Polyamide hollow fiber nanofiltration composite membrane and preparation method thereof

A technology of polyamide and composite membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. It can solve the problems of limiting the filling density of the membrane, increasing the shedding of the separation layer, and prone to fouling, etc., and achieves improvement. Hydrophilicity, the effect of improving easy peeling and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

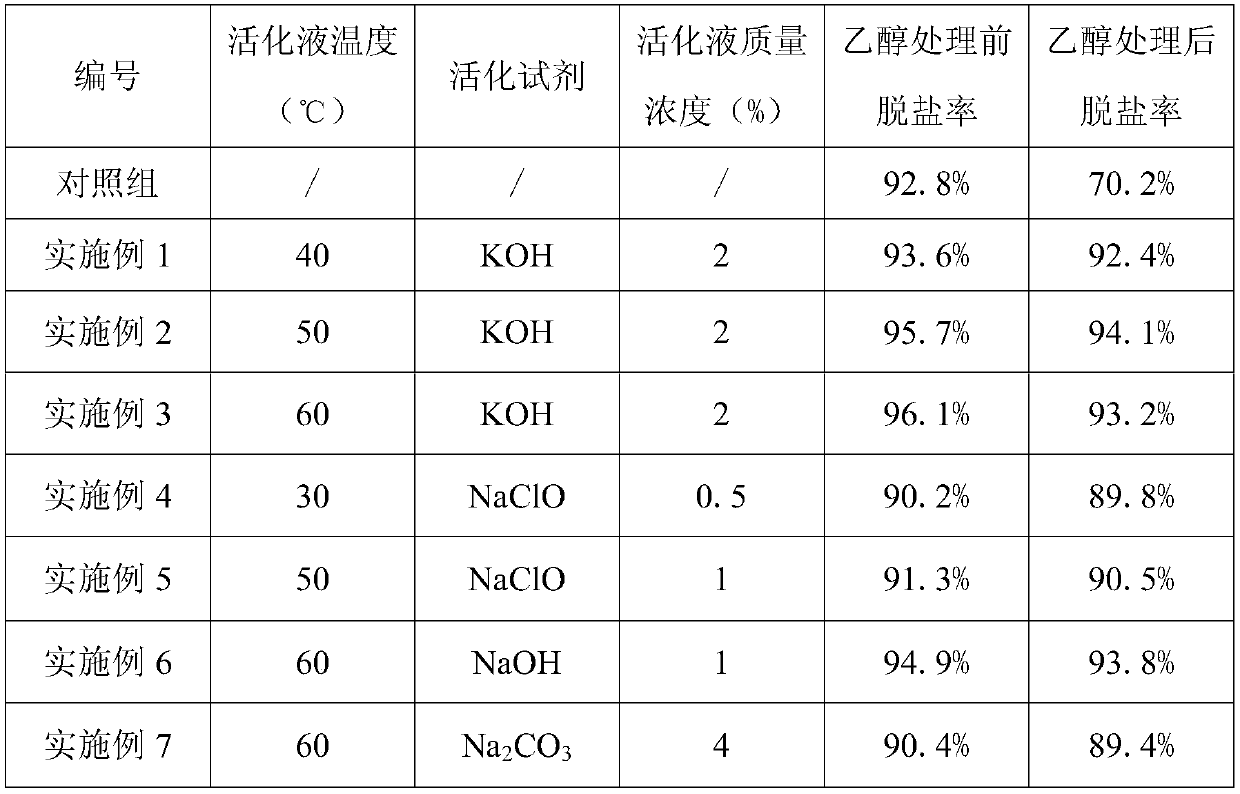

Embodiment 1

[0029] A preparation method of a polyamide hollow fiber nanofiltration composite membrane is provided in this embodiment, comprising the following steps:

[0030] Step 1: Use the polyamide hollow fiber ultrafiltration membrane as the base membrane, put the base membrane into a KOH (potassium hydroxide) solution with a temperature of 40°C and a mass concentration of 2% for 1 hour of hydrolysis activation treatment, after the activation treatment is completed Use pure water to wash the basement membrane until its pH (hydrogen ion concentration index) is neutral;

[0031] Step 2: Put the base film into an aqueous solution of polyethyleneimine with a mass concentration of 0.6% for 3 minutes. In this embodiment, the weight average molecular weight of polyethyleneimine is 8000;

[0032] Step 3: Take out the base film from the polyethyleneimine aqueous solution and hang it vertically for 8 minutes, wipe off the excess polyethyleneimine aqueous solution with a paper towel, and then im...

Embodiment 2

[0040] A preparation method of a polyamide hollow fiber nanofiltration composite membrane is provided in this embodiment, comprising the following steps:

[0041] Step 1: Use the polyamide hollow fiber ultrafiltration membrane as the base membrane, place the base membrane in a KOH solution with a temperature of 50°C and a mass concentration of 2% for 1 hour of activation treatment, and wash the base membrane with pure water after the activation treatment until its pH is neutral;

[0042]Step 2: Put the base film in an aqueous solution of polyethyleneimine with a mass concentration of 0.7% for 4 minutes. In this embodiment, the weight average molecular weight of polyethyleneimine is 10000;

[0043] Step 3: Take out the base film from the polyethyleneimine aqueous solution and hang it vertically for 8 minutes, wipe off the excess polyethyleneimine aqueous solution with a paper towel, and then immerse the base film in an organic solution of trimesoyl chloride with a mass concentr...

Embodiment 3

[0047] A preparation method of a polyamide hollow fiber nanofiltration composite membrane is provided in this embodiment, comprising the following steps:

[0048] Step 1: Use the polyamide hollow fiber ultrafiltration membrane as the base membrane, put the base membrane into a KOH solution with a temperature of 60°C and a mass concentration of 2% for 1 hour of hydrolysis activation treatment, and wash the base membrane with pure water after the activation treatment membrane until its pH is neutral;

[0049] Step 2: Put the base film in an aqueous solution of polyethyleneimine with a mass concentration of 0.7% for 5 minutes. In this embodiment, the weight average molecular weight of polyethyleneimine is 30000;

[0050] Step 3: Take out the base film from the polyethyleneimine aqueous solution and hang it vertically for 8 minutes, wipe off the excess polyethyleneimine aqueous solution with a paper towel, and then immerse the base film in an organic solution of trimesoyl chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com