Magnetic element

A technology of magnetic components and magnetic cores, which is applied in the field of magnetic components and coils including coil brackets, magnetic cores and insulating spacers, can solve the problems that it is difficult to realize the miniaturization of magnetic components, and achieve increased insulation distance and enhanced insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

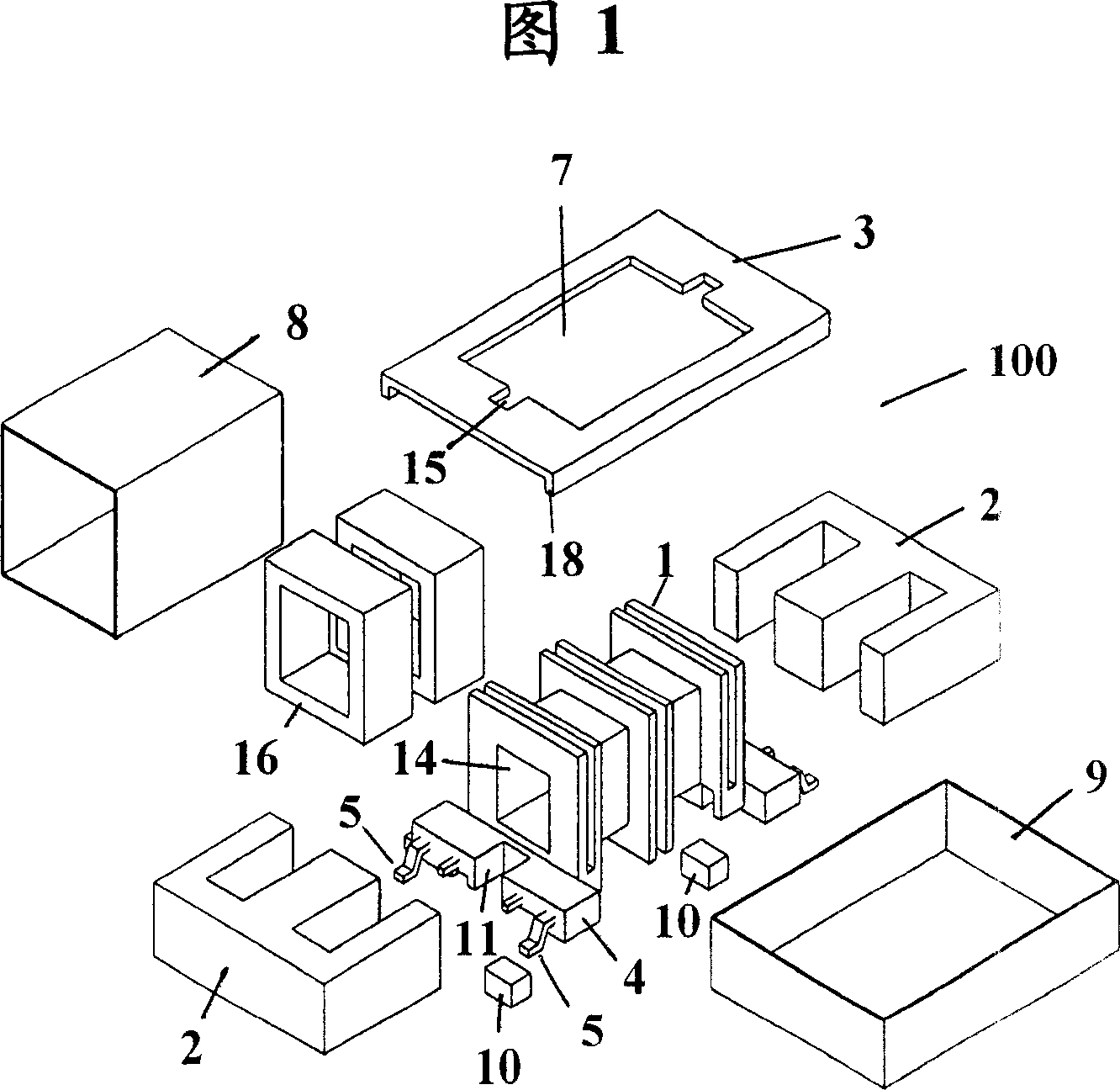

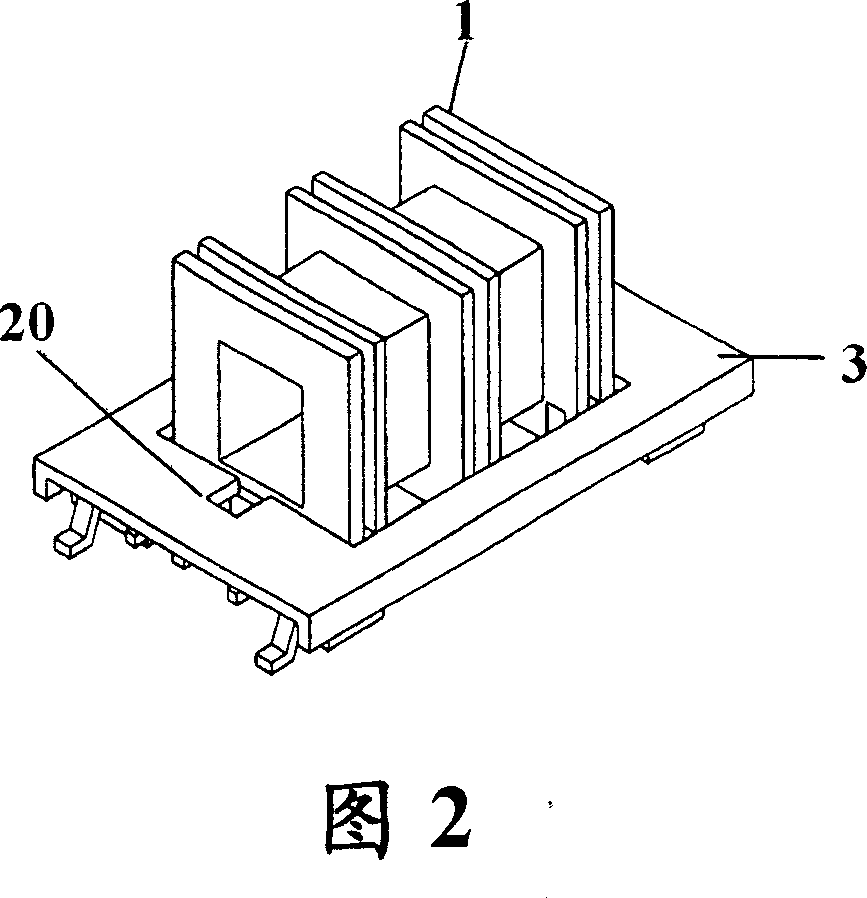

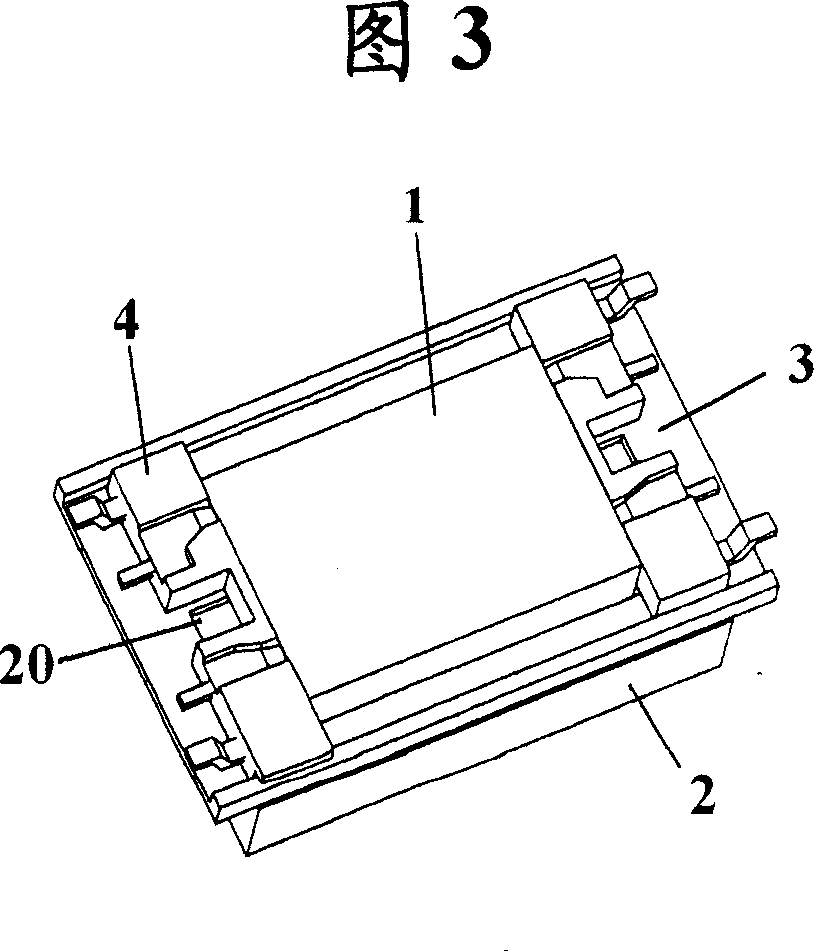

[0031] Referring to Figures 1 to 4, there is shown a magnetic element 100 according to a first embodiment of the present invention. As shown in FIG. 1 , the magnetic element 100 roughly includes a coil support 1 , a coil 6 , an insulating spacer 3 and a pair of magnetic cores 2 . The magnetic core 2 is a magnetic core similar to an "E" shape, which can be made of manganese-zinc alloy. The coil support 1 is a conventional type of coil support, which preferably consists of a liquid crystal polymer (LCP) material. The coil holder 1 includes a main body and bases 4 at both ends thereof. In the body of the coil holder 1 there is provided an opening 14 which is sized to allow the middle arm of the E-shaped magnetic core 2 to be inserted thereinto. Several coil terminals 5 are provided on each substrate 4 , two coil terminals 5 are shown in the figure. The insulating spacers 3 are likewise preferably made of a liquid crystal polymer (LCP) material and have a thickness of, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com