A kind of square lithium-ion battery wound electric core and manufacturing method thereof

A technology of lithium-ion battery and manufacturing method, which is applied in the field of square-shaped lithium-ion battery winding cells and its production, and can solve problems such as easy powder dropping, pole piece deformation, and easily wrinkled and deformed pole piece, so as to maintain consistency , Avoid deformation problems, weaken the effect of pole piece deformation and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

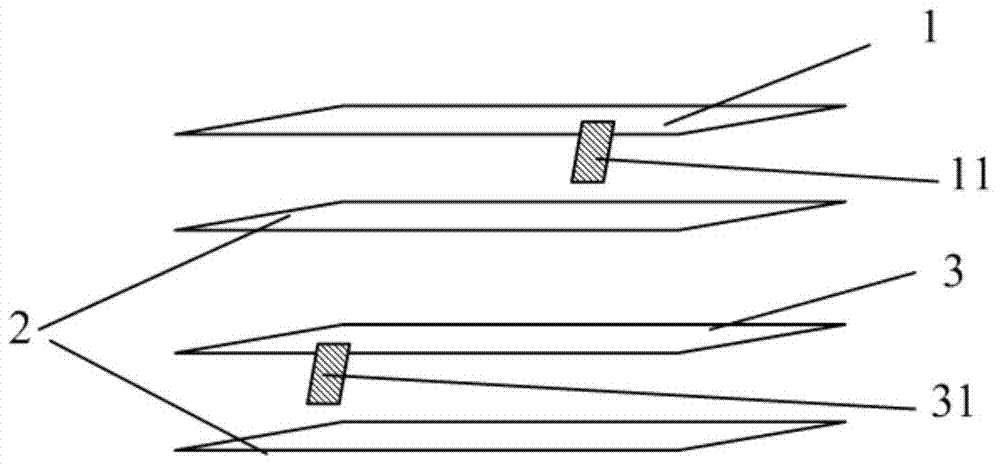

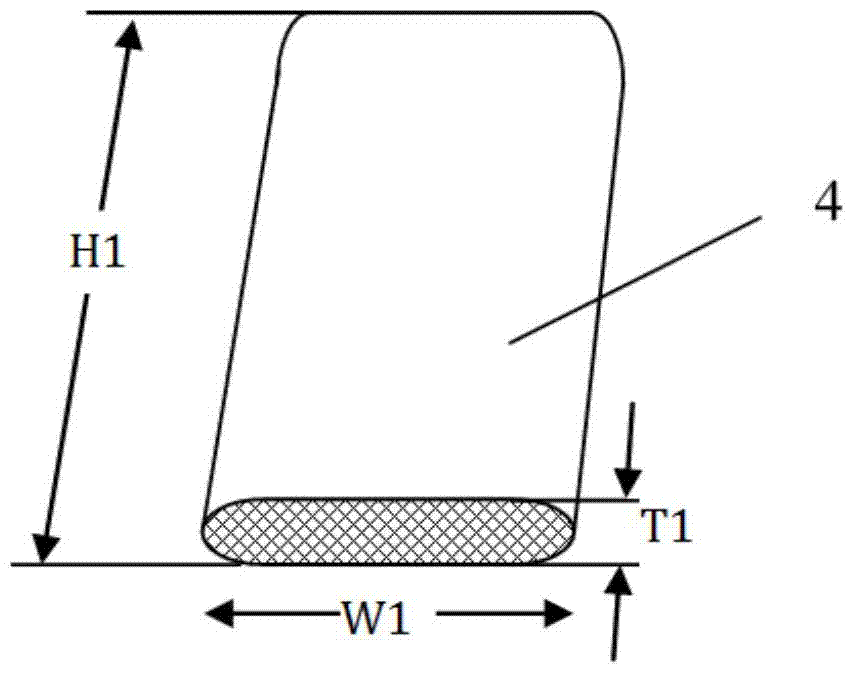

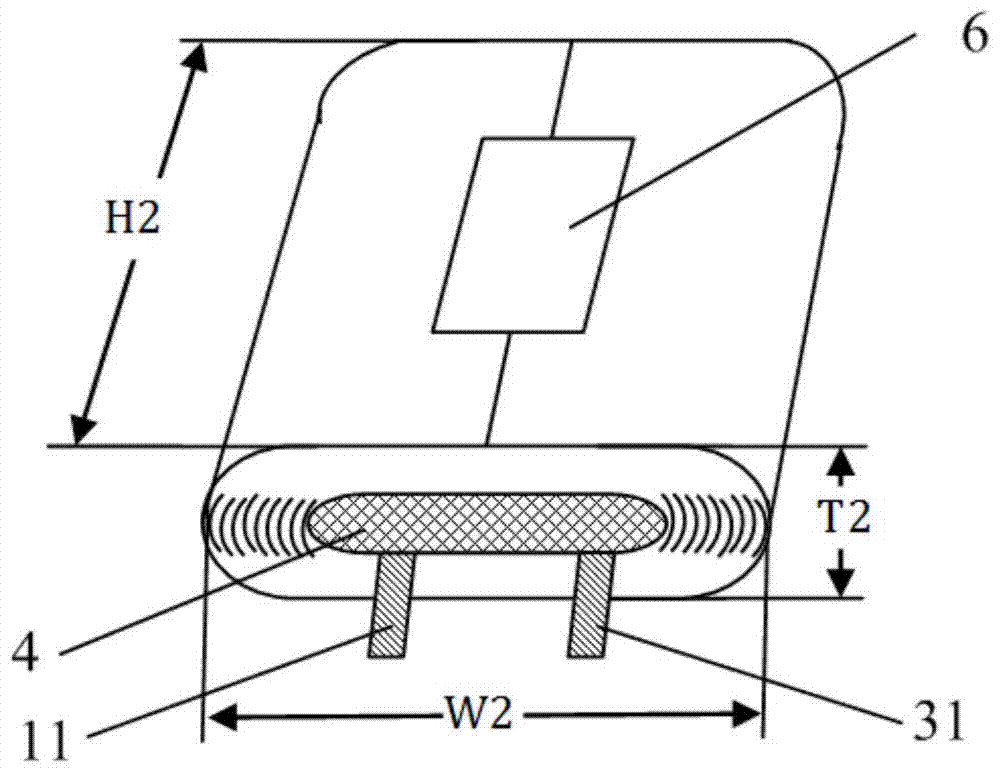

[0043] Such as Figure 1~Figure 3 As shown, a winding cell of a square lithium-ion battery includes a positive electrode sheet 1, a diaphragm 2 and a negative electrode sheet 3, the positive electrode sheet 1 is provided with a positive electrode tab 11, and the negative electrode sheet 3 is provided with a negative electrode tab 32 , the center of the winding cell of the square lithium-ion battery is provided with an internal support frame, the internal support frame is an insulating coil pin 4, and the size of the insulating coil pin 4 is: the thickness T1 is 10mm, and the length W1 is 280mm , the width H1 is 230 mm, such as figure 2 As shown; the size of the finished cell is: the cell thickness T2 is 40mm, the cell length W2 is 310mm, and the cell width H2 is 230mm; shape; the material of the insulating winding pin 4 is PTFE; the positive electrode tab 11 and the negative electrode tab 31 are located on the same side of the insulating rolling pin 4 .

