Patents

Literature

44results about How to "Control filling volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

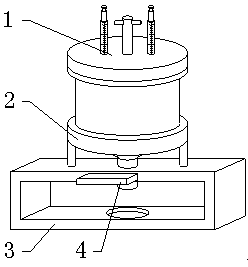

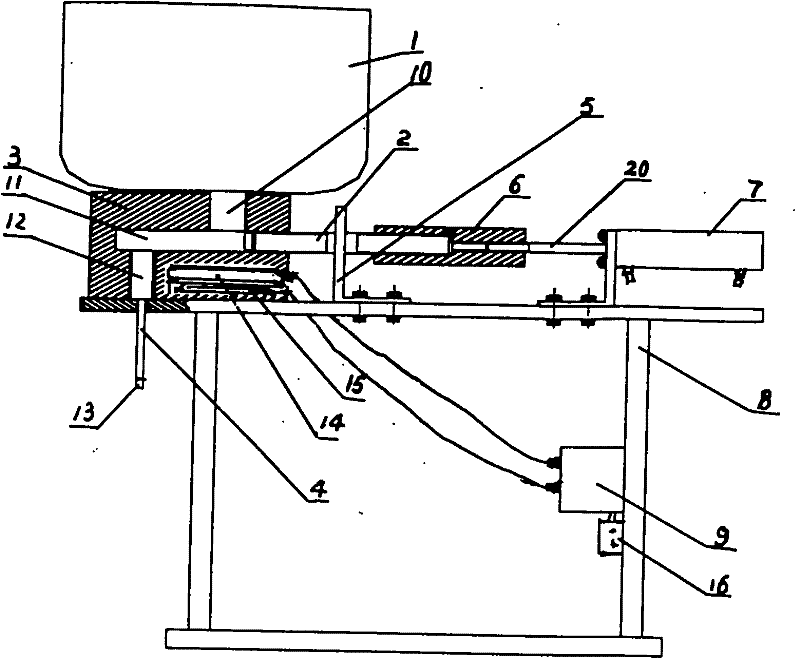

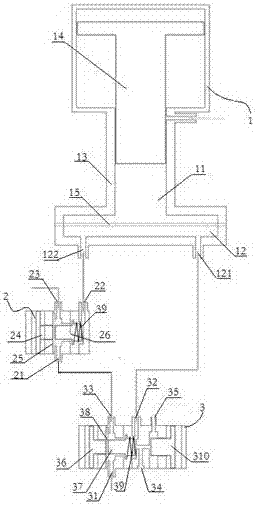

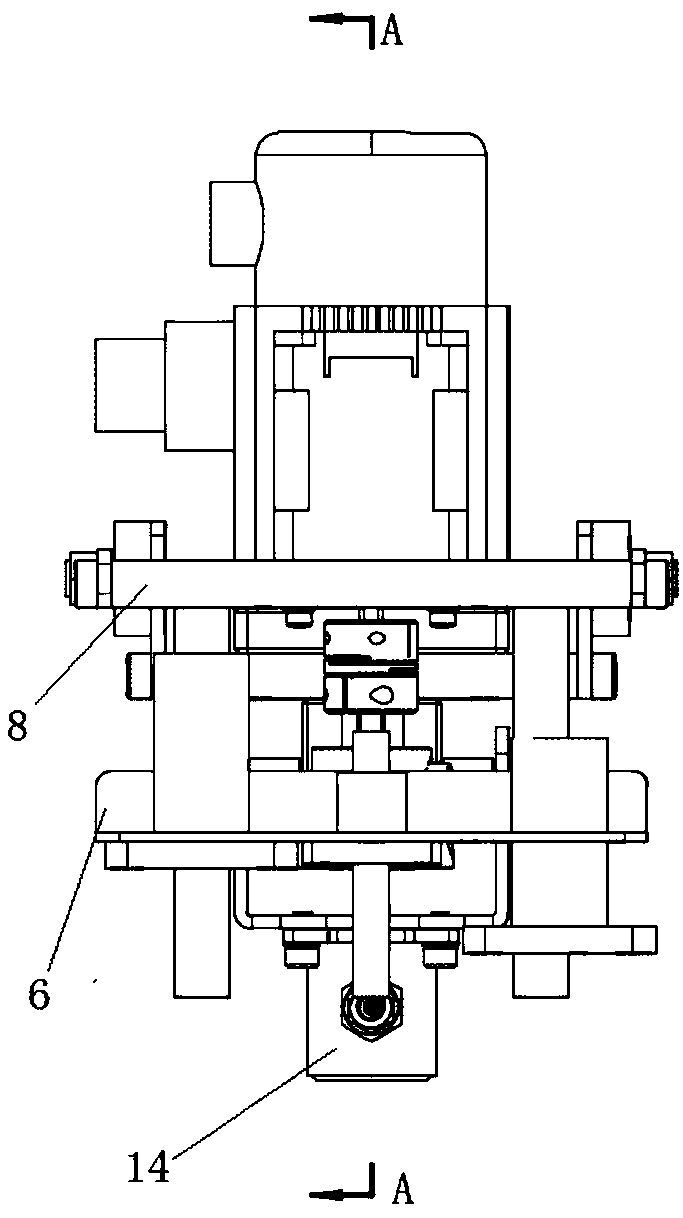

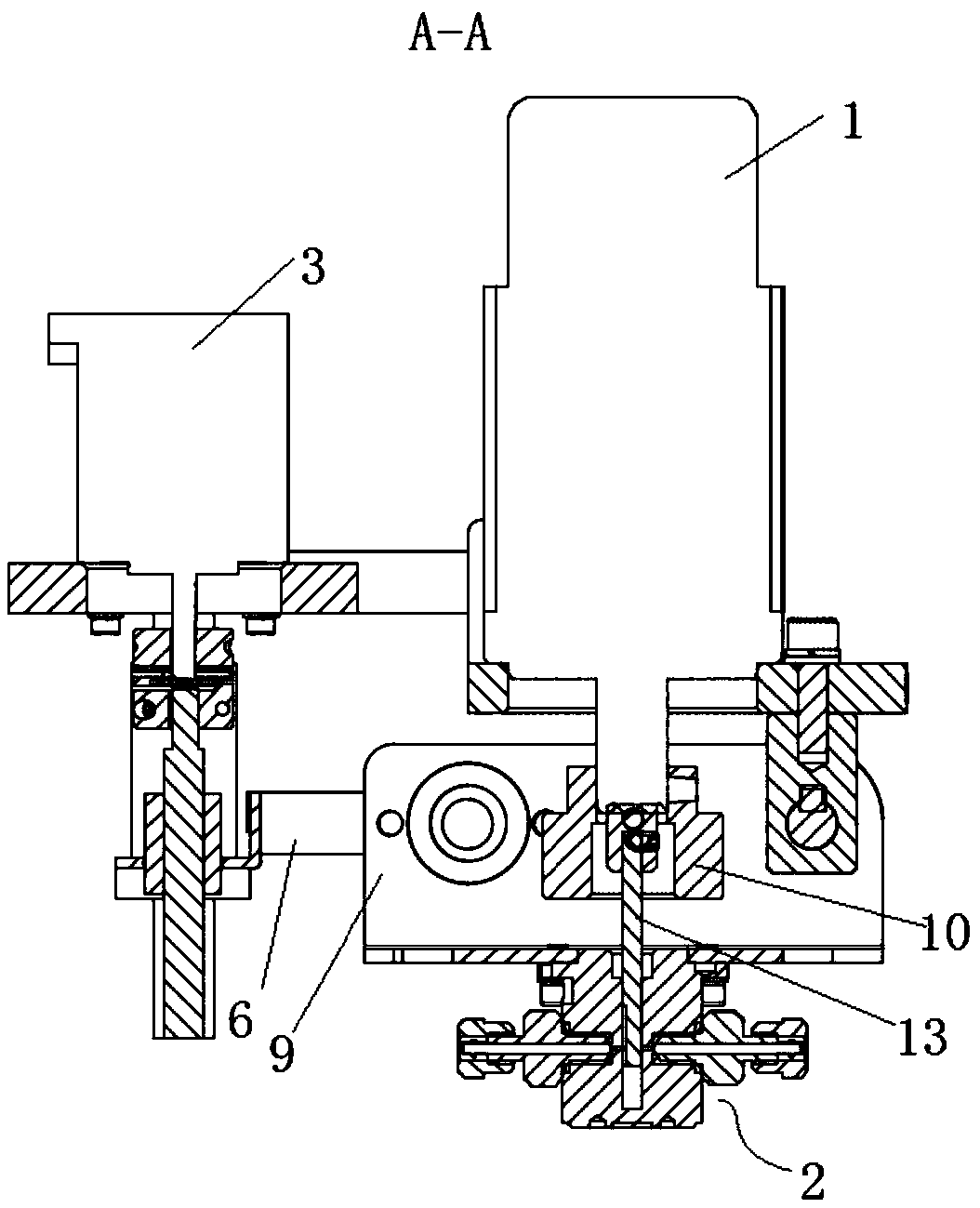

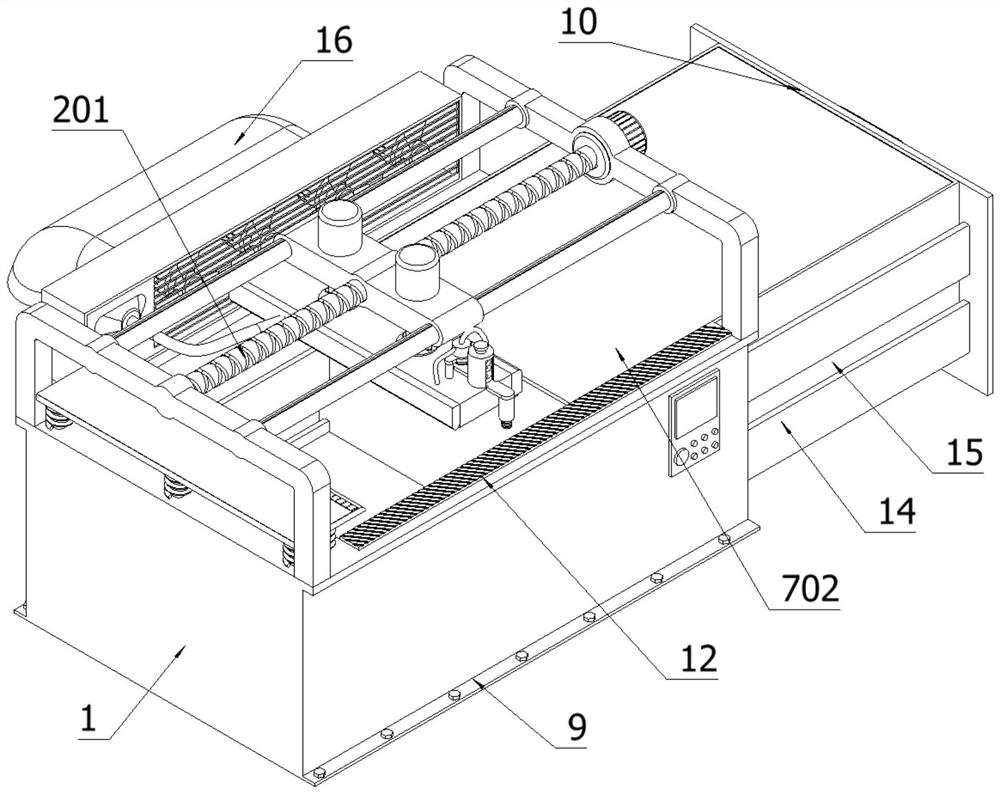

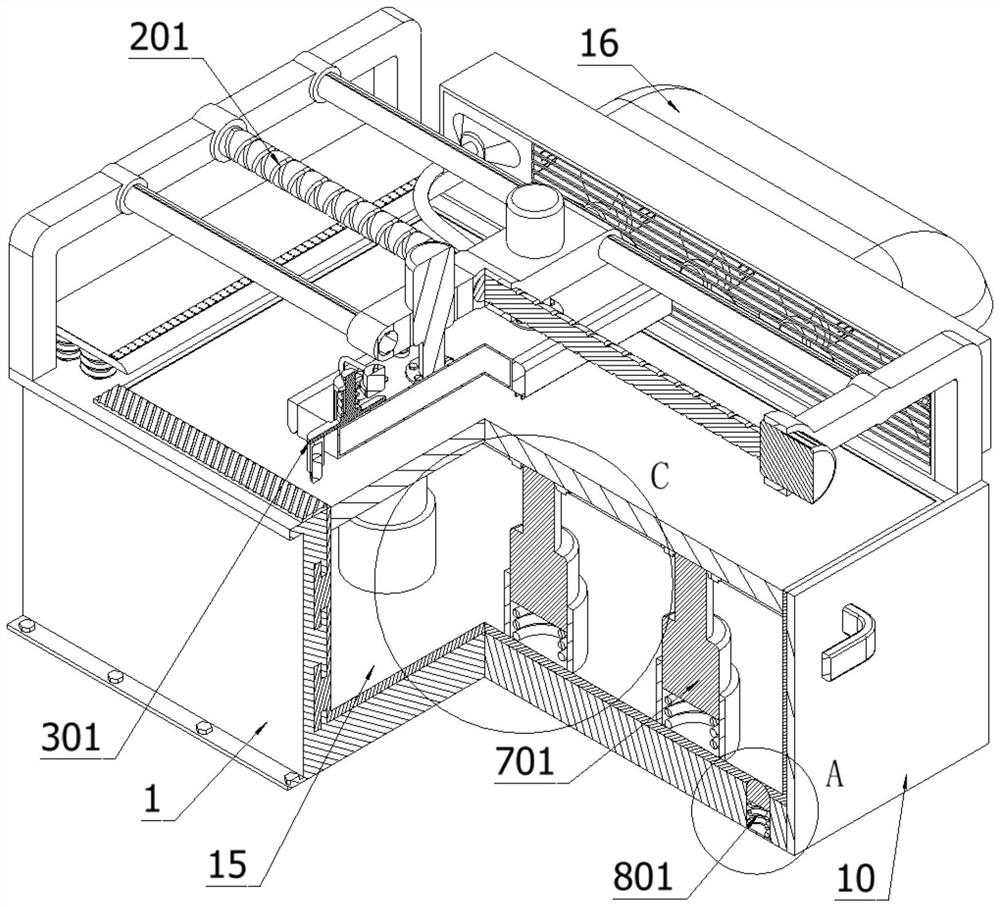

Quantitative filling machine of viscous material

ActiveCN102838069AImprove filling efficiencyEasy to installFilling using counterpressureEngineeringBottle

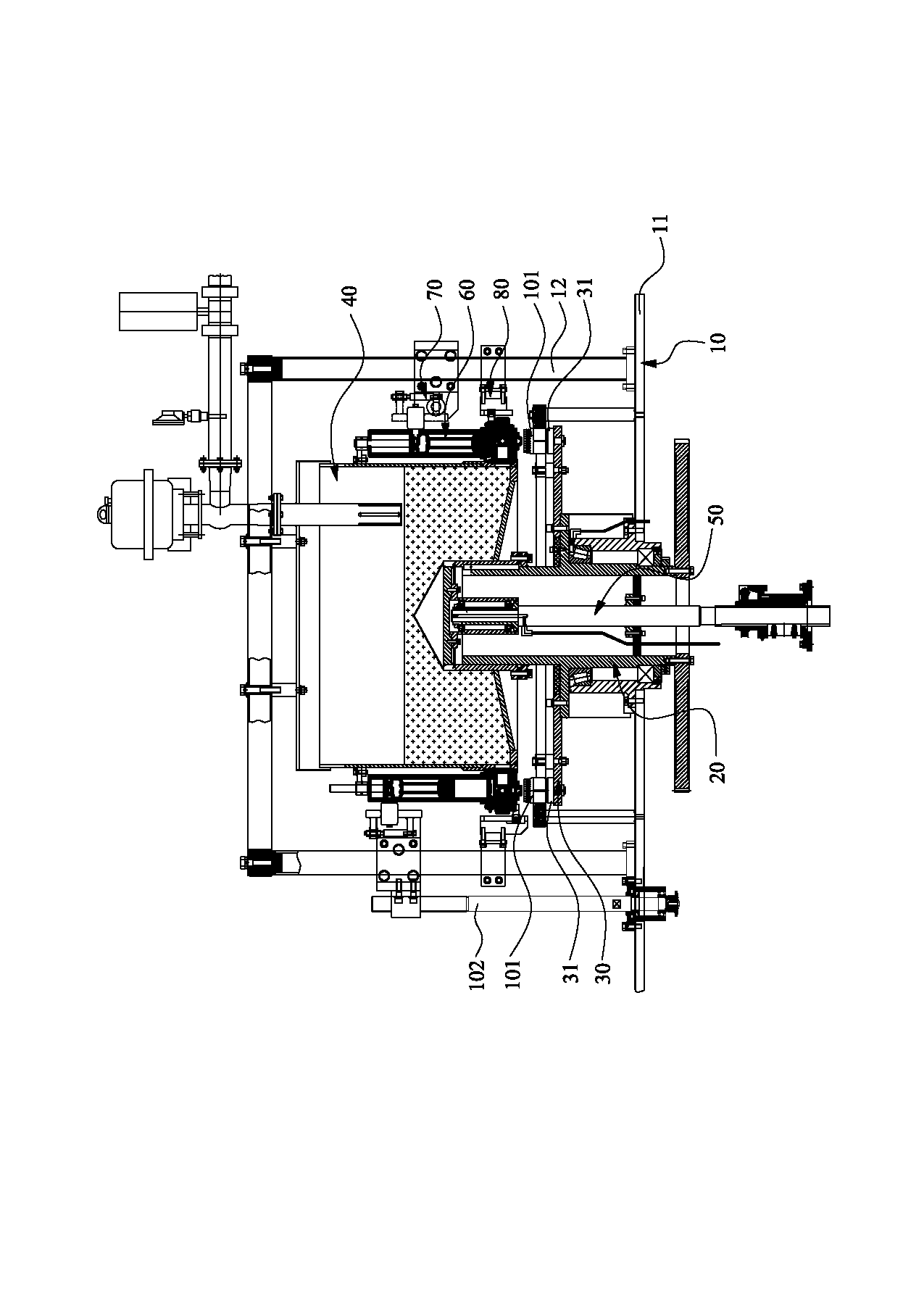

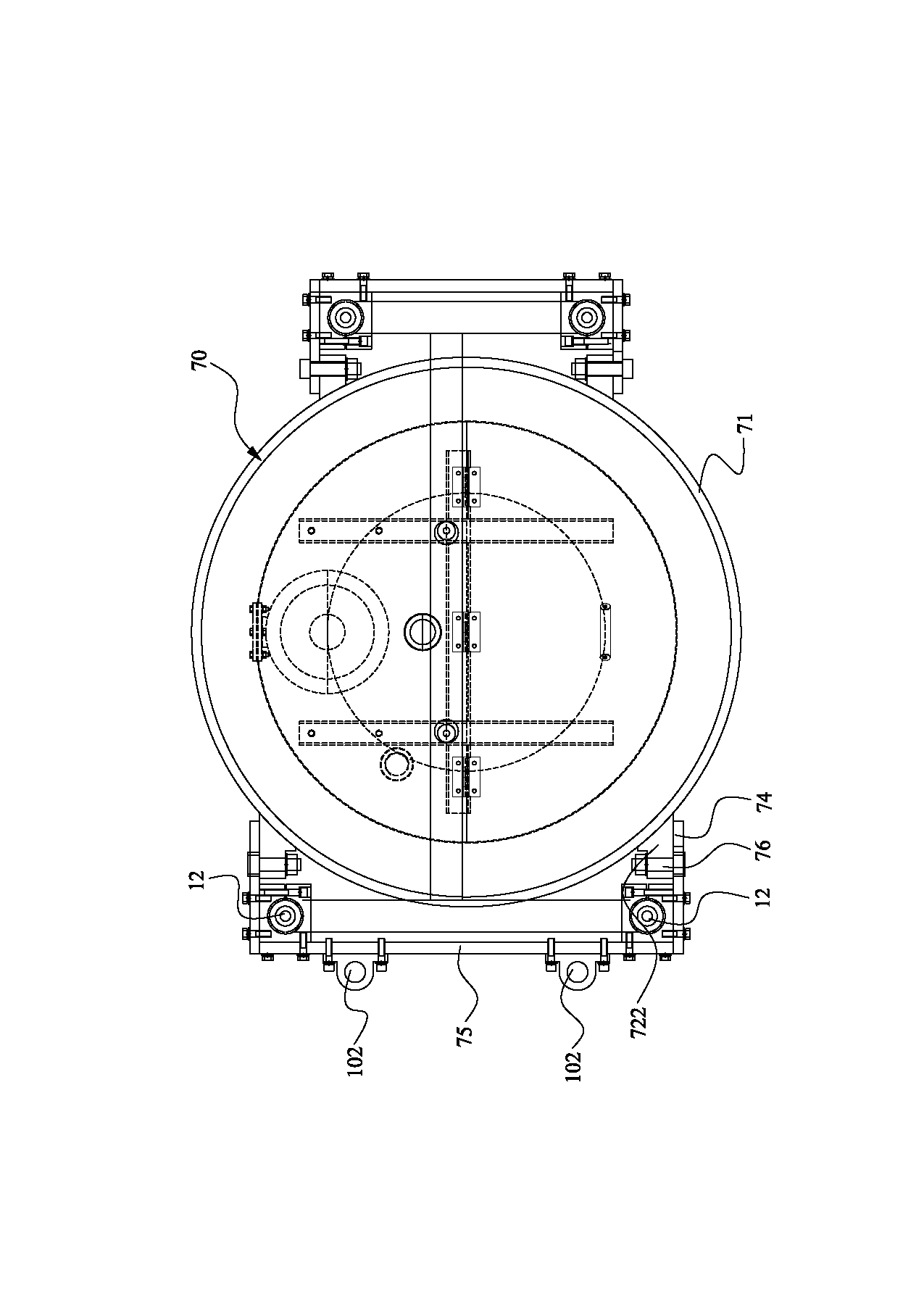

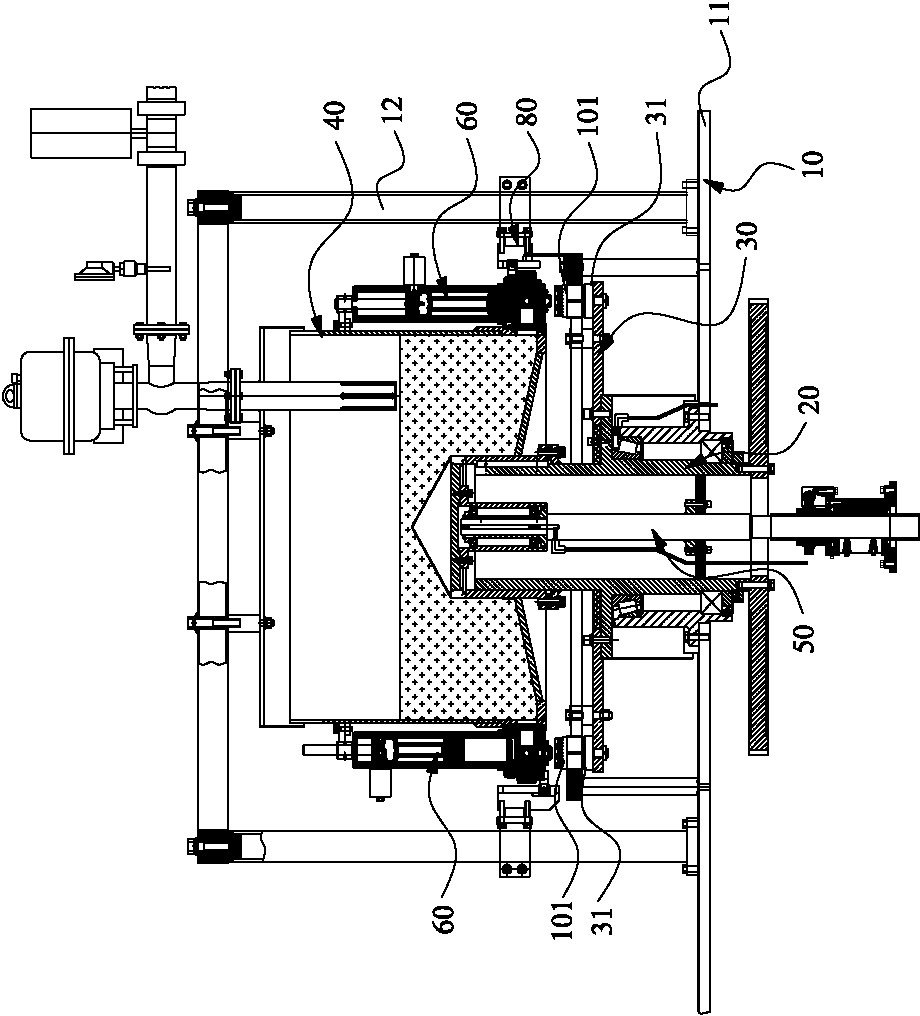

The invention discloses a quantitative filling machine of a viscous material. The quantitative filling machine comprises a rack, a revolving seat, a revolving platform and a material cylinder, wherein the circumferential face of the material cylinder is provided with a filling valve; a track which is arranged slantwise is constituted by an upper ring and a lower ring; a piston is controlled to alternately suck the material into a material cavity or press the material in the material out and fill in a bottle by using the track; meanwhile, a sensor is cooperatively used for controlling work of a driving mechanism, so that an ascending passage is opened or closed by a swing rod, thereby communicating a feed port and the material cavity by a feeding passage or communicating a filling port and the material cavity by a filling passage, effectively controlling output of the material and preventing a mistaken filling phenomenon; and thus, inlet and outlet of the material of all filling valves can be simultaneously and effectively controlled by using a piston control device and a switching control device, the quantitative filling machine has a simple structure and is convenient to operate, mount, debug and maintain, the degree of automation of the machine is greatly improved, and the filling efficiency of the material is effectively increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

