Electromagnetic relay with injection molded yoke

An electromagnetic relay and yoke technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as insufficient insulation creepage distance, broken enameled wires, and difficult assembly, and achieve improved dimensional consistency and increased size. Insulation distance, the effect of reducing the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

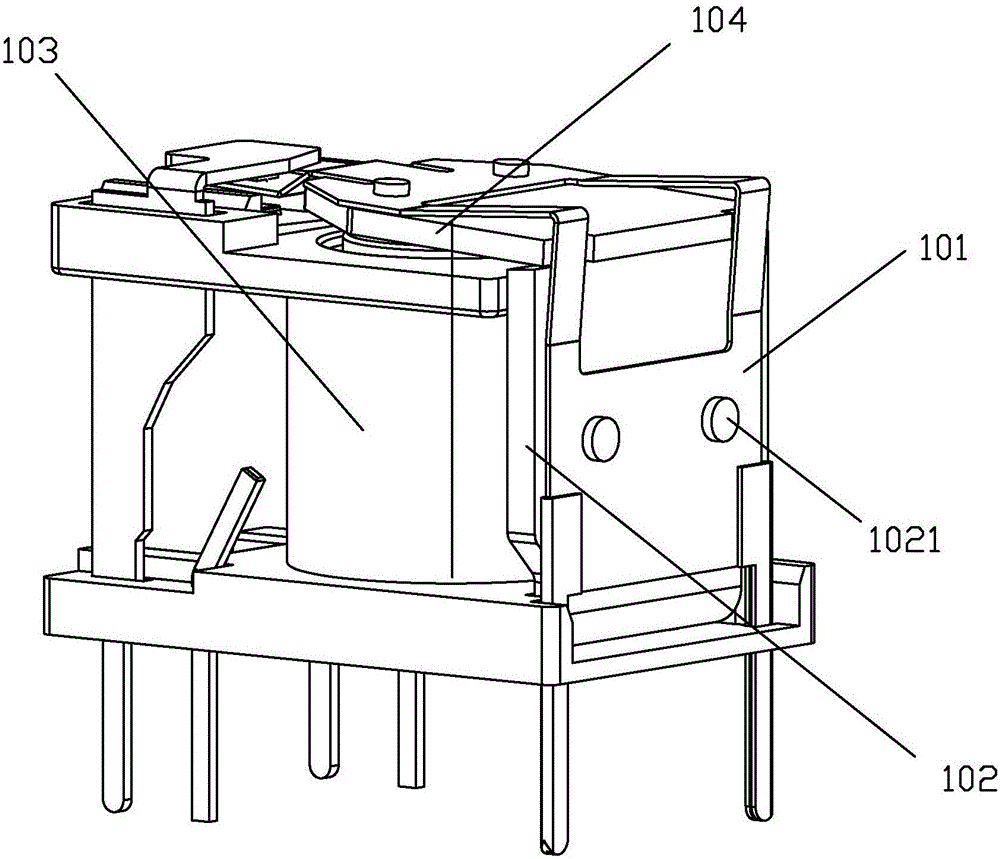

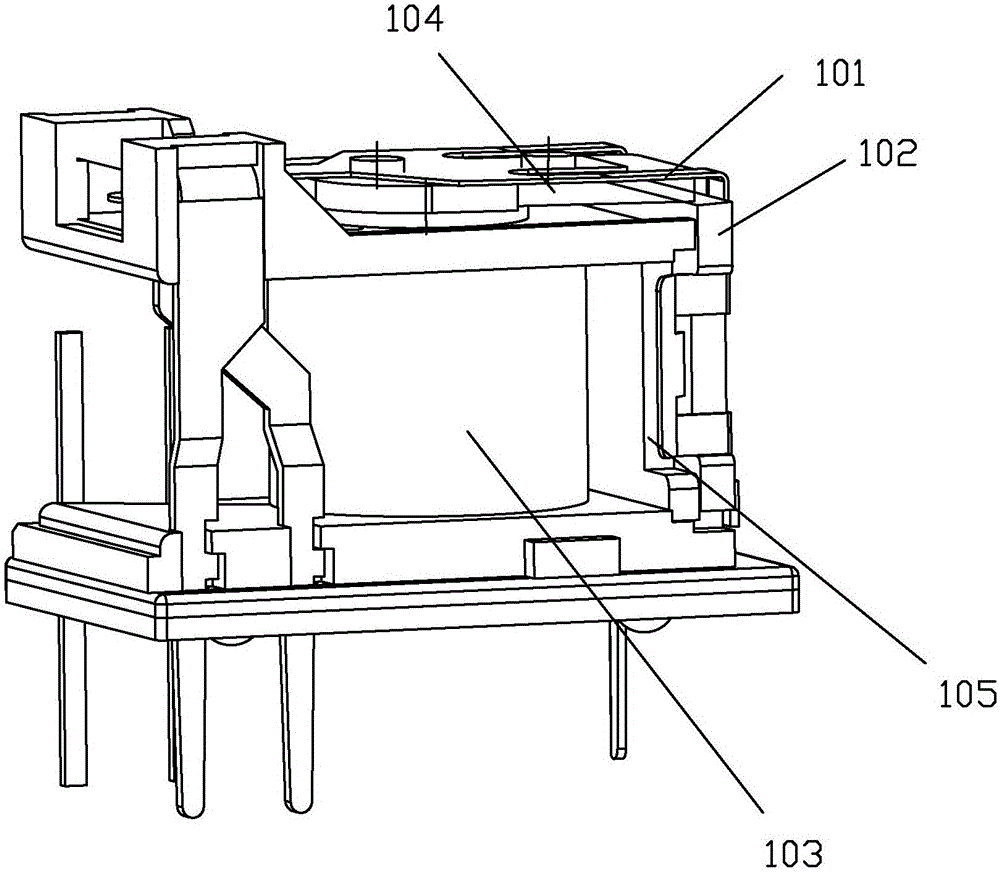

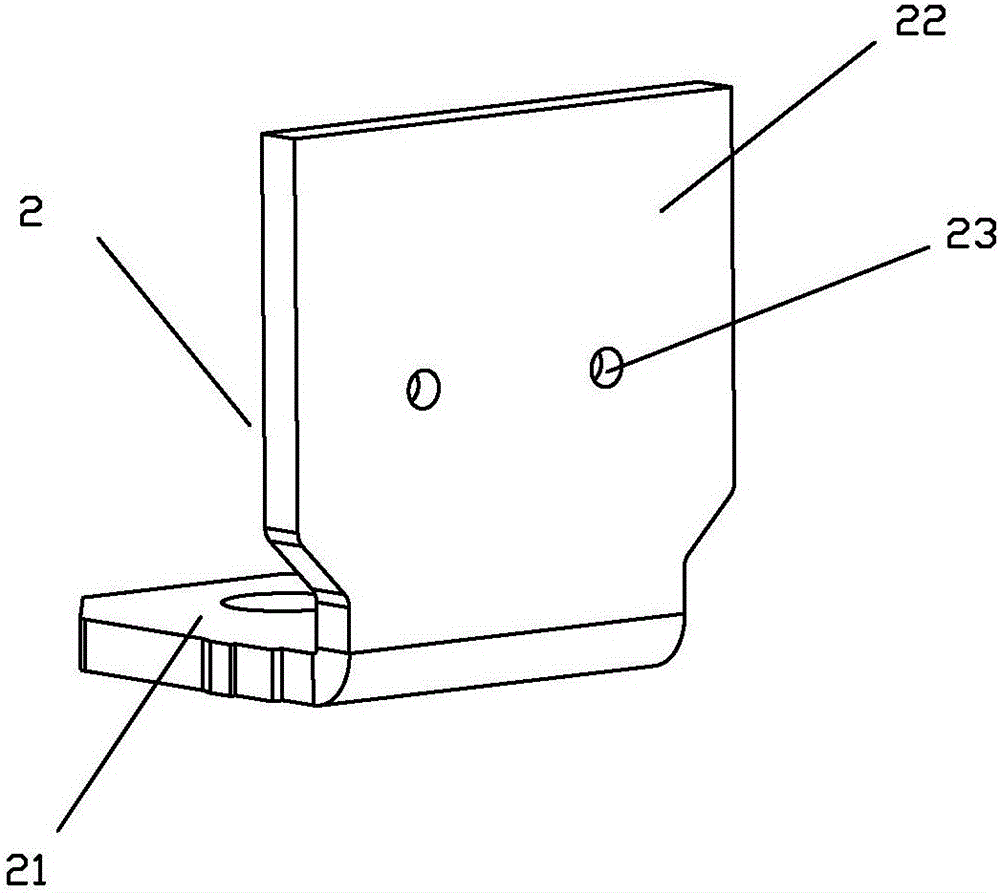

[0044] see Figure 3 to Figure 10 As shown, an electromagnetic relay of an injection molded yoke of the present invention includes a moving spring 1, a yoke 2 and a coil 3, wherein the yoke 2 is L-shaped, and the moving spring 1 and the armature 4 are assembled together to form a moving spring armature assembly The horizontal one side 21 of the yoke iron and the iron core in the coil 3 are fixed at the bottom of the coil 3 (the iron core is contained in the through hole of the coil frame 5 of the coil 3, and the through hole of the coil frame 5 is vertically arranged), The vertical side 22 of the yoke 2 is parallel to the axis of the iron core; in the vertical side 22 of the yoke 2, a plastic layer 61 formed by injection molding is provided on the side facing the coil 3, so as to use the plastic layer 61 to insulate It is arranged between the yoke 2 and the coil 3 (that is, the enameled wire of the coil), and on the side facing away from the coil 3, there is a plastic convex b...

Embodiment 2

[0062] see Figure 11 to Figure 13 As shown, the electromagnetic relay of an injection molded yoke in the present invention differs from the first embodiment in that the moving spring and the yoke are fixed in a different way. In this embodiment, the moving spring 1 and the yoke 2 are fixed It is to insert the plastic convex bud 62 formed on the yoke into the second through hole 11 of the moving spring 1. At this time, the second through hole 11 of the moving spring 1 plays a positioning role, because the through hole can be connected with the yoke. The convex bud 62 formed by the first through hole 23 of the moving spring 1 forms a clearance fit, and then, by hot riveting the plastic convex bud protruding outside the second through hole 11 of the moving spring 1, the plastic convex bud of this part is deformed 621 and All or part of the moving spring body other than the second through hole 11 of the moving spring 1 is covered to realize the fixing of the moving spring 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com