Patents

Literature

45results about How to "Prevent radial offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

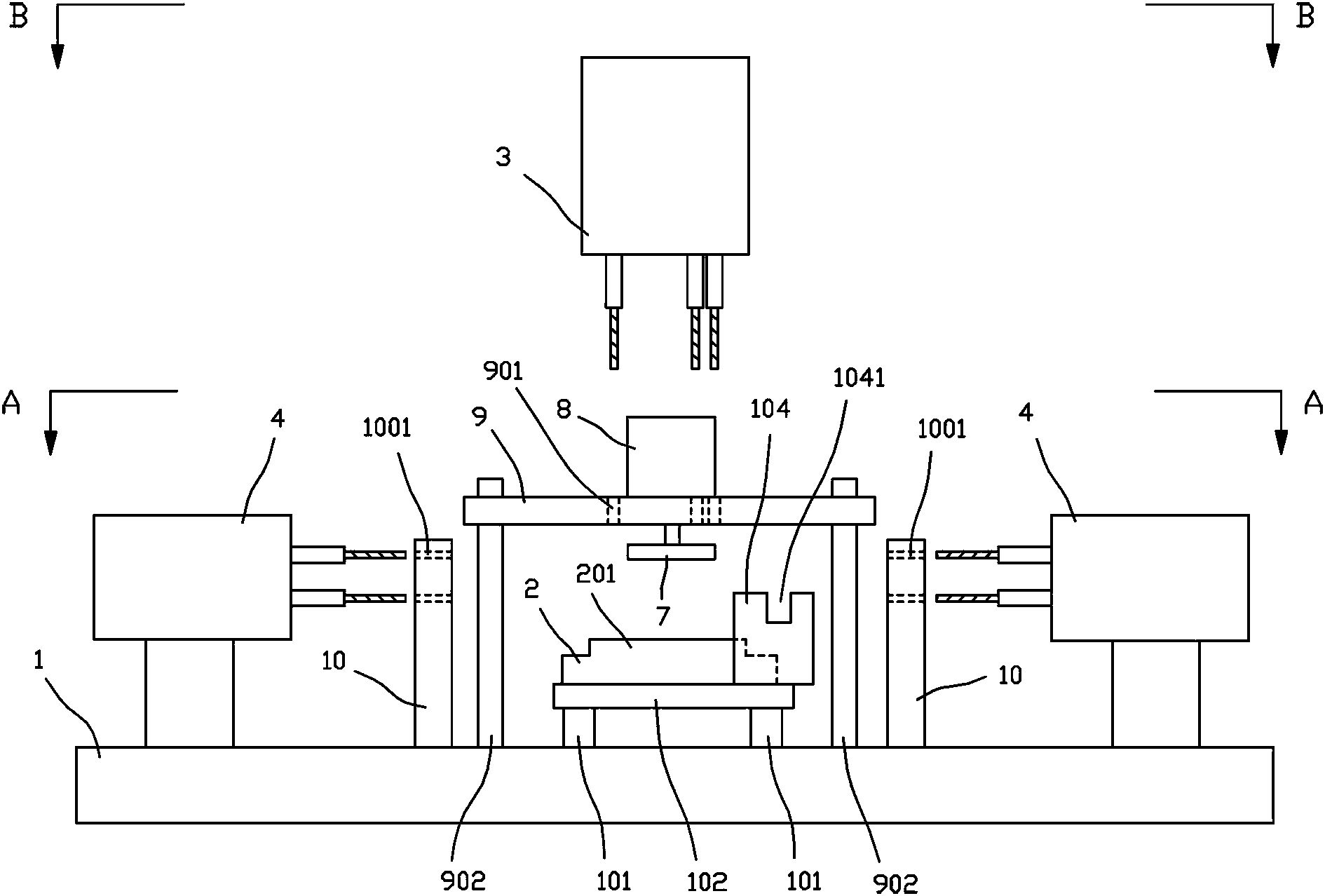

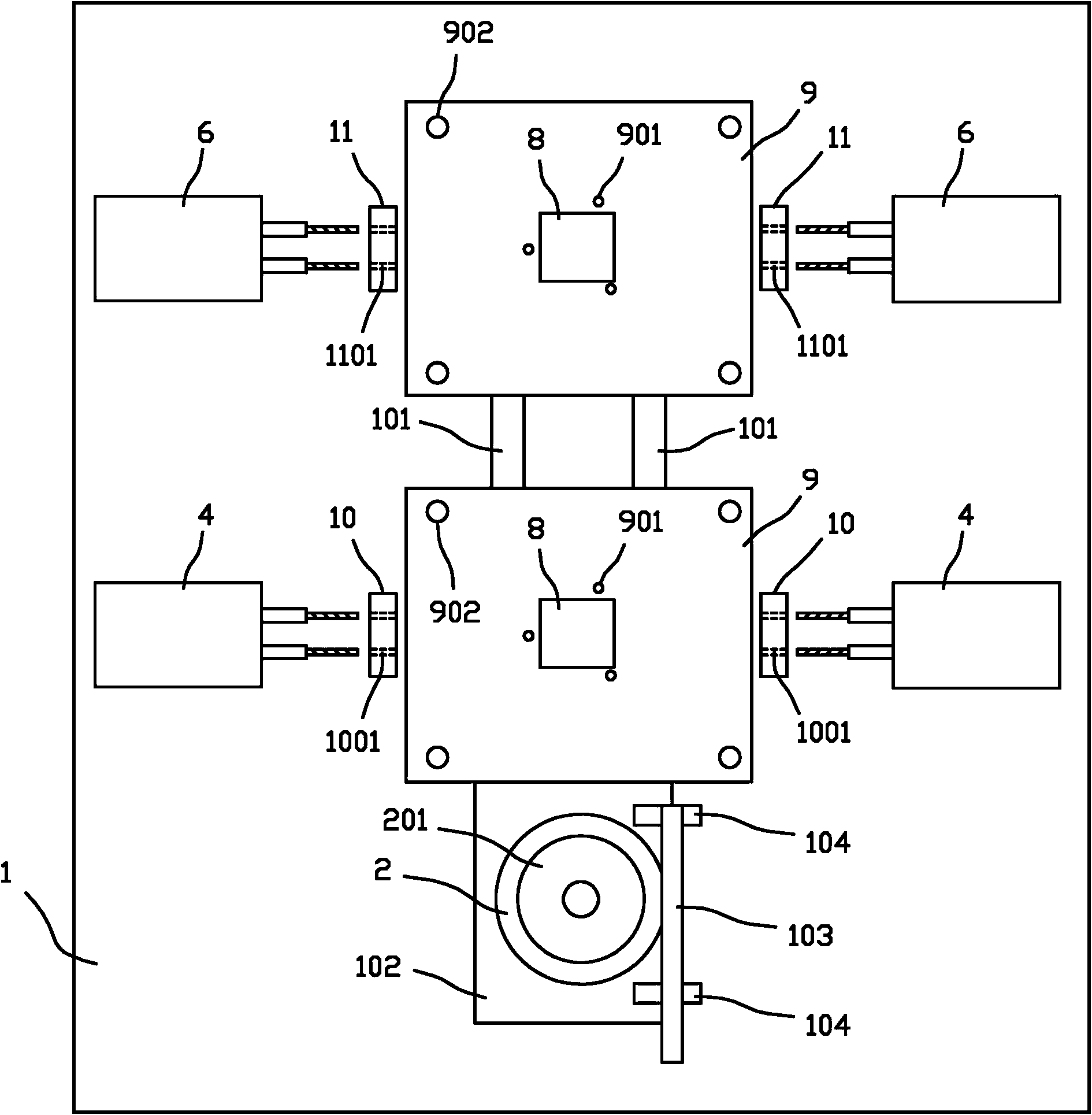

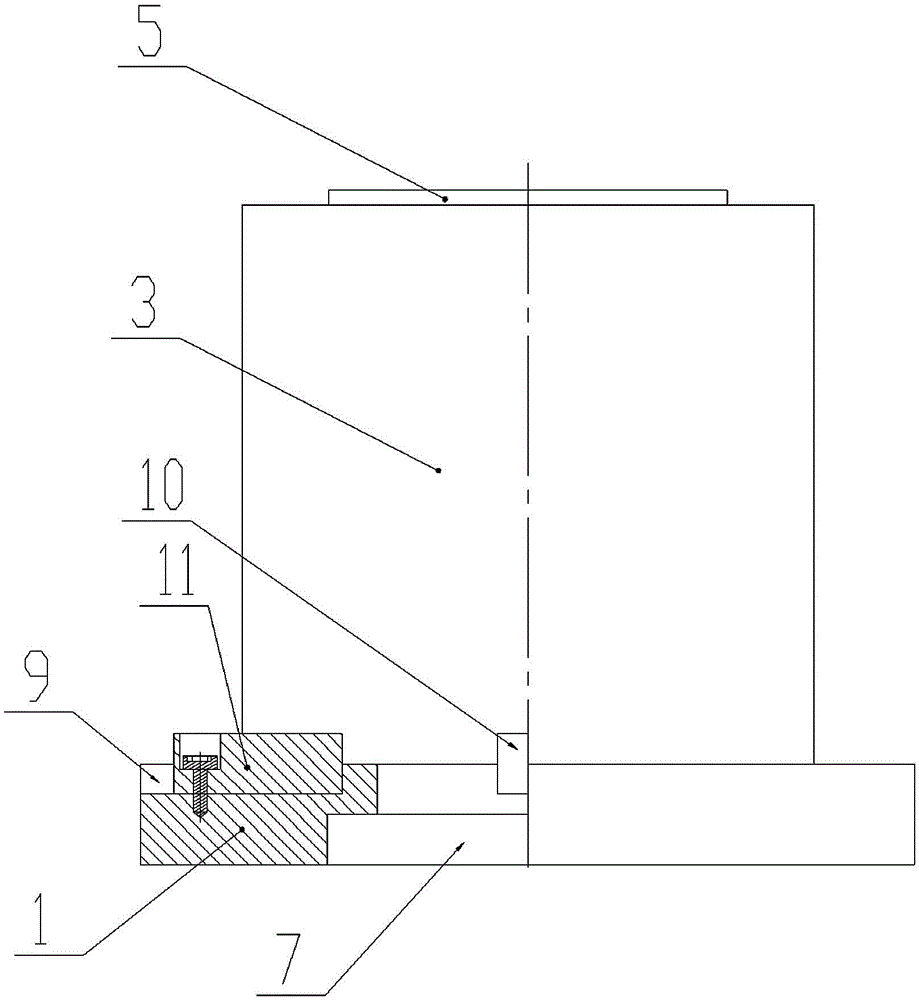

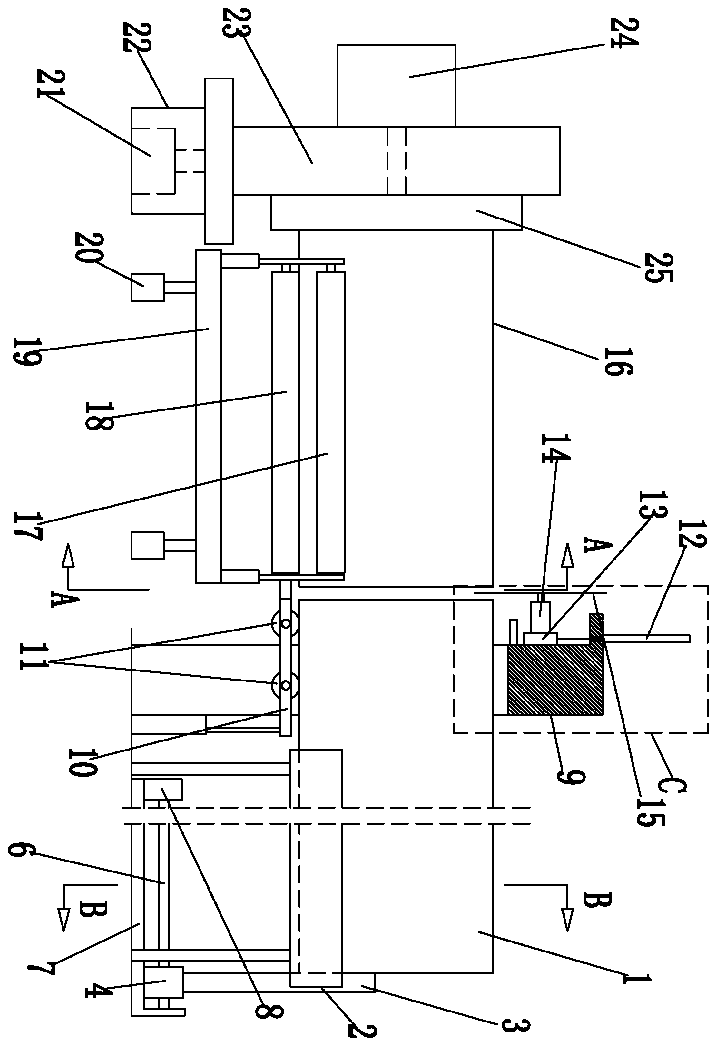

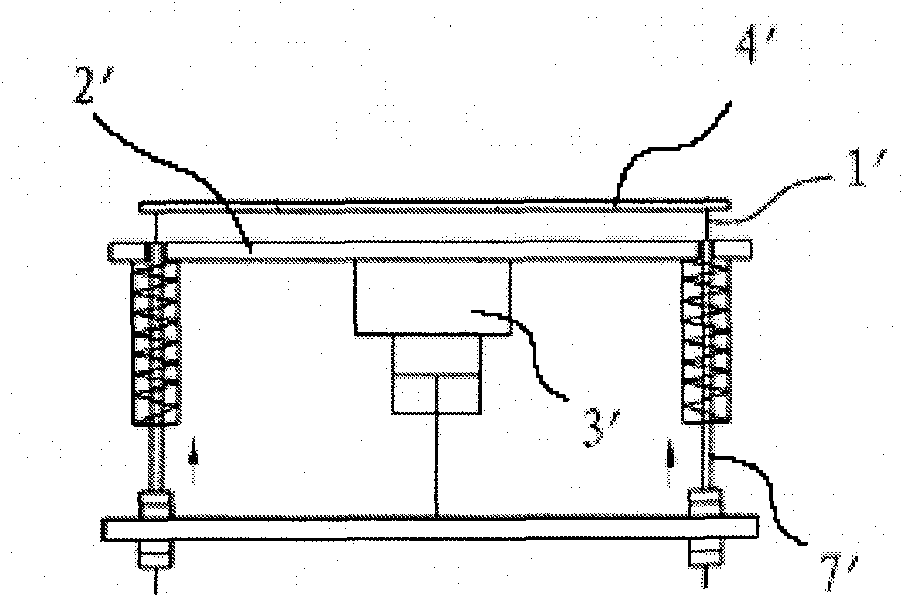

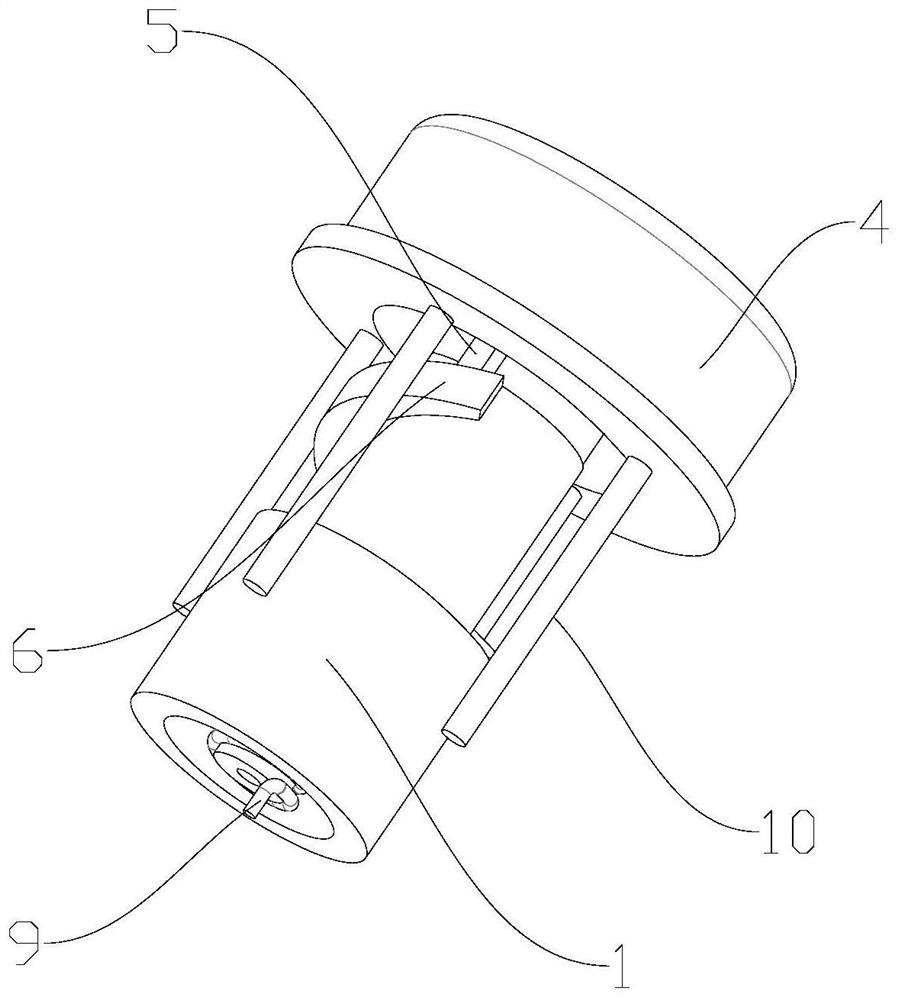

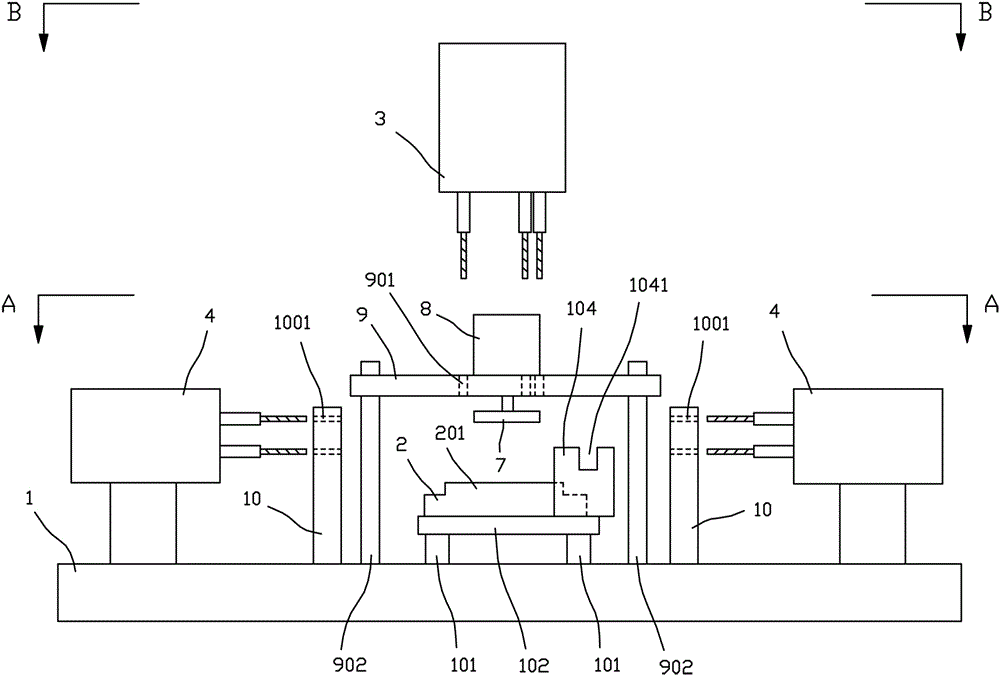

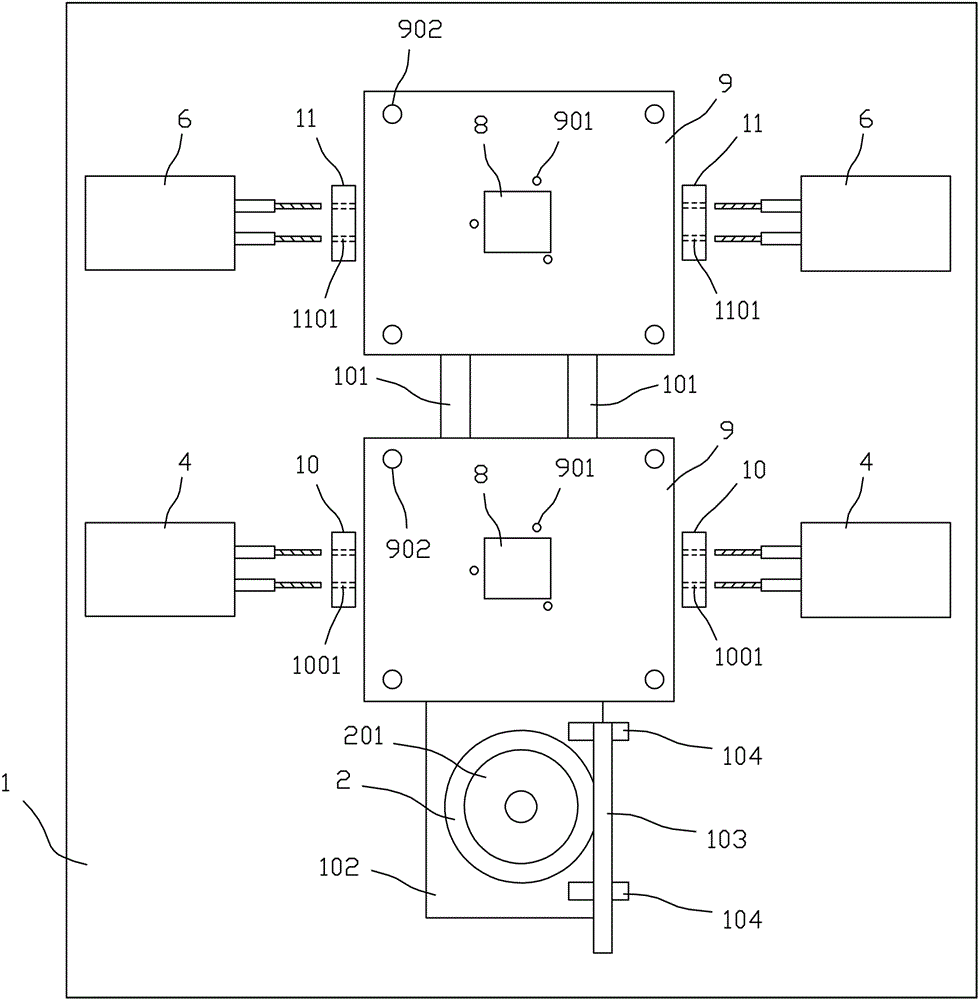

Tapping device for punching chassis

InactiveCN104070362AReduce processing stepsShort processing timeDrilling/boring measurement devicesWork clamping meansPunchingScrew thread

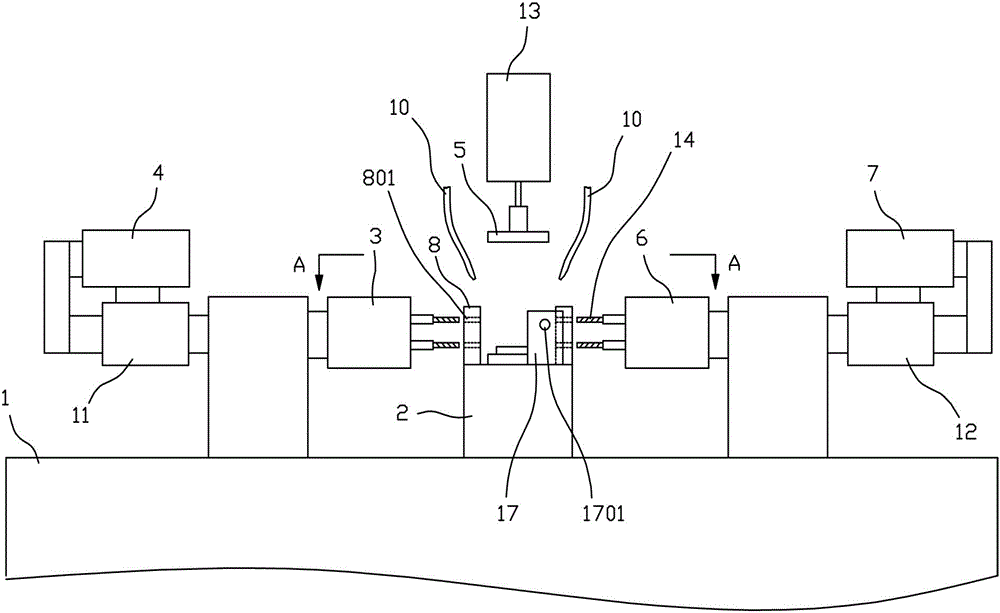

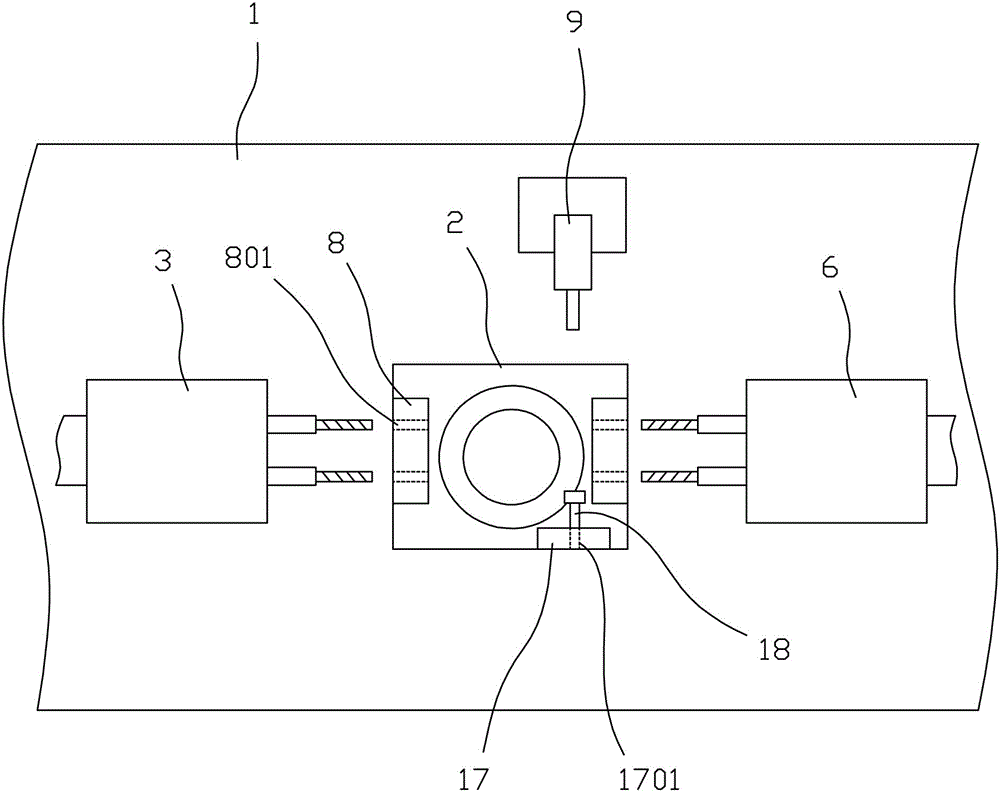

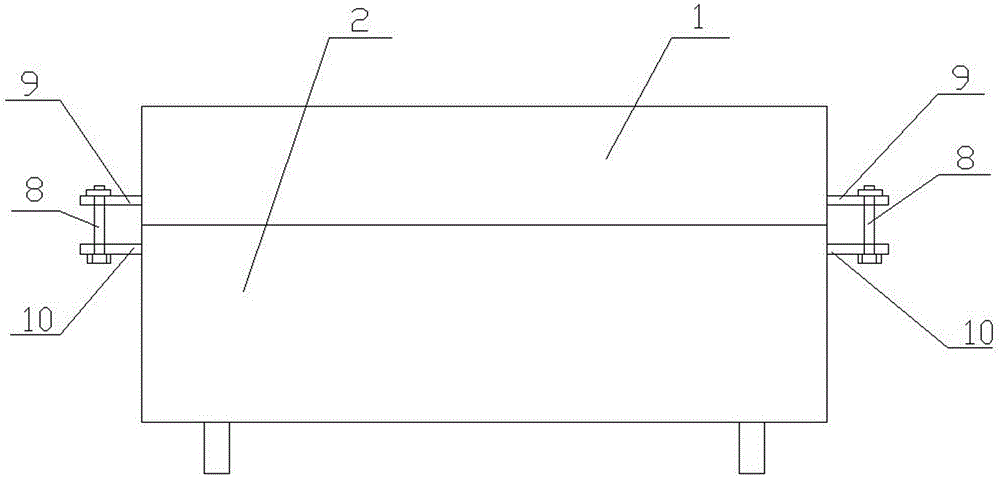

The invention discloses a tapping device for punching a chassis. The tapping device comprises a horizontally arranged workbench, a pedestal which can linearly move to and fro and is arranged on the workbench for holding the chassis, and a punching assembly and a tapping assembly sequentially arranged along the moving direction of the pedestal, wherein the punching assembly can be used for simultaneously punching in the left side, right side and bottom surface of the chassis; the tapping assembly can be used for simultaneously tapping on the left side, right side and bottom surface of the chassis. According to the tapping device for punching the chassis, the machining efficiency of thread holes in the chassis is high.