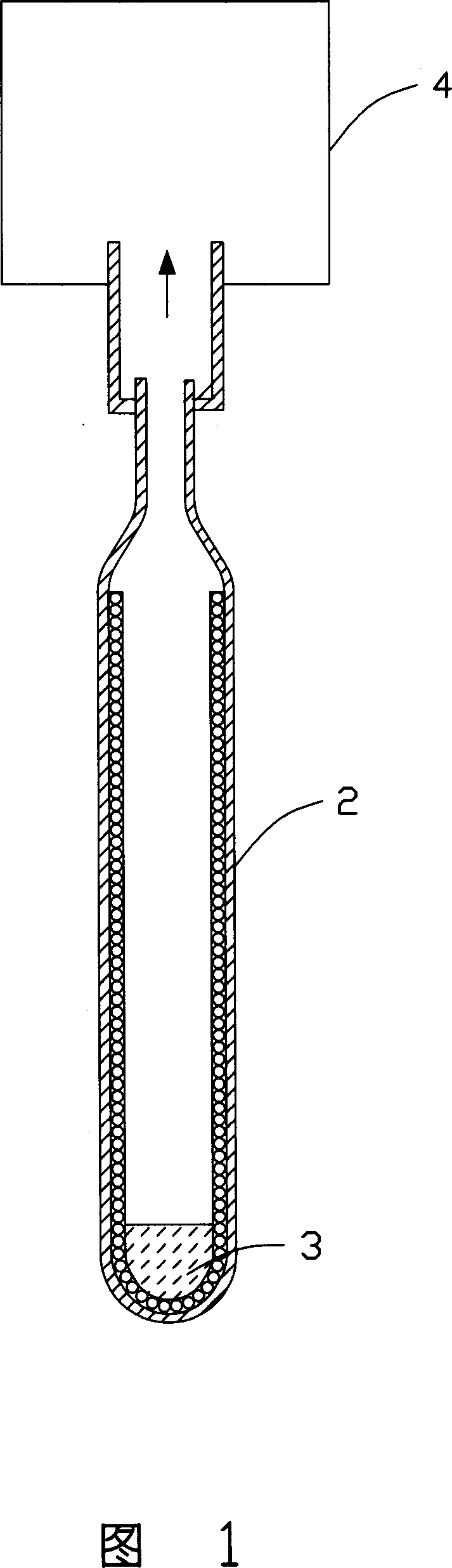

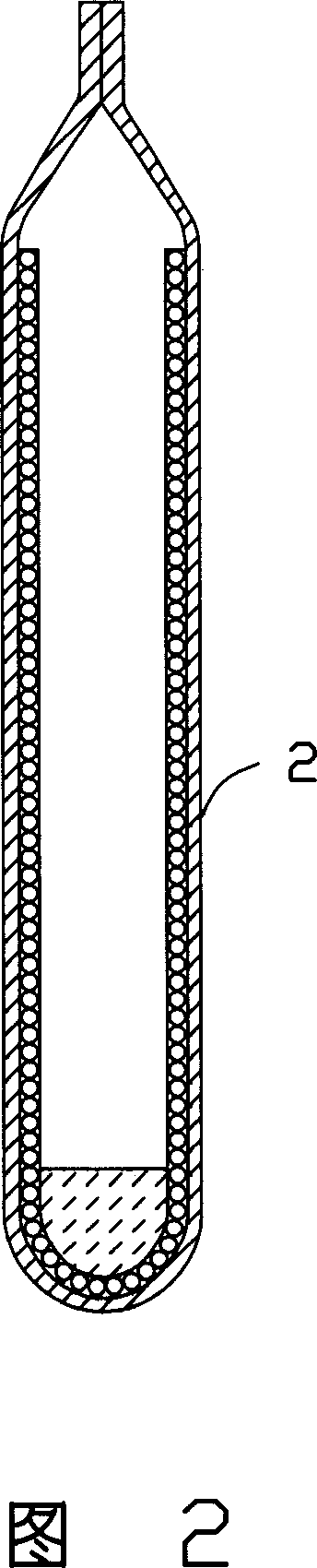

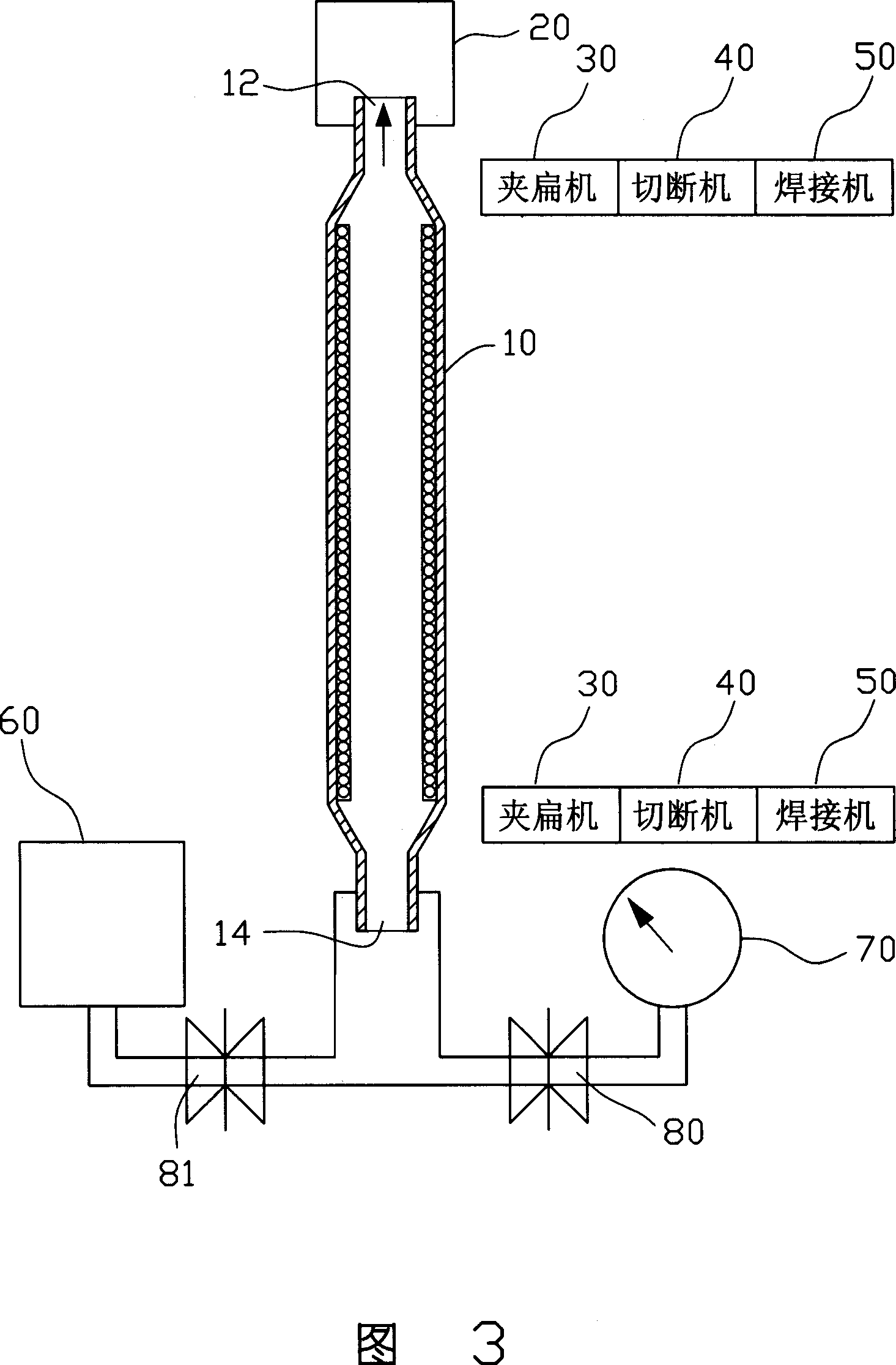

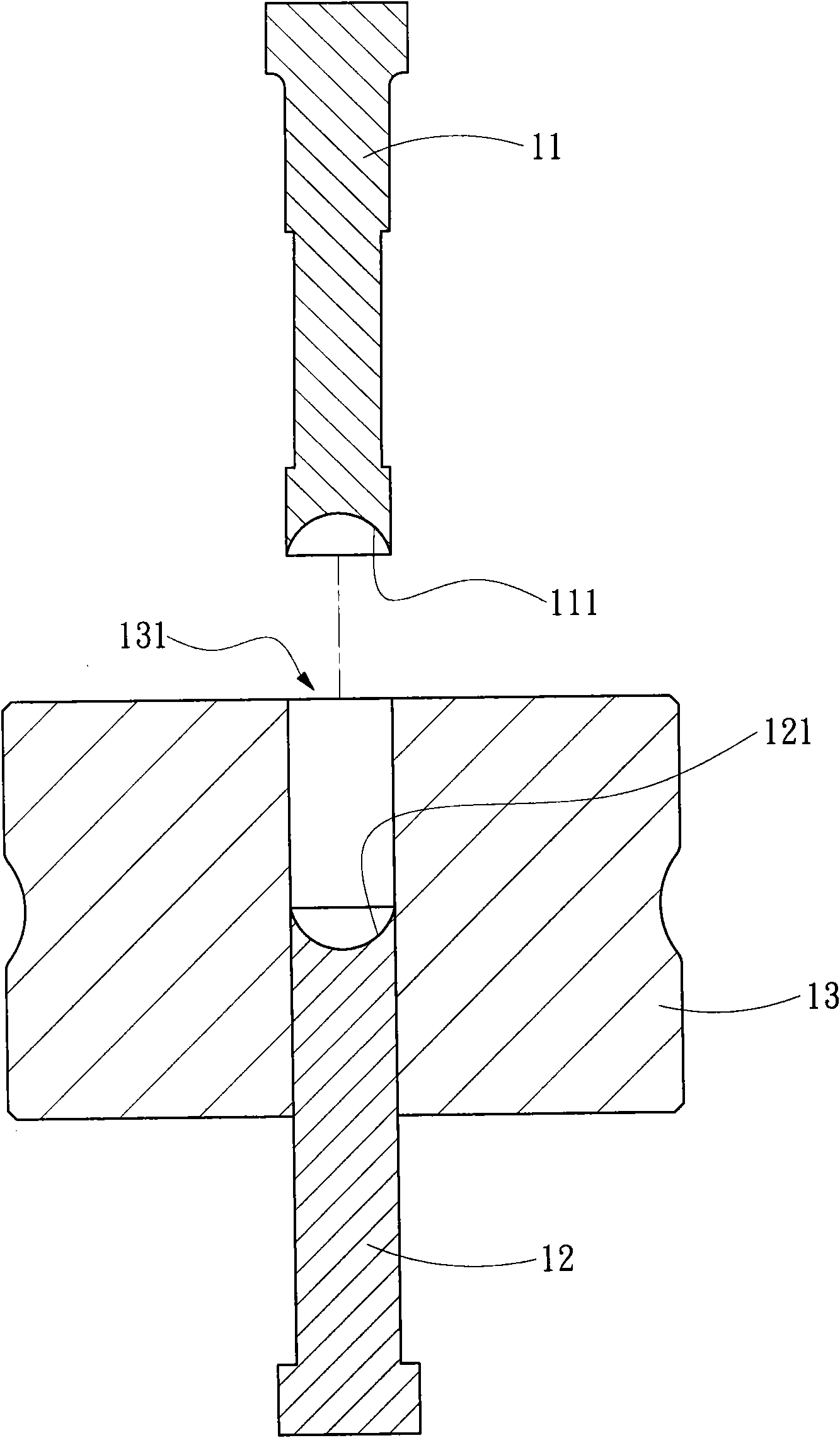

Heat-conductive pipe and mfg. method

InactiveCN1936479AControl vacuumControl filling volumeSemiconductor/solid-state device detailsSolid-state devicesGuide tubeBiomedical engineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Solid and cementing body composite filling coal mining method

ActiveCN105298494AAvoid the inadequacy of not being able to effectively connect the roofControl deformationUnderground miningSurface miningMining engineeringFilling materials

The invention discloses a solid and cementing body composite filling coal mining method, and relates to the technical field of coal mining methods. The method comprises the steps that digging is conducted on a working face coal conveying lane, a material filling lane and a cutting hole; solid filing equipment is erected; a lane filling pipe and a working face filling pipe are paved; the lane filling pipe and the working face filling pipe are connected; a working face is propelled; pushing and dense filling are conducted on goaf solid materials; cementing body material filling is conducted in solid filling materials; the working face filling pipe is closed; solid-cementing body filling coal mining operation of the next cycle is conducted. The solid and cementing body composite filling coal mining method can overcome the defect that an overall push dense effect is poor in the solid filling coal mining method, the detect that paste material filling and high water material filling can not achieve effective roof contacting can be overcome, roof settling before filling is effectively made up, and the filling body and surrounding rock deformation is accurately controlled.

Owner:JIZHONG ENERGY GRP

Filling equipment for honey processing and production

The invention provides filling equipment for honey processing and production. The filling equipment comprises transparent guiding rods, a storing tank, a conveying screw, a rotating rod, first stirring rods, second stirring rods and a sealing floating plate. The transparent guiding rods are fixed to the upper end of the sealing floating plate, and the sealing floating plate is arranged in the storing tank. The transparent guiding rods are arranged on the left side and the right side of the rotating rod, and the conveying screw is fixed to the lower side of the rotating rod and arranged at thelower edge inside the storing tank. The first stirring rods are fixedly mounted at the left end and the right end of the rotating rod through fixing rings, and the second stirring rods are slidably connected to the left side and the right side of the rotating rod through sliding rings and arranged on the lower side of the sealing floating plate. The first stirring rods are arranged under the second stirring rods, and the rotating rod penetrates through the sealing floating plate. According to the design, the filling effect is improved, and the filling equipment is convenient to use and operate, good in filling effect and capable of conducting accurate measurement.

Owner:枞阳县鲍记蜂业有限责任公司

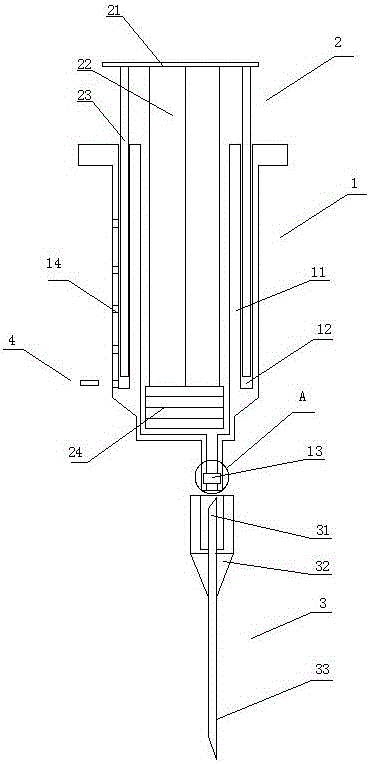

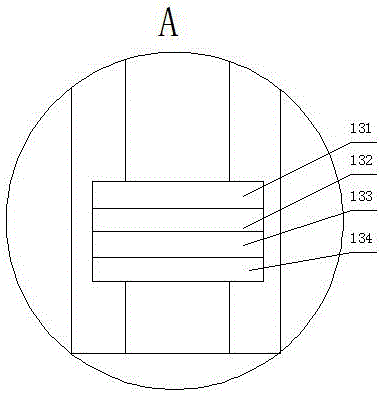

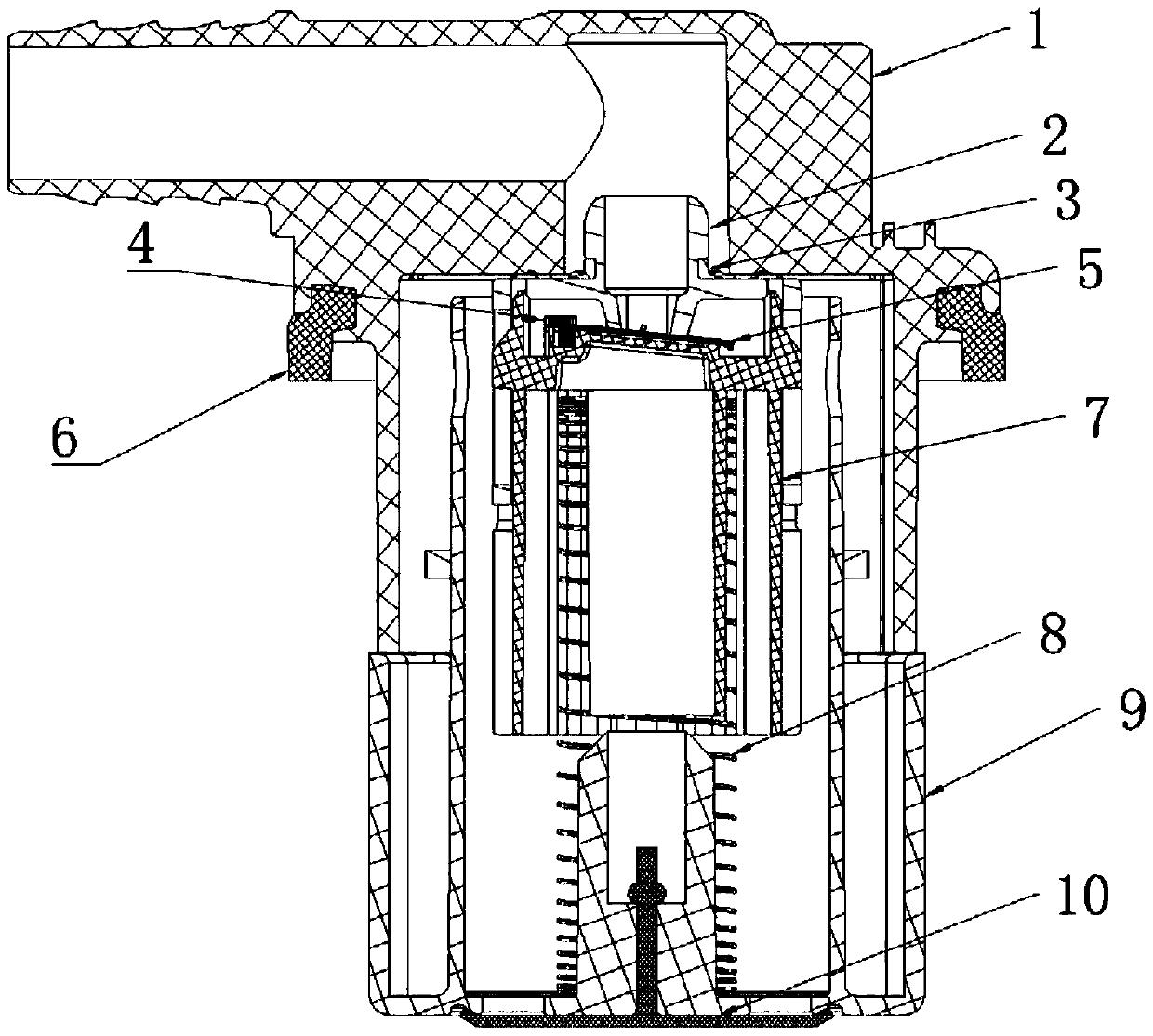

Syringe

ActiveCN106823068AControl injection speedReduce propulsion speedEngine sealsInfusion syringesInjection portInjection equipment

The invention relates to the field of injection equipment, in particular to a syringe. The syringe comprises a syringe canister, a syringe piston and an entry needle; the injection port of the syringe canister is provided with a sealing part, and the connecting end of the entry needle is provided with an acicular part used for piercing the sealing part. The arrangement of the sealing part and the entry needle corresponding to the sealing part can prevent the syringe from being polluted at the mouth portion of the syringe by bacteria and improve the anti-bacteria and sterilization effect. The structure can make it convenient to produce the syringe and the entry needle separately, and accordingly the production difficulty is reduced. The sealing part is thin film integrally shaped with the syringe canister. The thin film is integrally shaped, better in leakproofness and lower in cost, and can prevent the bacteria completely with the characteristic of being disposable. Through control over resistance of push of a limiting rod, the push speed of the piston is effectively reduced, the precise control over added quantity of the syringe is improved, and the lower the push speed is, the preciser the added quantity control is.

Owner:PANZHIHUA JIUDINGZHIYUAN INTPROP OPERATION CO LTD

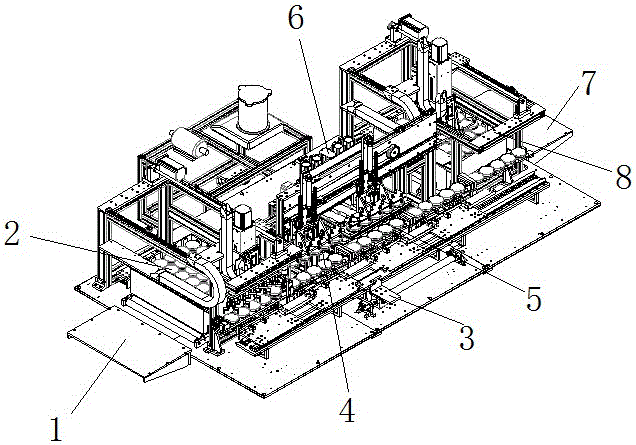

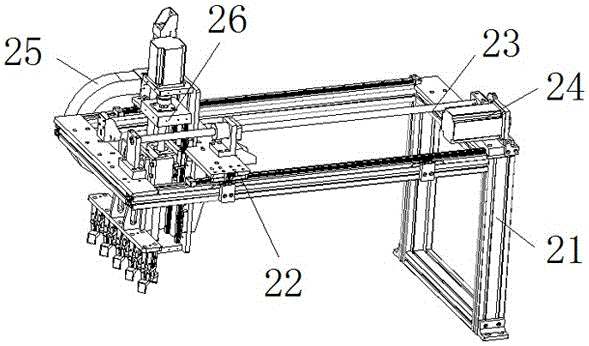

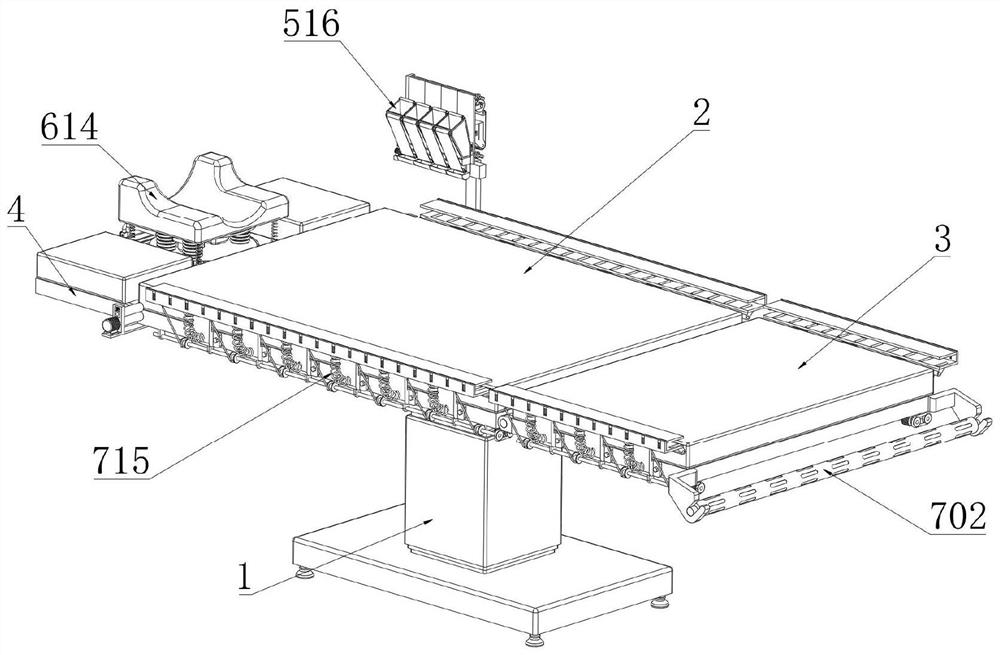

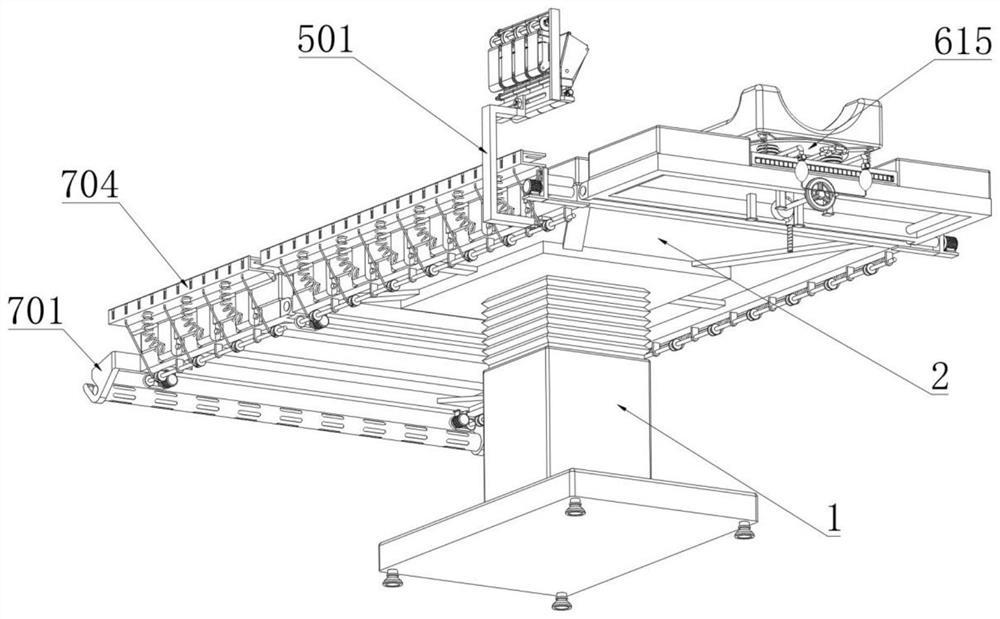

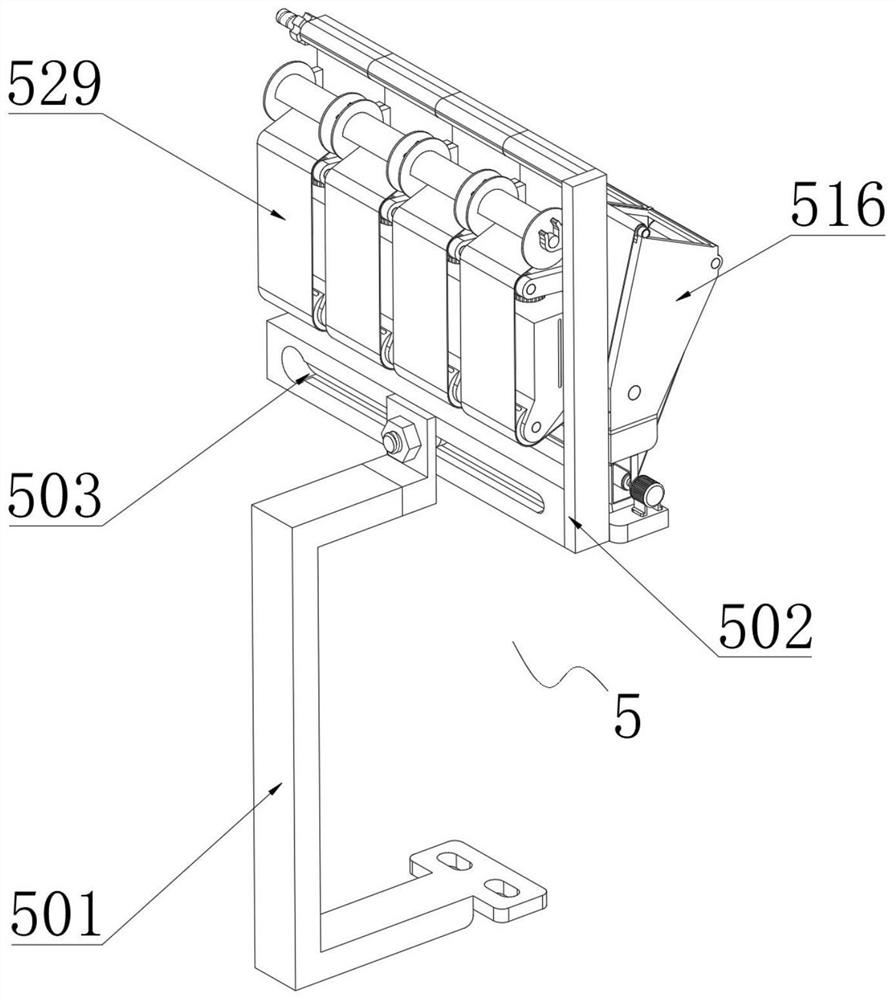

Automatic diverging and filling machine for plant nutrition cultivation solution

InactiveCN105667850AControl filling volumeConsistent filling volumeLiquid materialAutomatic controlPlant nutrition

The invention relates to an automatic diverging and filling machine for a plant nutrition cultivation solution. The automatic diverging and filling machine comprises a solution storage tank feeding rack, a solution storage tank feeding mechanism, a solution storage tank delivery mechanism, a solution storage tank cover delivery mechanism, a solution storage tank cover exchange temporary storage rack, a cultivation solution diverging mechanism, a solution storage tank discharging rack, a solution storage tank discharging mechanism and a cultivation solution conveying mechanism, wherein the solution storage tank cover exchange temporary storage rack is arranged at the back of the solution storage tank delivery mechanism. The automatic diverging and filling machine integrates automatic delivery of the solution storage tank, automatic positioning, automatic lifting height adjustment, automatic cap removal of the solution storage tank, automatic removed cap temporarystorageof the solution storage tank, automatic filling of the solution storage tank, automatic control on solution storage amount, automatic capping of the solution storage tank after filling, and automatic discharging, and can control the filling amount of the cultivation solution with high precision, so that the filling amount of the cultivation solution of each bottle of the solution storage tank is consistent, deviation of the filling amount is small, intelligent operation degree is high, efficiency is high, effect is good and cost is low.

