, 1.6g of N,N-methylenebisacrylamide, and 168g of deionized water into a magnetic stirrer to stir and dissolve to prepare a premix. Put 222.7g of SiC powder, 2.78g of tetramethylammonium strong ammonium oxide, 1.86g of polyvinyl alcohol, and 186g of premix into a nylon resin ball mill jar, add alumina balls at a speed of 350r / min, and mill for 6 hours to obtain a slurry. Weigh 300g of the ball-milled slurry and pour it into a beaker, add 5.4g of sodium lauryl sulfate, 0.36g of ammonium persulfate and 0.18g of tetramethylethylenediamine in turn, and use a magnetic stirrer at a stirring speed of 200r / min Stir and foam, then stir at a stirring speed of 40r / min until the bubbles are uniform. Pour the evenly foamed slurry into the mold, keep it warm in a water bath at 35°C for 0.5h, remove the mold after the gel solidifies, put it in a...

Embodiment 3

[0076] Example 3: A metal-ceramic composite material

[0077](1) Preparation of foamed SiC ceramics: 30 g of acrylamide, 2 g of N,N-methylenebisacrylamide, and 210 g of deionized water were put into a magnetic stirrer and stirred to dissolve to prepare a premix. Put 278.4g of SiC powder, 3.48g of strong tetramethylammonium oxide, 2.32g of polyvinyl alcohol, and 232g of the premix into a nylon resin ball mill jar, add alumina balls, and mill at a speed of 350r / min for 6 hours to obtain a slurry. Weigh 400g of the ball-milled slurry and pour it into a beaker, add 7.2g of sodium lauryl sulfate, 0.48g of ammonium persulfate and 0.24g of tetramethylethylenediamine in turn, and use a magnetic stirrer at a stirring speed of 240r / min Stir and foam, then stir at a stirring speed of 60r / min until the bubbles are uniform. Pour the uniformly foamed slurry into the mold, keep it warm in a water bath at 40°C for 0.5h, remove the mold after the gel solidifies, put it in a constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com