Preparation method of zinc oxide-hydroxyapatite composite anticorrosive pigment

A hydroxyapatite and anti-corrosion pigment technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. Additional performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a zinc oxide-hydroxyapatite composite anticorrosion pigment, characterized in that nano-scale flaky zinc oxide is synthesized on flaky hydroxyapatite by a hydrothermal in-situ composite method, comprising the following steps:

[0020] (1) Add calcium chloride powder and urea to the disodium hydrogen phosphate dodecahydrate solution, carry out hydrothermal reaction in the reactor after ultrasonic mixing, and obtain flaky hydroxyapatite powder through washing and drying;

[0021] (2) Stir the hydroxyapatite powder in deionized water evenly, add zinc acetate dihydrate and sodium hydroxide in turn, and ultrasonically mix evenly, carry out hydrothermal reaction in a reactor, wash and dry to obtain zinc oxide-hydroxyapatite Composite anti-corrosion pigments.

[0022] Wherein, the mass ratio of disodium hydrogen phosphate dodecahydrate and calcium chloride described in step (1) is 1:1.5~1.7, and urea is added to adjust the pH to be 8~10; the temperature ...

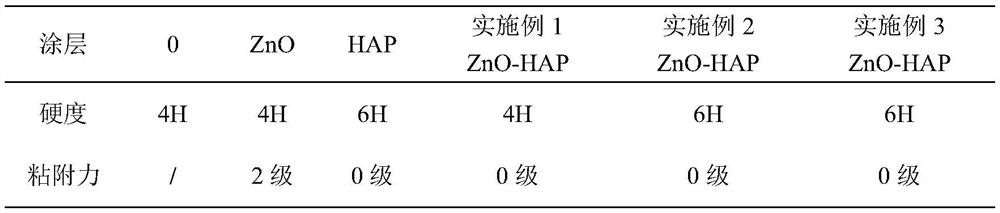

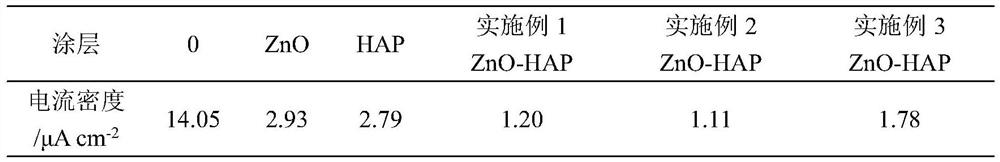

Embodiment 1

[0027] Preparation of zinc oxide-hydroxyapatite composite anti-corrosion coating, the specific steps are as follows:

[0028] 1. Preparation of Zinc Oxide-Hydroxyapatite Composite Anticorrosion Pigment

[0029] (1) Preparation of flaky hydroxyapatite (HAP)

[0030] Mix disodium hydrogen phosphate dodecahydrate and calcium chloride at a mass ratio of 1:1.67, add urea as a pH regulator, adjust the pH value of the solution to 9, and ultrasonically uniformly mix the solution and pour it into a reaction kettle. The hydrothermal reaction was carried out at ℃ for 6 hours, and the synthesized product was washed by centrifugation after the reaction. The washed synthetic product was dried at 100° C. for 2 h to obtain flaky hydroxyapatite powder.

[0031] (2) Preparation of Zinc Oxide-Hydroxyapatite (ZnO-HAP) Composite Anticorrosion Pigment

[0032] Take 0.2g of hydroxyapatite powder and stir evenly in deionized water, add 2.158g of zinc acetate dihydrate in proportion during the stir...

Embodiment 2

[0037] Preparation of zinc oxide-hydroxyapatite composite anti-corrosion coating, the specific steps are as follows:

[0038] 1. Preparation of Zinc Oxide-Hydroxyapatite Composite Anticorrosion Pigment

[0039] (1) Preparation of flaky hydroxyapatite

[0040] Mix disodium hydrogen phosphate dodecahydrate and calcium chloride at a ratio of 1:1.67, add urea as a pH regulator, adjust the pH value of the solution to 9, ultrasonically homogenize the mixed solution and pour it into the reaction kettle, at 180°C The hydrothermal reaction was carried out for 6 hours, and the synthesized product was washed by centrifugation after the reaction. The washed synthetic product was dried at 100° C. for 2 h to obtain flaky hydroxyapatite powder.

[0041](2) Preparation of Zinc Oxide-Hydroxyapatite Composite Anticorrosion Pigment

[0042] Take 0.35g of hydroxyapatite powder and stir evenly in deionized water. During the stirring process, add 1.753g of zinc acetate dihydrate in proportion to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com