Owner:DONGGUAN MING HUA AUTOMATION EQUIP

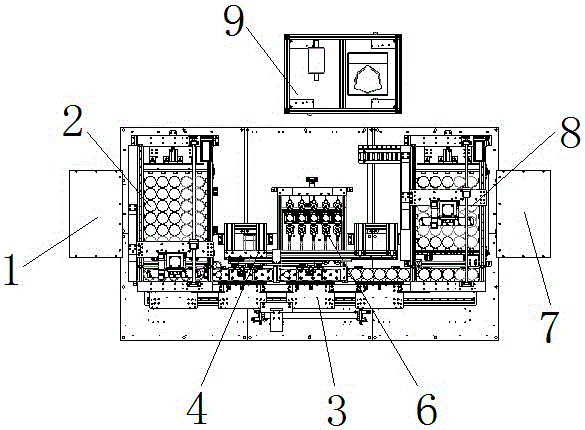

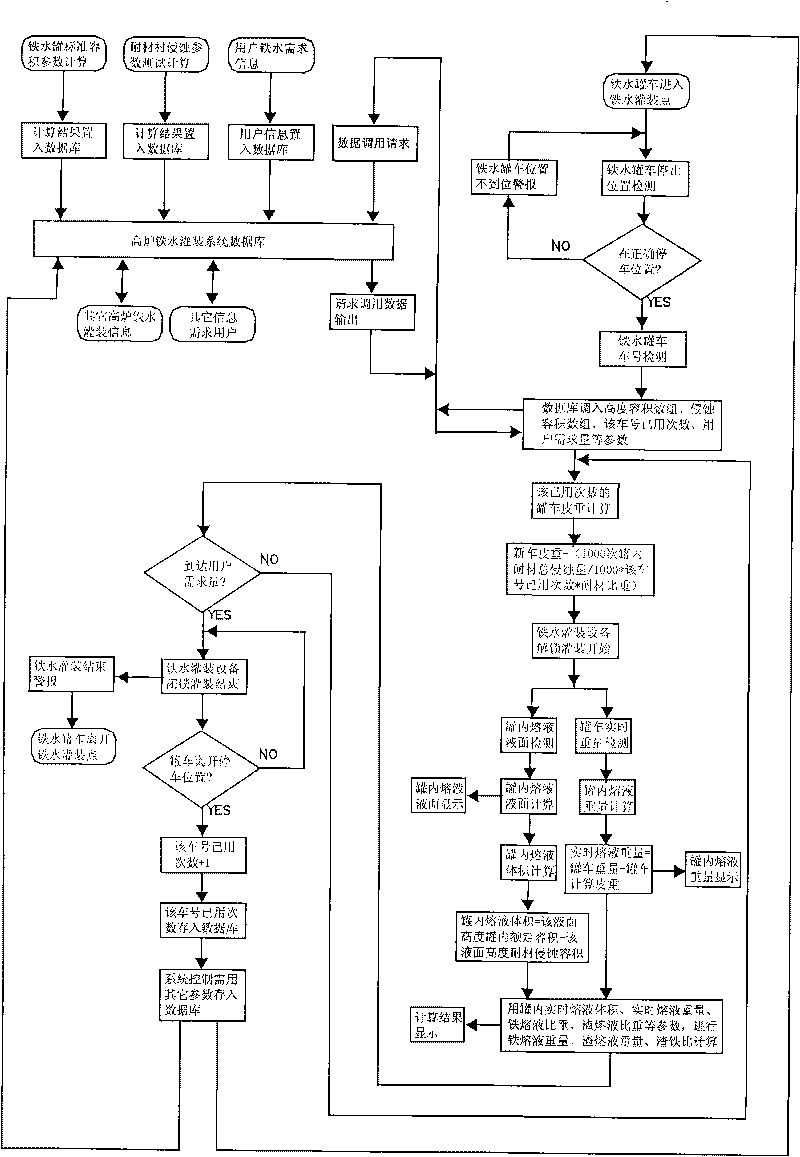

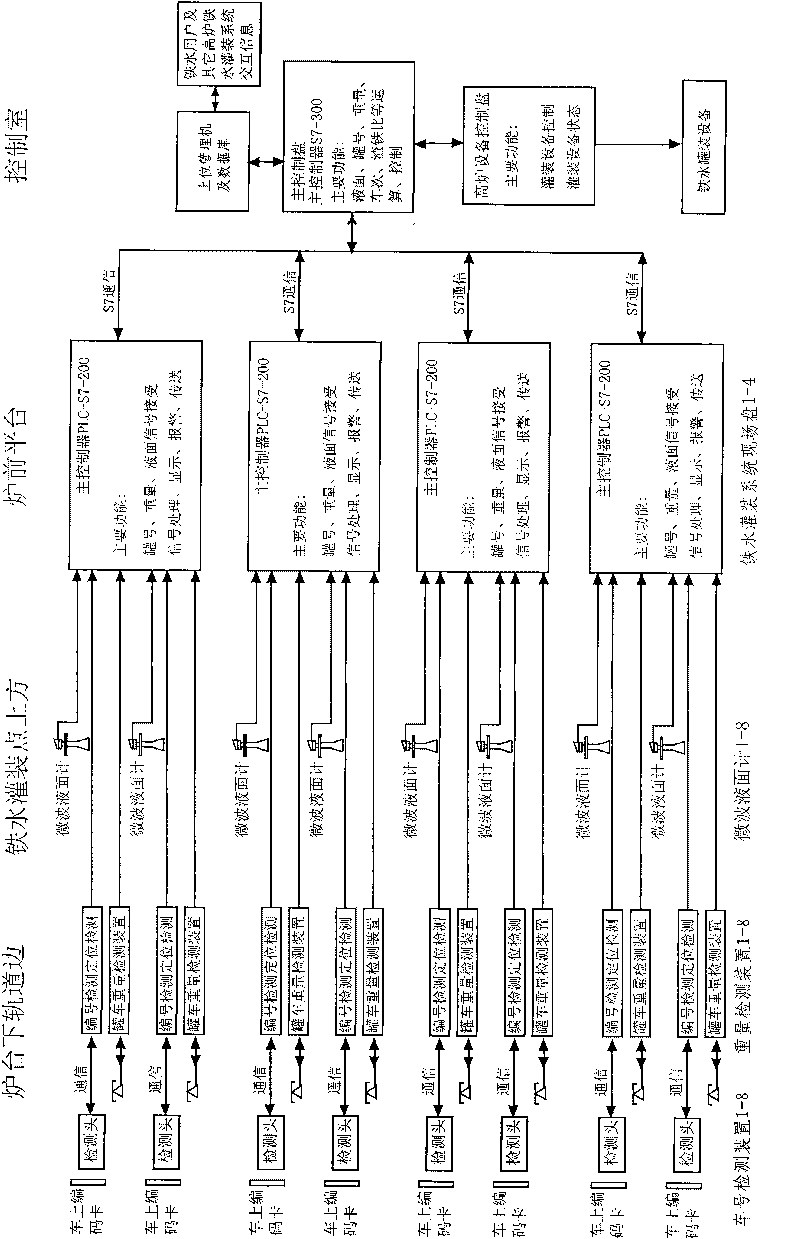

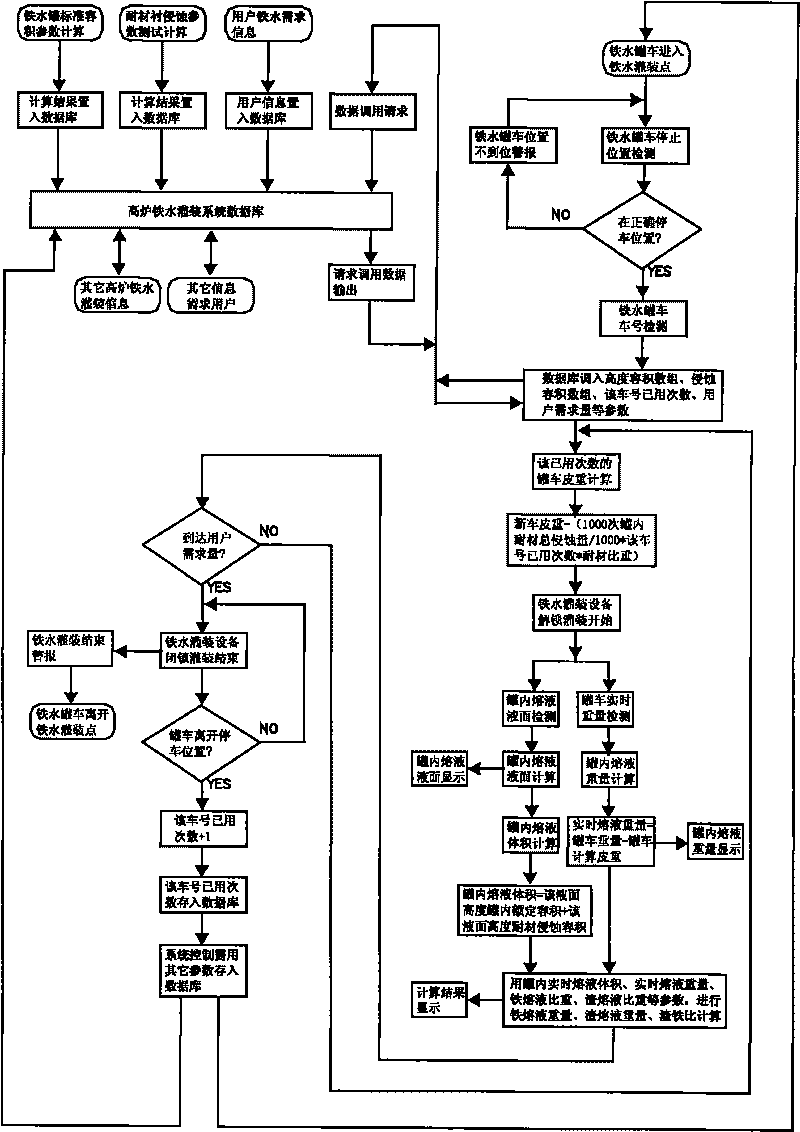

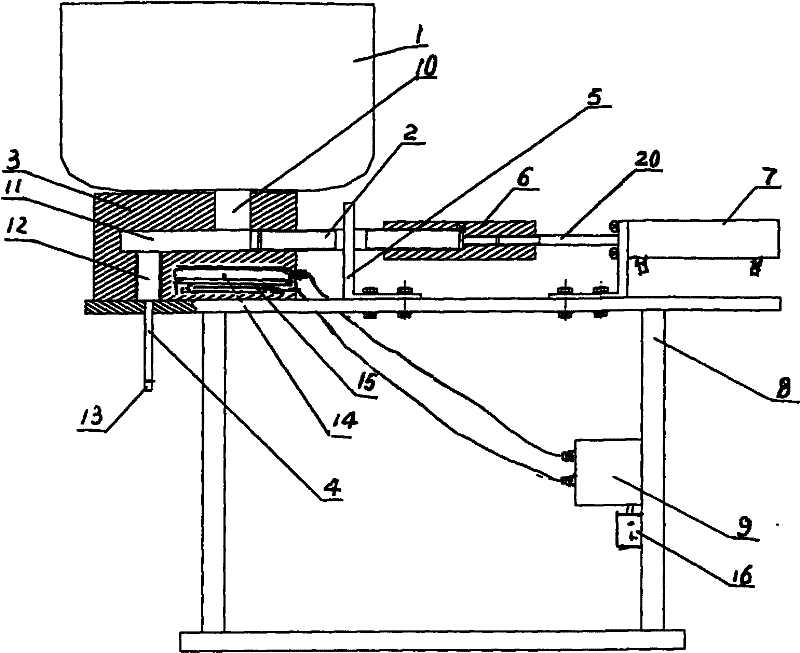

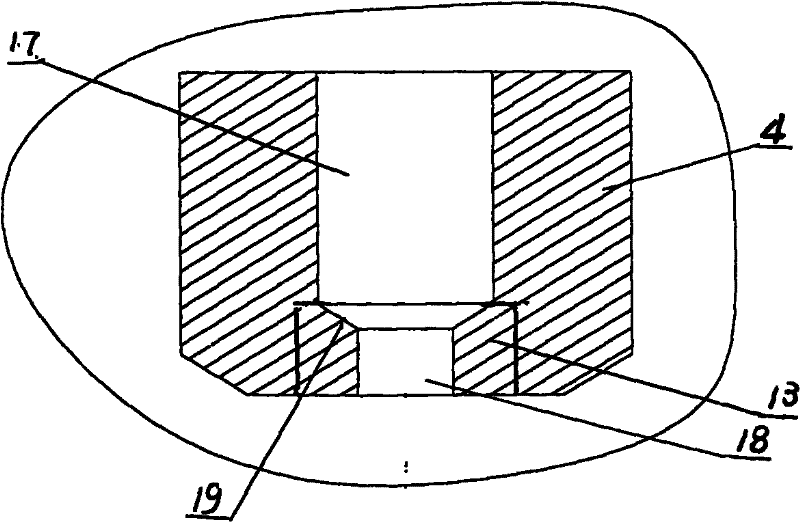

Method for controlling filling quantity of slag-iron mixed molten liquid in ladle of ladle car

InactiveCN101727109AControl filling volumeThe calculation result is accurateMelt-holding vesselsLevel controlSlagFerric

The invention relates to a method for controlling the filling quantity of slag-iron mixed molten liquid in a ladle when molten iron is filled into a ladle car from a metallurgical blast furnace tap hole. The control method comprises the following steps of: obtaining the gross weight of the ladle car through a weighing type weight detecting device, and then obtaining the real-time weight of the slag-iron mixed molten liquid in the ladle through a series of computations; obtaining the liquid level of the slag-iron mixed molten liquid in the ladle through the detection of a molten iron liquid level detecting device, and further computing the real-time volume of the slag-iron mixed molten liquid in the ladle; and then further computing the slag-iron proportion and the slag-iron weight of the slag-iron mixed molten liquid in the ladle by utilizing the real-time weight and volume of the slag-iron mixed molten liquid in the ladle so as to control the filling quantity of the slag-iron mixed molten liquid in the ladle. The automatic detection count for the used times of the ladle of the ladle car is introduced into computation, and a ladle volume increment parameter and a ladle car tare parameter under the specific used times of the ladle are obtained to participate in the computation, so that a computed result is more accurate. The invention enables the filling quantity of the ladle to be more accurate.

Owner:BAOSHAN IRON & STEEL CO LTD

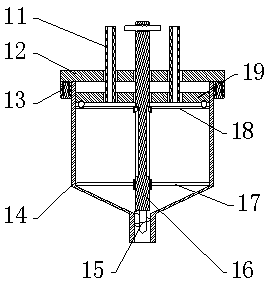

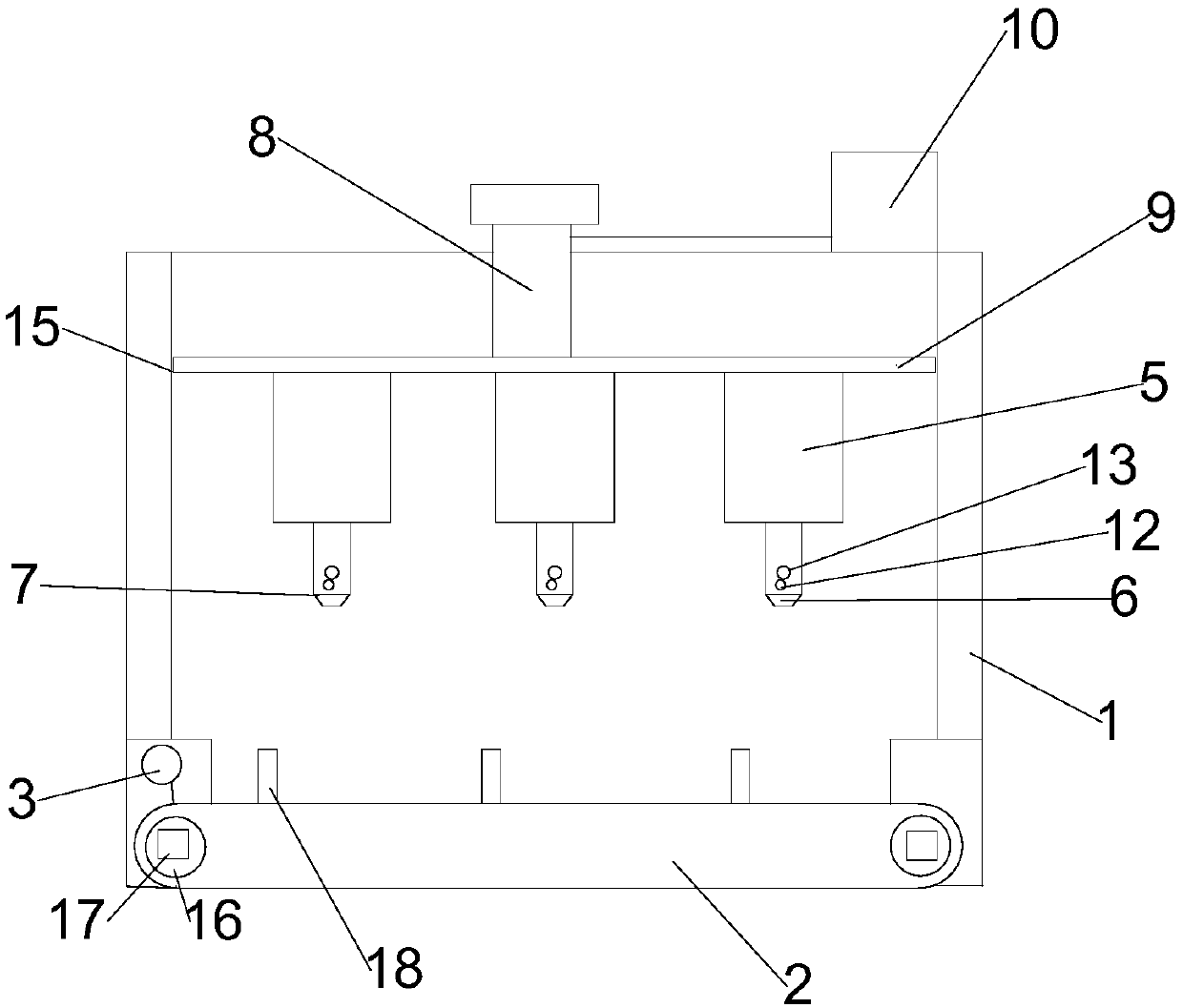

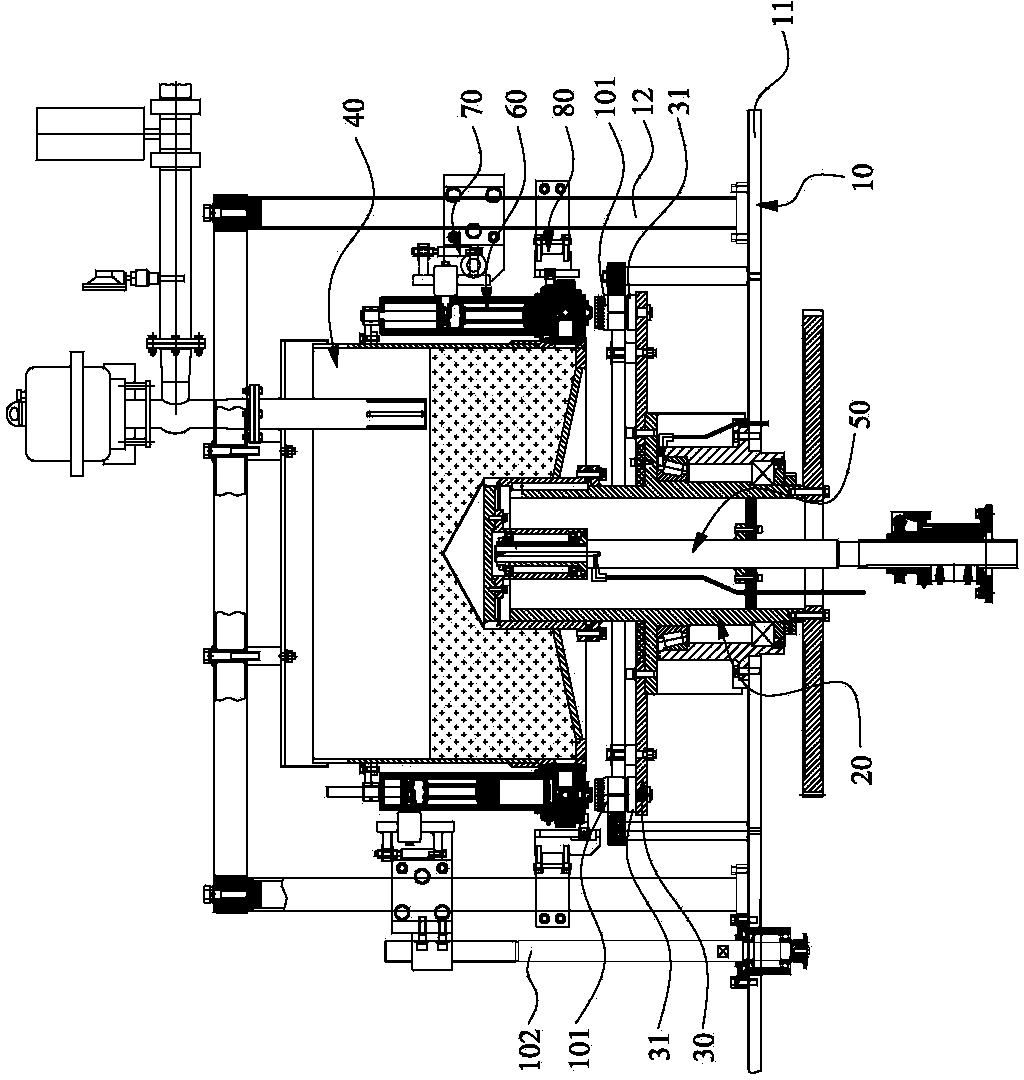

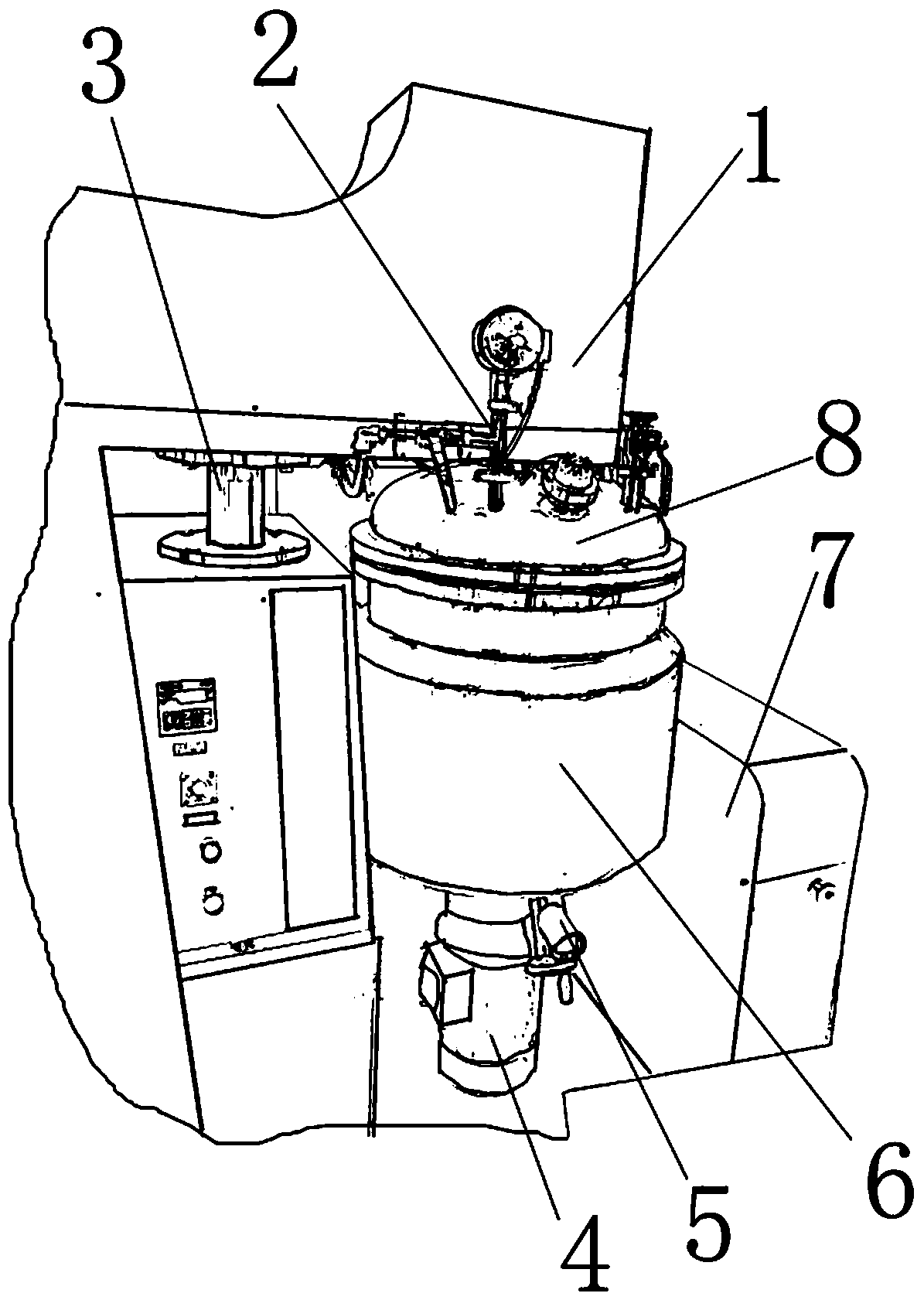

Blood separating gel filling machine

InactiveCN101780937BReasonable designCompact structureLiquid bottlingBiochemical engineeringBlood tube

The invention relates to a blood separating gel filling machine used for equipment for filling the blood separating gel in the process of producing disposable vacuum blood tubes. The blood separating gel filling machine comprises a rack, a thermostatic heater and a quantitative filler, wherein the quantitative filler comprises a body, a filling head, a push rod, an adjusting plate, a connector, acylinder and a glue barrel; the body is arranged above the rack and is provided with a quantitative cavity; a glue inlet is arranged on the upper part of the quantitative cavity and a glue outlet is arranged on the lower part of the quantitative cavity; the glue barrel is arranged above the body; the glue outlet of the glue barrel is connected with the glue inlet of the quantitative cavity; the filling head is arranged at the glue outlet on the lower part of the quantitative cavity and is provided with a glue filling hole; a spoiler is arranged at the lower end of the glue filling hole; the push rod is arranged in the quantitative cavity; the cylinder is arranged above the rack and is provided with a piston and a piston rod which is connected with the push rod by the connector; and the thermostatic heater comprises a temperature controller, an electric heating tube, a solid-state relay and a temperature sensor.