Owner:NINGBO LIONBALL VENTILATOR

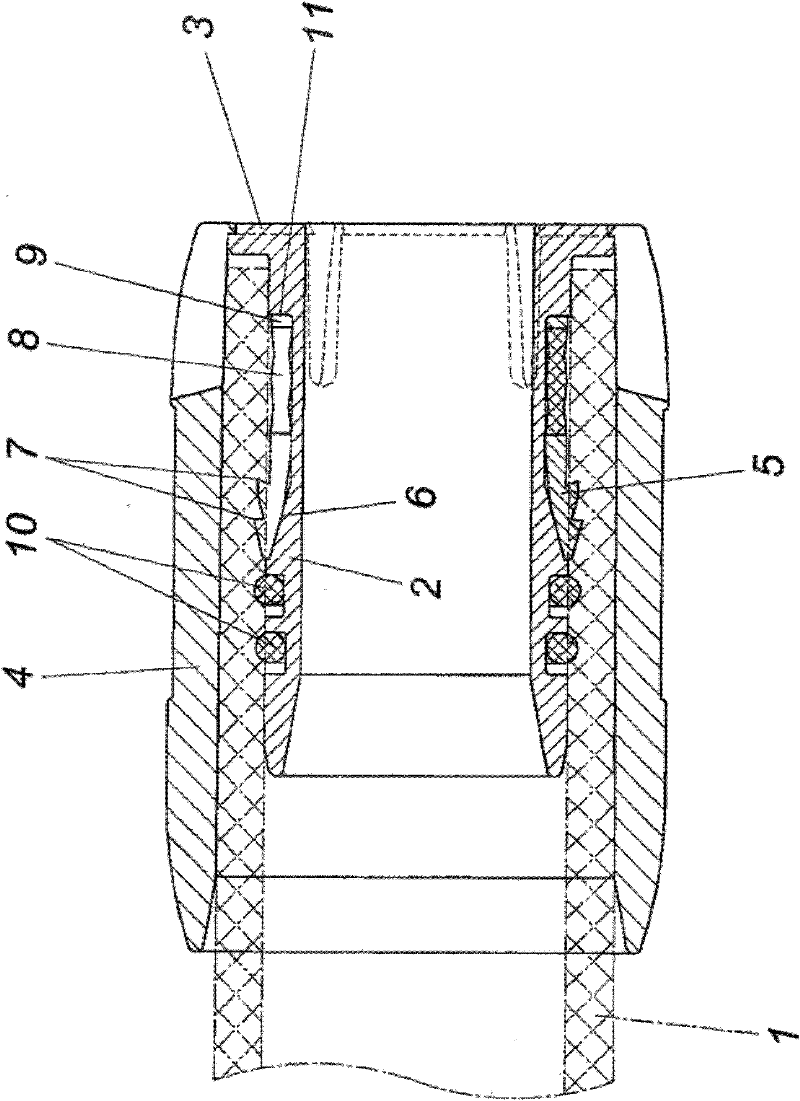

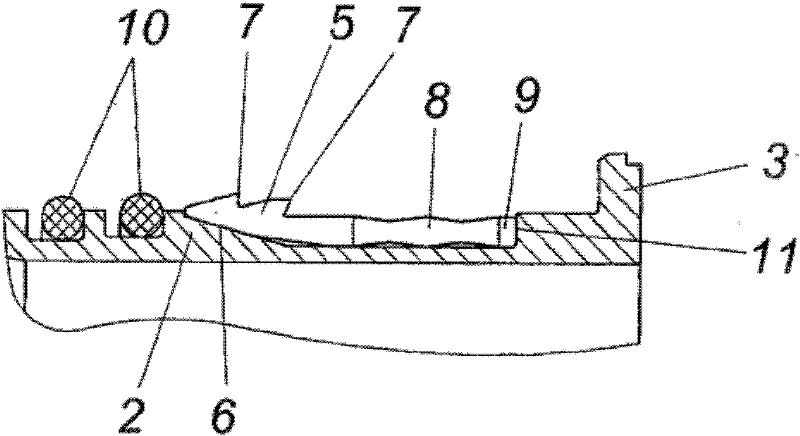

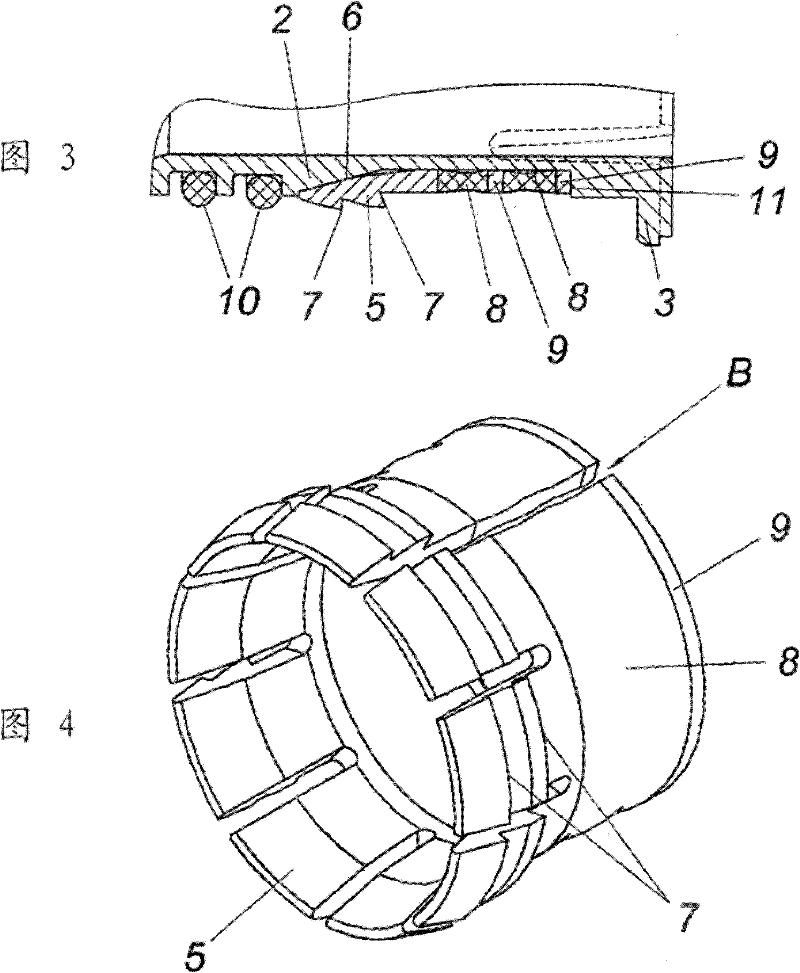

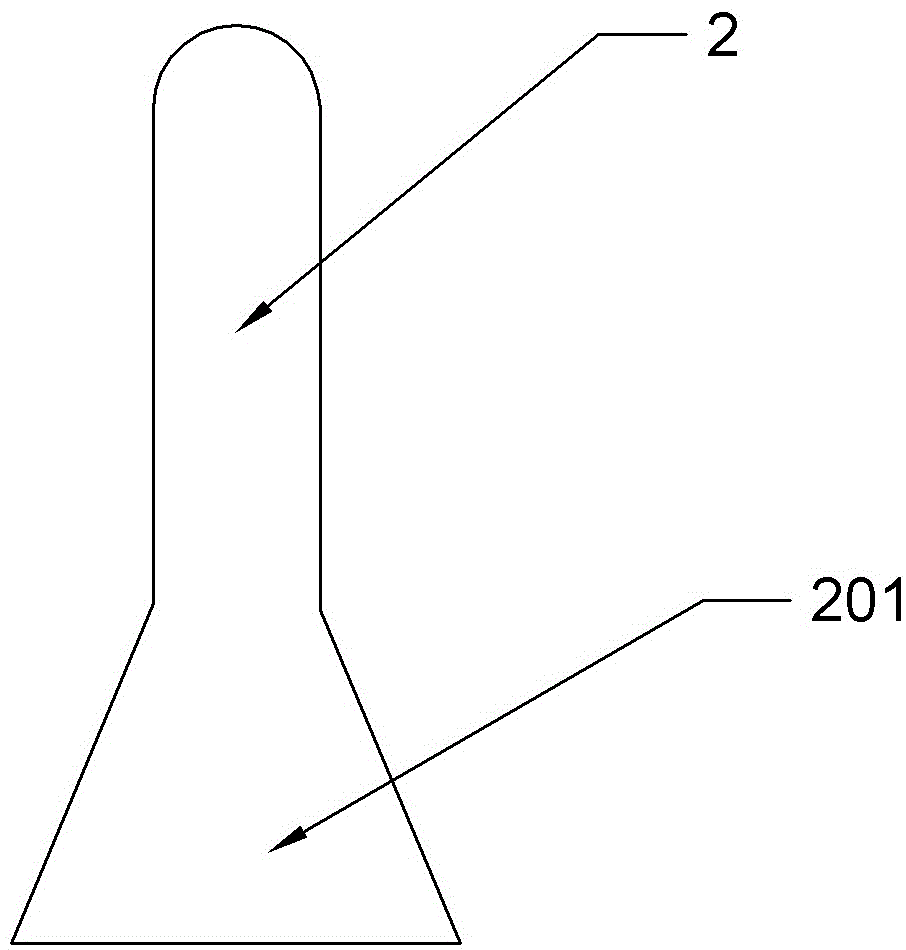

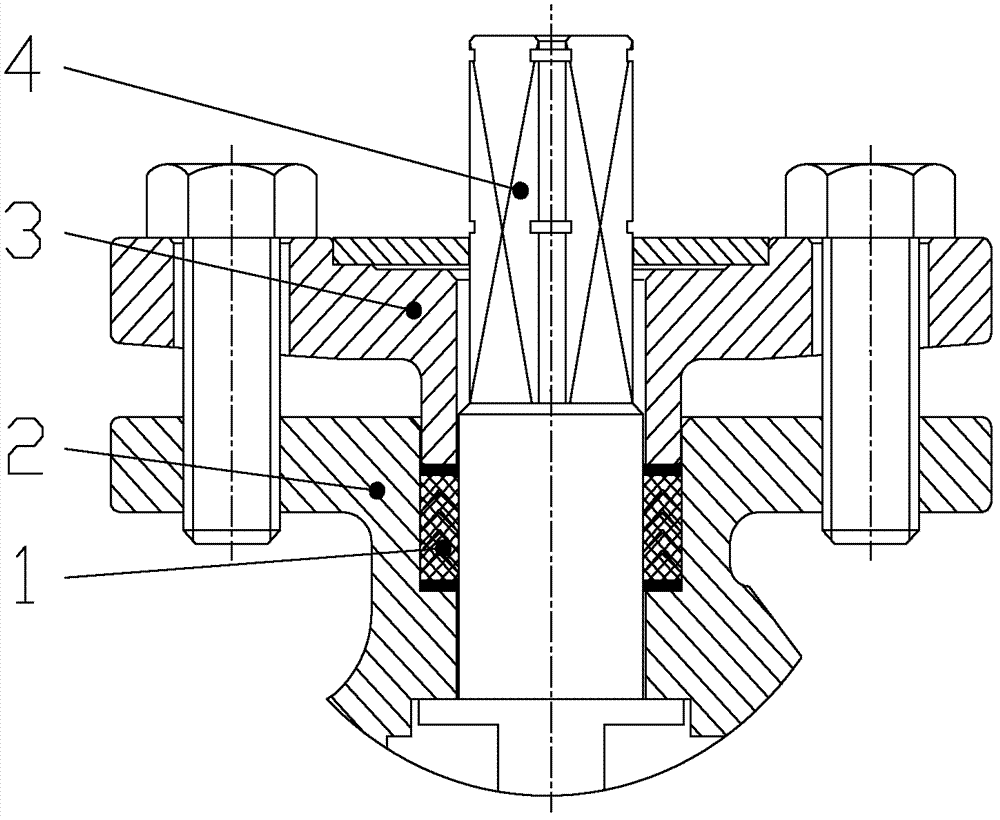

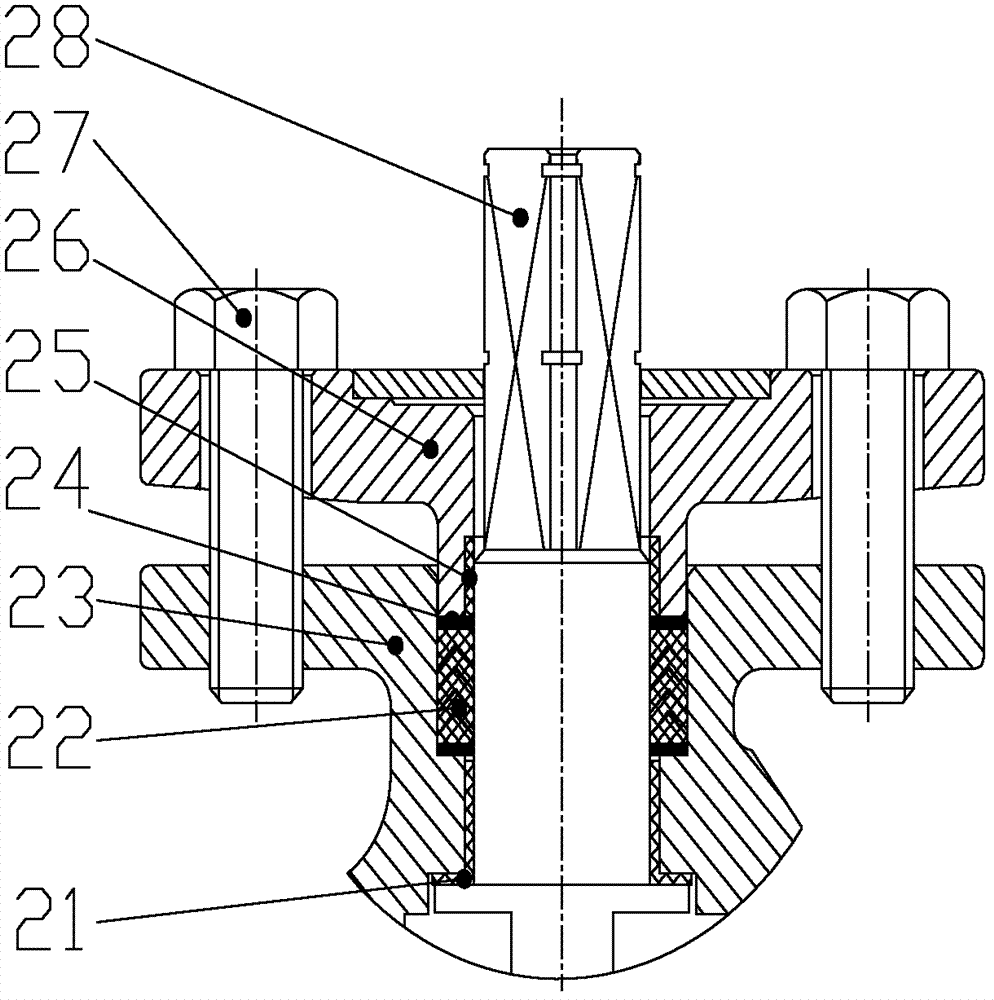

Connection device for a plastic tube

ActiveCN102472422AReduced clamping tendencyEasy to installCouplingsHose connectionsEngineeringAbutment

The invention relates to a connection device for a plastic tube (1), comprising a connection nipple (2) that receives the plastic tube (1) and forms an outer cone (6) widening towards the free nipple end. An expansion ring (5) that can be slid over the outer cone (6) and comprises outwardly protruding retaining claws (7) is provided between the outer cone and an axial abutment (11), said expansion ring being supported on the axial abutment (11) of the connection nipple (2) by means of a supporting ring (9). Said device also comprises a sleeve (4) surrounding the plastic tube (1) that has been pushed onto the connection nipple (3) and gripping in a traction-resistant manner onto an abutment flange (3) of the connection nipple. In order to create advantageous assembly conditions, a rubber-elastic spring ring (8) is arranged between the expansion ring (5) and the supporting ring (9). The expansion ring (5), the supporting ring (10) and the spring ring (8) are interconnected in a shear-resistant manner.