[0044] The design ...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 1~Figure 3 As shown, a winding battery cell of a square lithium-ion battery, the material of the insulating rolling pin 4 in this example is PP, and the size of the insulating rolling pin 4 is: thickness T1 is 5 mm, length W1 is 215 mm, width H1 is 210 mm, such as figure 2 As shown; the size of the finished cell is: cell thickness T2 is 20mm, cell length W2 is 230mm, and cell width H2 is 210mm; the cross-section of the outer surface of the left and right side walls of the insulating needle 4 is a semicircular arc shape; the positive pole tab 11 and the negative pole tab 31 are located on the same side of the insulating needle 4 .

[0048] The design capacity of the finished cell is 45Ah, 3.2V. The positive electrode 1 is lithium iron phosphate, the negative electrode 3 is graphite, and the electrodes are arranged in a sandwich structure.

[0049] Such as Figure 5 As shown, when 16 batteries are used in series, the dynamic ...

Embodiment example 3

[0051] Such as figure 1 and Figure 6 As shown, a winding cell of a square lithium-ion battery includes a positive electrode sheet 1, a diaphragm 2 and a negative electrode sheet 3, the positive electrode sheet 1 is provided with a positive electrode tab 11, and the negative electrode sheet 3 is provided with a negative electrode tab 32 , the center of the winding cell of the square lithium-ion battery is provided with an internal support frame, the internal support frame is a hollow support 5, and the hollow support 5 is formed by winding and bonding pole pieces; the positive pole lug 11 and the negative pole tab 31 are located on the same side of the hollow bracket 5 .

[0052] The hollow bracket 5 is a bracket structure formed by applying glue to the semicircular position where the pole piece bends during the pole piece winding process, so that the pole pieces are bonded together as a whole. The winding and bonding part of the pole piece is a material blank area. First, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com