Owner:张晨东

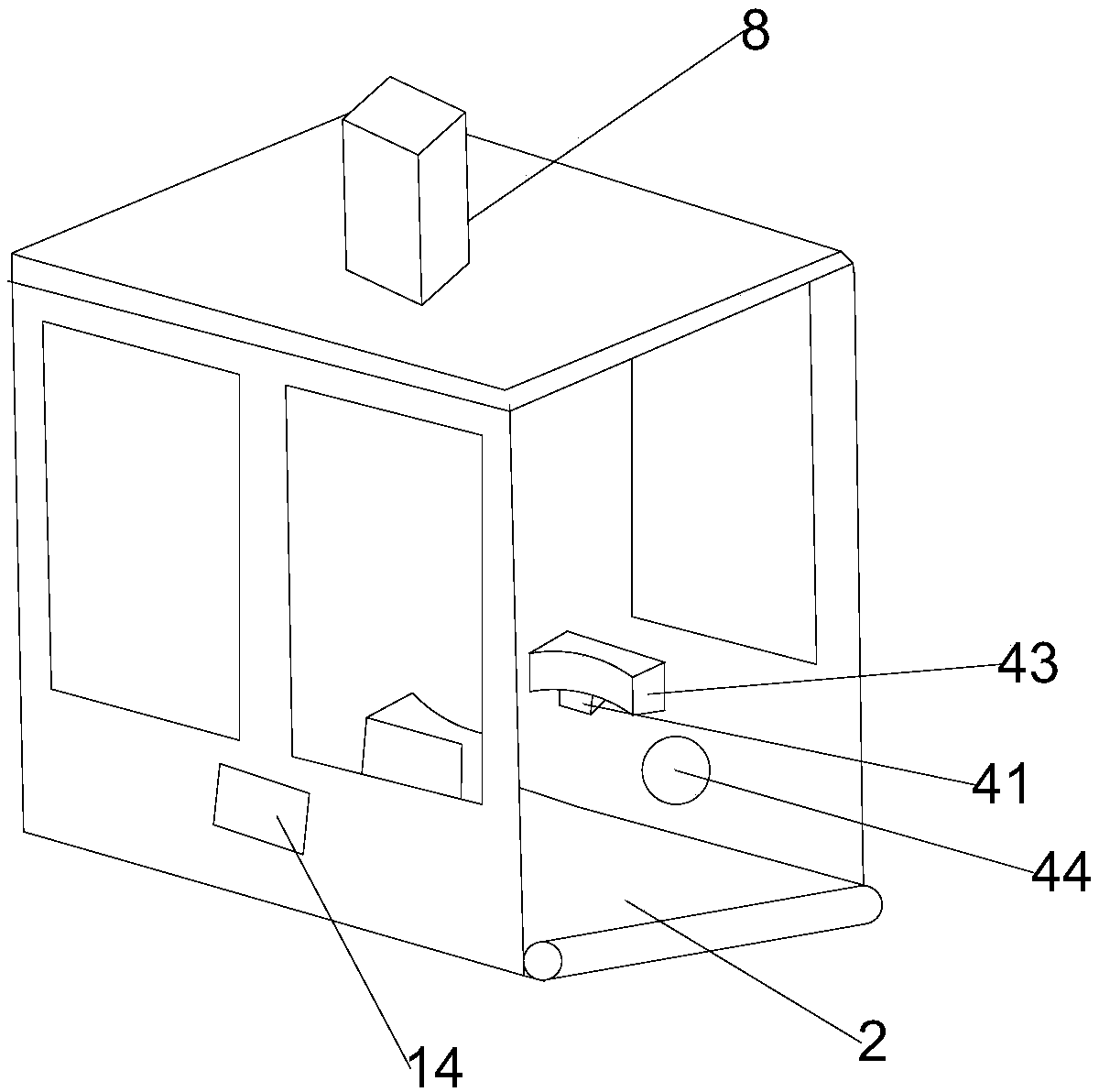

Dialysate filling machine

PendingCN109607460AEasy to controlControl filling volumeBarrels/casks fillingControl systemFast filling

The invention provides a dialysate filling machine for filling a dialysate into a dialysate bucket. The dialysate filling machine comprises a machine frame, the machine frame is provided with a conveying mechanism, a positioning mechanism, a filling mechanism and a control system for controlling operating of the conveying mechanism, the positioning mechanism and the filling mechanism; and the conveying mechanism is configured to convey the dialysate bucket to a filling position, the positioning mechanism comprises a clamping device and is used for positioning the dialysate bucket, so that thefilling is enabled to be more precise, and liquid leakage is prevented. The control system comprises a microprocessor, a predetermined number of position sensors and a predetermined number of flow sensors, is used for sensing the position of the dialysate bucket and controlling positioning of the clamping device and is used for accepting flow information to control the start or stop of filling. The dialysate filling machine achieves quantitative control, real-time monitoring and precise and fast filling processes, increasing production efficiency.

Owner:GUANGZHOU QIJI BIOTECH CO LTD

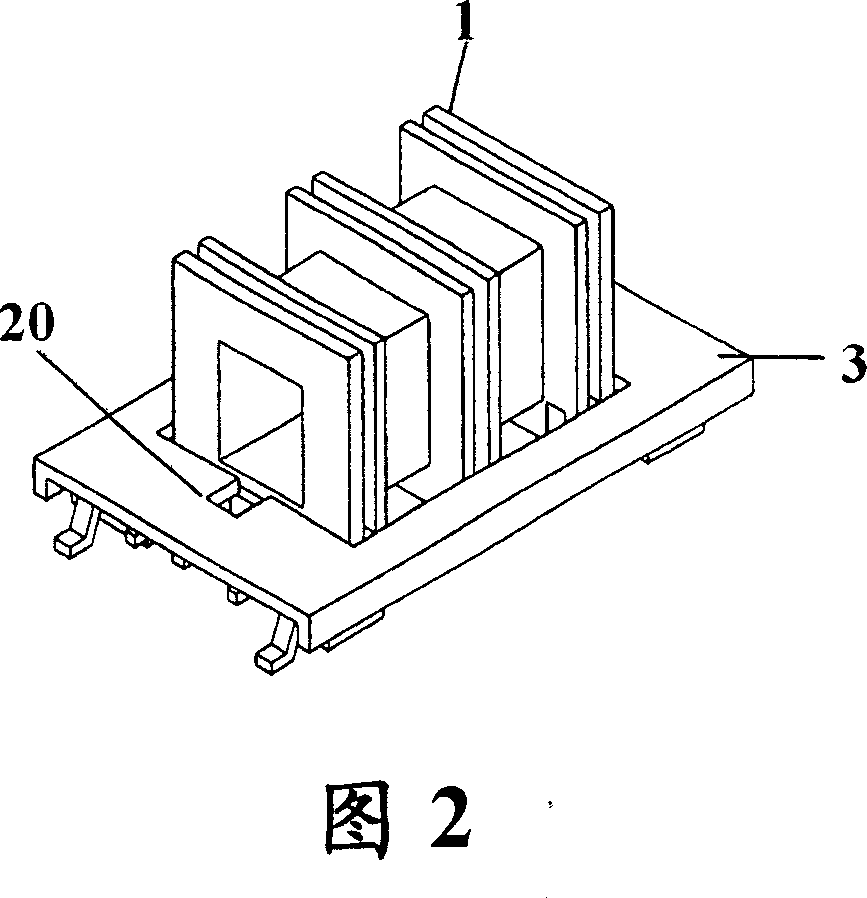

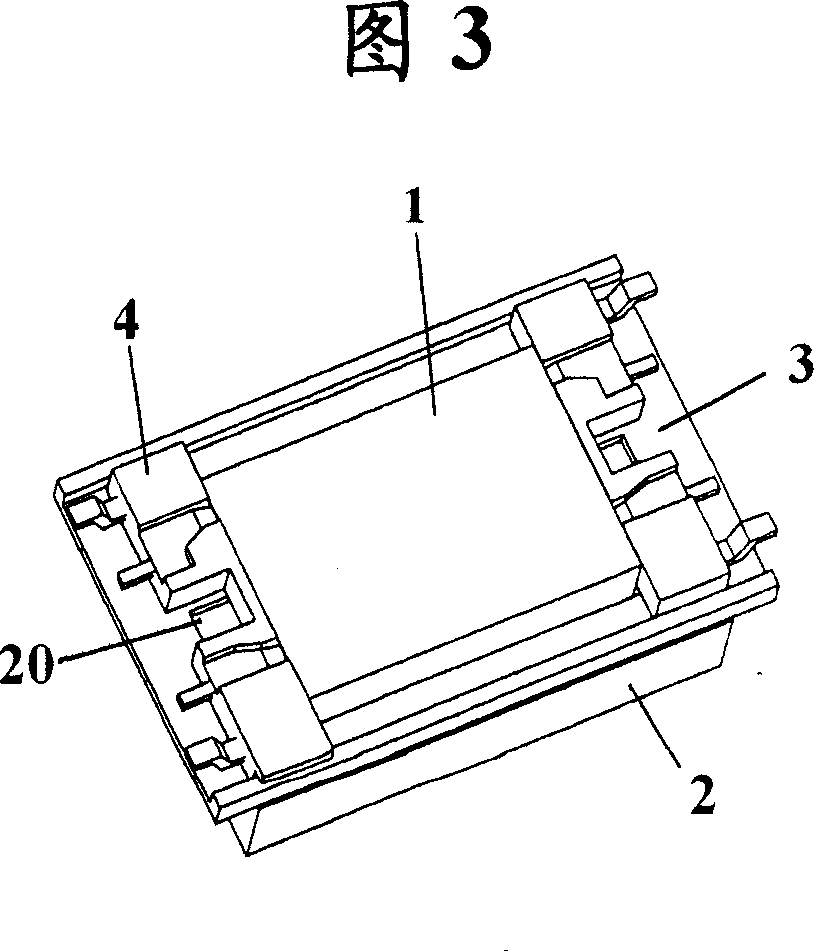

Magnetic element

InactiveCN1967746AIncrease insulation distanceGuaranteed miniaturizationTransformers/inductances coils/windings/connectionsFixed transformersEngineeringConductor Coil

The invention relates to a magnetic element, which comprises winding support with terminal base; winding coiled on the winding support; insulated baffle plate with hollow open to cover the base via the winding support; and the magnetic corn inserted into the winding support, wherein said base has the first positioning part; the baffle plate has second positioning part; the first and second positioning part can form adhesive stuff part through to the magnetic corn via mounting winding support, magnetic corn and insulated baffle plate together; therefore, it only needs to fill stuff into stuff part, to fix winding support, magnetic corn and baffle plate together. The invention can reduce cost and simplify process.