Owner:KE KELIT KUNSTSTOFFWERK GMBH

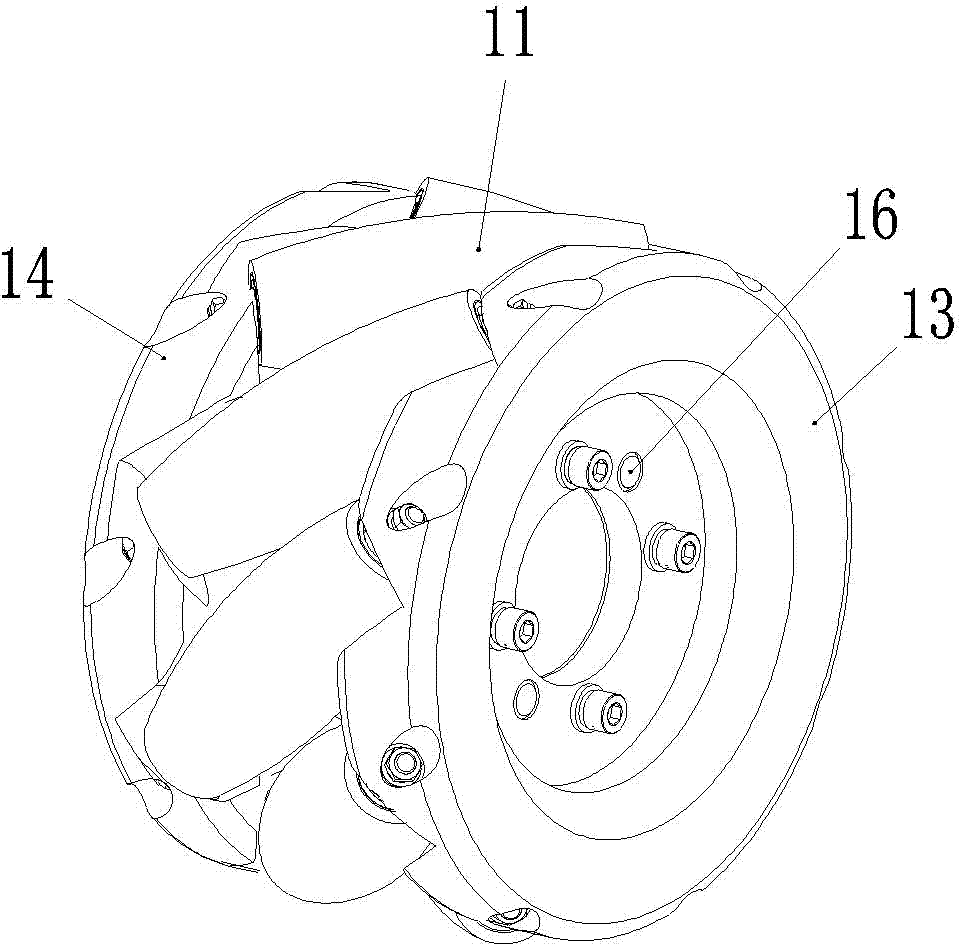

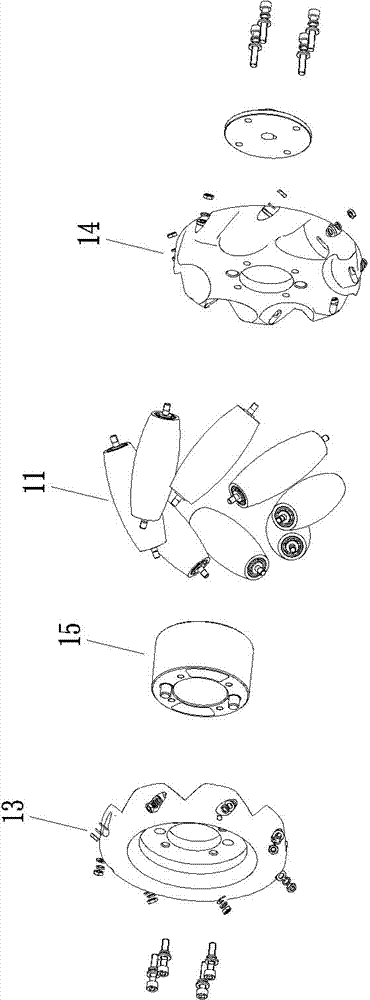

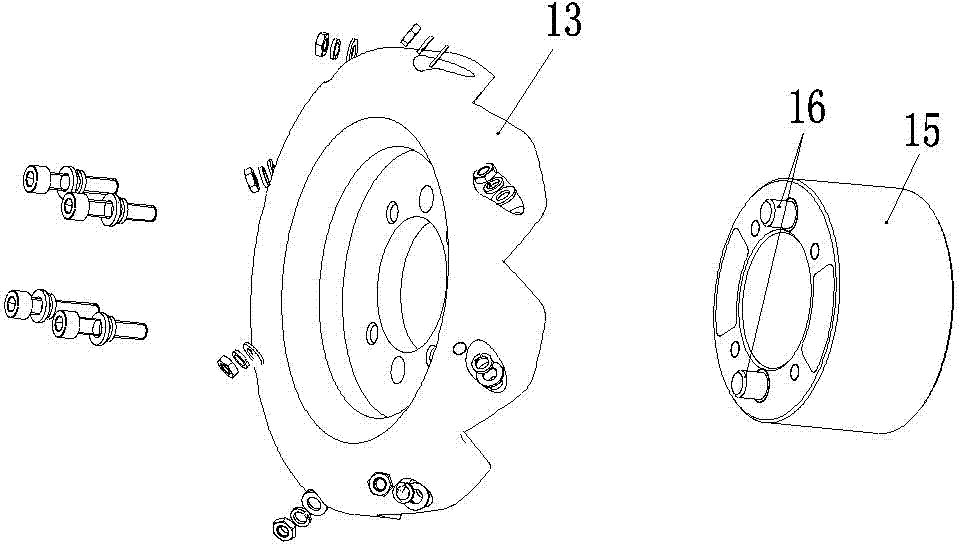

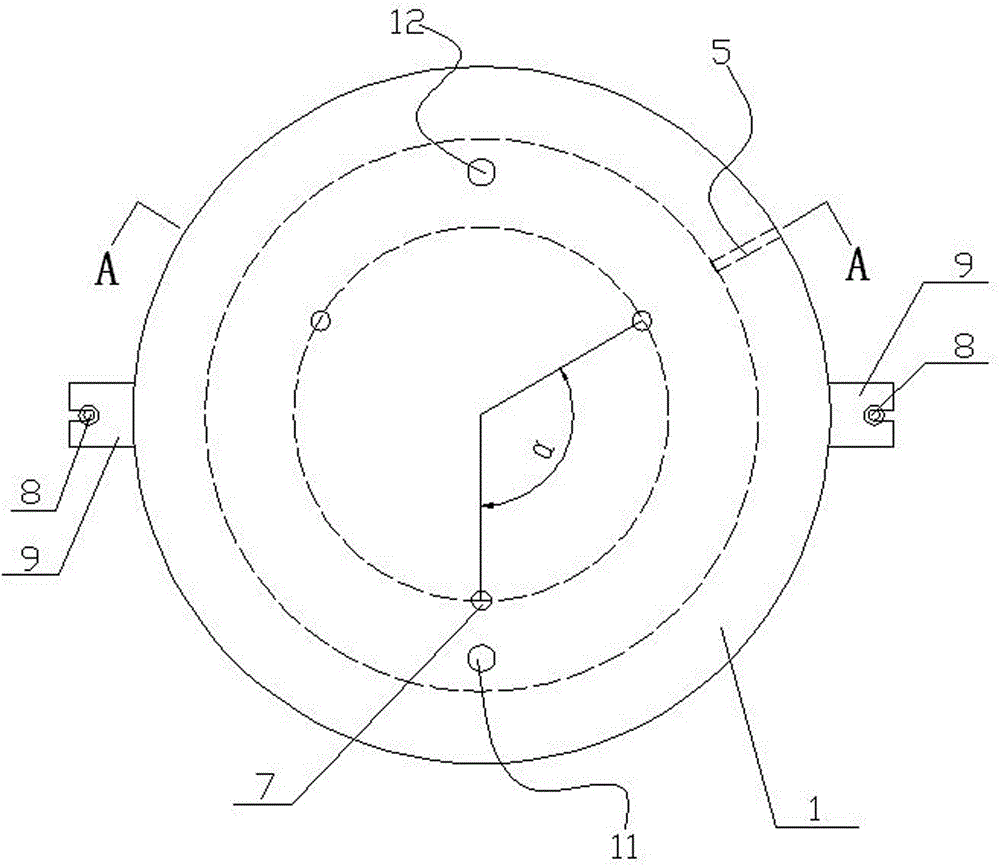

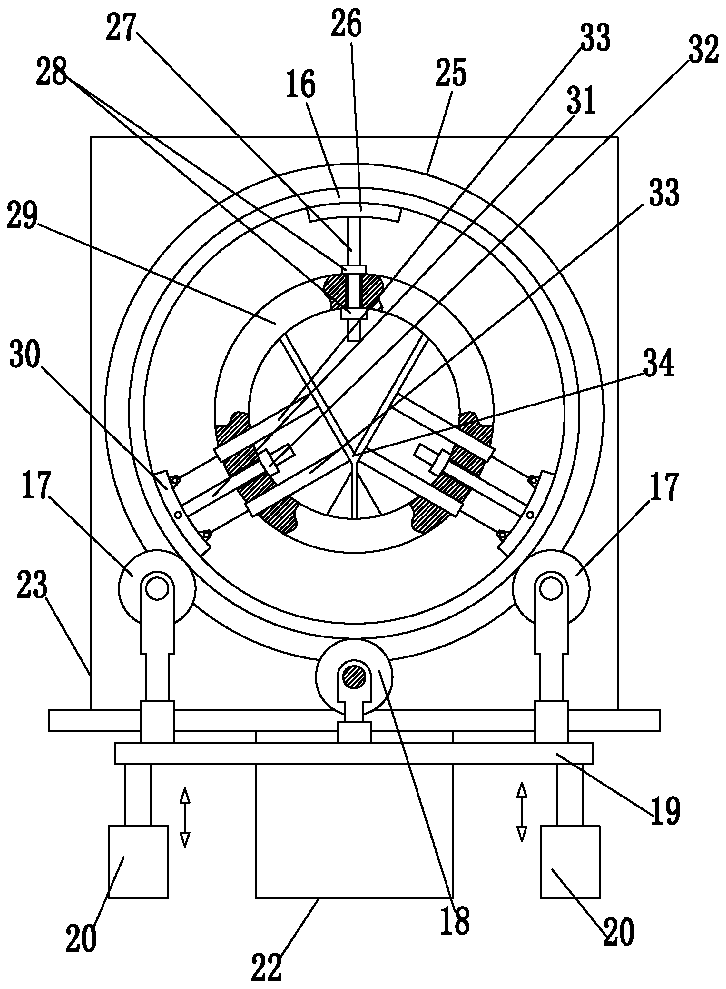

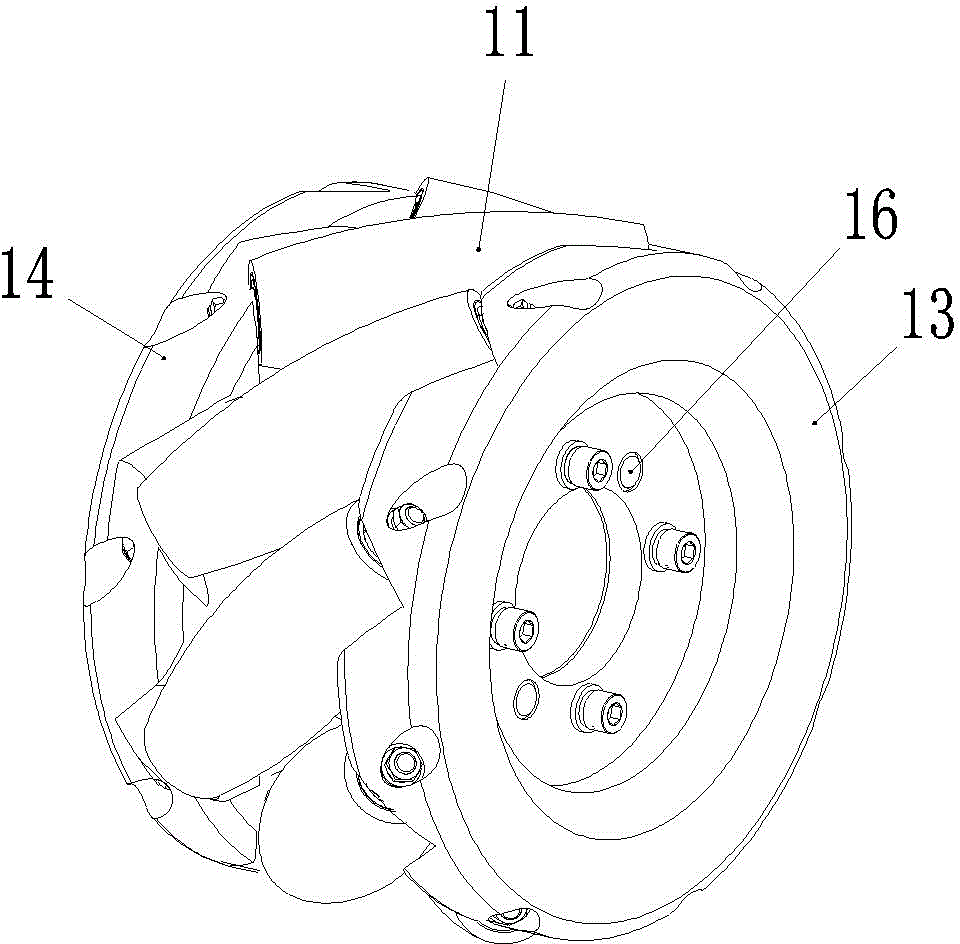

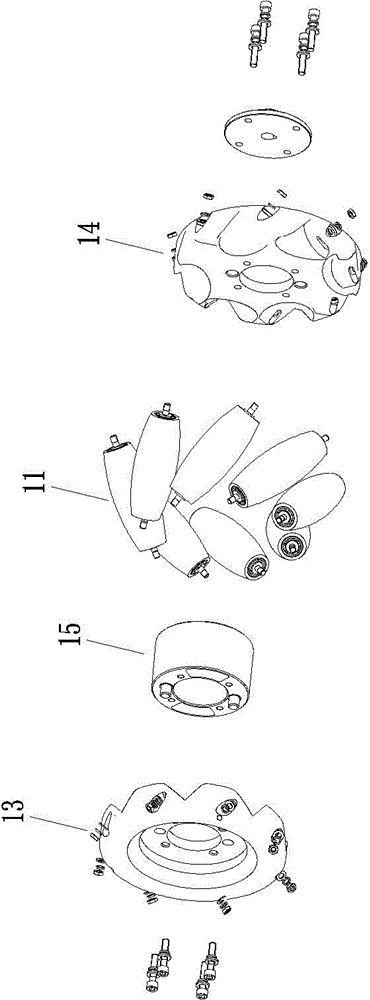

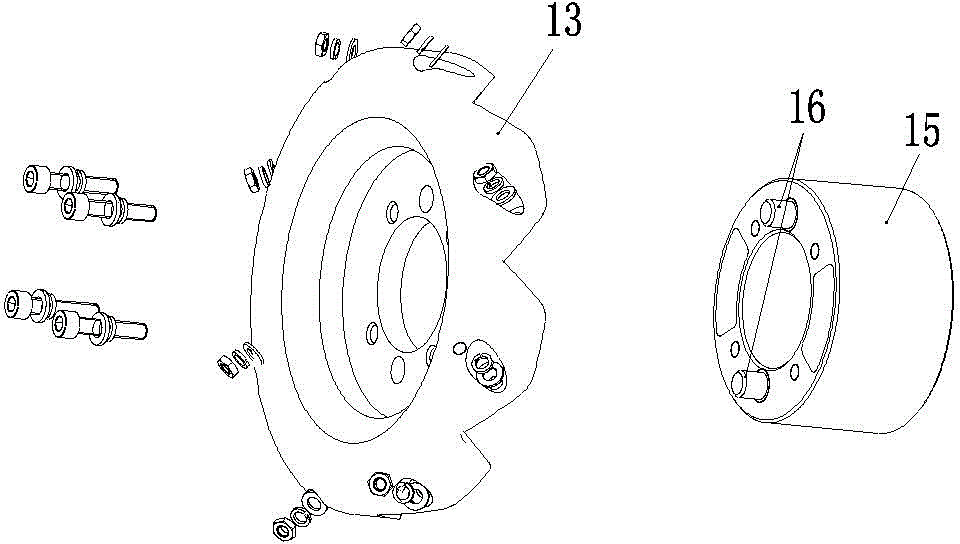

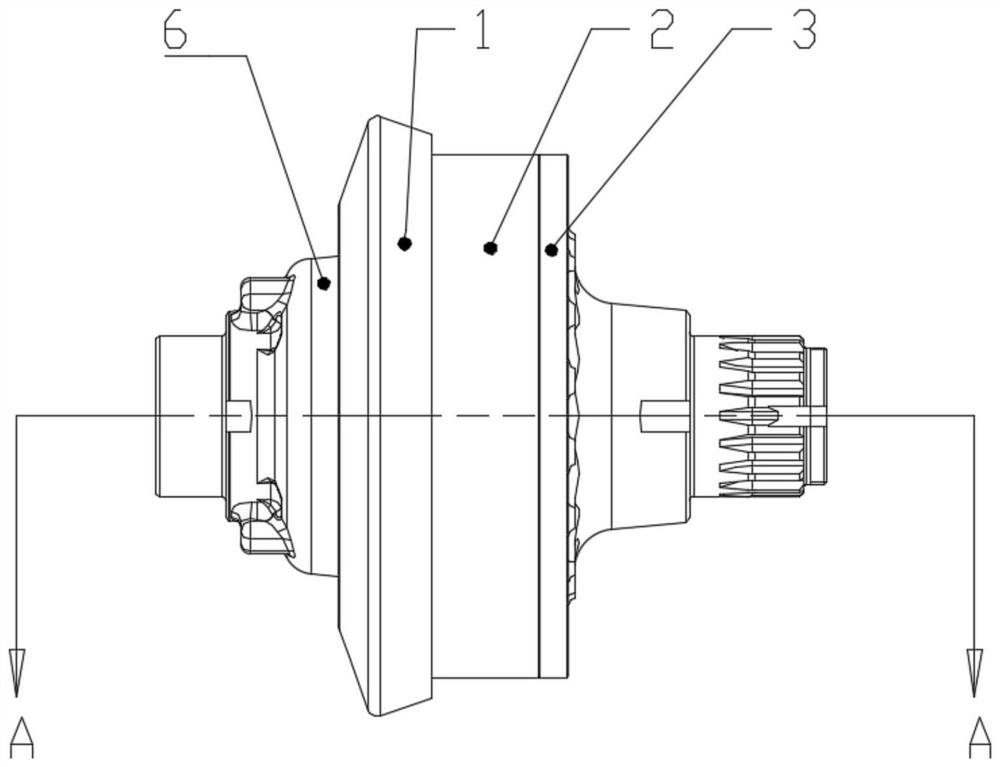

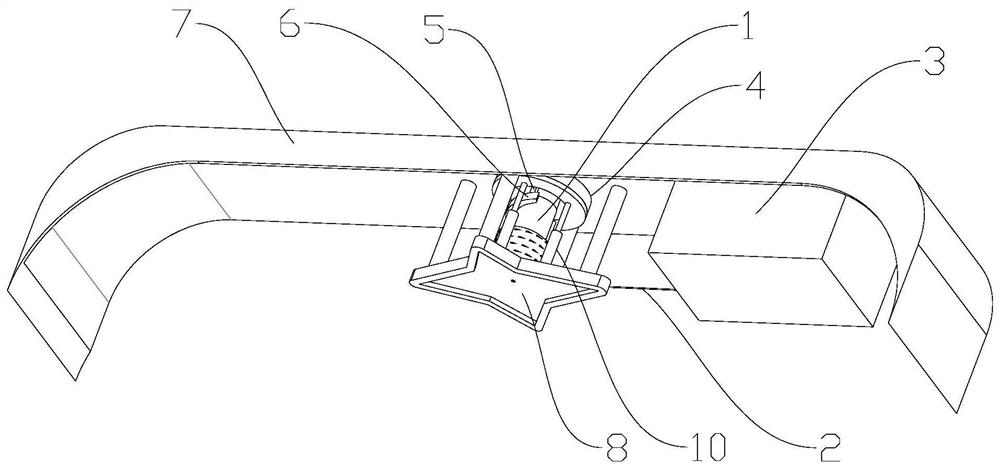

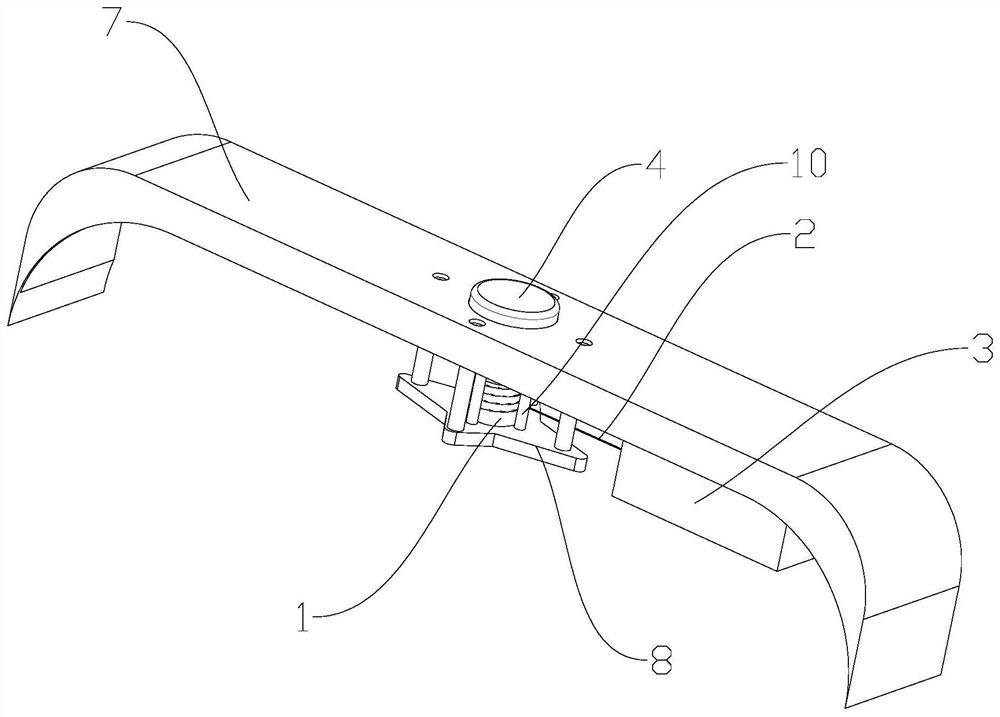

All-dimensional wheel and all-dimensional mobile platform using same

ActiveCN102896971ASolve the strength problemSolve the problem of failureWheelsScrew threadEngineering

The invention relates to the field of movement mechanism, in particular to an all-dimensional wheel and an all-dimensional mobile platform using the same. The all-dimensional wheel comprises a hub and an integral roller assembled on the hub through a roller shaft, two ends of the roller shaft protrude out of corresponding rollers, external threads are arranged on portions protruding out of the rollers, the hub comprises a left support rotation disc, a right support rotation disc and a shaft sleeve, the left support rotation disc and the right support rotation disc are relatively arranged, the shaft sleeve is coaxially connected between the left support rotation disc and the right support rotation disc, one end of the roller shaft is inserted in an installation hole arranged on the left support rotation disc and fixed through a nut, the right support rotation disc is close to the shaft sleeve and is detachably and fixedly connected with the shaft sleeve when the roller shaft is fixed on the left support rotation disc, an abdicating hole which abdicates for the roller shaft relative to movement of the right support rotation disc in a process that the right support rotation disc is close to the shaft sleeve from right to left is arranged on the right support rotation disc, one end of the roller shaft far away from the left support rotation disc is inserted in the corresponding abdicating hole and fixed through a nut, and a problem that the all-dimensional wheel is poor in strength and prone to lose efficiency is solved.

Owner:凯迈(洛阳)测控有限公司

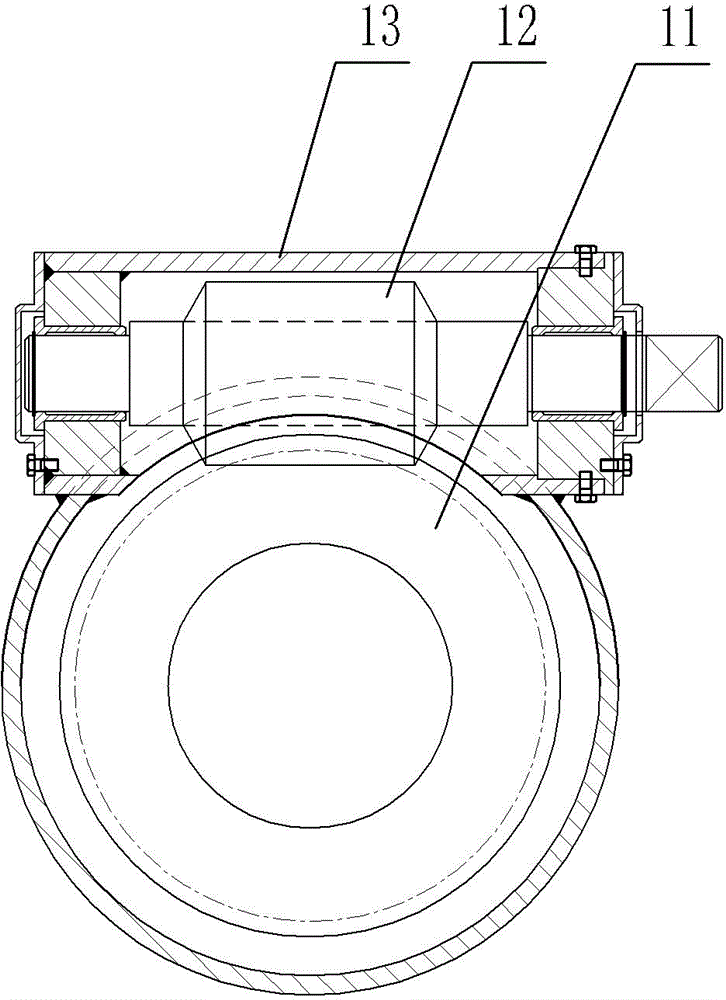

Bearing assembling tool for mounting bearing in shaft sleeve part

InactiveCN104139289ASolve the problem of easy collapse and flying bearingsGuaranteed alignmentMetal working apparatusMechanical engineeringExtrusion

Owner:STATE GRID CORP OF CHINA +1

Housing drill

InactiveCN103949690AGuaranteed machining accuracyGuaranteed coaxialityDrilling/boring measurement devicesLarge fixed membersDrill holeDrill bit

The invention discloses a housing drill, which comprises a working table, a base for the placement of a housing is arranged on the working table, a first drilling head module, a first motor for driving the first drilling head module to act and a first feeder for driving the first drilling head module to move are arranged on one side of the base, a positioning mechanism which is used for positioning the housing when the housing is placed on the base is arranged on the base, a holddown for pressing the housing on the base and a driver for driving the holddown to move up and down are arranged over the base, a second drilling head module, a second motor for driving the second drilling head module to act and a second feeder for driving the second drilling head module to move are arranged on the other side of the base, both the first drilling head module and the second drilling head module are multi-spindle drilling heads, and drill bits on the first drilling head module and the second drilling head module are correspondingly and coaxially arranged. The housing drill can effectively ensure the coaxiality between the mounting holes of both sides of the housing.

