Drilling method for thick copper circuit board

A technology of thick copper circuit board and production method, which is applied in drilling/drilling equipment, repairing drills, drilling tool accessories, etc., can solve the problems of voids, gaps, copper layer dislocation, etc., so as to increase the bonding area and ensure the adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

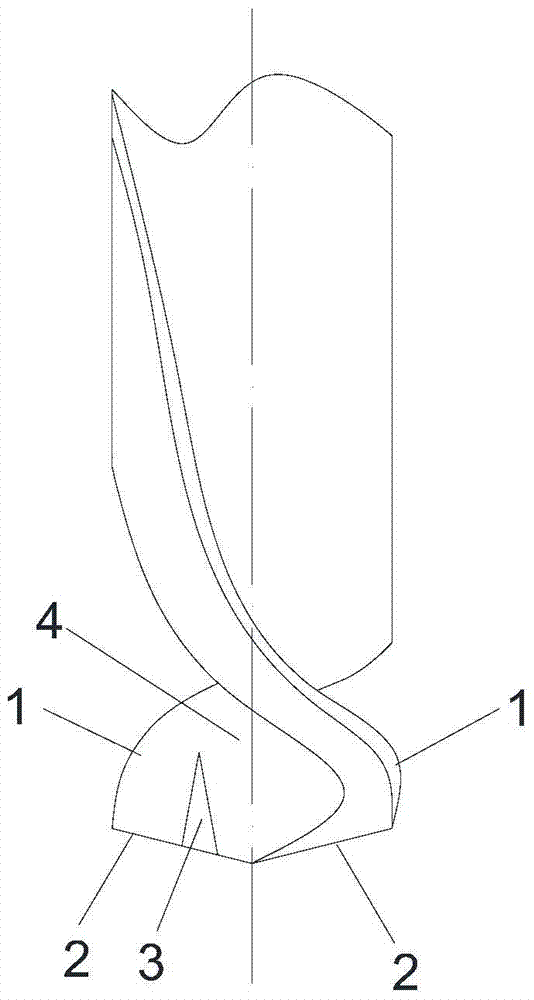

[0023] Such as figure 1 As shown in the drill bit, the drill tip is composed of a drill rod and a drill bit. The drill bit has a diameter of 1.9mm, including a double helix cutting blade 1, and the double helix of the cutting blade 1 forms two helical chip removal grooves 4, the chip removal groove 4 A groove 3 is provided in the axial direction at the drilling end 2 of the drill bit. The groove 3 is triangular in cross section and extends to the drilling end 2 of the drill bit. The groove 3 gradually decreases in axial width and depth from the drilling end 2 of the drill bit. The maximum depth of the groove 3 is 1 / 2 of the thickness of the cutting blade 1 , and the smallest width end is connected with the surface of the cutting blade 1 . The axial angle between the drilling end 2 of the drill bit and the drill bit is 67.5°.

[0024] Use the drill bit above to make circuit board drilling. The circuit board is a laminated board with 6 layers of copper lines. The copper thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com