Owner:SUMIDA ELECTRIC H K COMPANY

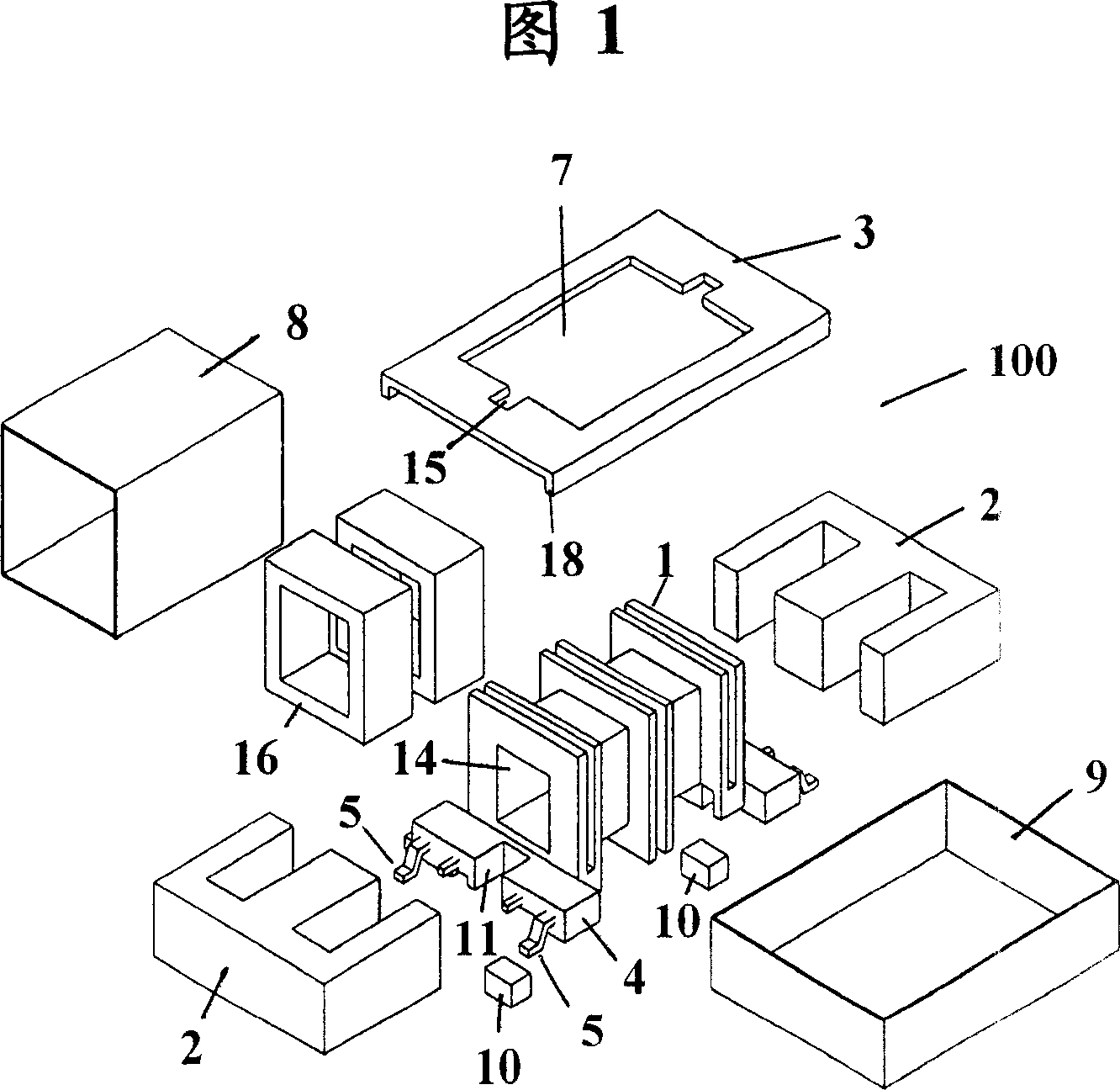

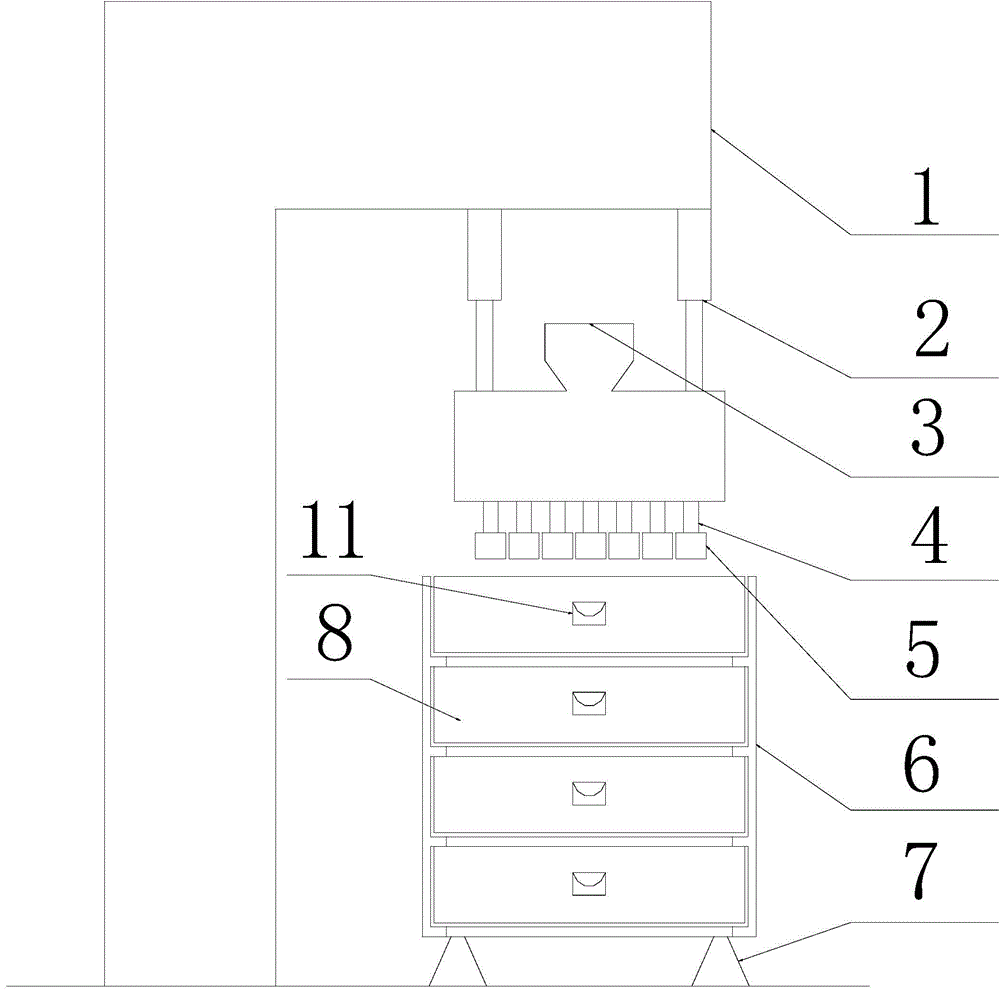

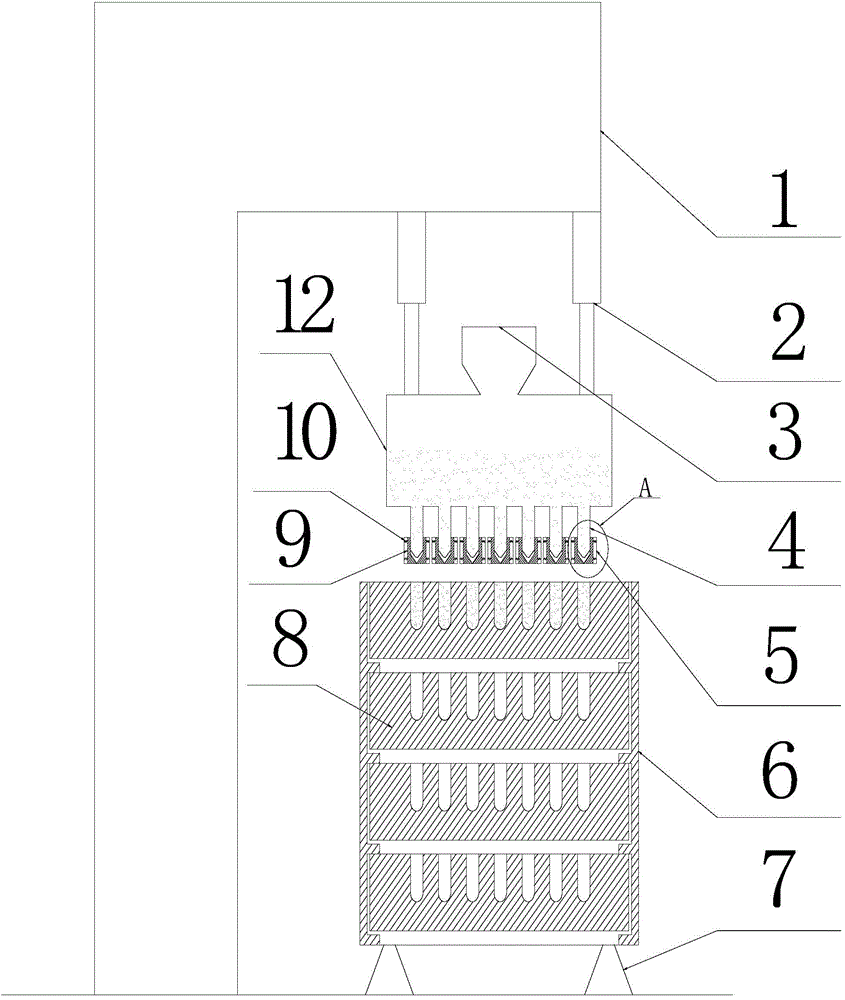

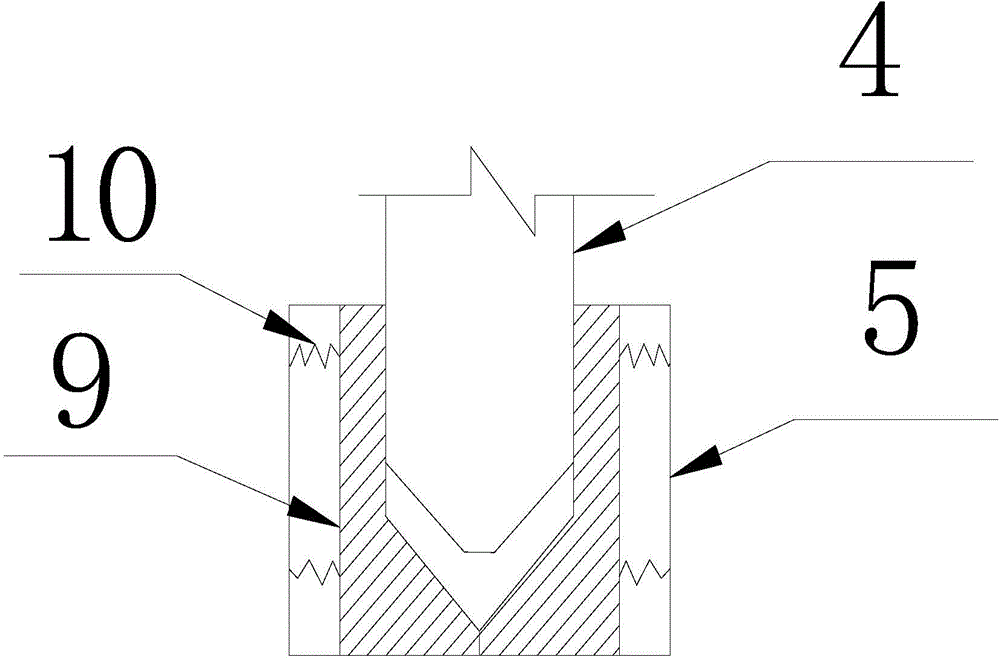

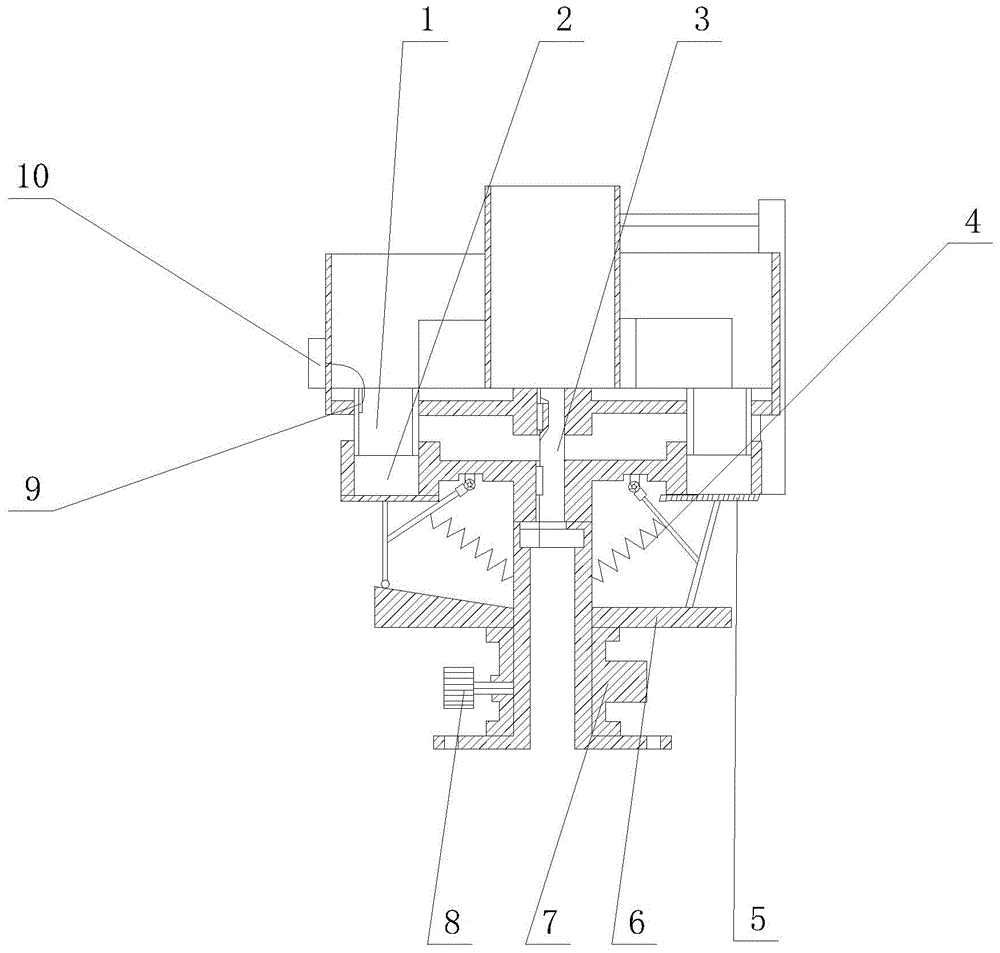

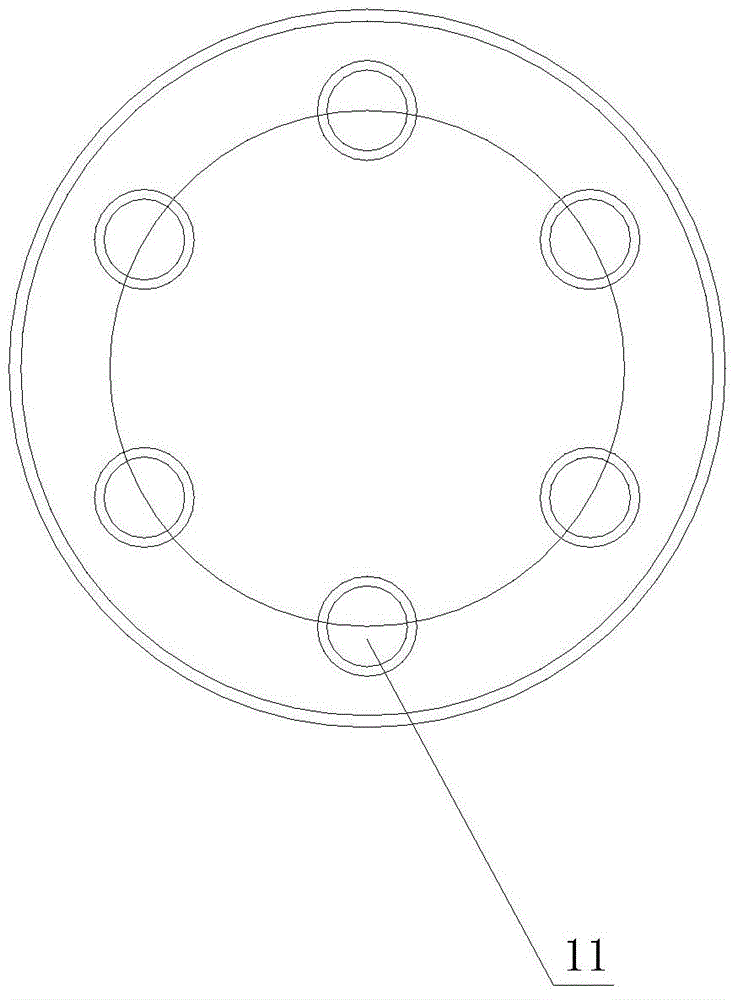

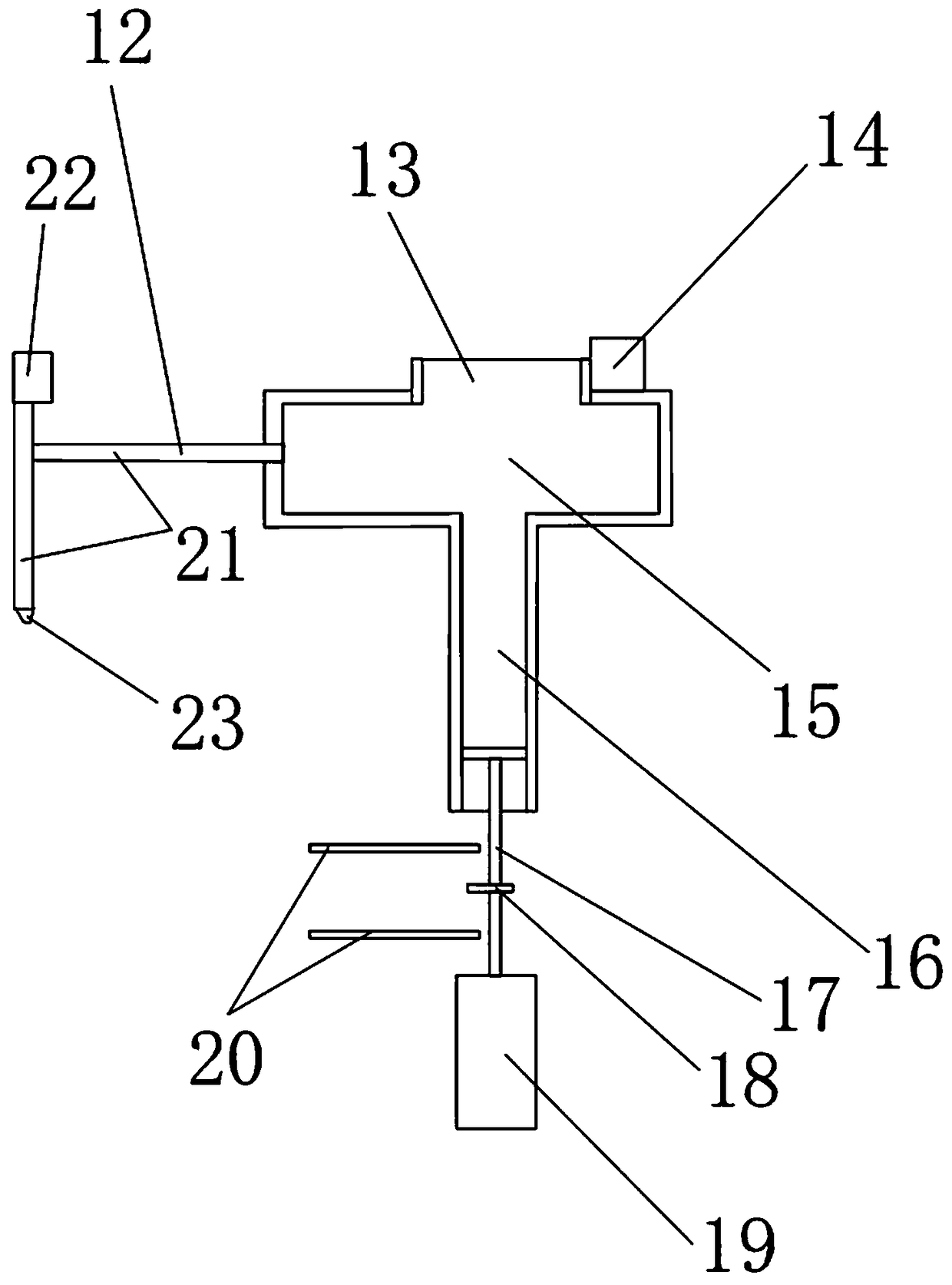

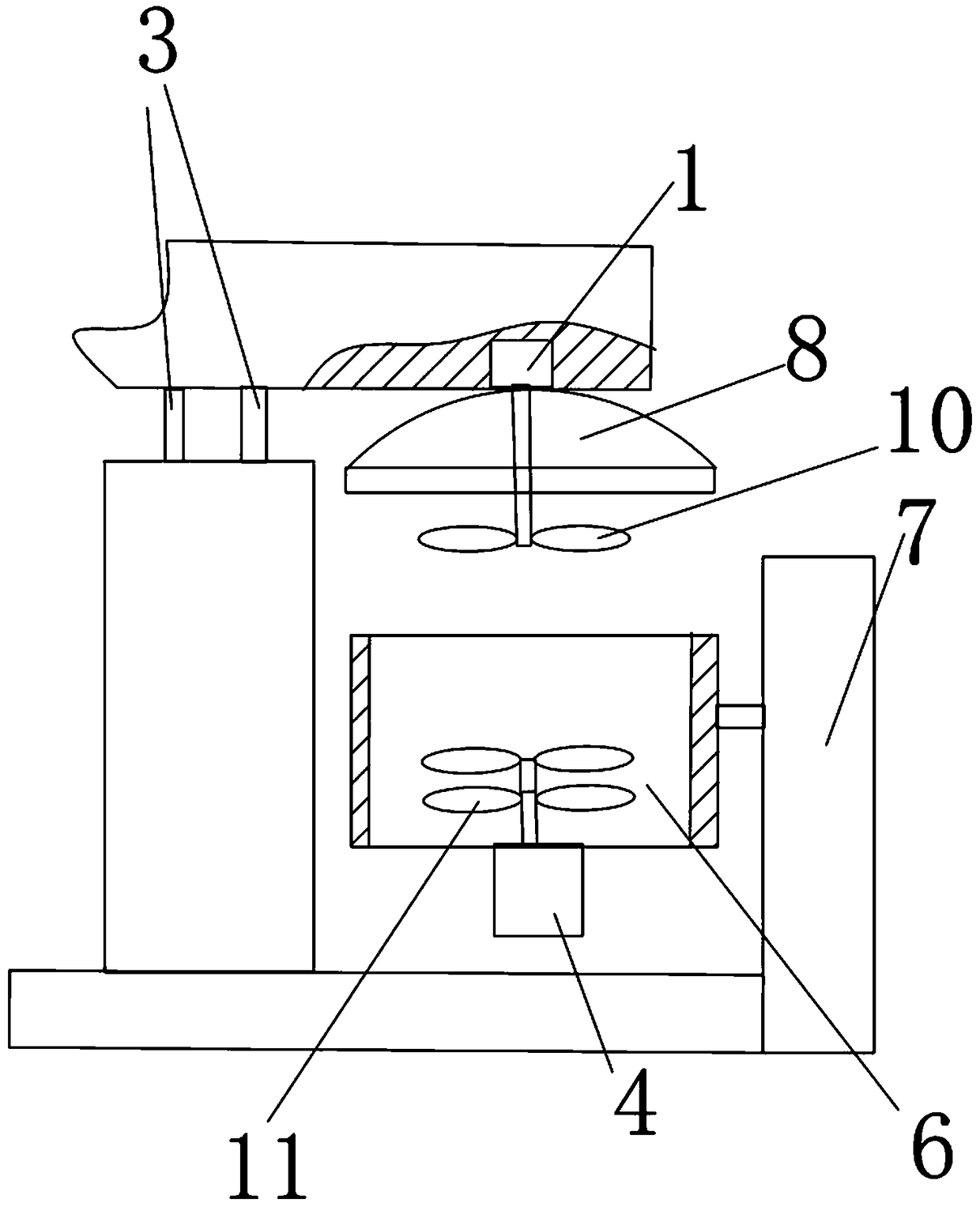

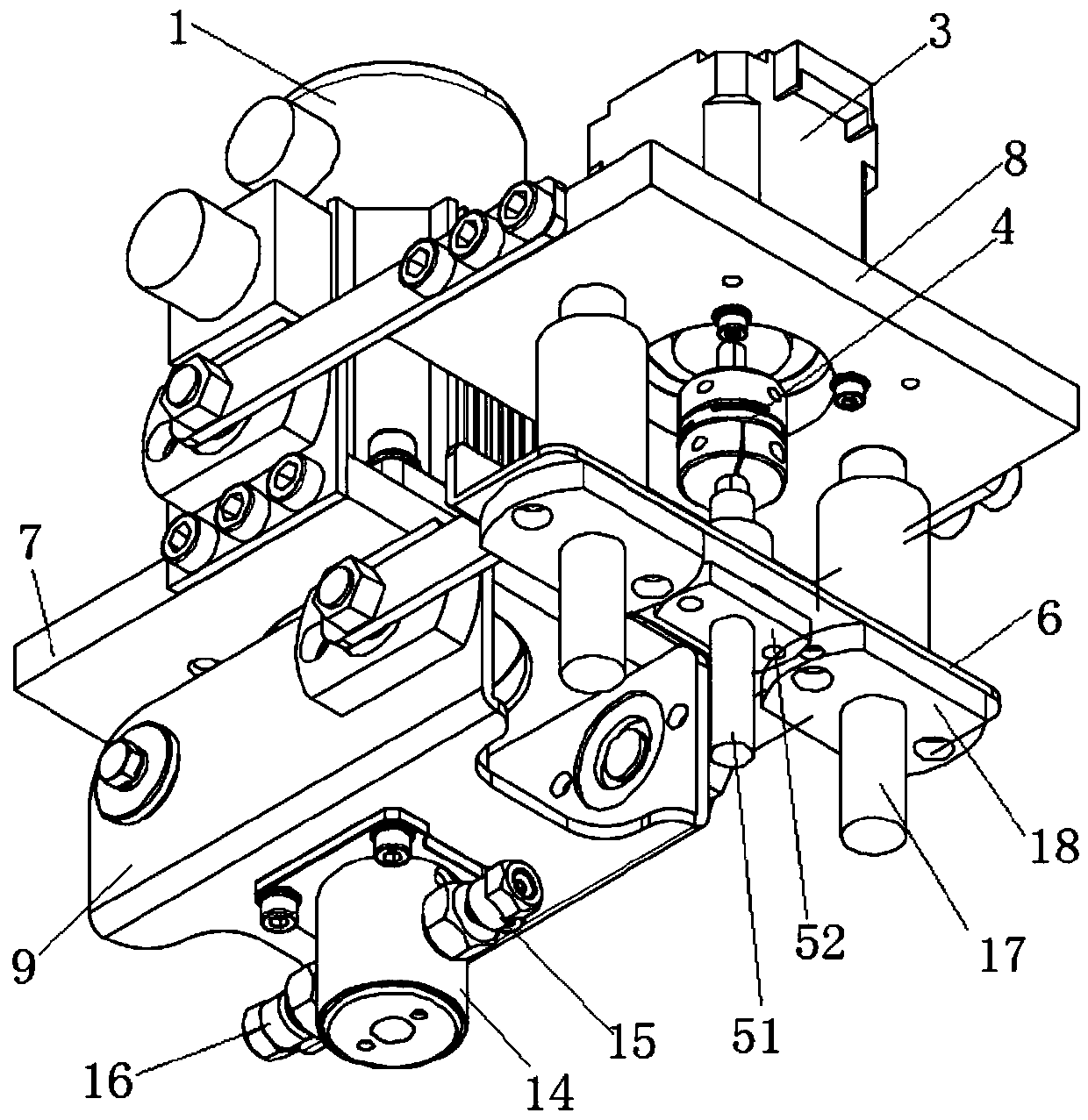

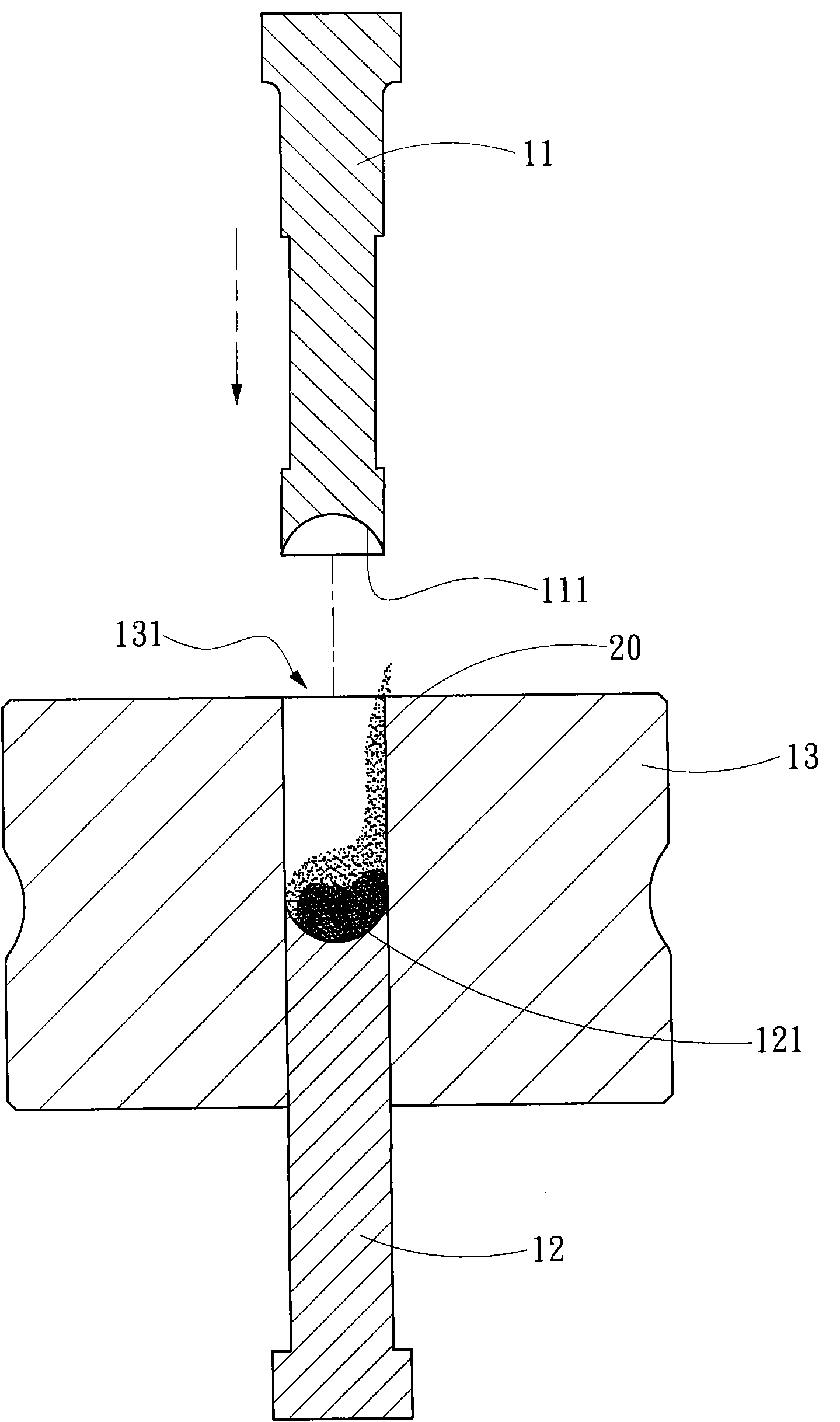

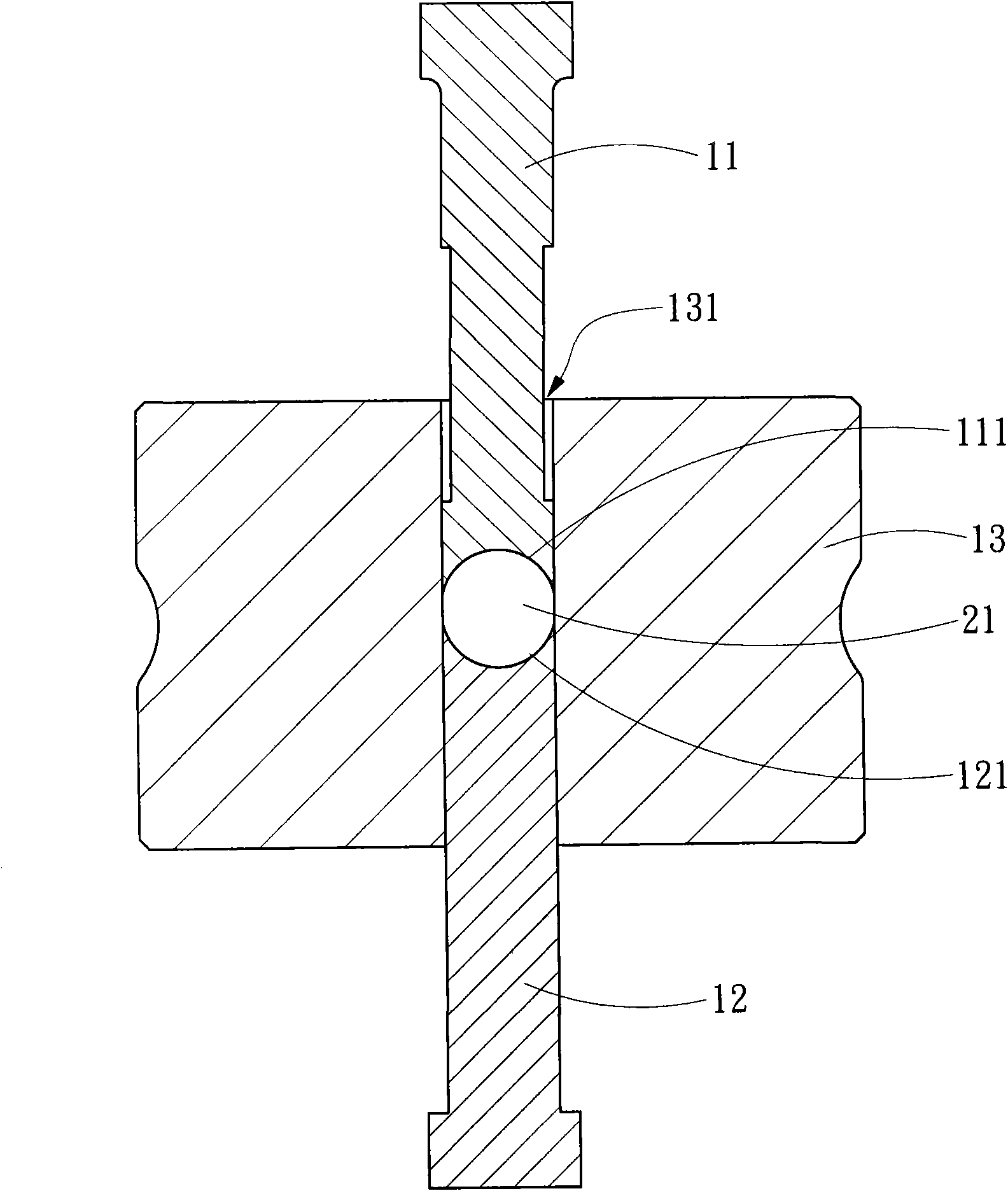

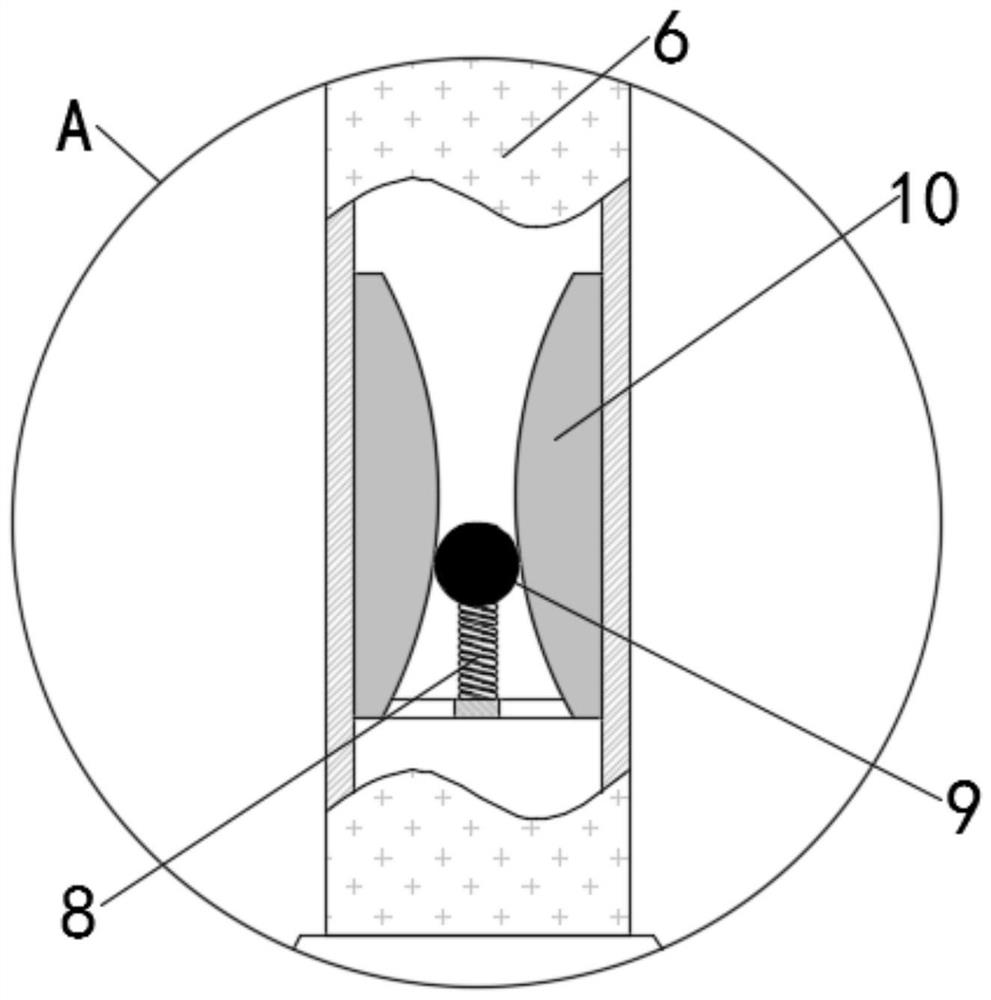

Viscous material quantitative filling machine

ActiveCN102838069BImprove filling efficiencyEasy to installFilling using counterpressureEngineeringBottle

The invention discloses a viscous material quantitative filling machine, which includes a frame, a rotary seat, a rotary platform and a material cylinder; The set track is used to control the piston to alternately draw the material in the material cylinder into the material cavity or press the material in the material cavity to pour into the bottle, and at the same time cooperate with the sensor to control the driving mechanism to make the swing rod open or close and rise channel, so that the feeding channel is connected between the feeding port and the material cavity or the filling channel is connected between the filling port and the material cavity, so as to effectively control the output of the material and prevent the occurrence of incorrect filling. In this way, the present invention adopts The piston control device and the switching control device can effectively control the material in and out of all filling valves at the same time. filling efficiency.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