Owner:NINGBO LIONBALL VENTILATOR

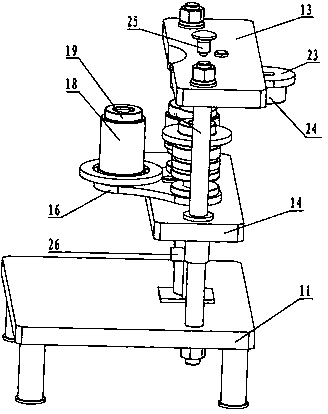

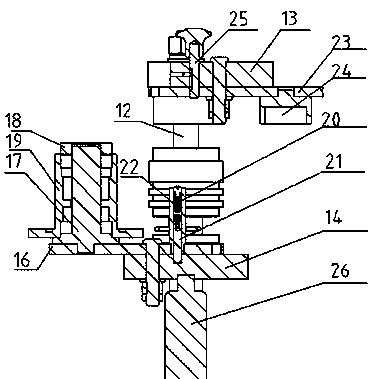

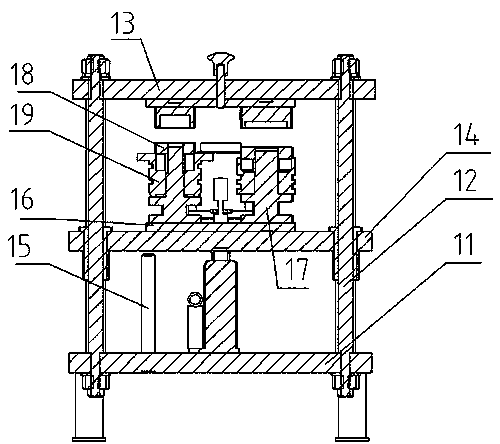

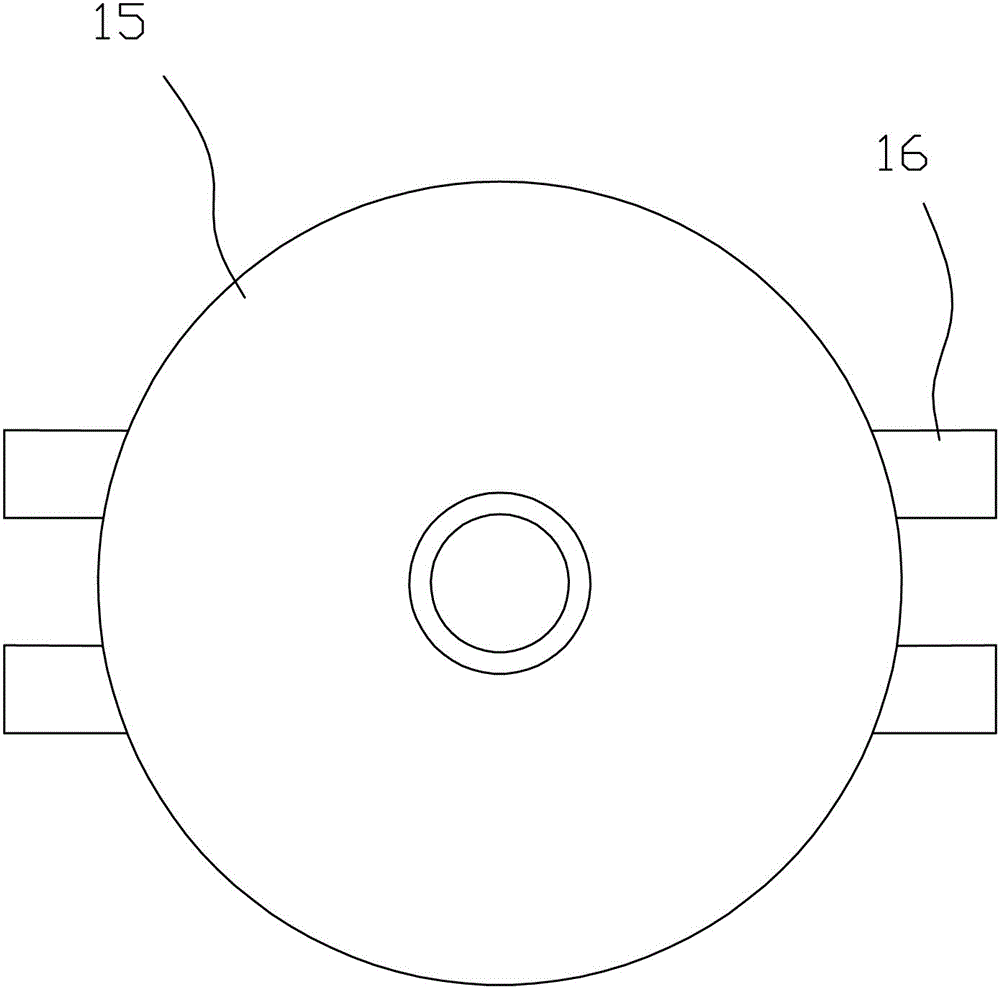

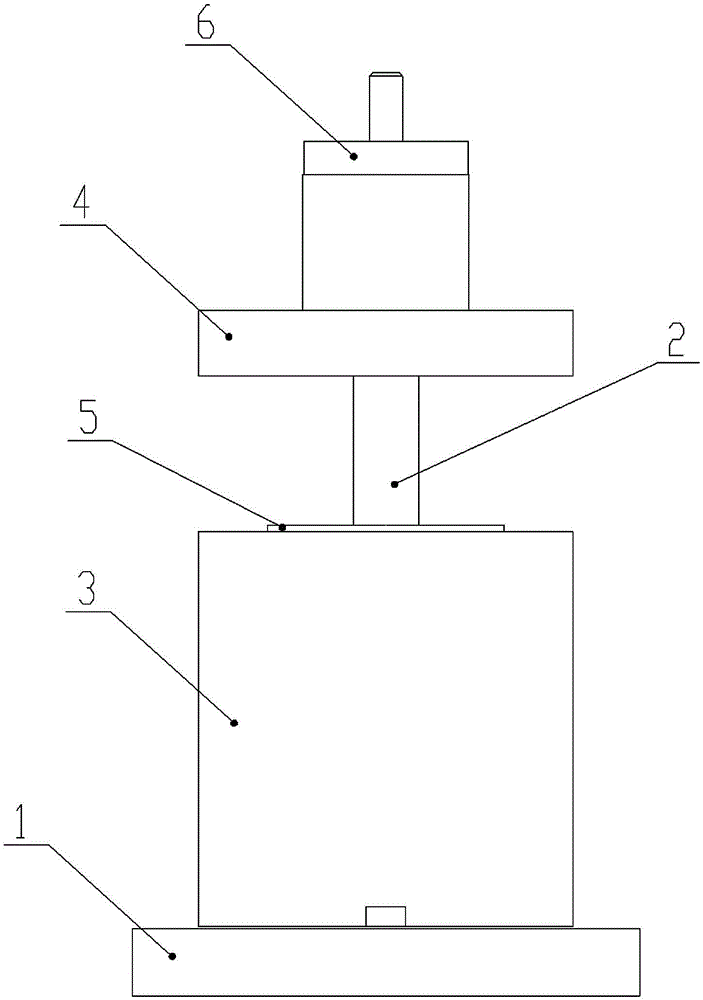

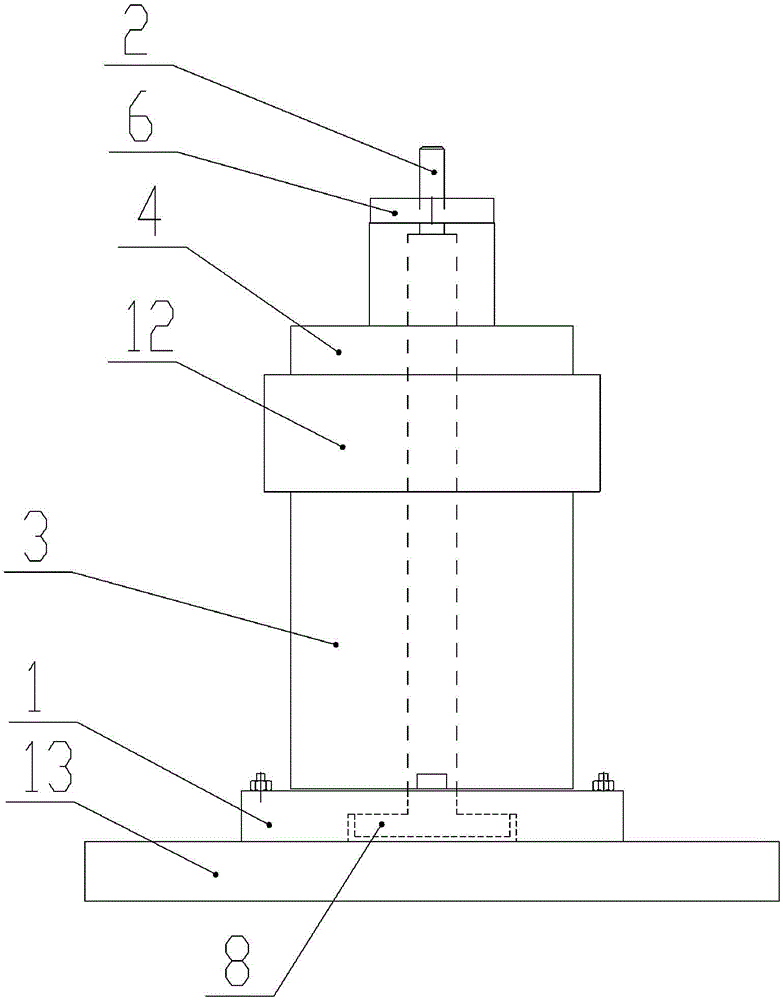

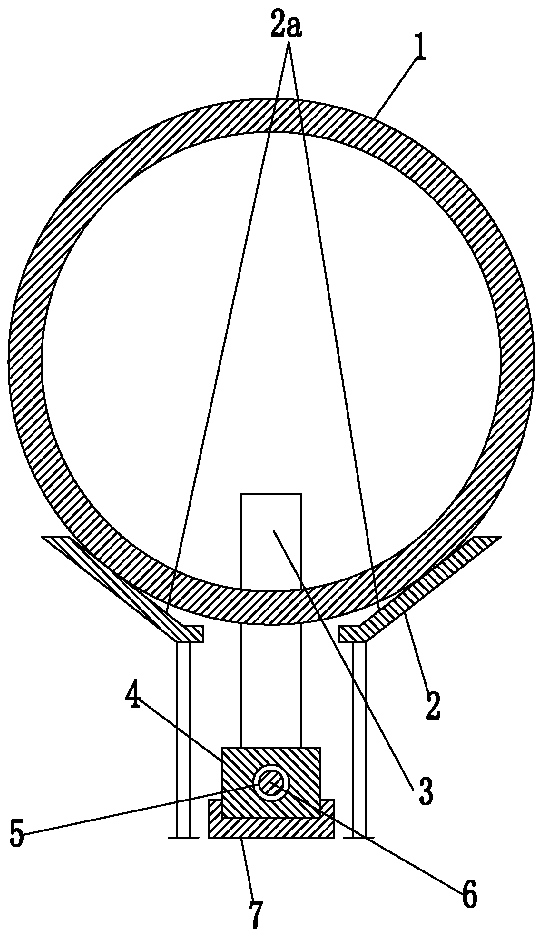

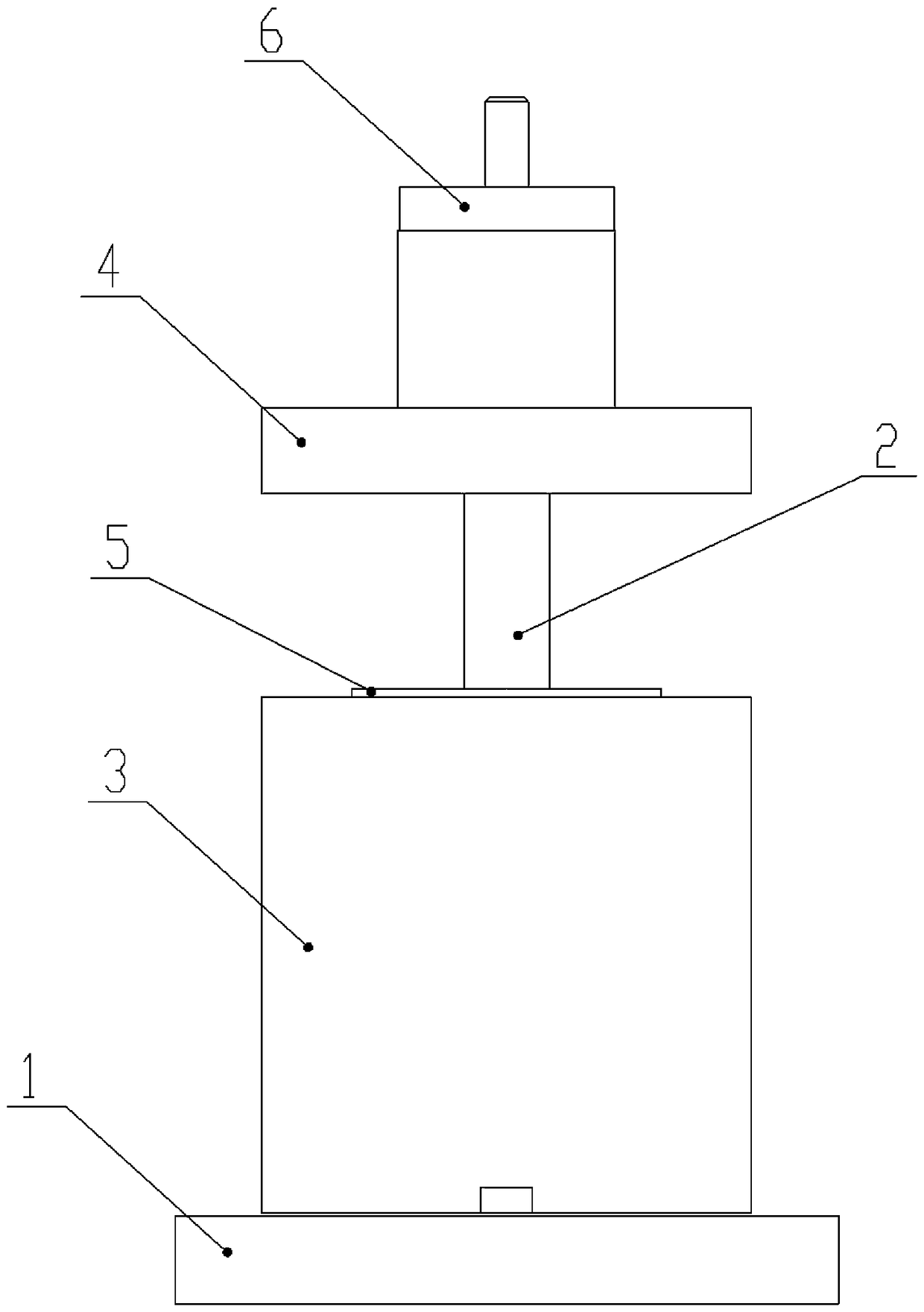

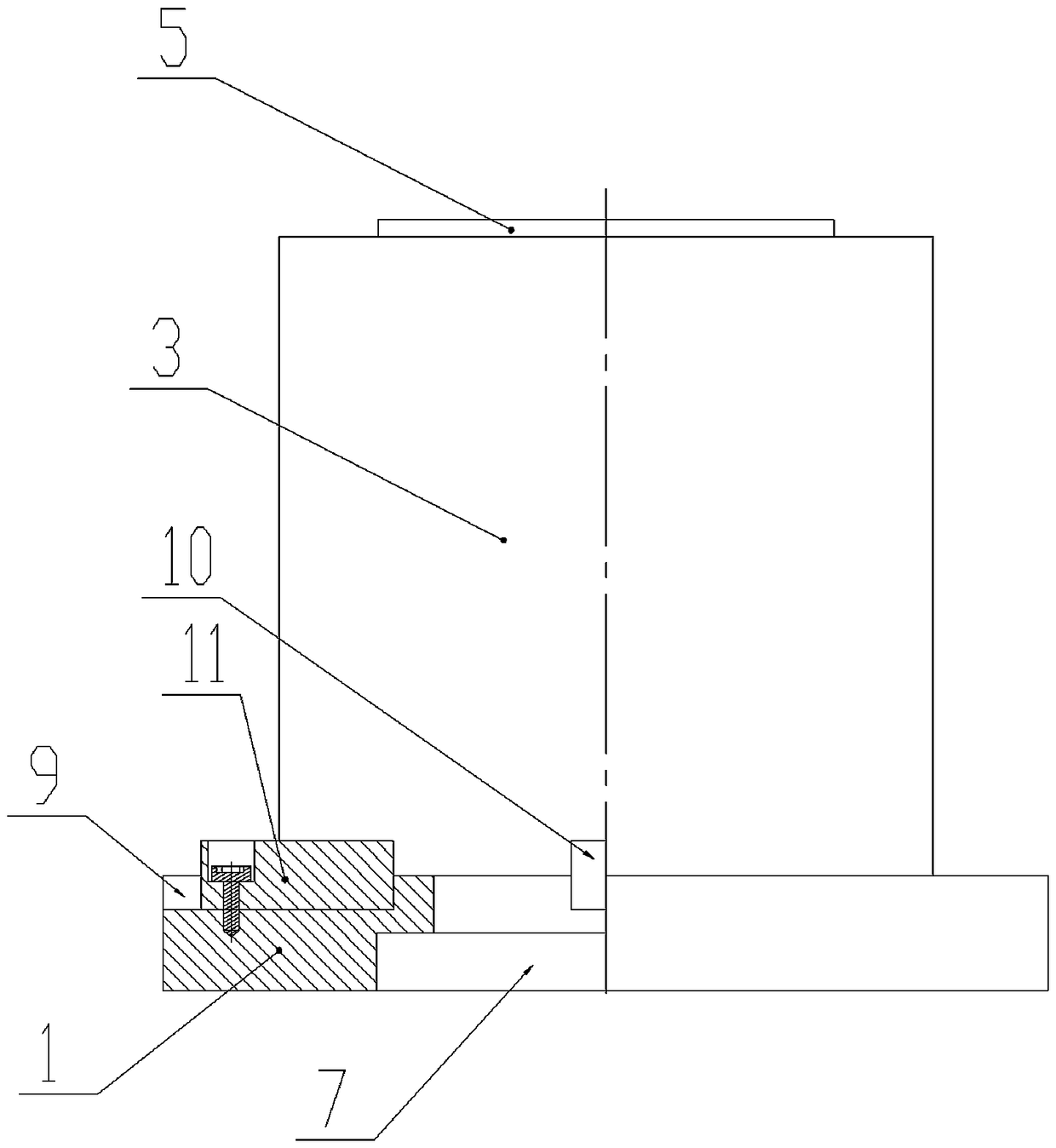

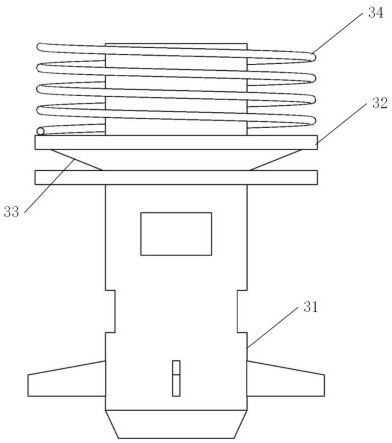

Pressing tool for large gear hob

ActiveCN105269084APrevent rotationStable supportGear-cutting machinesGear teethEngineeringScrew thread

The invention relates to a pressing tool for a large gear hob. The pressing tool comprises a base, wherein a center shaft which extends vertically upward is fixedly arranged on the base, the lower end of the center shaft is movably sleeved with a support sleeve, the upper end of the center shaft is movably sleeved with a press block, a space interval for instilling a workpiece is reserved between the support sleeve and the press block, the lower end of the support sleeve is fixed with the periphery of the base, a locating seam allowance which is used for centering the workpiece is arranged at the upper end of the support sleeve, a hydraulic nut is connected to an axial section, above the press block, of the center shaft through threads, and the hydraulic nut presses the press block. The pressing tool for the large gear hob is suitable for pressing the workpiece when the operation space is small and the hob is effectively and heavily cut, and enough clamping pressing force and clamping efficiency can be effectively guaranteed.

Owner:CHONGQING WANGJIANG IND

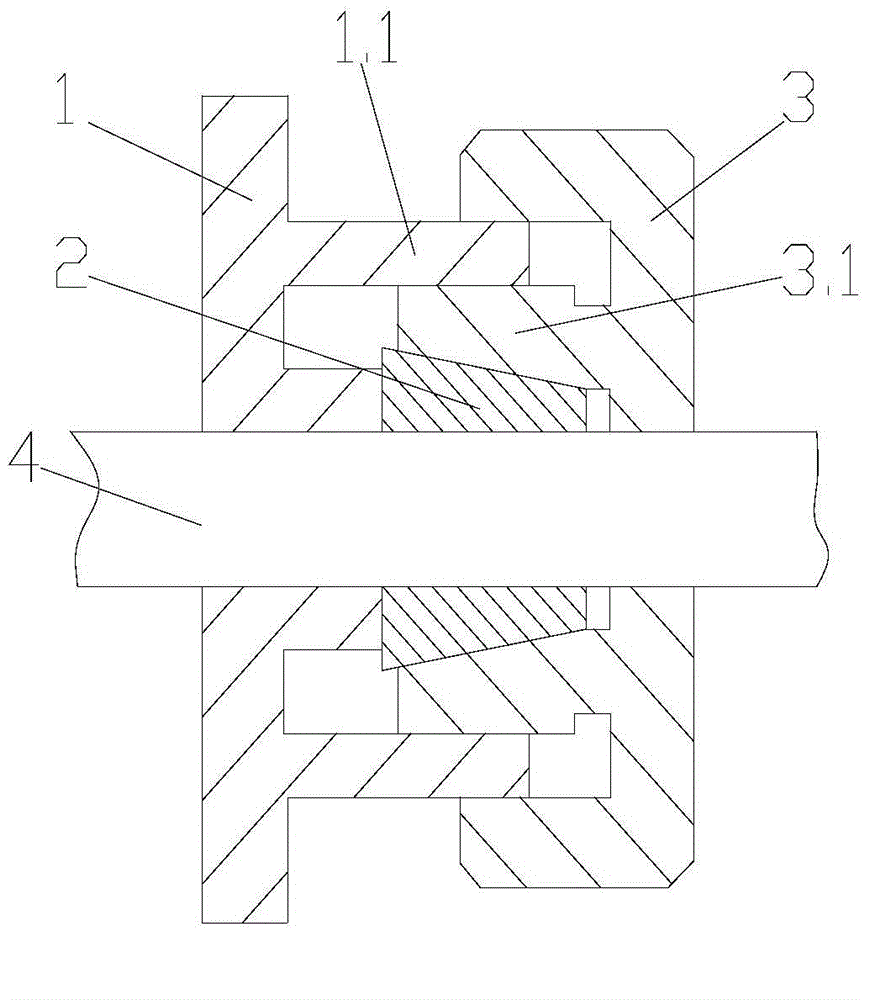

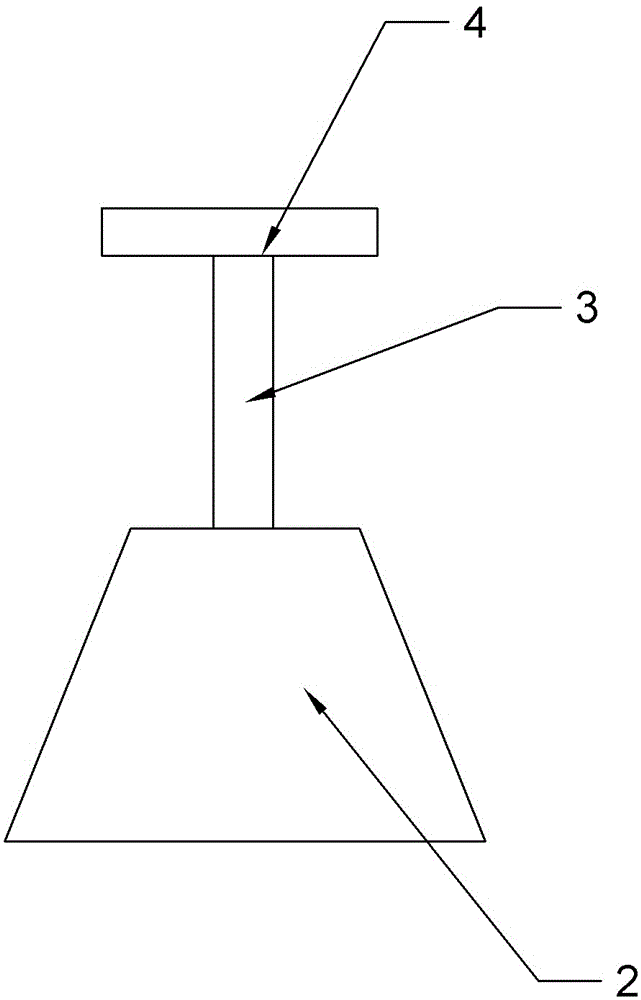

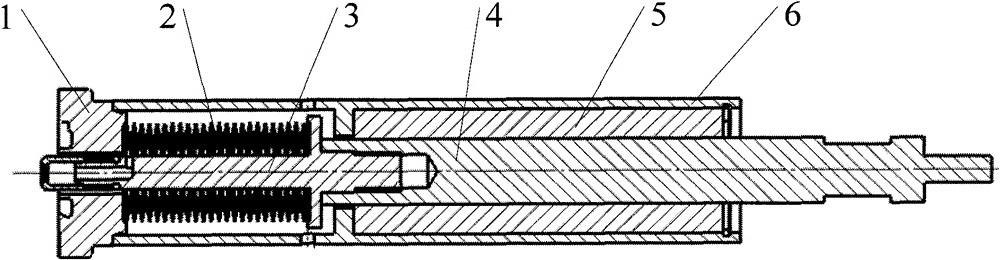

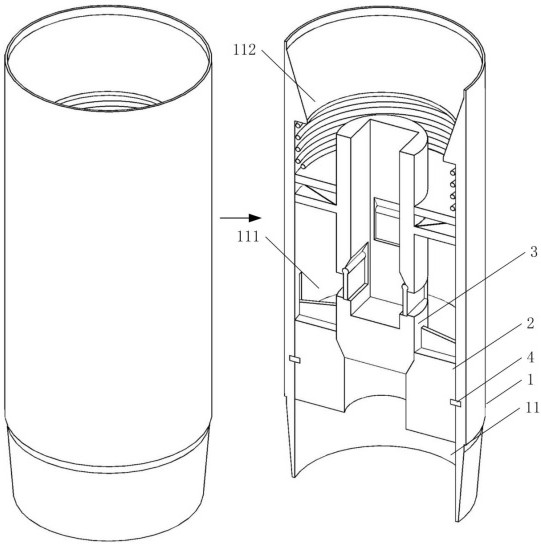

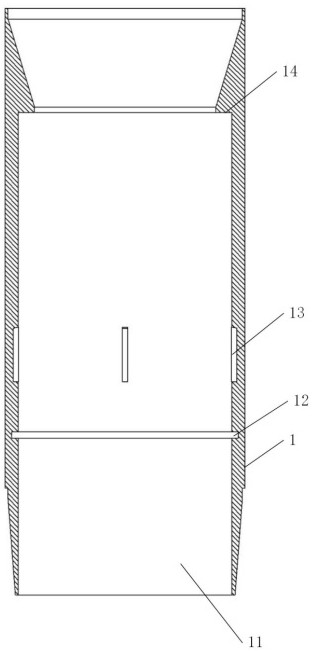

Quick locking and positioning mechanism for axis parts

InactiveCN104454877AEven by forcePrevent radial offsetFastening meansConvex structureLocking mechanism

The invention relates to the technical field of locking mechanisms, in particular to a quick locking and positioning mechanism for axis parts. The quick locking and positioning mechanism for axis parts comprises a shaft sleeve, a conical elastic sleeve and a screw cap. The shaft sleeve is a step-type shaft sleeve, the small-diameter front end of the shaft sleeve is a tubular connecting part, the axis of the shaft sleeve is an axis hole, the elastic sleeve is arranged in the connecting part, the largest diameter of the elastic sleeve is smaller than the inner diameter of the connecting part, the small-diameter end of the elastic sleeve faces the opening side of the connecting part, the position where the shaft sleeve and the large-diameter rear end of the elastic sleeve are connected is of a convex structure, the screw cap is in thread fit with the outer circumferential face of the connecting part of the shaft sleeve, an extrusion connecting part matched with the elastic sleeve is arranged in an end cover, the inner circumferential face of the extrusion connecting part is a conical face matched with the conical face of the elastic sleeve, and the outer circumferential face of the extrusion connecting part is in thread fit with the inner circumferential face of the connecting part of the shaft sleeve. The mechanism can be locked and positioned to any position of a shaft, locking force is evenly distributed in the radial direction of the shaft, and the shaft is prevented from shifting in the radial direction.

