A method for making an aluminum substrate solder resist screen plate to prevent photosensitive paste from falling off

A production method and technology of photosensitive paste, applied in the field of solder mask printing, can solve the problems of incomplete improvement of the end of the scraper, reduced screen life, slow efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

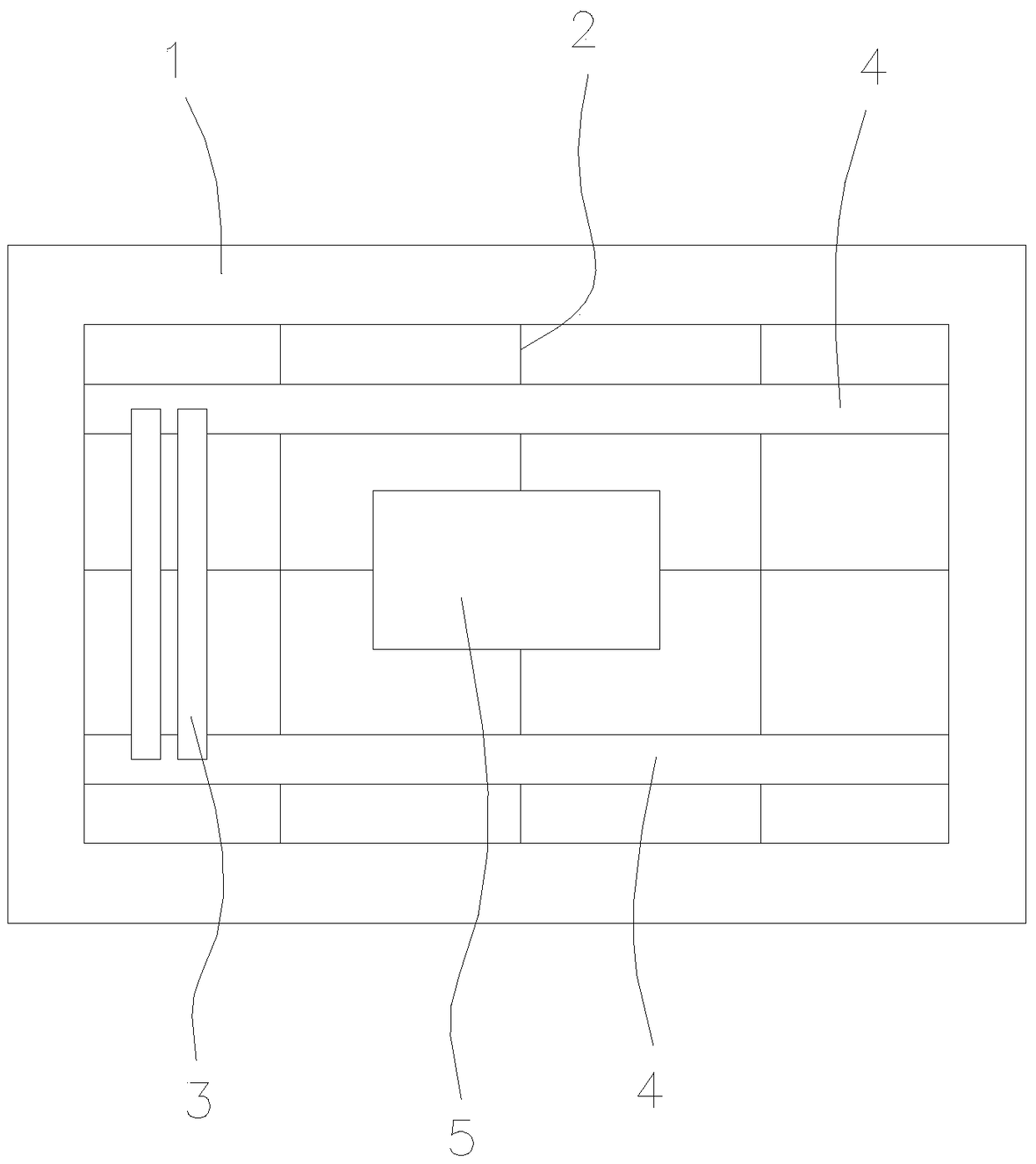

[0027] like figure 1 As shown, a method for making an aluminum substrate solder resist screen plate to prevent photosensitive paste from falling off, comprising:

[0028] 1) Use double-sided tape to paste a PET protective film on the front of the screen screen corresponding to the positions of the two ends of the scraper. Preferably, the thickness of the PET protective film is 0.05 mm, the width is 50 mm, and the center of the PET protective film in the width direction is flush with the end plane of the scraper.

[0029] 2) Apply a layer of glue on the back of the mesh screen corresponding to the position of the PET protective film, and let the glue dry naturally for 5 minutes to further solidify the PET protective film on the mesh screen.

[0030] 3) Before applying the photosensitive paste, add boiled oil and water to the photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com