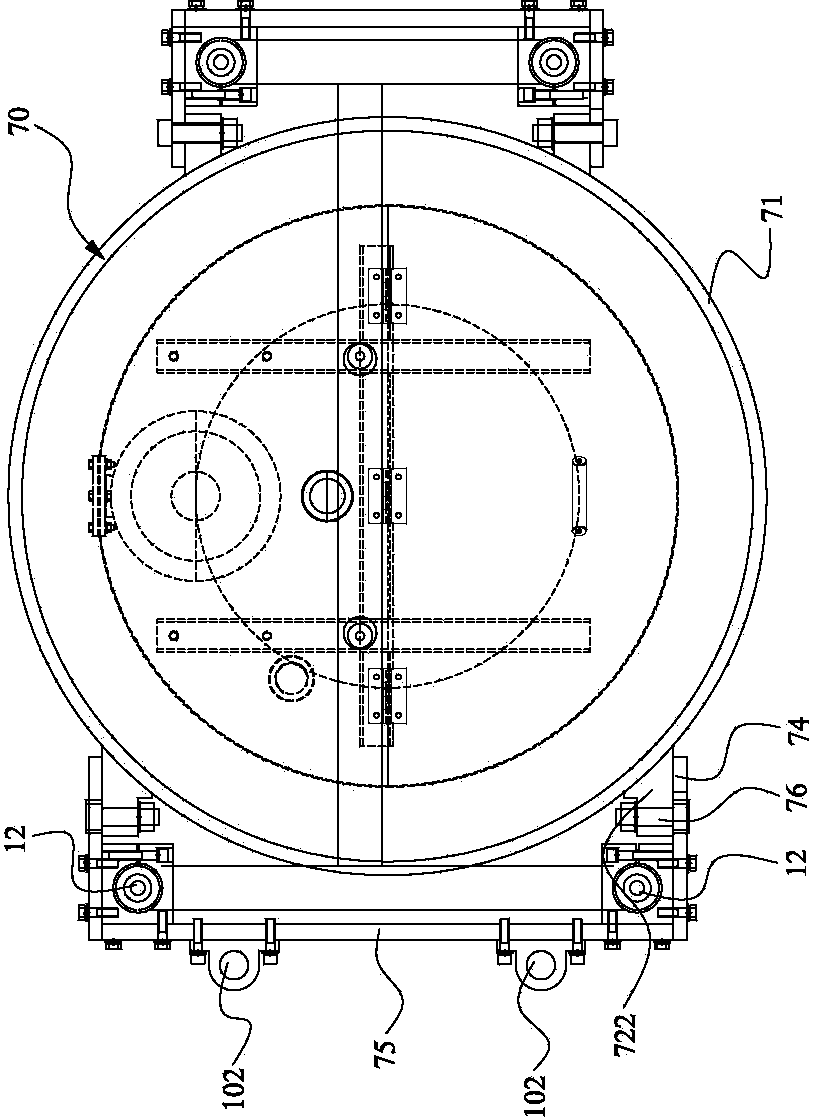

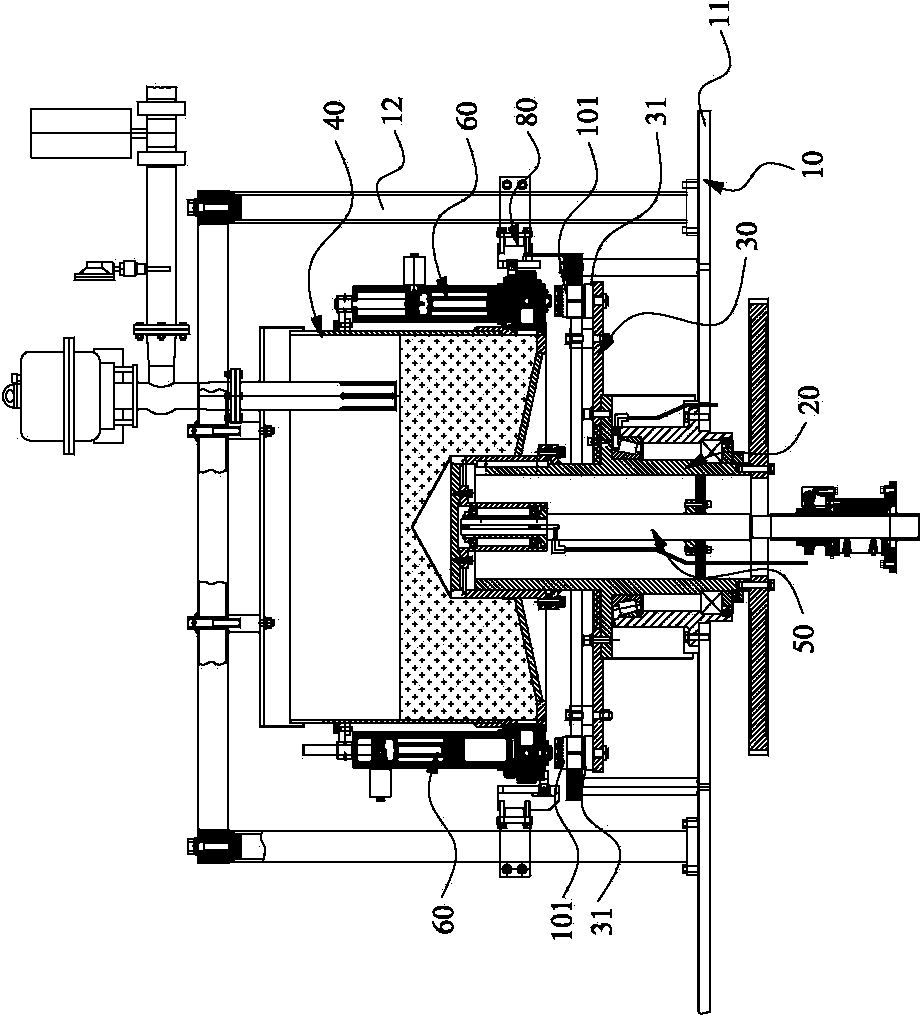

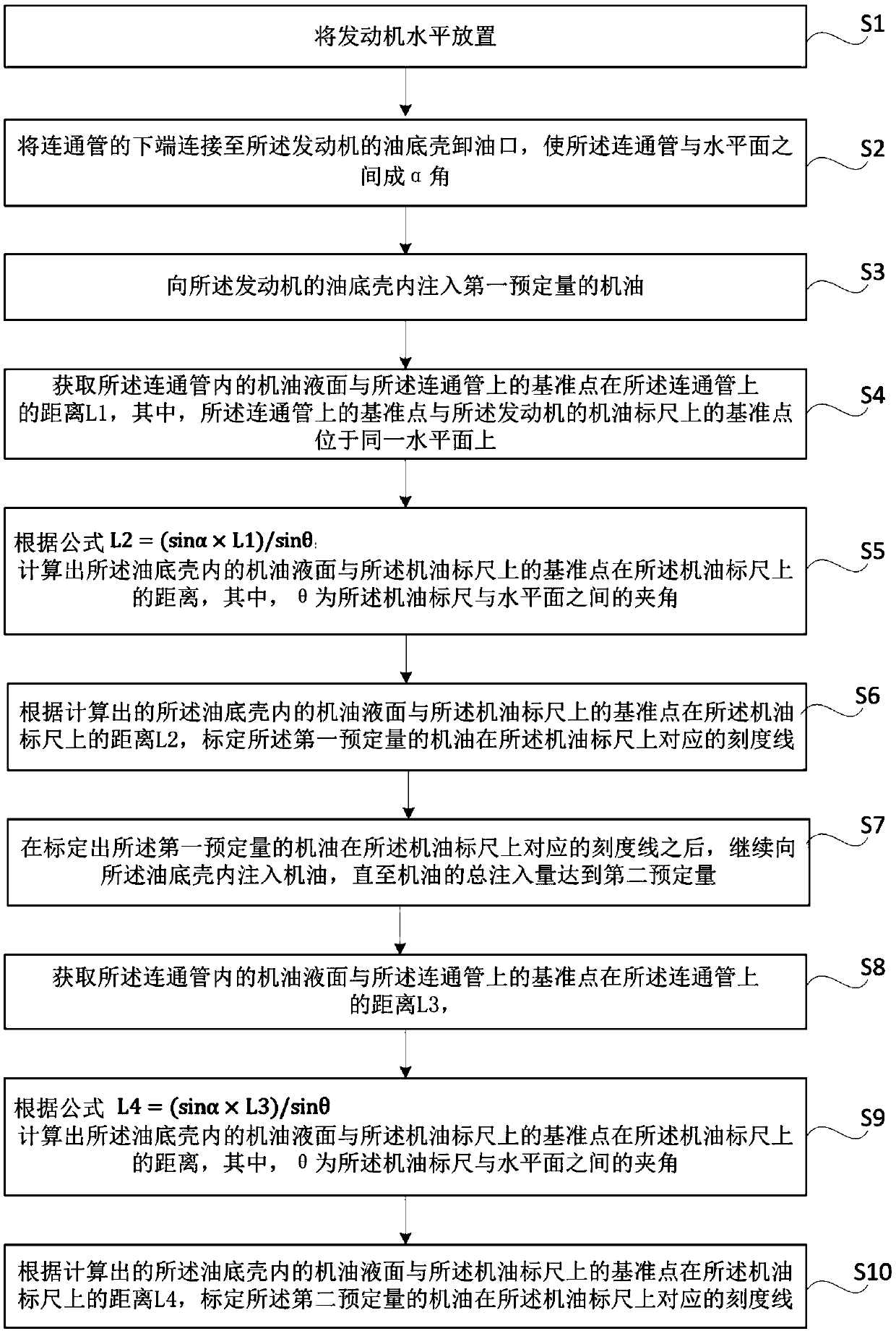

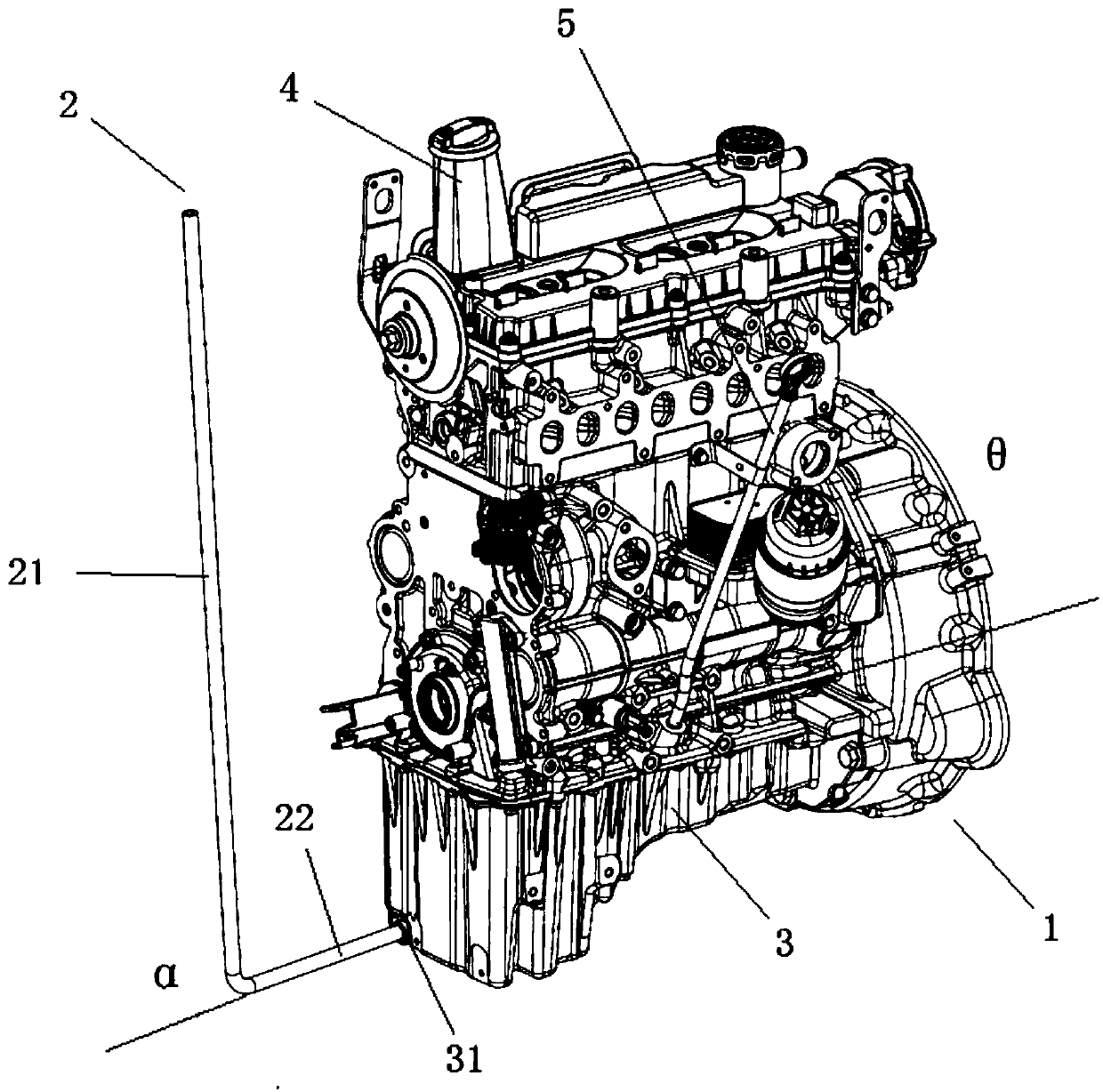

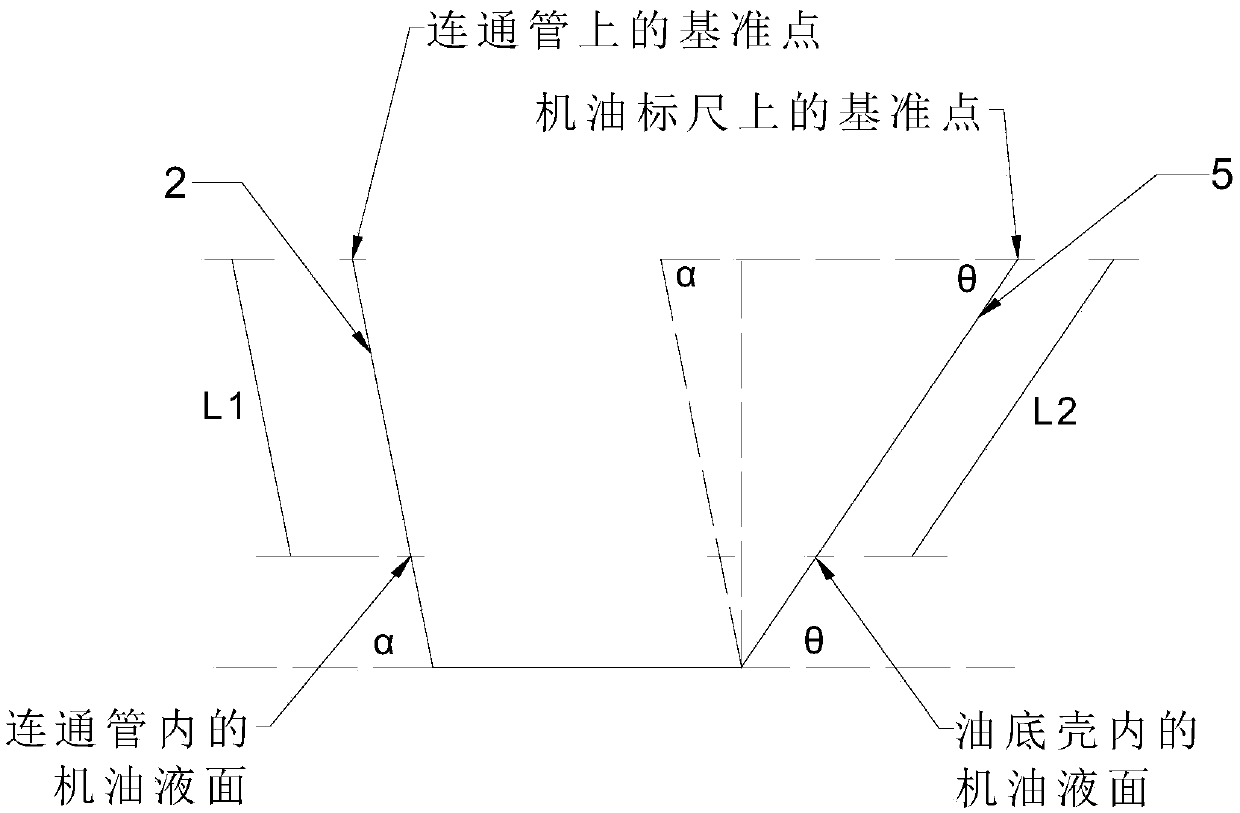

Calibration method of engine oil dipstick

InactiveCN110579263AControl filling volumeImprove accuracyTesting/calibration apparatusAngle alphaDipstick

The invention relates to a calibration method of an engine oil dipstick. The calibration method comprises the steps of: horizontally placing an engine; connecting the lower end of a communicating pipeto an oil pan oil discharging opening of an engine, so that an angle alpha is formed between the communicating pipe and the horizontal plane; injecting a first predetermined amount of engine oil intoan oil pan of the engine; acquiring a distance L1 between an engine oil liquid level in the communicating pipe and a datum point of the communicating pipe on the communicating pipe, wherein the datumpoint on the communicating pipe and a datum point on the engine oil dipstick are positioned on the same horizontal plane; calculating a distance between the engine oil liquid level in the oil pan andthe datum point of the engine oil dipstick on the engine oil dipstick according to a formula L2=(sin alpha*L1) / sin theta, wherein theta is an included angle between the engine oil dipstick and the horizontal plane; and calibrating a corresponding scale line of the first predetermined amount of engine oil on the engine oil dipstick according to the calculated distance L2 between the engine oil liquid level in the oil pan and the datum point of the engine oil dipstick on the engine oil dipstick.

Owner:BEIQI FOTON MOTOR CO LTD

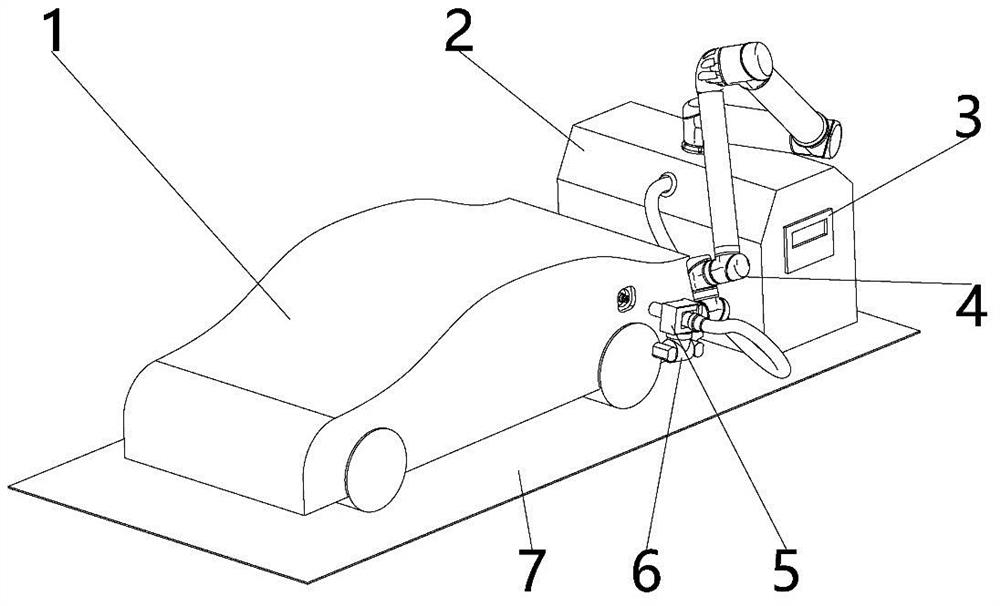

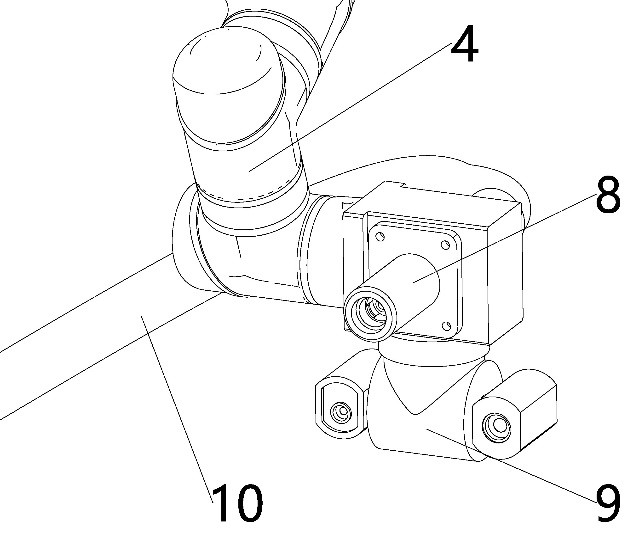

Automatic identification hydrogenation system and hydrogenation method

PendingCN113983347AMeet the needs of hydrogenationControl filling volumeLiquid transferring devicesRoad vehiclesInformation processingEngineering

The invention belongs to the technical field of hydrogen filling, and particularly relates to an automatic identification hydrogenation system and hydrogenation method. The system comprises a ground positioning module, a hydrogen storage module, a mechanical arm, a filling module, an automatic identification module and an information processing module; the ground positioning module is provided with a sensor; a hydrogen conveying pipeline is connected with the filling module; the hydrogen storage module is arranged at the tail end of the ground positioning module, the mechanical arm, the information processing module and the hydrogen conveying pipeline are connected to the hydrogen storage module, the information processing module controls the mechanical arm to drive the filling module to preliminarily find the position of a filling connector on the fuel automobile after receiving the signal of the sensor, and the automatic identification module identifies the accurate position of the filling connector; the information processing module drives the mechanical arm to move until the hydrogenation gun head is in butt joint with the filling connector, and the information processing module monitors and controls the filling amount and pressure of the filling module. The use of manpower in the filling process is reduced, and the filling efficiency is improved; the safety coefficient is increased; and the service life of the filling system is prolonged.

Owner:ZHONGBEI UNIV

Filling device special for injectable suspension

ActiveCN107539507AGuaranteed circulating flowAvoid concentration changesLiquid materialMedicineInjectable Suspension

The invention discloses a filling device special for an injectable suspension. The filling device comprises a dosing device, a dosing control valve and a filling head. The dosing device comprises a piston booster device and a dosing cavity. A dosing cavity inlet and a dosing cavity outlet are formed in the lower part of the dosing cavity. The dosing cavity is connected with the filling head. The dosing control valve is a three-way valve and comprises two inlets and a liquid outlet. One of the inlets is connected with the filling head. The other inlet is connected with the dosing cavity outlet.The filling head is internally provided with a control valve set. A liquid inlet, a dosing cavity connecting opening, a dosing control valve connecting opening, a filling opening and a liquid discharging opening are formed in the filling head. The dosing cavity connecting opening in the filling head is connected with the dosing cavity inlet. The dosing control valve connecting opening is connected with one inlet of the dosing control valve. The liquid discharging opening is controlled to communicate with the filling opening through a piston. A filling container is arranged at the lower part of the filling opening. Liquid can be made to be always at a circulation state in the filling process, the consistency of concentration of the injectable suspension is ensured, the filling quality is ensured, and a non-mixed suspension liquid can be filled.

Owner:苏州康乐辉医药科技有限公司

Production process of paraffin-based self-lubricating bearing

InactiveCN108916630ATake advantage ofAccurately control fill firmnessAdditivesEngine lubricationParaffin waxEngineering

The invention discloses a production process of a paraffin-based self-lubricating bearing. The production process comprises the following steps: S1, processing a plurality of lubricant holes along theradial direction of the self-lubricating bearing, wherein the ends, facing the axis of the self-lubricating bearing, of the lubricant holes are opened and the ends, opposite to the axis of the self-lubricating bearing, of the lubricant holes are closed; S2, preparing a paraffin solid lubricant and heating the paraffin solid lubricant till the paraffin solid lubricant is of flowability; S3, heating the self-lubricating bearing, and filling the lubricant holes with the paraffin solid lubricant with flowability from the lubricant holes to the end of the axis of the self-lubricating bearing through a pressure conveying pipeline; and S4, cooling the self-lubricating bearing and the paraffin solid lubricant, wherein the paraffin solid lubricant is solidified. According to the production process, the solid lubricant can fill the holes of the bearing through a mechanical operation, so that the production efficiency is high and the labor intensity is low. The degree of packing and the fillingamount of the solid lubricant in each hole can be controlled accurately.

Owner:芜湖龙兴合金股份有限公司

Oil tank liquid level control valve integrated with one-way valve

PendingCN109578642AGuaranteed reflowControl filling volumeOperating means/releasing devices for valvesCheck valvesFuel oilEngineering

An oil tank liquid level control valve integrated with a one-way valve comprises an upper valve body and a lower valve body. The upper valve body and the lower valve body are connected to limit a cavity. A first venting hole is formed in the top of the upper valve body, and a liquid level window is arranged on the side face of the upper valve body and communicates with an oil tank. A first floater, a second floater and a spring are arranged inside the cavity. A first valve plate is arranged on the first floater, and a second venting hole is formed in the first floater. The second floater is arranged at the bottom of the first floater and connected with the first floater. A second valve plate is arranged at the upper end of the second floater, the bottom of the second floater is connected with the upper end of the spring, and a spring base is arranged at the lower end of the spring. An oil return opening is formed in the bottom of the lower valve body, and an umbrella valve plate is arranged at the bottom of the lower valve body and comprises an umbrella rod and a circular valve plate. The upper end and the lower end of the umbrella rod are connected with the lower valve body and the circular valve plate correspondingly, and the circular valve plate is located at the lower end of the oil return opening. By the adoption of the oil tank liquid level control valve integrated with the one-way valve, the refueling amount of fuel oil is accurately controlled by the umbrella valve plate and the liquid level window, the umbrella valve plate can also guarantee one-way backflow of thefuel oil, and the phenomenon that due to leakage of the fuel oil, the danger exists is avoided. The structure is simple, and the production cost is low.