Owner:CHANGZHOU CHANGOU METAL PROD

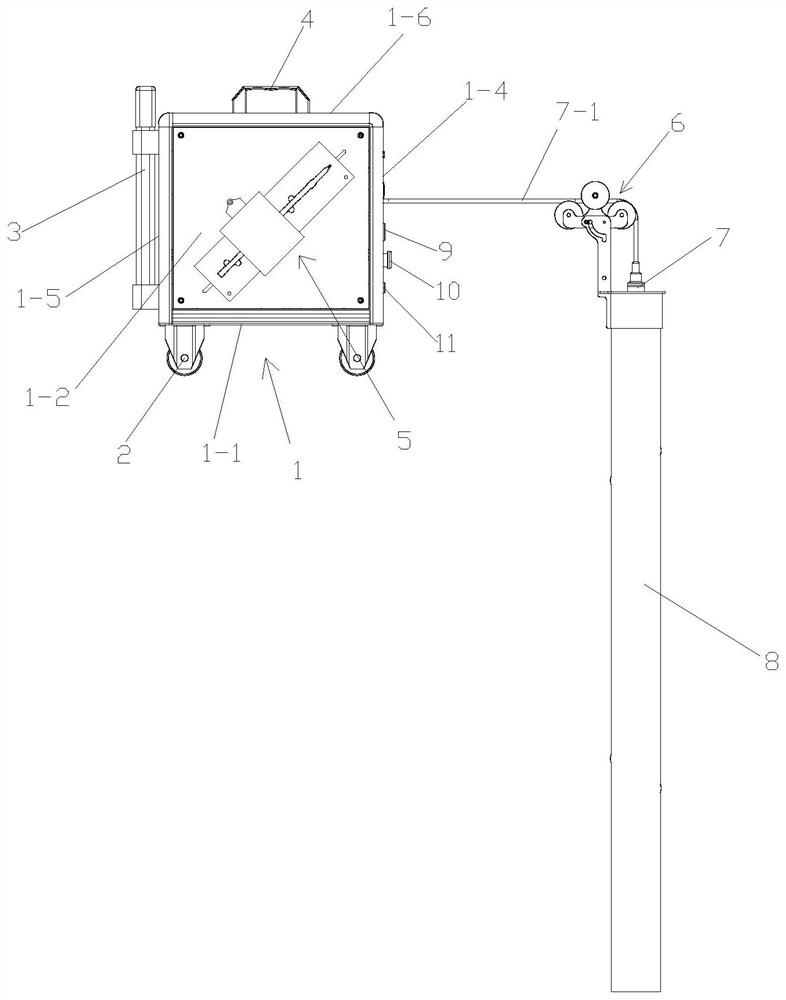

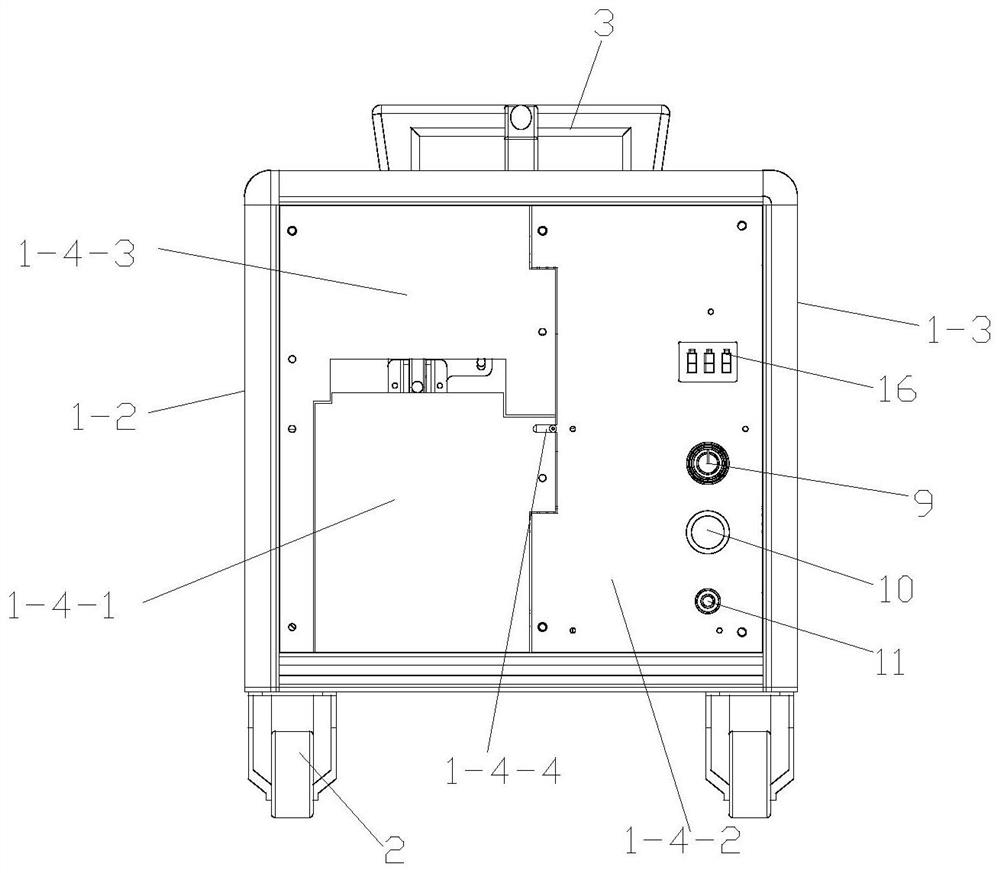

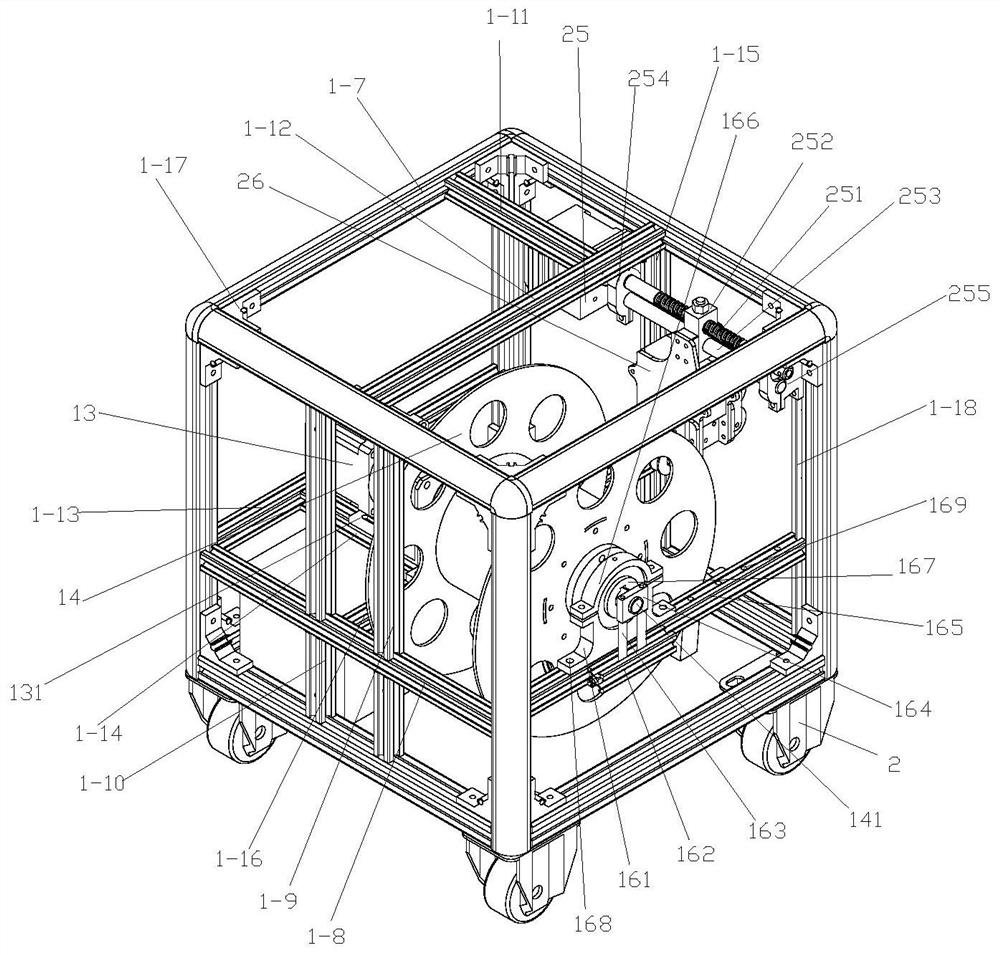

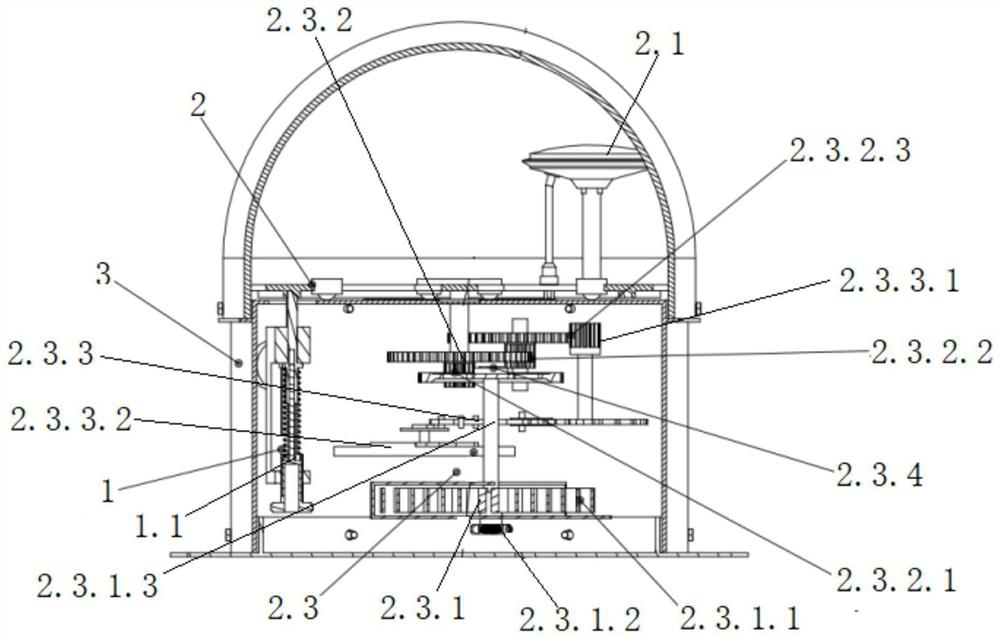

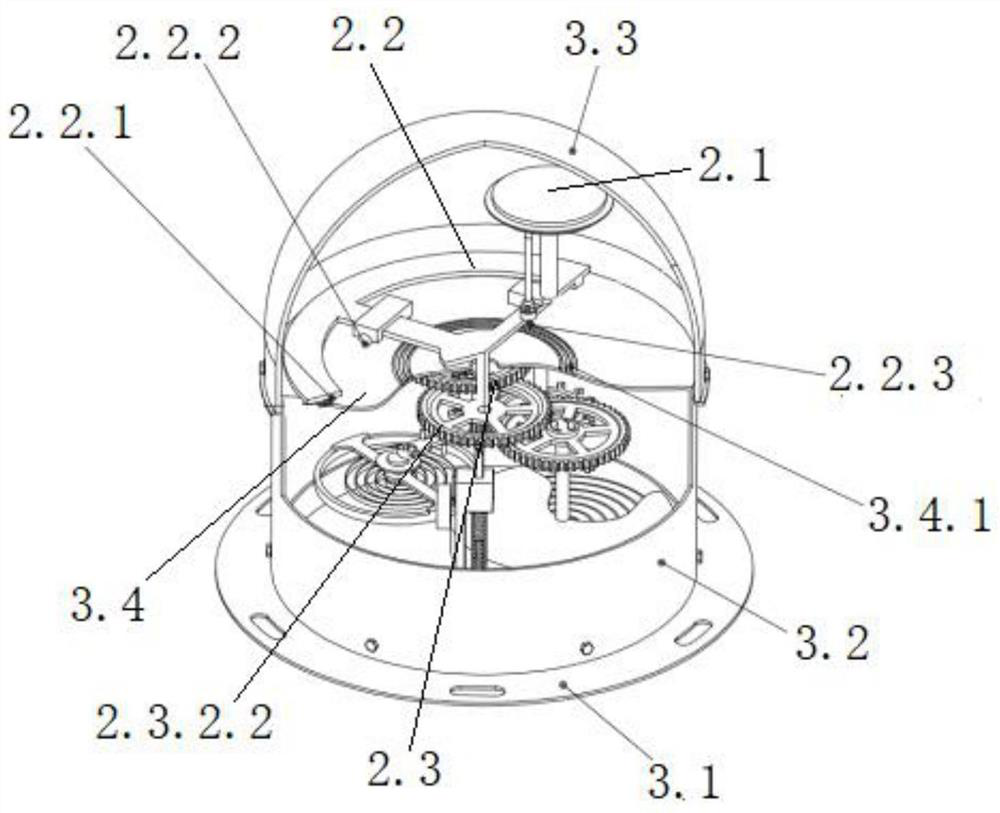

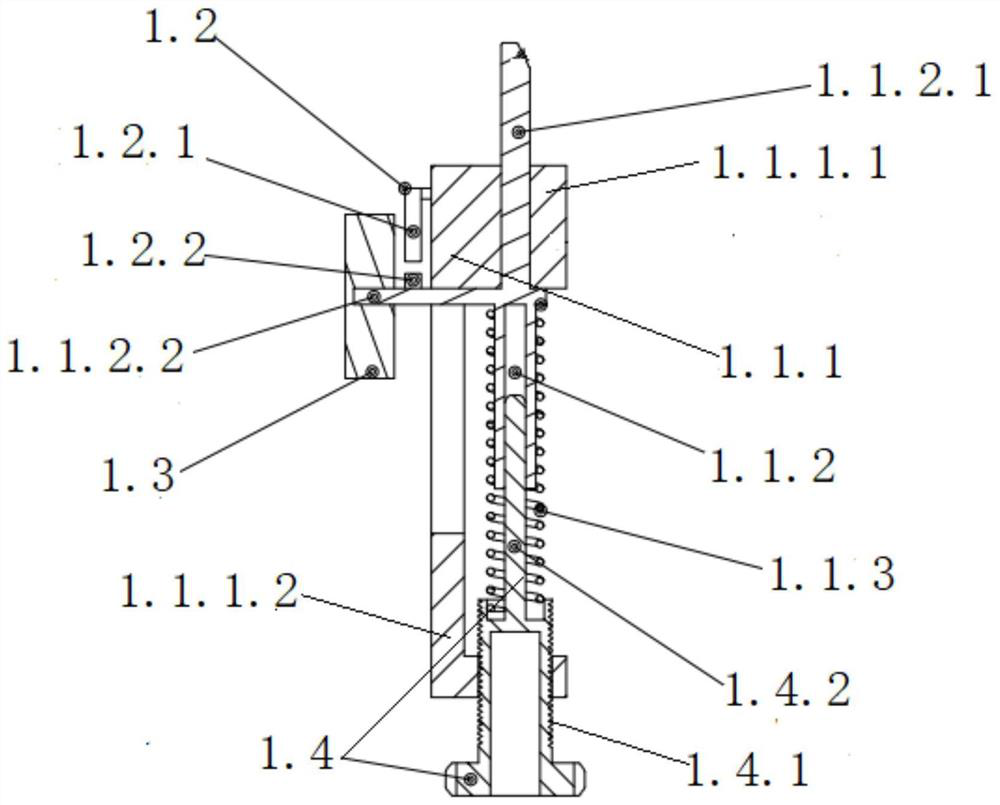

Full-automatic inclinometer and using method thereof

PendingCN111649722ASimple structureReasonable designUsing electrical meansElectric/magnetic depth measurementElectric machineryEngineering

The invention discloses a full-automatic inclinometer and a using method thereof. The inclinometer comprises an inclinometer device and an inclinometry probe. The inclinometer device comprises a box body, a winding mechanism, a positioning mechanism, a monitoring module and a walking mechanism. A containing mechanism and a protective cover mechanism are arranged on the box body. The winding mechanism comprises a reel mechanism, a reel motor and a limiting mechanism. The reel mechanism comprises a reel and a reel disc. The positioning mechanism comprises a reel mechanism and a sliding mechanism. The method comprises the following steps of: 1, installing a top limiting mechanism at a detection hole; 2, arranging a signal cable in a penetrating manner; 3, collecting inclinometry data; and 4,processing inclinometry data. The device is reasonable in design and low in cost, ensures that the measurement probe accurately reaches a measurement position, facilitates repeated monitoring at a specified position, is small in positioning error of the measurement probe, and improves the measurement accuracy; and in addition, the signal cable can be guided, and the signal cable is prevented frombeing wound and piled.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN +1

