Conductive film replacing aluminum foil, and preparation method thereof

A conductive film and aluminum foil technology, which is applied to the conductive layer on the insulating carrier, equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, etc., can solve the problem that the metal plating layer is easy to fall off, the conductive film conduction effect is not good, Unstable barrier properties and other issues, to achieve good ductility and strength, improve the problem of easy falling off, stabilize chemical properties and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

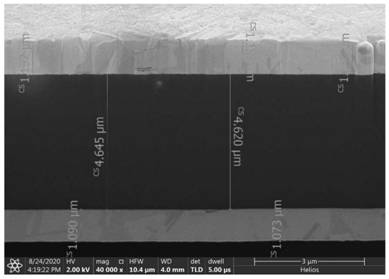

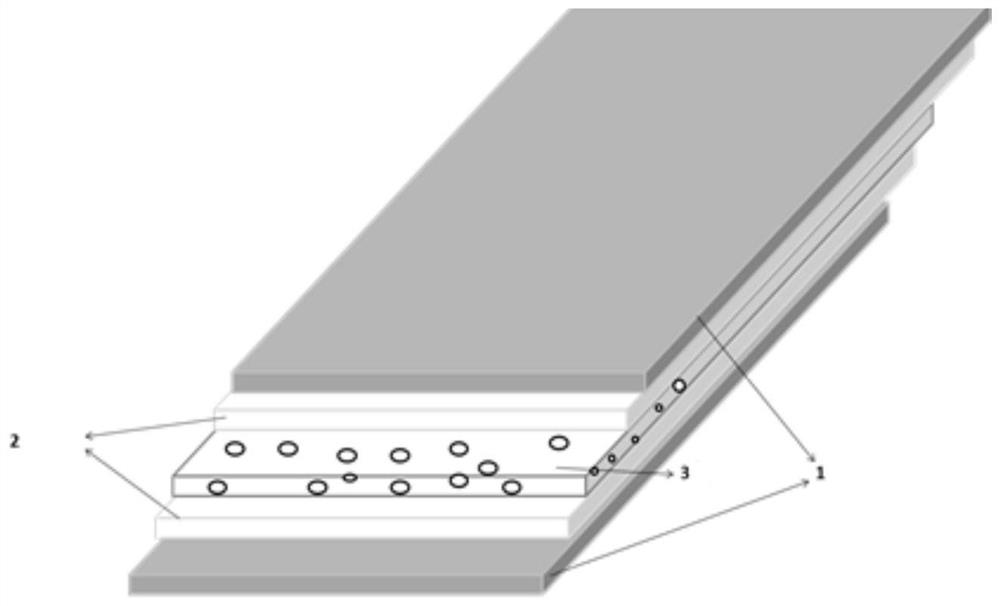

[0040] A conductive film replacing aluminum foil, comprising a 6 μm thick PET layer, a 50nm thick aluminum oxide layer evaporated on both sides of the PET layer, and a 500nm thick metal aluminum layer evaporated outside the aluminum oxide layer.

[0041] The preparation method of described conductive film is:

[0042] 1) carry out the surface plasma treatment that power is 5kW to the surface of PET layer;

[0043] 2) Preheat the evaporation boat, and evacuate the chamber of the evaporation machine to 10 -5 mbar, control the vacuuming time to be 10min, and then carry out the middle reinforcement layer on both sides of the PET layer in step 1), the thickness of single-coated aluminum oxide is 50nm, the evaporation boat type wire feeding speed is 500mm / min, and the cooling temperature is -10 ℃, membrane speed 12m / s;

[0044] 3) Evaporate a metal aluminum layer on the outer side of the intermediate reinforcement layer obtained in step 2), the heating method is resistance heating...

Embodiment 2

[0047] A conductive film that replaces aluminum foil, including a 4.5 μm thick OPP layer, a nickel-chromium alloy intermediate reinforcement layer with a total thickness of 100 nm is coated on both sides of the OPP layer by magnetron sputtering, and a total thickness of 1000 nm is vacuum-evaporated on the outside of the intermediate layer. Metallic aluminum layer.

[0048] The preparation method of described conductive film is:

[0049] 1) The surface of the OPP layer is subjected to surface plasma treatment with a power of 7kW;

[0050] 2) Carry out magnetron sputtering on both sides of the OPP layer in step 1) to coat the nickel-chromium alloy intermediate layer, the magnetron sputtering process parameters are: power 150kW, substrate transmission speed 8m / min, argon flow speed 30L / min , ion source voltage 250V;

[0051] 3) Evaporate a metal aluminum layer on the outer side of the middle reinforcing layer obtained in step 2). The evaporation coating used is resistance heati...

Embodiment 3

[0054] A conductive film replacing aluminum foil, comprising a 12 μm thick PET layer, an 80nm thick aluminum oxide layer vacuum-evaporated on both sides of the PET layer, and a 1000nm thick metal aluminum layer vacuum-evaporated outside the aluminum oxide layer.

[0055] The preparation method of described conductive film is:

[0056] 1) carry out the surface plasma treatment that power is 6kW to the surface of PET layer;

[0057] 2) Preheat the evaporation boat, and evacuate the chamber of the evaporation machine to 10 -5 mbar, control the vacuuming time to be 10min, and then carry out the middle reinforcement layer of evaporation coating on both sides of the PET layer in step 1), the thickness of single plating aluminum oxide is 80nm, the speed of evaporation boat type wire feeding is 500mm / min, and the cooling system temperature is - 10°C, the film running speed is 8m / s;

[0058] 3) Evaporate a metal aluminum layer on the outer side of the intermediate reinforcing layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com