Owner:苏州振业楚硕科技有限公司

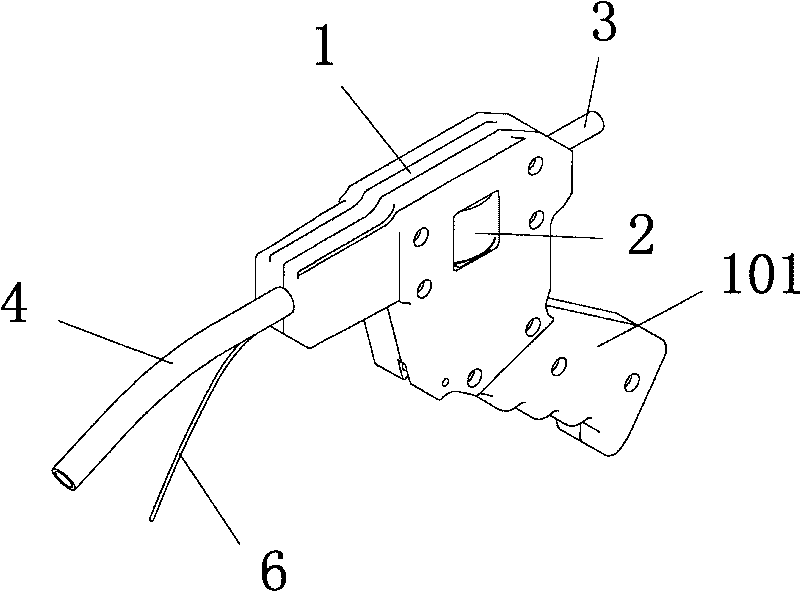

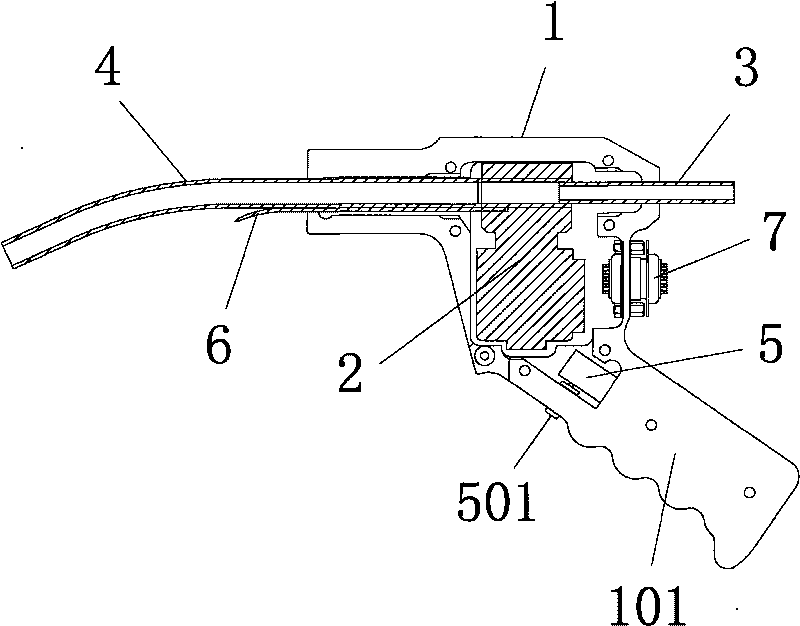

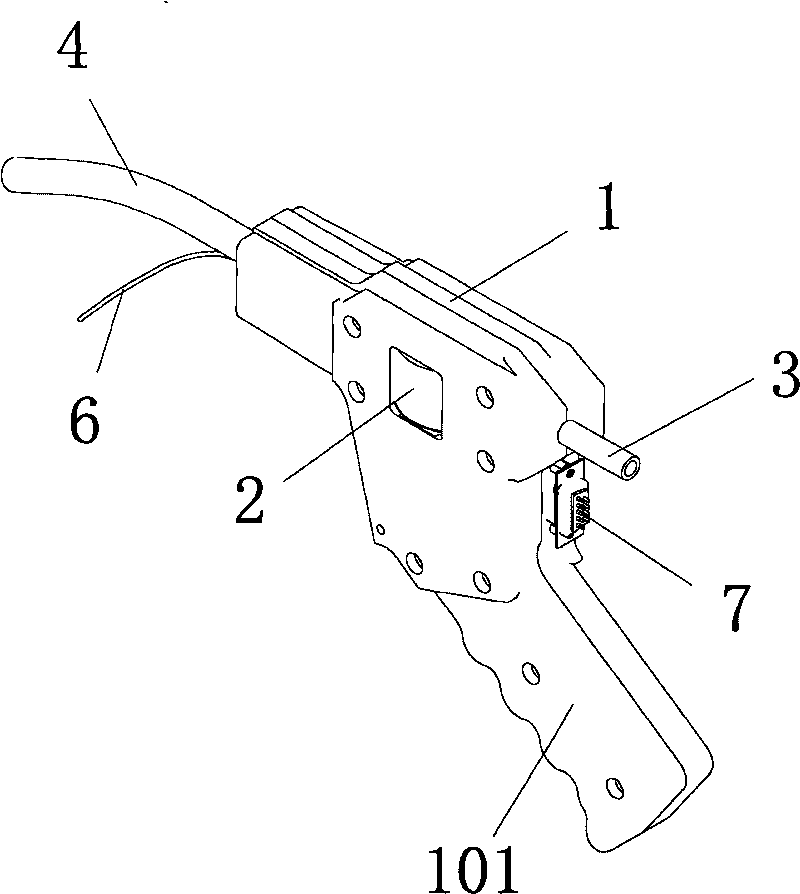

Novel secondary refrigerant liquid filling gun

InactiveCN101723302AEffective and accurate filling volumeAvoid polluting the production environmentLiquid transferring devicesEngineeringSolenoid valve

The invention discloses a novel secondary refrigerant liquid filling gun, which comprises a gun-shaped shell, and is characterized in that: the gun-shaped shell is provided with a solenoid valve inside; the inlet and outlet of a valve core of the solenoid valve are respectively connected with a liquid inlet pipe and a liquid outlet pipe; the liquid inlet pipe extends out of the back end of the gun-shaped shell, while the liquid outlet pipe extends out of the front end of the gun-shaped shell; a gun handle position of the gun-shaped shell is provided with a micro-switch which is electrically connected with the solenoid valve; and a button of the micro-switch protrudes out of the gun-shaped shell. The outflow of the secondary refrigerant liquid is stopped in time through the solenoid valve in the novel secondary refrigerant liquid filling gun, so that the novel secondary refrigerant liquid filling gun can effectively control the filling quantity and prevent environmental pollution caused by leakage of the secondary refrigerant liquid.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

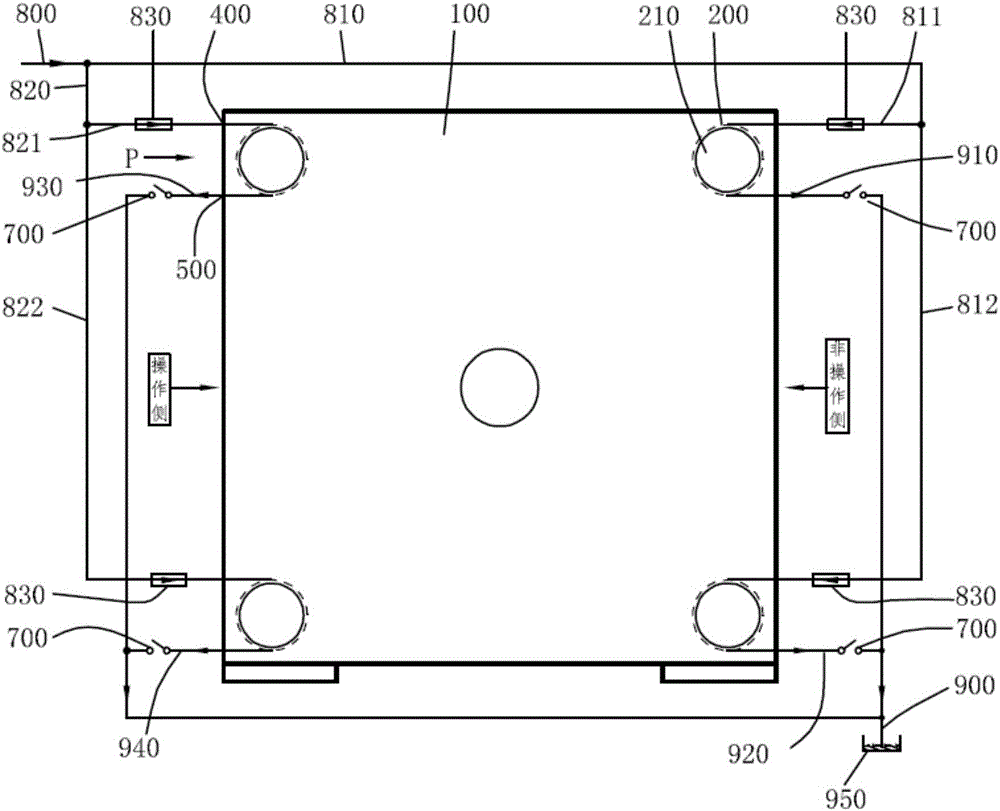

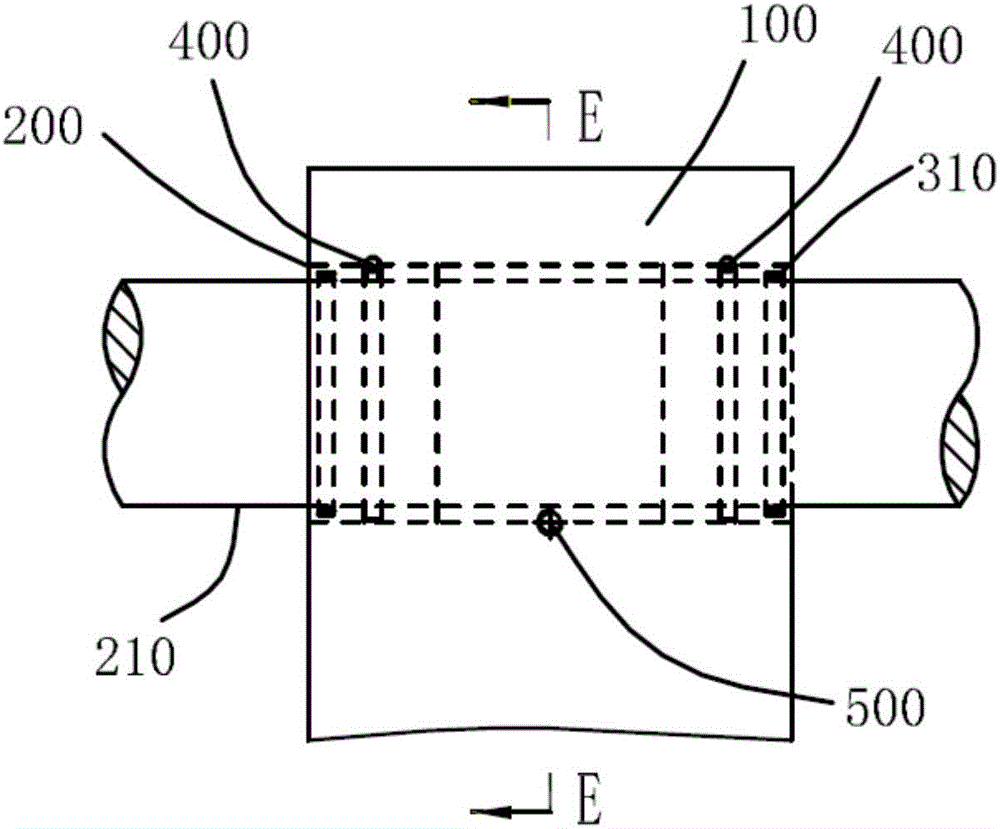

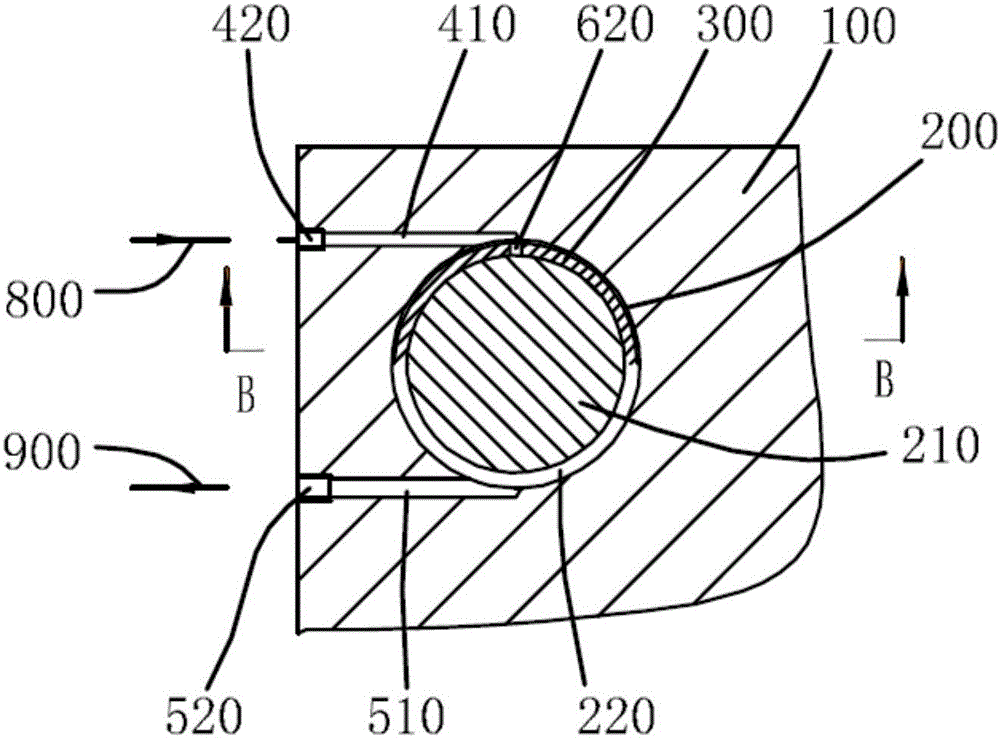

Lubricating device for draw-bar guide sleeves of moving mold plate of injection molding machine and system thereof

The invention provides a lubricating device for draw-bar guide sleeves of a moving mold plate of an injection molding machine and a system thereof and relates to the technical field of lubrication of the moving mold plate of the injection molding machine. The device comprises the movable mold plate and the guide sleeves; draw bar through holes are formed in the movable mold plate, and the guide sleeves sleeve the inner sides of two ends of each of the draw bar through holes; oil inlet through holes are formed in the upper side walls, close to ports on two sides, of each of the draw bar through holes, an oil through hole is formed in the side wall of each of the guide sleeves, and the oil inlet through holes communicate with the oil through holes; oil outlet through holes are formed along the lower side walls of the axial middle part of each of the draw bar through holes; and switches are mounted on the outer sides of the oil outlet through holes. The lubricating device provided by the invention solves the technical problem that the adding amount of grease cannot be examined and impurities in the movable mold plate cannot be immediately discharged when lubricating grease is added into a conventional movable mold plate. By adopting the device and the system thereof, whether the filling amount is full or not when the lubricating grease is filled can be detected. Waste oil in a lubricating chamber can be discharged by controlling the switches before the lubricating grease is filled or the lubricating grease is being filled.

Owner:WUXI HAITIAN MACHINERY

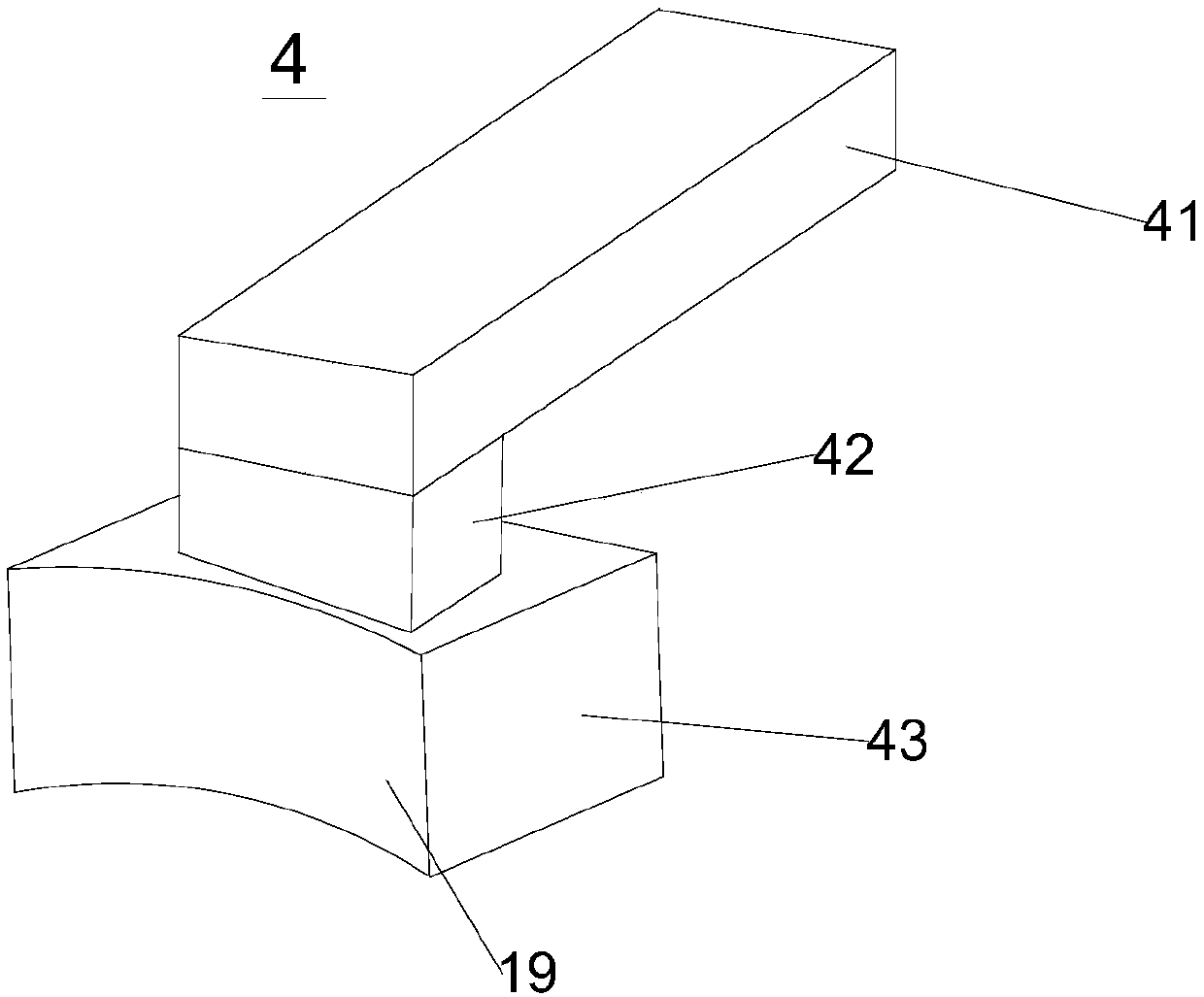

Efficient semi-automatic capsule filling device

InactiveCN104887518AControl filling volumeQuality assuranceCapsule deliverySemi automaticEngineering

The invention provides an efficient semi-automatic capsule filling device. The efficient semi-automatic capsule filling device comprises a hydraulic pressure producing device, a hydraulic telescopic rod, a hopper, a discharge port, a filling loading cartridge, an arrangement plate support, an arrangement plate support base, arrangement plates, a filling loading cartridge inner core, a spring, an arrangement plate handle and a storage box. The hydraulic pressure producing device is connected with the storage box through the hydraulic telescopic rod. The hopper is fixed to the storage box. The discharge port is directly communicated with the storage box. The filling loading cartridge is connected to the discharge port through the spring in a sleeving mode. The arrangement plate support base is fixed to the lower surface of the storage box. The arrangement plates are placed on the arrangement plate support in a layered mode. The efficient semi-automatic capsule filling device is simple in structure and convenient to operate, a plurality of layers of capsule shells to be filled can be placed in sequence and are sequentially filled layer by layer, and the production efficiency is greatly improved.

Owner:SHAOXING HAIBANG PHARMA

Adjustable volumetric measuring cup filling mechanism

InactiveCN104401516AAdjustable measuring cup capacityControl filling volumeSolid materialCamLiquid level sensor

The invention discloses an adjustable volumetric measuring cup filling mechanism. The filling mechanism comprises an upper measuring cup, an adjustable lower measuring cup, a central shaft, a material tray, a cam, an adjustable sleeve, a set screw, a liquid level sensor and an intelligent display controller, wherein the upper measuring cup is arranged on the adjustable lower measuring cup; the liquid level sensor is arranged on the side wall of the upper measuring cup and is connected with the intelligent display controller through a shielded conductor; the intelligent display controller is arranged on the outer wall of the adjustable volumetric measuring cup filling mechanism; the adjustable lower measuring cup is connected with the central shaft through a stationary shaft; the bottom of the adjustable lower measuring cup is provided with the material tray; the material tray is connected with the cam through the supporting rod; the adjustable sleeve is arranged below the cam; the cam is arranged on the central shaft. By rotating an adjustable measuring cylinder up and down, position change of the upper and lower cups is realized, so that adjustable volume of the measuring cup of the volumetric measuring cup filling mechanism is realized; the mechanism can adapt to packing machines for packing different medicaments.

Owner:成都索伊新材料有限公司

Vertical pneumatic filling device and using method thereof

PendingCN108216710ALoss or affect qualityAffect qualityLiquid materialFilling materialsComputer module

The invention provides a vertical pneumatic filling device and a using method thereof. The filling mechanism of the filling device comprises a control module, a temporary storage cavity, a suction mechanism and an extrusion mechanism, wherein an input port of the filling mechanism is arranged at the cavity wall of the temporary storage cavity and is provided with a check valve; the suction mechanism is connected to the temporary storage cavity through a suction cylinder; and when filling operation is carried out, the check valve communicates with the input port of the filling mechanism, the suction mechanism drives the suction cylinder to suck to-be-filled materials with the preset temporary storage amount into the temporary storage cavity, then the check valve closes the input port of thefilling mechanism, the suction mechanism reversely drives the suction cylinder to apply pressure to the to-be-filled materials in the temporary storage cavity, and an extruding mechanism is used forextracting the materials in the temporary storage cavity according to the preset filling amount and guiding the materials into an external packaging container. According to the vertical pneumatic filling device and the using method thereof, the high-viscosity high-value materials can be conveniently subjected to small-batch filling, the attractiveness and the packaging amount of finished productsare further not prone to be influenced due to bubbles, and the device can be conveniently cleaned and maintained.

Owner:福州法莫优科机械科技有限公司

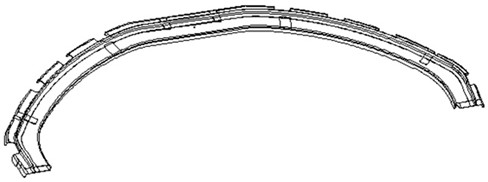

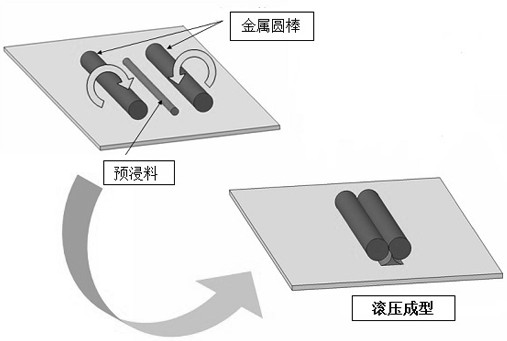

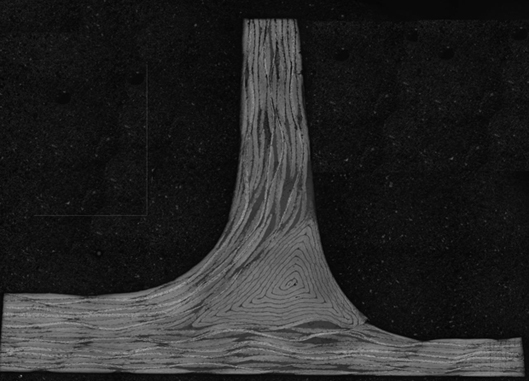

A method for making carbon twisted yarn in the r-angle region

The invention discloses a method for manufacturing carbon-twisted yarns in the R-angle area. The carbon-twisted yarns are prepared by manual laying, and the manufacturing process of the carbon-twisted yarns for the C-shaped frame composite material structural parts is completed, ensuring that each thin strip can be Completely follow the shape, so that the surface quality and internal quality of the triangular area meet the design requirements, ensuring product quality stability. Moreover, the method of the present invention can control the filling amount through the external mold pressing, avoiding the phenomenon of insufficient filling or excessive filling, and ensuring the stability of product quality. Moreover, the preparation method of the present invention can ensure the continuity of the carbon twisted filaments, thereby improving the requirements for product molding quality and the like. In addition, the method of the present invention does not require pre-compacting tooling, which saves manufacturing costs.

Owner:航天海鹰(镇江)特种材料有限公司

Adjustable plunger pump

InactiveCN109611309AAdjust the size of the angleChange the size of the anglePump controlPumpsPump headControl theory

The invention relates to an adjustable plunger pump. The adjustable plunger pump comprises a stepping motor, a plunger pump, a servo motor, a coupling, a ball screw, a connecting plate, a touch screenand a PLC. The touch screen is connected with the stepping motor and the servo motor through the PLC. The plunger pump comprises a driving section and a pump head. The stepping motor is fixedly arranged on a first motor seat frame. An output shaft of the stepping motor is connected with the driving section. The output end of the driving section is connected with the pump head. The pump head is fixed on a pump seat frame. One end of the pump seat frame is hinged to the first motor seat frame. The servo motor is fixedly connected with the stepping motor through a second motor seat frame. An output shaft of the servo motor is arranged in the same direction as the output shaft of the stepping motor. The output shaft of the servo motor is connected with a screw shaft of a ball screw through acoupling. One end of the connecting plate is connected with a screw nut of the ball screw, and the other end of the connecting plate is connected with the other end of the pump seat frame. The adjustable plunger pump has the beneficial effects of being easy to adjust and operate and capable of accurately adjusting and controlling the filling amount of the plunger pump.

Owner:GUANGZHOU A & J AUTOMATION EQUIP

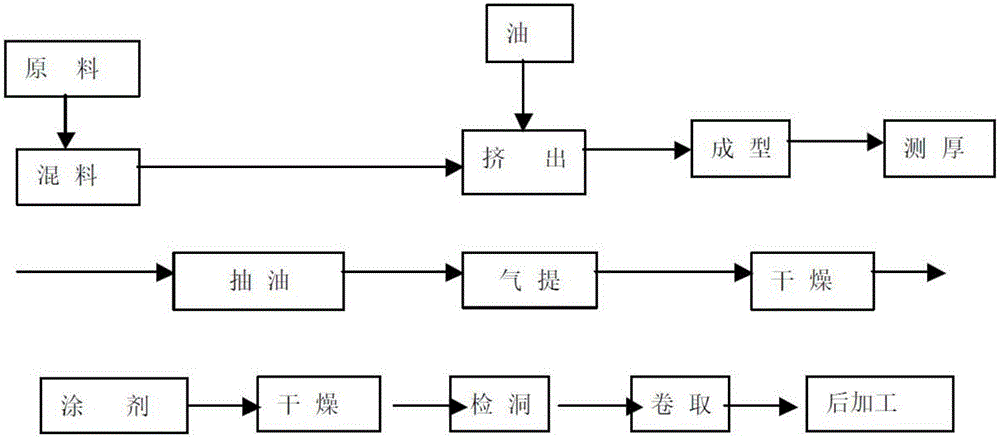

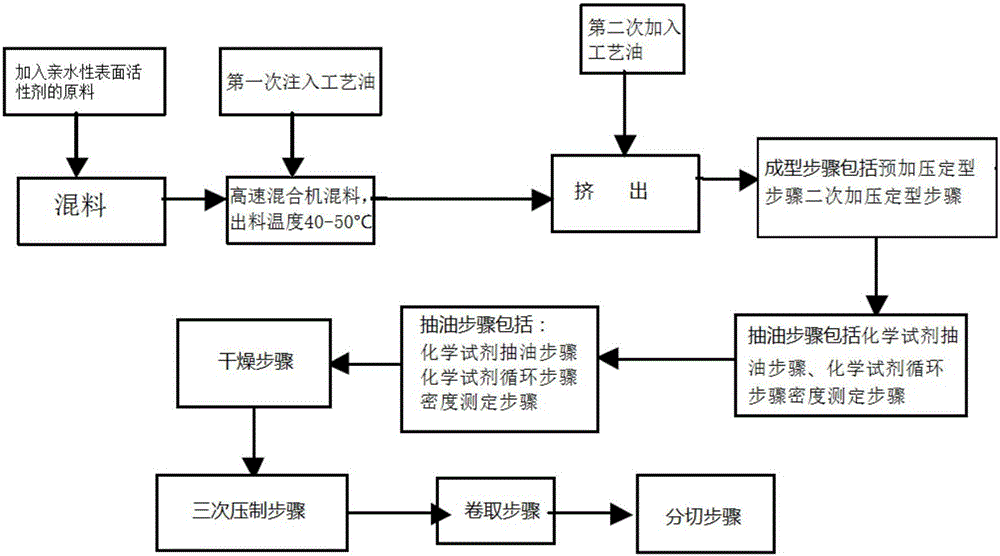

Production process for PE isolation plate of lead-acid storage battery

InactiveCN106129304AReasonable viscosityImprove puncture resistanceCell component detailsMixed materialsSURFACTANT BLEND

The invention belongs to the technical field of a lead-acid storage battery, and specifically to a production process for a PE isolation plate of the lead-acid storage battery. The invention aims to solve problems existing in six aspects; a second oil injection process is adopted to ensure that a mixed material has reasonable viscosity; the conventional coating process for a hydrophilic surfactant is changed; a pressing process which includes the steps of pre-pressing, pressing for the second time and pressing for the third time is adopted for pressing reinforcing ribs; an opposite pressing method with adjustable spacings is adopted, so that the pressing distance can be adjusted according to requirements of customers without adjusting rollers, so that continuous production can be realized and the productivity can be increased; and a process of recycling a chemical reagent and a process of drying in three modes are performed. By adoption of the production process, the production process obtains prominent industrial practicability; compared with the conventional production process, the product quality and the production efficiency are greatly improved by the production process provided by the invention; and in addition, the production process is environment-friendly and can protect health of workers, so that the production process has an outstanding improvement effect.