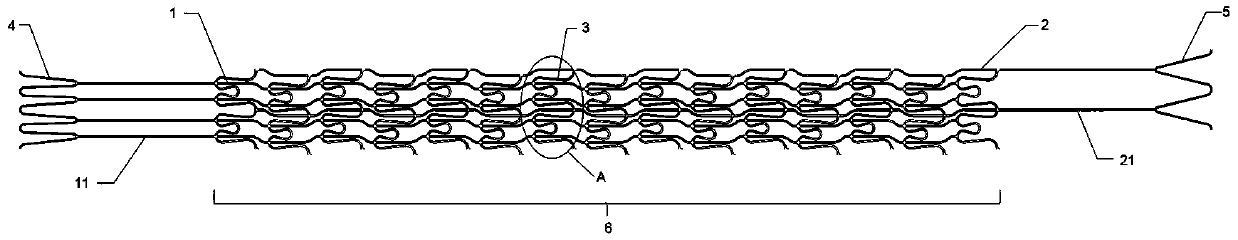

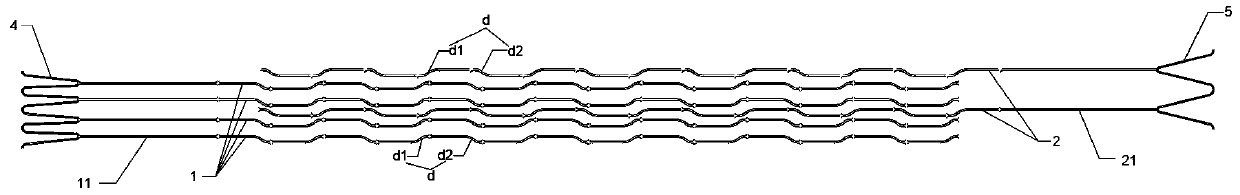

Distal and proximal asymmetric balloon restraint stent and high-stability balloon catheter with restraint stent

PendingCN110732077APrevent circumferentialPrevent radial offsetBalloon catheterEngineeringBalloon catheter

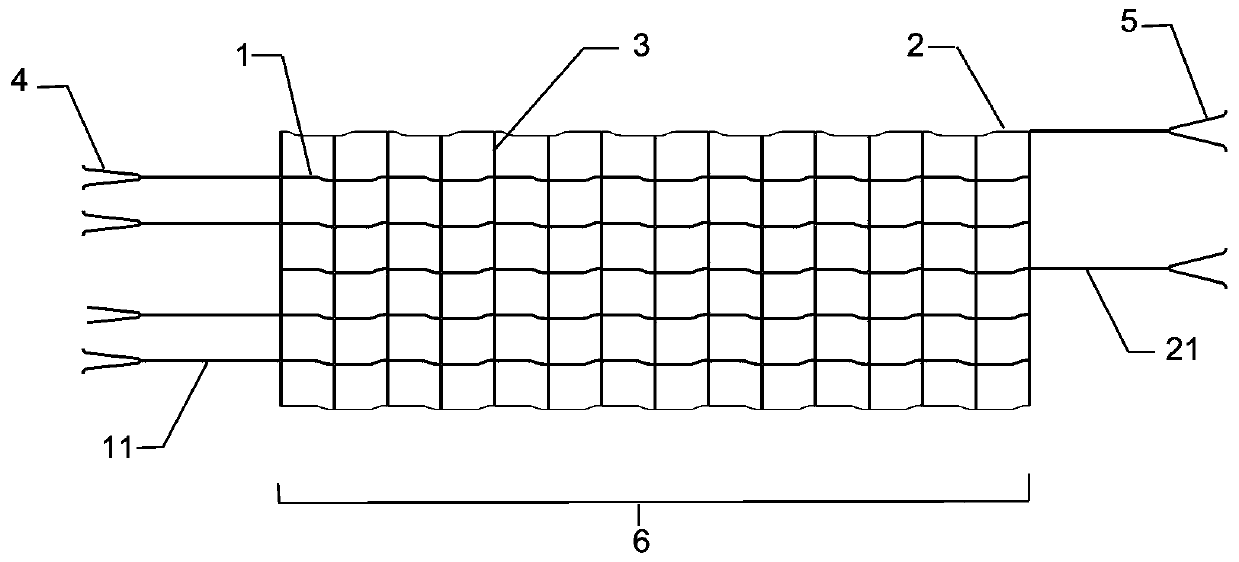

The invention discloses a distal and proximal asymmetric balloon restraint stent. The distal and proximal asymmetric balloon restraint stent comprises a plurality of first axial restraint rods, a plurality of second axial restraint rods, a plurality of radial restraint rings, a balloon proximal connecting ring and a balloon distal connecting ring, wherein the first axial restraint rods and the second axial restraint rods are circumferentially arranged at intervals, n2 second axial restraint rods are arranged at an interval of n1 first axial restraint rods, and the numerical value of n1 is larger than that of n2; the radial restraint rings are axially arranged at intervals and are connected with the first axial restraint rods and the second axial restraint rods; the balloon proximal connecting ring is connected with the first axial restraint rods; and the balloon distal connecting ring is connected with the second axial restraint rods. The product provided by the invention is simple instructure, high in strength and excellent in pushing performance, smooth feeding and withdrawing are realized, circumferential or radial deviation of a balloon in the expanding process is effectivelyprevented, and the product is worthy of popularization and application in the field.

Owner:HANGZHOU BARTY MEDICAL TECH CO LTD

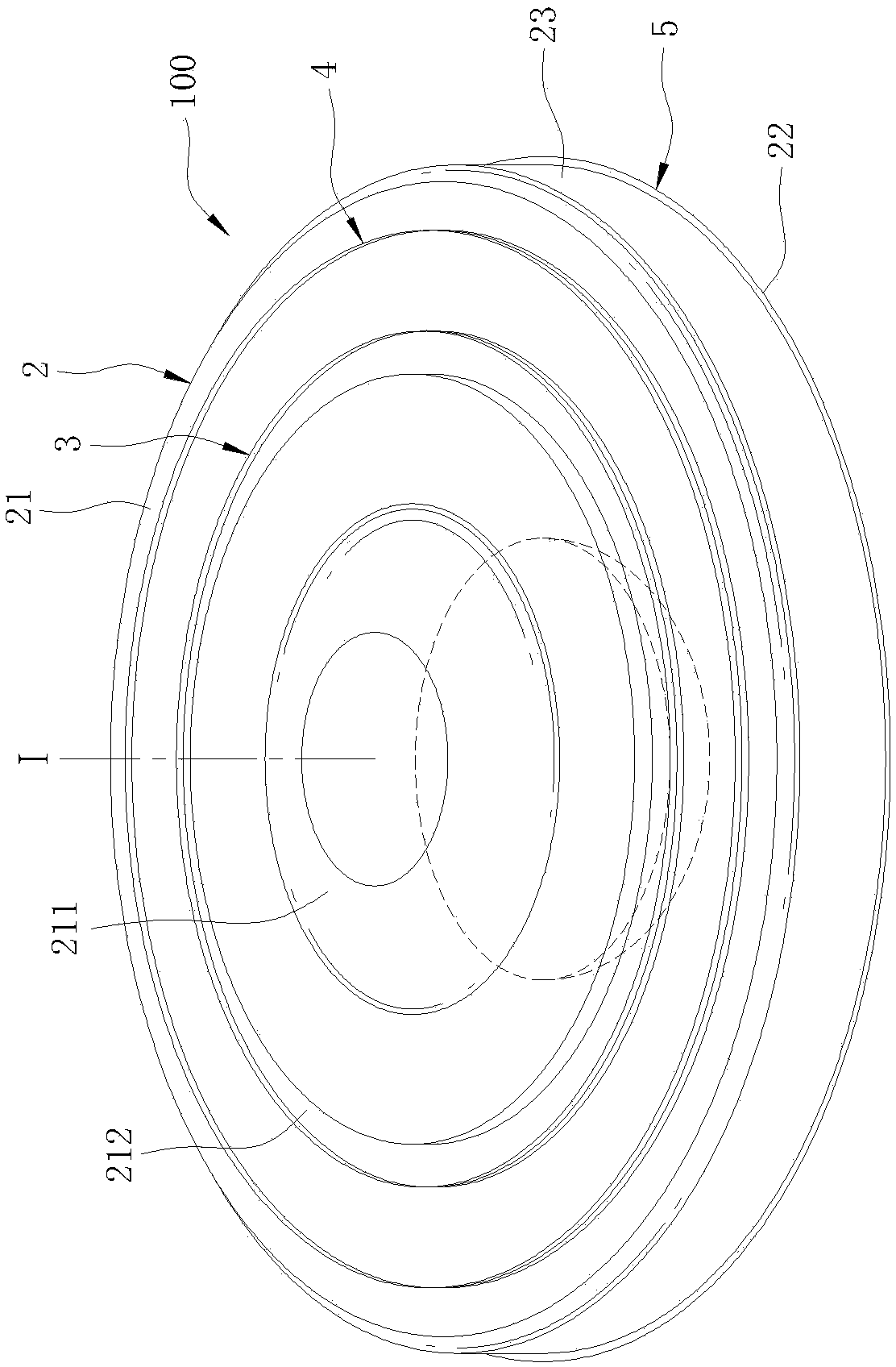

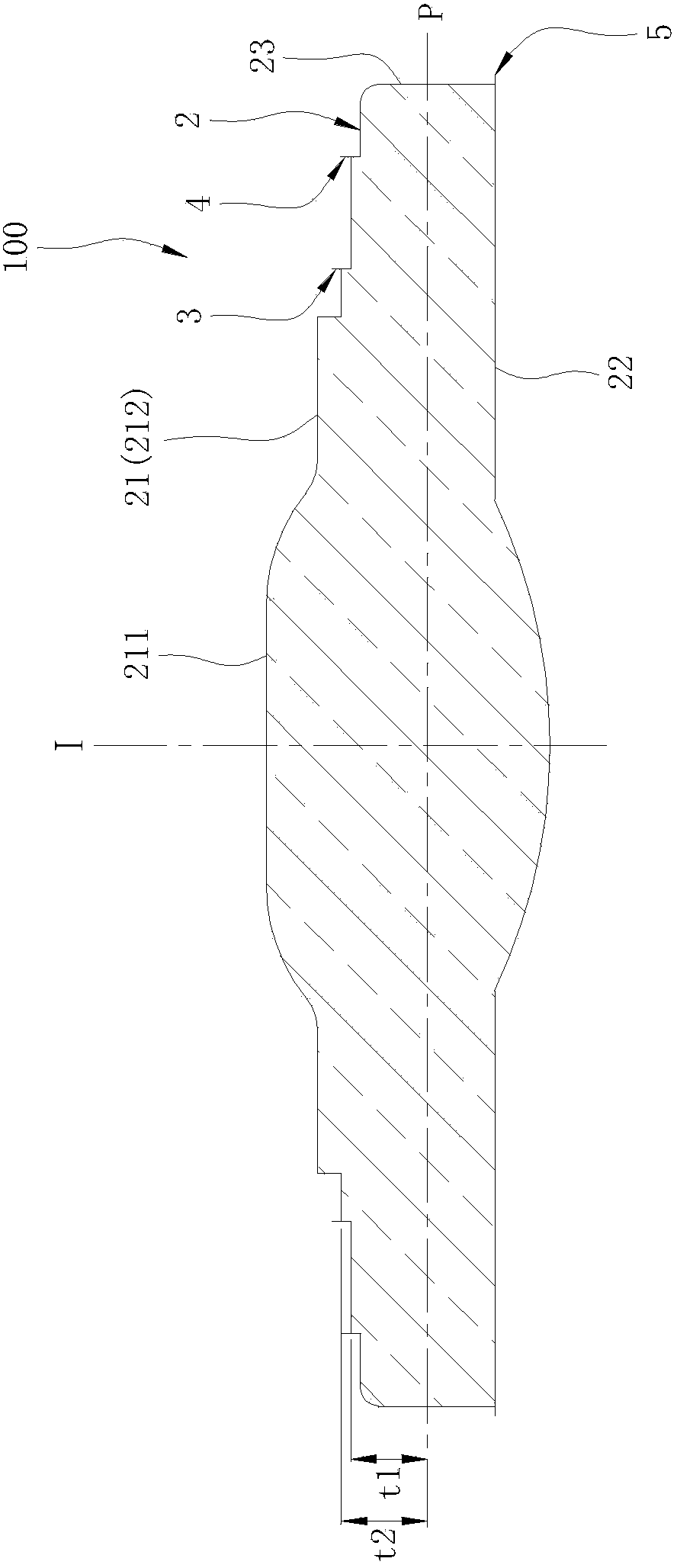

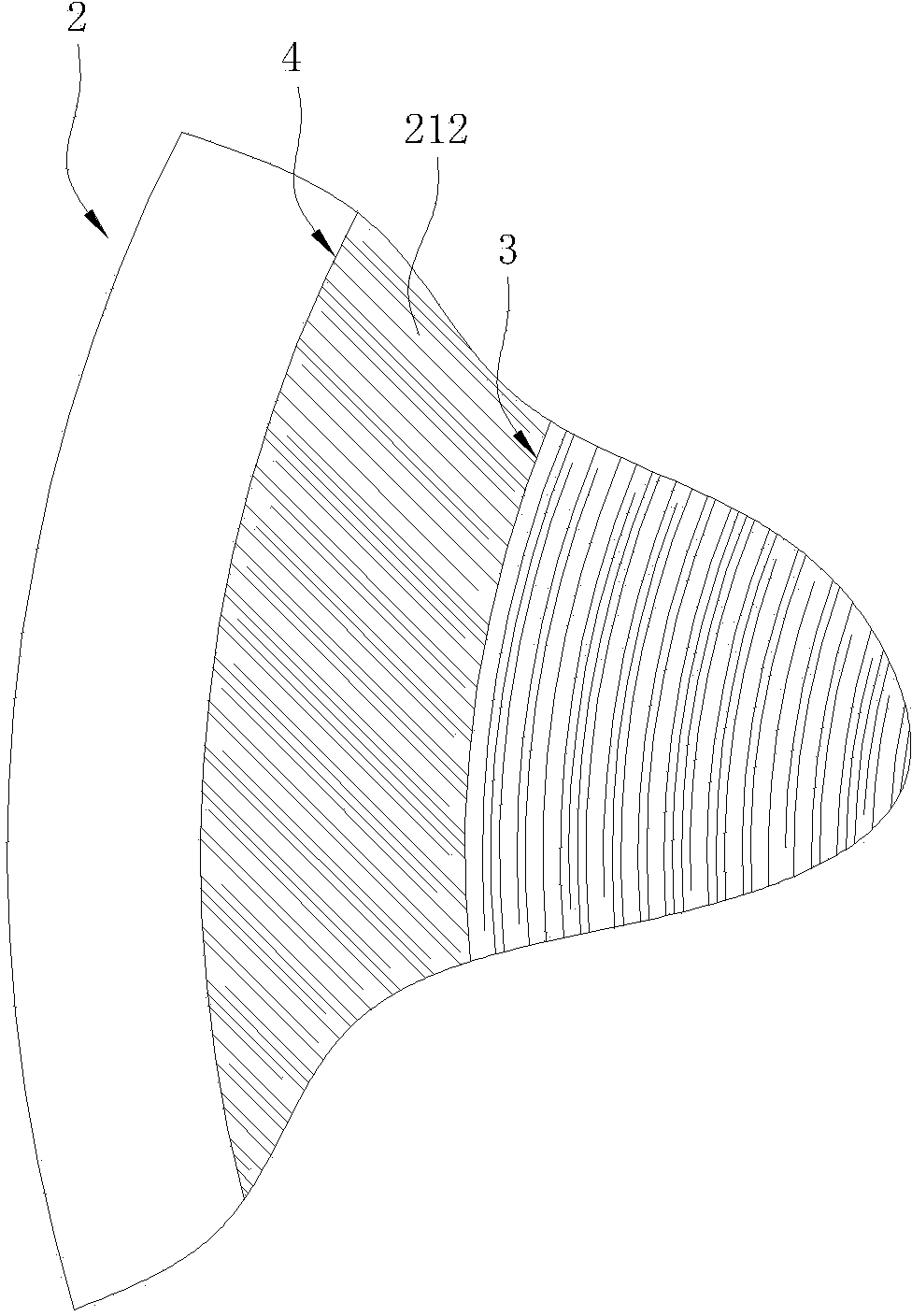

Plastic eyeglass capable of improving eccentricity and manufacturing method thereof

The invention relates to a plastic eyeglass capable of improving eccentricity and a manufacturing method thereof. The plastic eyeglass capable of improving eccentricity comprises a main body, a first rough edge and a second rough edge; the main body comprises a first surface and a second surface arranged along the optical axis, and an annular periphery face; the first surface comprises a curved surface part nearby the optical axis and a plane part encircling the curved surface part; the first rough edge is annular, is disposed at the plane part of the first surface and encircles the optical axis; and the second rough edge is annular, is disposed at the plane part of the first surface and encircles the first rough edge. The manufacturing method of the plastic eyeglass capable of improving eccentricity comprises the steps: step a, providing a mold; step b, injecting a plastic blank material into the cavity of the mold, cooling and solidifying the blank material to form the plastic eyeglass; step c, keeping the combination of different mold parts away from each other; step d, moving a pushing pipe of the mold to a first mold holder and a first mold core to push out the plastic eyeglass; and step e, taking out the plastic eyeglass. The manufacturing method aims at manufacturing the plastic eyeglass with unmigrated center.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

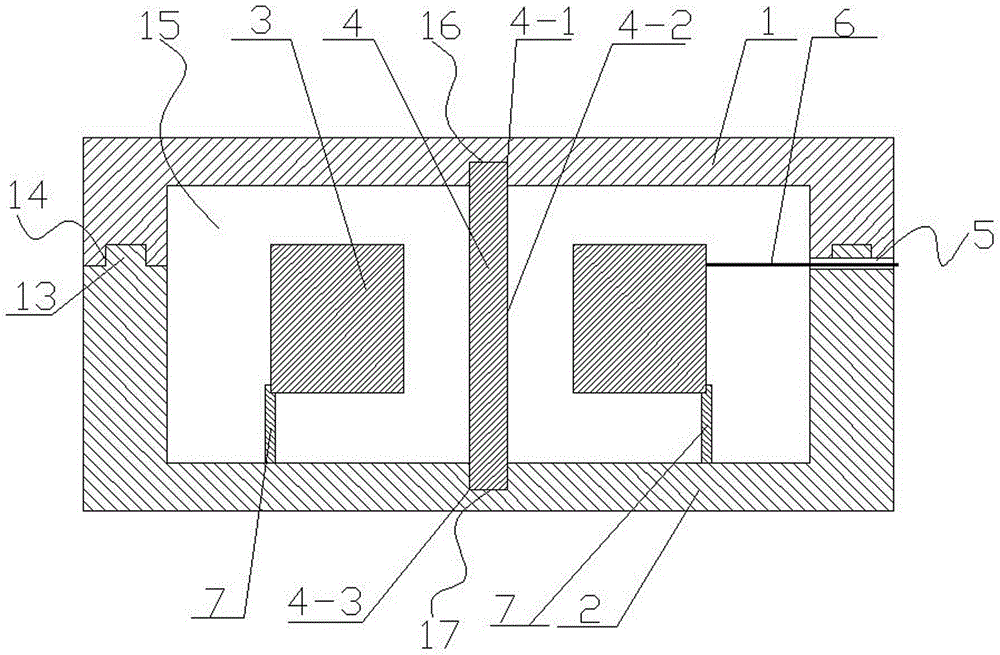

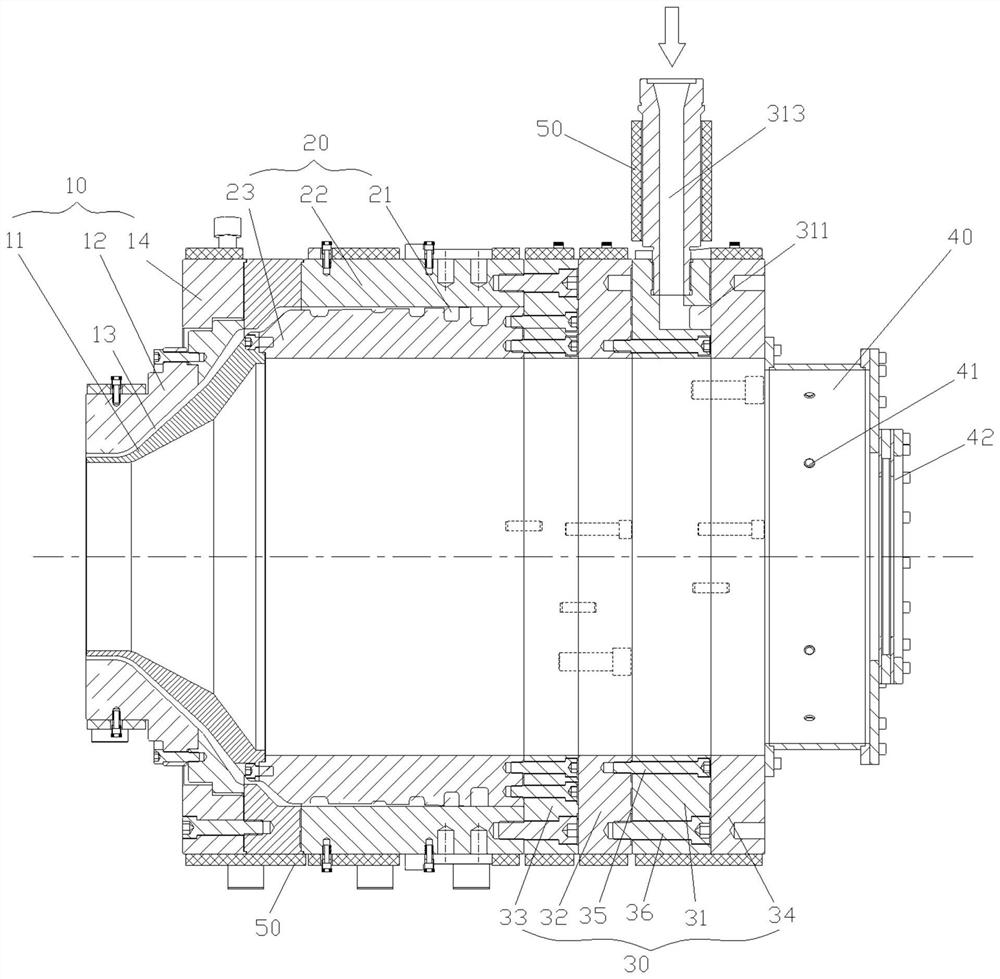

Forming die of outdoor mutual inductor, and casting fixing and sealing method of outdoor mutual inductor