Owner:镇江奥美机电设备有限公司

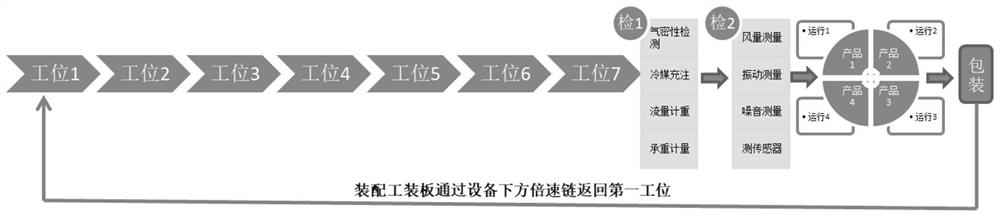

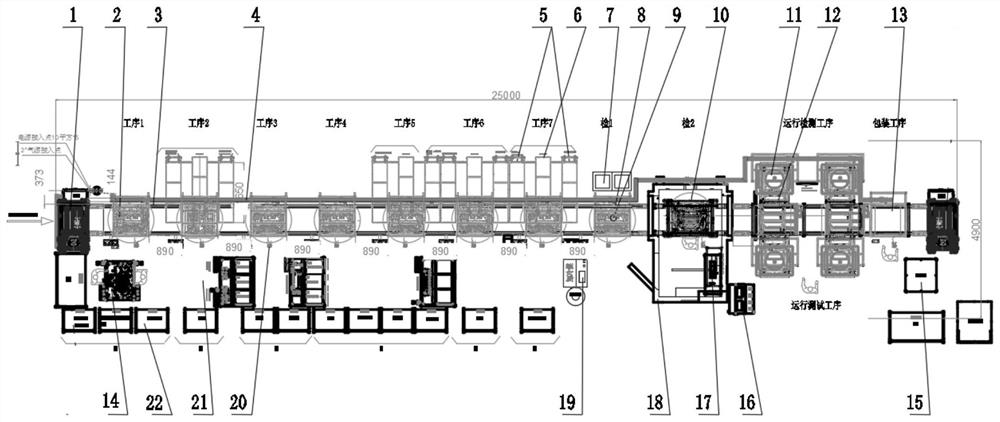

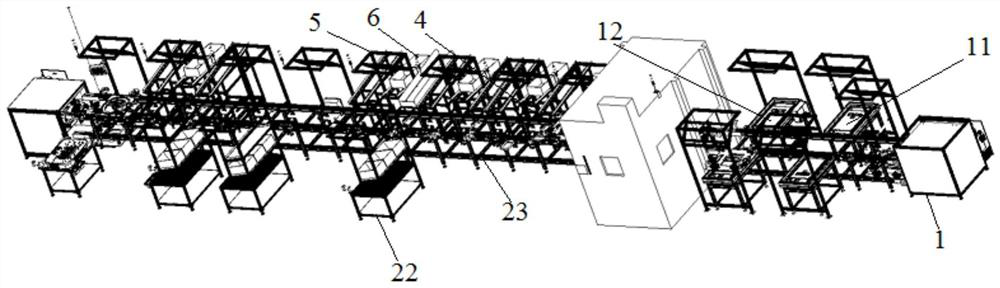

Assembly and detection production line suitable for parking air conditioner host

PendingCN114749909AControl filling volumePrevent outflowAssembly machinesFluid-tightness measurement using fluid/vacuumProduction lineEngineering

The assembly and detection production line comprises a line body support, a first conveying mechanism and a second conveying mechanism are arranged in the line body support, the first conveying mechanism is located below the second conveying mechanism, and line following tool plates are arranged on the first conveying mechanism and the second conveying mechanism; elevators are arranged at the two ends of the line body support respectively, and a plurality of stations, a first detection system, a second detection system and an operation detection system are sequentially arranged on the line body support; the multiple stations sequentially complete assembly of all parts of the air conditioner main unit, the first detection system is used for completing airtightness detection of the assembled air conditioner main unit, refrigerant filling and refrigerant filling amount monitoring are conducted after the airtightness detection is qualified, and detection data are stored in the industrial personal computer for storage and recording.

Owner:陕西泰德汽车空调有限公司

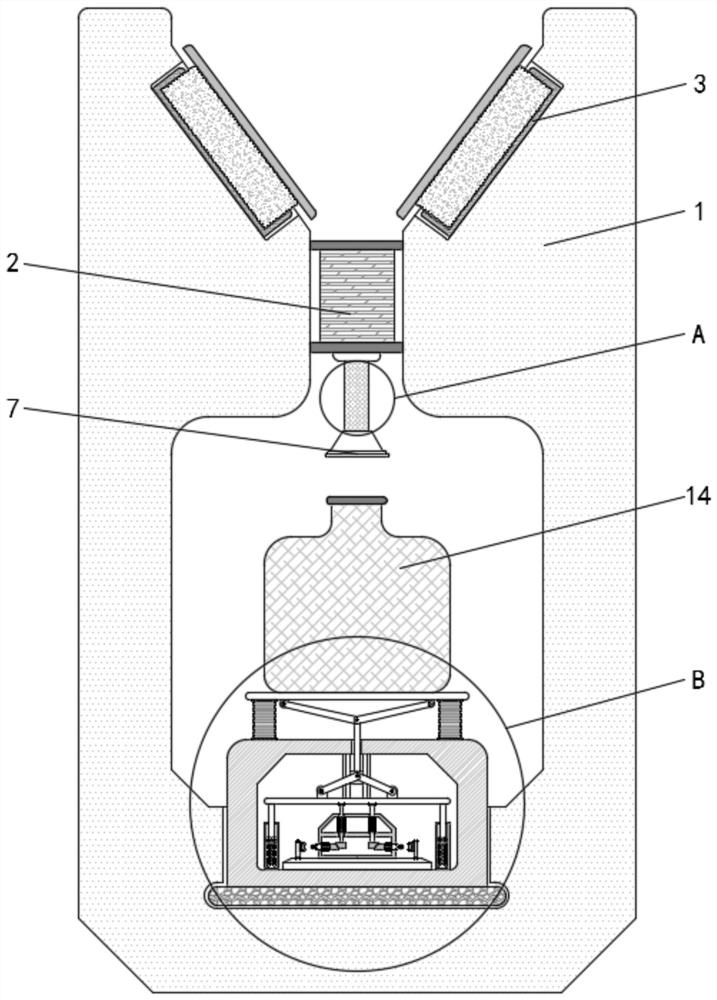

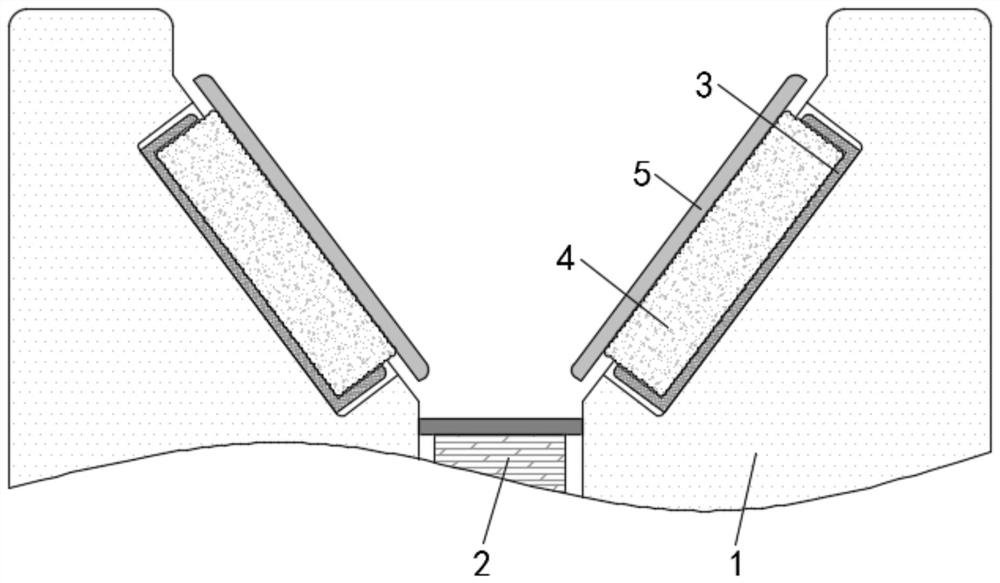

BB pill forming device

The invention relates to a BB pill forming device comprising a top die part, a bottom die part and a middle die part. The opposite ends of the top die part and the bottom die part are respectively provided with a first forming tank and a second forming tank, the opposite faces of the first forming tank and the second forming tank respectively form a first cambered surface and a second cambered surface, a first pushing member and a second pushing member making pushing motions are respectively arranged in the first cambered surface and the second cambered surface, the top die part and the bottom die part are oppositely displaced, and a pressed forming path is limited between the top die part and the bottom die part. The middle die part is provided with a pressing channel for inserting the top die part and the bottom die part on the pressed forming path, at least one feeding opening is arranged in the pressing channel, and a feeding pipe communicated with the feeding opening is arranged in the middle die part.

Owner:ZIPPY TECH

Self-weight-based uniform filling device for sewage treatment agent production

PendingCN113336170AImprove filling effectReduce impact forceBarrels/casks fillingInductorProcess engineering

The invention provides a self-weight-based uniform filling device for sewage treatment agent production. The device comprises a shell, a filling device body is arranged on the upper side of the shell, a buffer device is embedded in the shell, a filling pipeline is arranged on the lower side of the filling device body, a filling port is fixedly formed in the lower side of the filling pipeline, and a fixing part is mounted on the bottom side of the interior of the shell. According to the self-weight-based uniform filling device for sewage treatment agent production, a treatment agent in a collecting barrel is continuously added, so that a second pushing block is used for driving an induction piece to synchronously move outwards, the induction piece is made to make contact with an inductor, at the moment, current changes, then an electric signal is sent out to make filling of the treatment agent stopped, meanwhile, the next procedure is drive to start to run, the device is drive to run on the basis of the weight of the treatment agent, the filling amount of the treatment agent is effectively controlled, and the filling effect of the device is further improved.

Owner:杨端芹

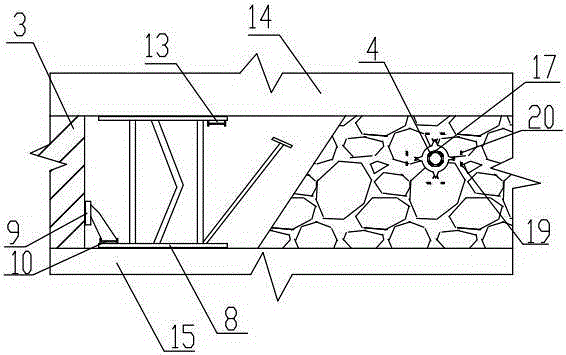

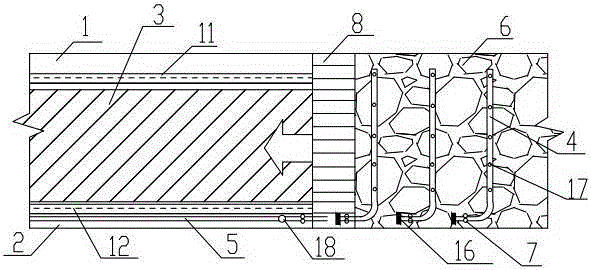

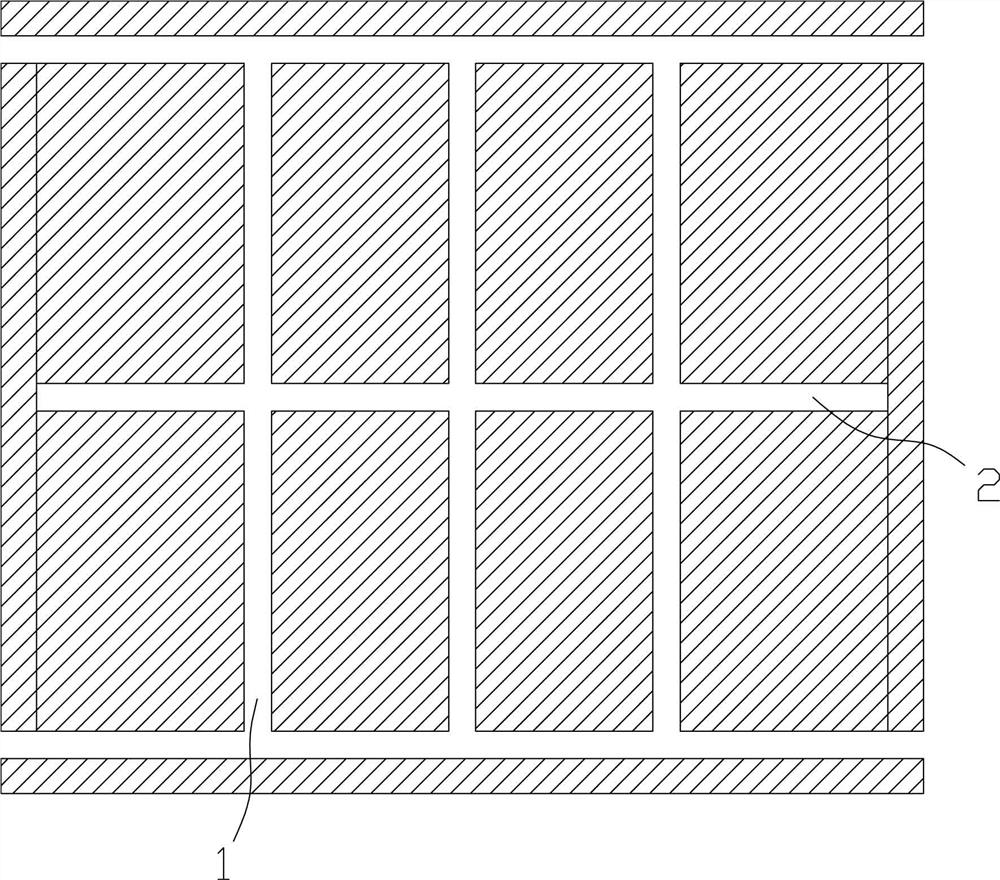

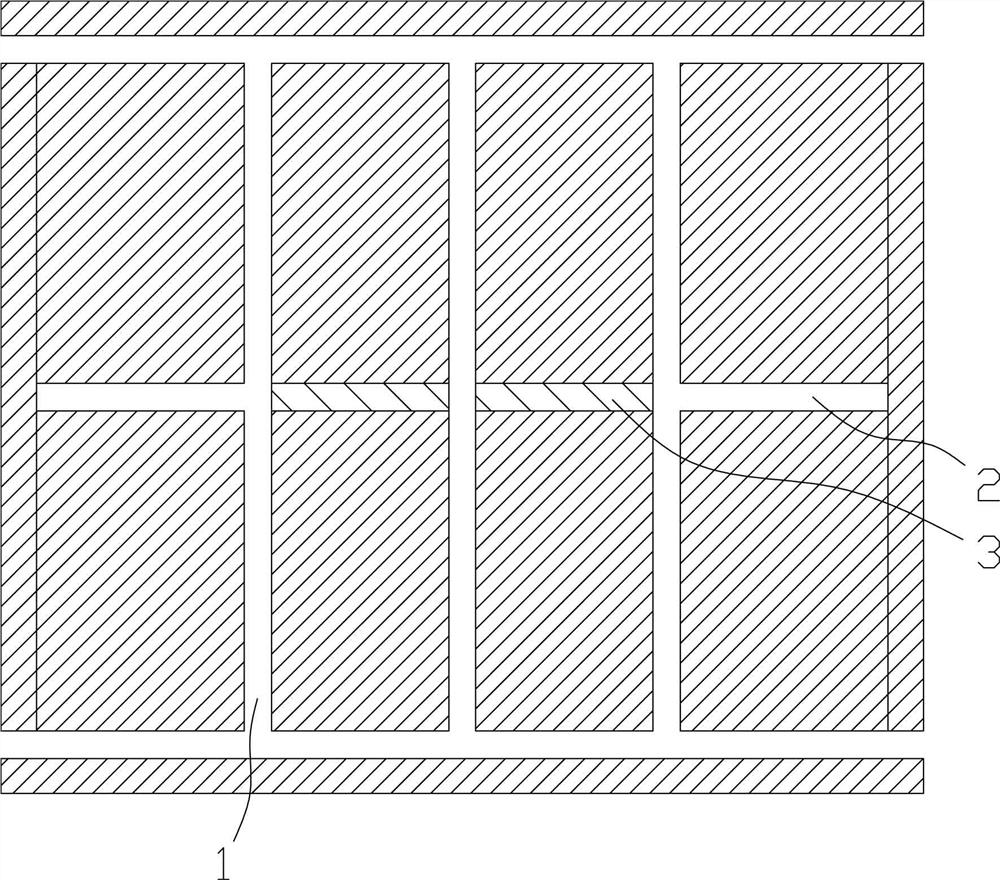

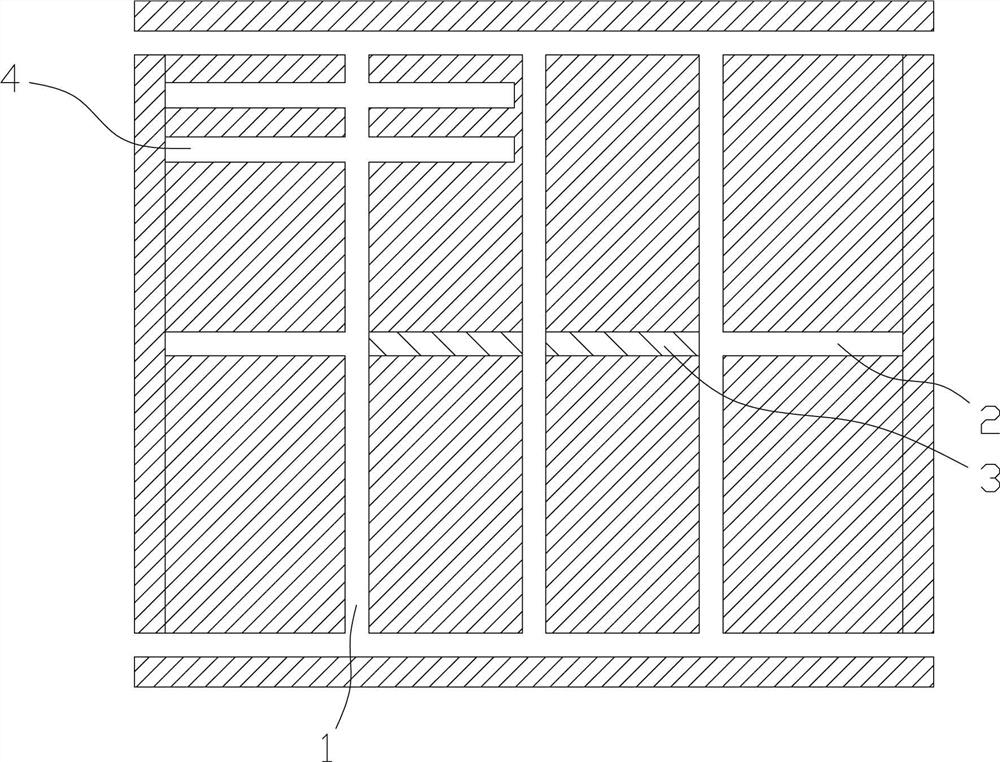

A Strip Wet Filling and Roofing Mining Method

ActiveCN112127889BImprove securityImprove recovery efficiencyUnderground miningSurface miningMining engineeringStructural engineering

A strip wet filling and roofing mining method, which specifically includes: 1) construction cutting and section roadway; 2) construction of filling and unloading yard; 3) construction of bottom roadway; 4) construction of bottom roadway at the same time of wet filling and roof connection ;5) Mining the intercolumns and pulling the bottom, and performing wet filling at the same time; 6) Backfilling the intercolumns with dry material, and constructing the bottom roadway at the same time; 7) Mining the intercolumns again and pulling the bottom, and performing wet filling at the same time; 8) Sequential cycle operation , Multiple security channel recovery. The present invention adopts the above-mentioned method, fills with dry and wet filling strips at intervals, ensures that the safety exit is continuously advanced with the advance of withdrawal, always ensures that the safety exit does not exceed three rows of ore pillars in the mining area, and improves the safety factor of the safety exit; The mining and filling operations are carried out in different areas at the same time, avoiding cross operations, and the recovery efficiency of the mine room is doubled; the size of the bottom roadway is controlled and does not penetrate the structure, which improves the filling efficiency.

Owner:HUBEI SHANSHUYA MINING SCI & TECH DEV

Tumor resection system for maxillofacial surgery

ActiveCN113749893AScientific and reasonable structureEasy to useOperating tablesApparatus instrumentsReoperative surgery

The invention discloses a tumor resection system for maxillofacial surgery. The tumor resection system comprises a lifting base, wherein a middle bed plate is arranged in the middle of the top end of the lifting base, a rear bed plate is arranged at one end of the middle bed plate, a front bed plate is arranged at the other end of the middle bed plate, a mounting bent frame is connected to one end of one side of the middle bed plate through a bolt, and a splicing frame is connected to one side of the top end of the mounting bent frame through a bolt. According to the tumor resection system, used surgical instruments are automatically wiped by virtue of continuously advancing wet cleaning gauze, so that the working intensity of auxiliary medical personnel is reduced, the transfer process of medical instruments is omitted, accidents caused by the transfer process of the medical instruments are effectively avoided, and the safety of a tumor resection operation of the maxillofacial surgery is effectively improved; and meanwhile, the appropriate medical instruments are selected by an operator, so that the intermittent time in the operation process is effectively shortened, and the efficiency of the tumor resection operation of the maxillofacial surgery is effectively improved.

Owner:JIAMUSI UNIVERSITY

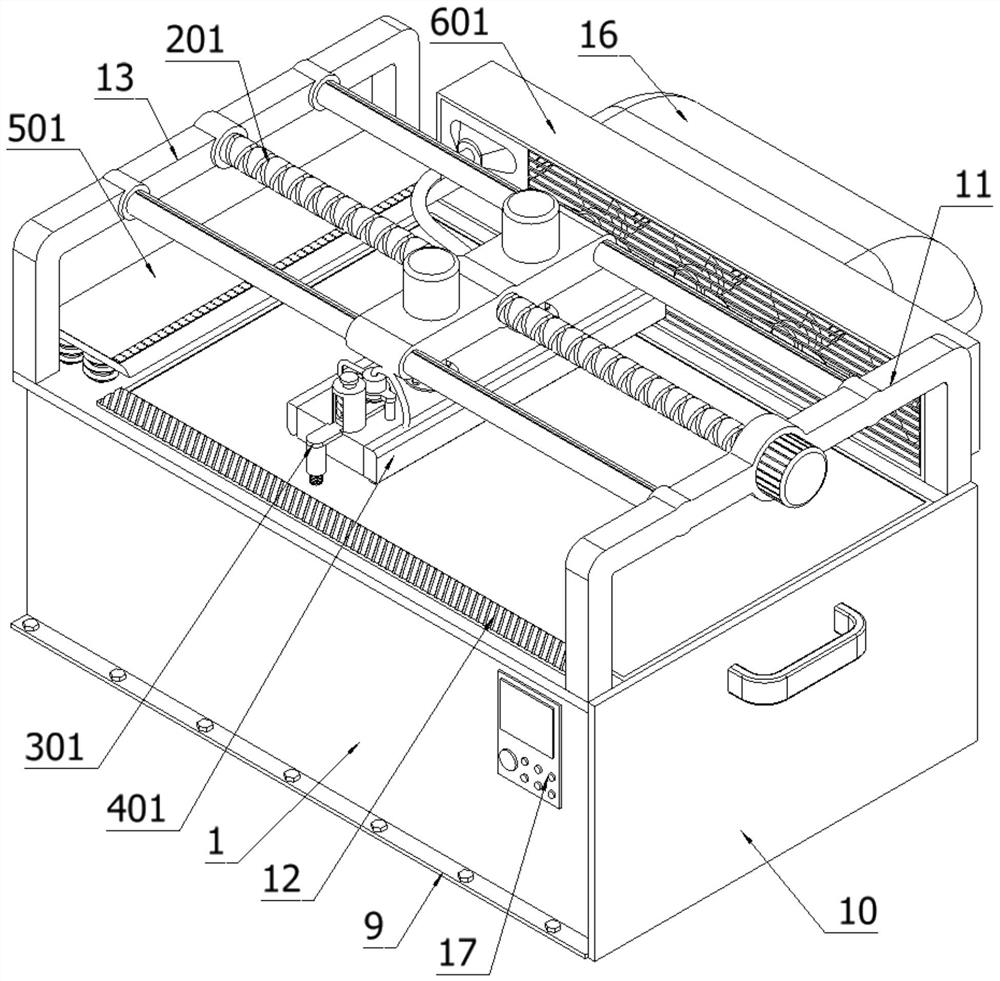

Green and environment-friendly printing process method

PendingCN113103751AImprove sealingAvoid pollutionRotary pressesPrinting press partsProcess equipmentMechanical engineering

The invention provides a green and environment-friendly printing process method. According to the green and environment-friendly printing process method, a printing process is completed by using green and environment-friendly printing process equipment, wherein the green and environment-friendly printing process equipment comprises a mounting shell; shell mounting plates are fixedly connected to two sides of the bottom of the mounting shell, and the bottoms of the shell mounting plates are flush with the bottom of the mounting shell; the top of the front end of the mounting shell is fixedly connected with a lead screw mounting frame; the lead screw mounting frame is fixedly sleeved with a driving device; the shaft end of the driving device fixedly sleeves a shaft end fixing support; the bottom of the shaft end fixing support is fixedly connected to the top of the rear side of the mounting shell; the bottom of the driving device is fixedly connected with an accurate printing device; and the top of the accurate printing device is fixedly connected with a pressurizing device.

Owner:莱西市蔚来设计中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com