InactiveCN104526940APrevent radial offsetEasy to processInductances/transformers/magnets manufactureEngineeringInductor

The invention discloses a forming die of an outdoor mutual inductor, and a casting fixing and sealing method of the outdoor mutual inductor. The forming die comprises an upper die and a lower die which are used for forming a die cavity, the upper die is provided with a casting hole connected with the die cavity and an air outlet, a die core is arranged in the die cavity, the upper end and the lower end of the die core are connected with the upper die and the lower die respectively, the upper end and the lower end of the die core are jointed into the upper groove of the upper die and the lower groove of the lower die respectively, and the part of the die core positioned in the die cavity is cylindrical in shape; and a group of fixed pillars for supporting mutual inductor coils is arranged in the die cavity surrounding the die core, the fixed pillars are fixedly connected with the lower die, and the upper end of each of the fixed pillars is provided with a stepped clamping platform for jointing the external edge and the lower edge of each of the mutual inductor coils. The forming die and the method improve the resin casting fixing and sealing efficiency of the outdoor mutual inductor, reduce the unit energy consumption and the defective index of the outdoor mutual inductor and improve the insulation degree of the outdoor mutual inductor.

Owner:XUCHANG YONGXIN ELECTRIC

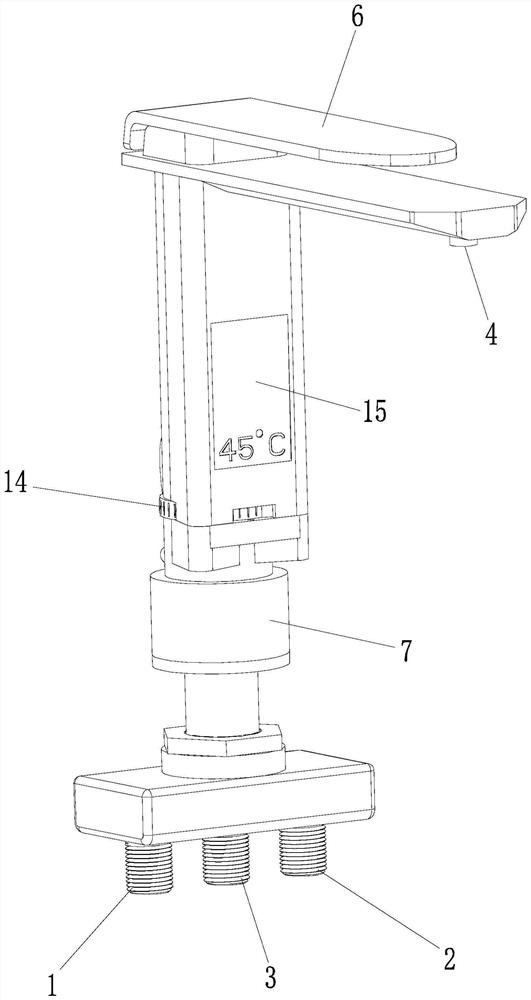

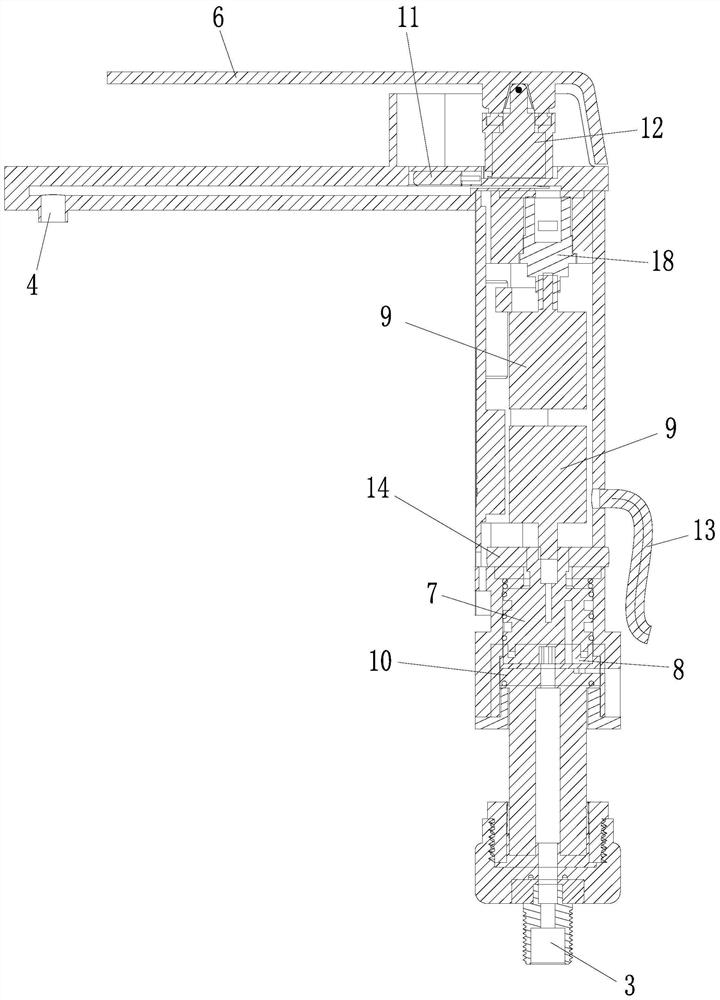

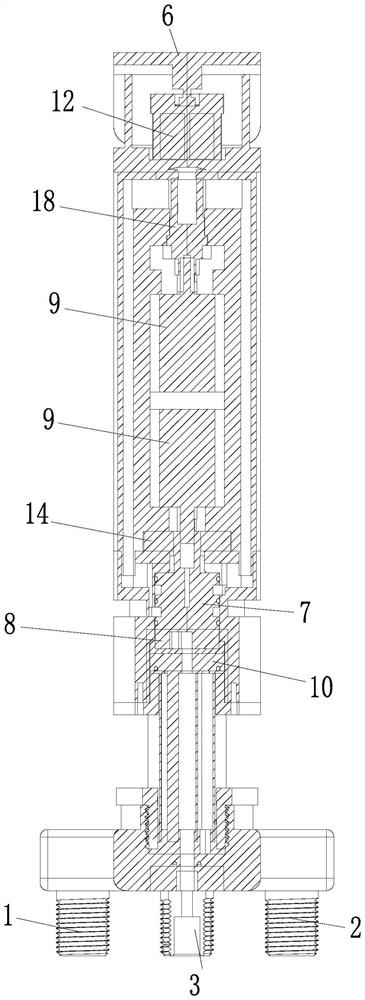

Self-temperature-adjusting faucet, control method of self-temperature-adjusting faucet and water supply system

PendingCN112145731AAutomatically adjust water temperatureWill not connectMultiple way valvesSlide valveElectric machineryWater supply network

The invention relates to a self-temperature-adjusting faucet, a control method of the self-temperature-adjusting faucet and a water supply system. The self-temperature-adjusting faucet comprises a faucet body, a flow valve, a water adjusting switch, a water control valve, a motor, a water temperature sensor, a temperature setting module and a processor. During use, a target temperature is set through the temperature setting module, the processor receives a signal of the water temperature sensor, and the water control valve is switched among a water return working state, a water supply workingstate and a water cut-off working state under the control of the processor; and a movable valve body of the water control valve rotates around the axis of a water return hole, according to the set temperature, the water control valve is driven by the motor to rotate around the axis of the water return hole to change the flow ratio of cold water to hot water flowing to the flow valve, so that the temperature of mixed water flowing to the flow valve is automatically adjusted, and the temperature is accurately controlled.

Owner:SHANGHAI XINGYE MATERIALS TECH CO LTD

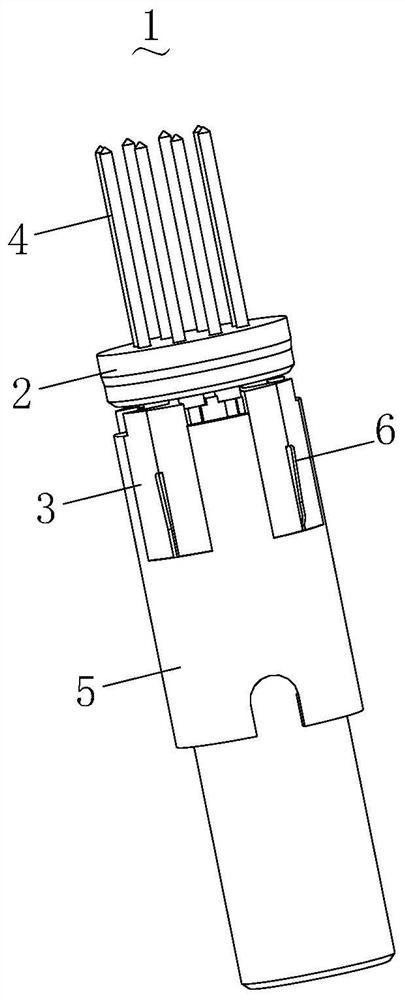

Drilling equipment with high machining precision

InactiveCN112935899APrevent radial offsetImprove cooling effectFeeding apparatusDriving apparatusDrive shaftEngineering

The invention relates to drilling equipment with high machining precision. The drilling equipment comprises a shell, a handle, a transmission shaft, a connector and a drill rod, the shell is cylindrical, the handle is arranged on the outer wall of the shell, a mounting hole is formed in one end of the shell, the transmission shaft and the drill rod are both coaxially arranged with the shell, the transmission shaft penetrates through the mounting hole, the transmission shaft is connected to the inner wall of the mounting hole in a sliding and sealed mode, a driving device is arranged in the shell and is in transmission connection with one end of the transmission shaft, the drill rod is arranged at the other end of the transmission shaft through the connector, at least three supporting mechanisms are arranged on the shell, the supporting mechanisms are uniformly distributed in the circumferential direction with the axis of the shell as the center, and a cleaning mechanism is arranged in the shell. According to the drilling equipment with the high machining precision, the drilling precision is improved through the supporting mechanisms, the drill rod is prevented from generating radial deviation, and in addition, the function of automatically cleaning the drill rod is achieved through the cleaning mechanism.

Owner:南京依扬知识产权代理有限公司

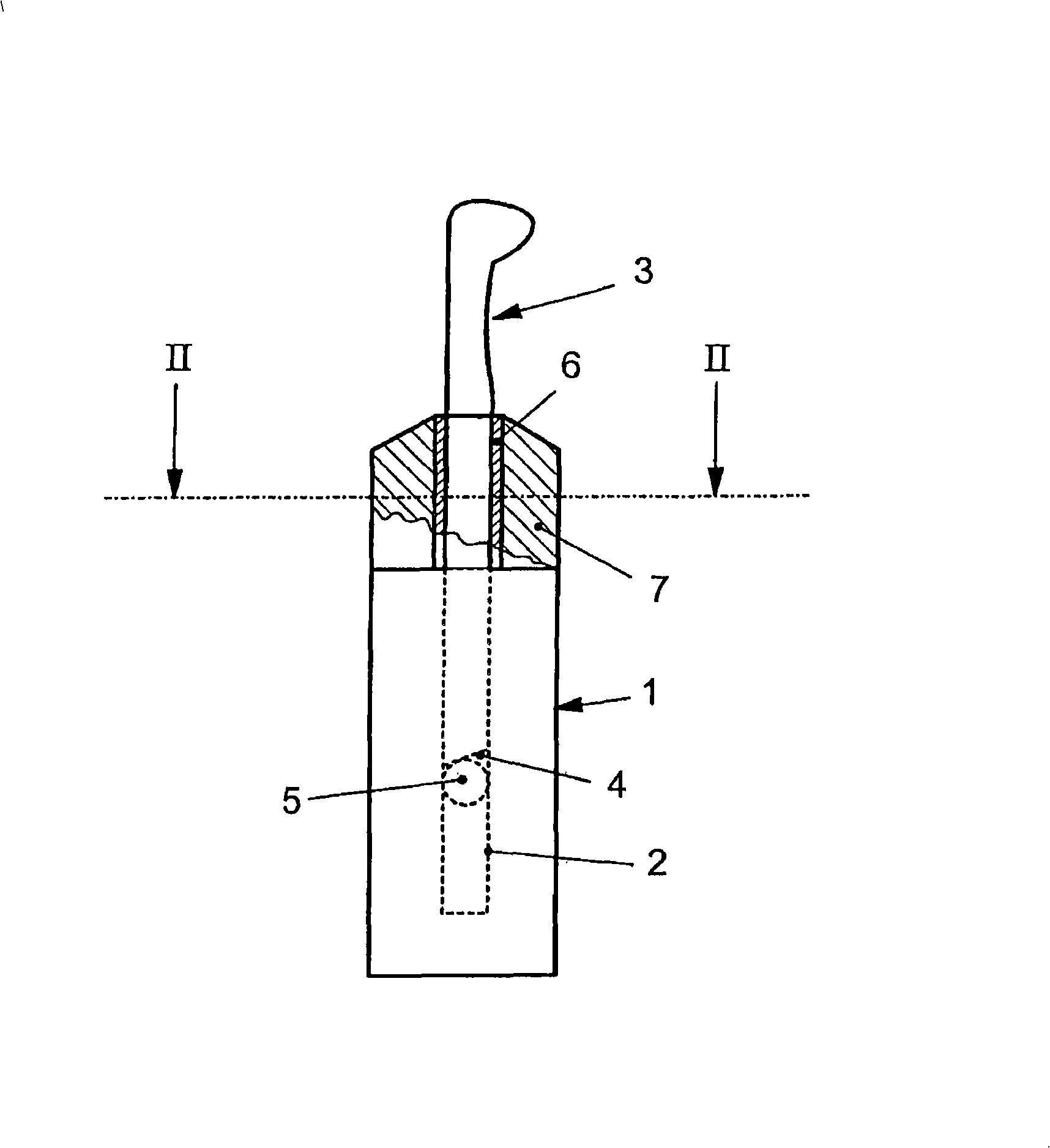

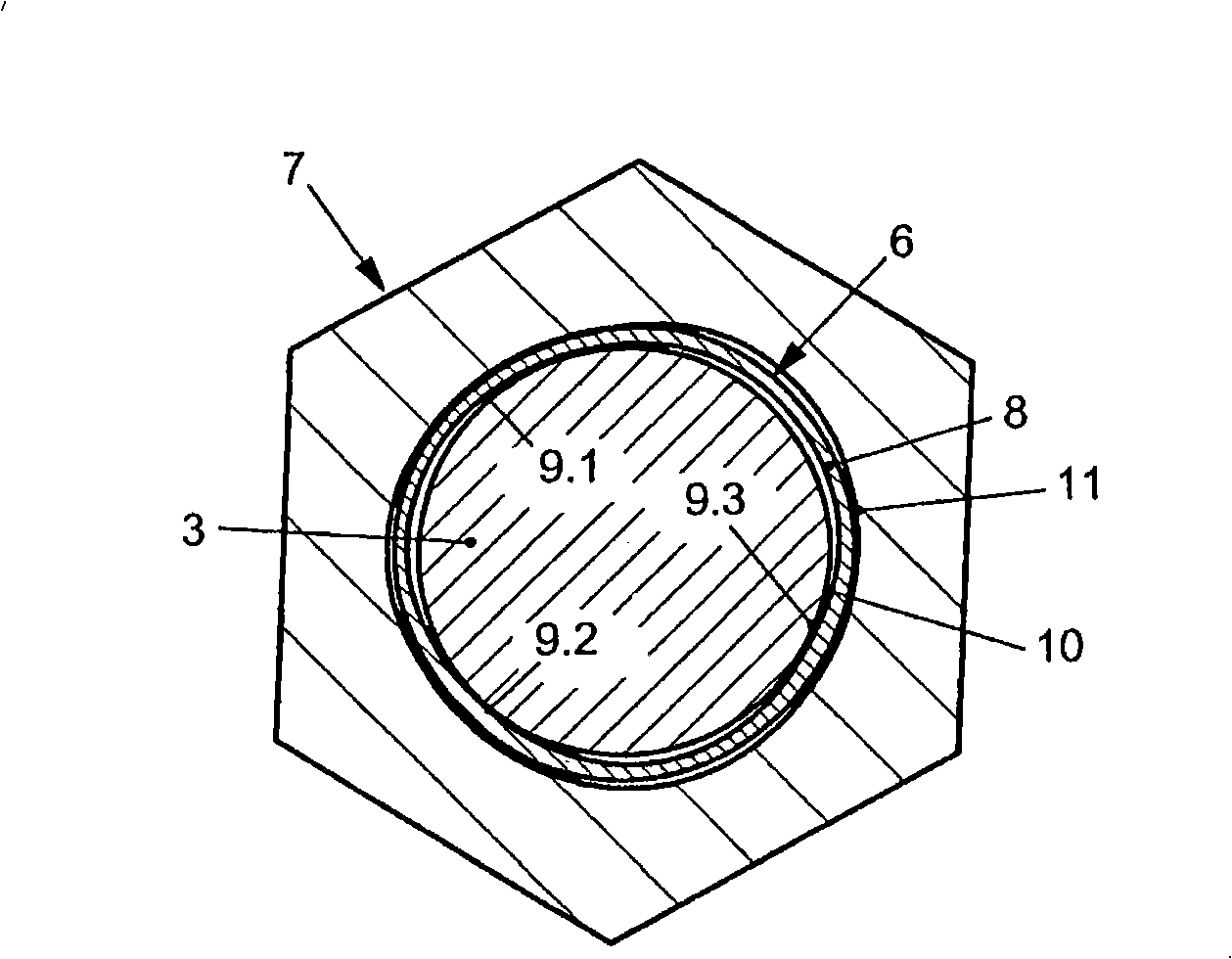

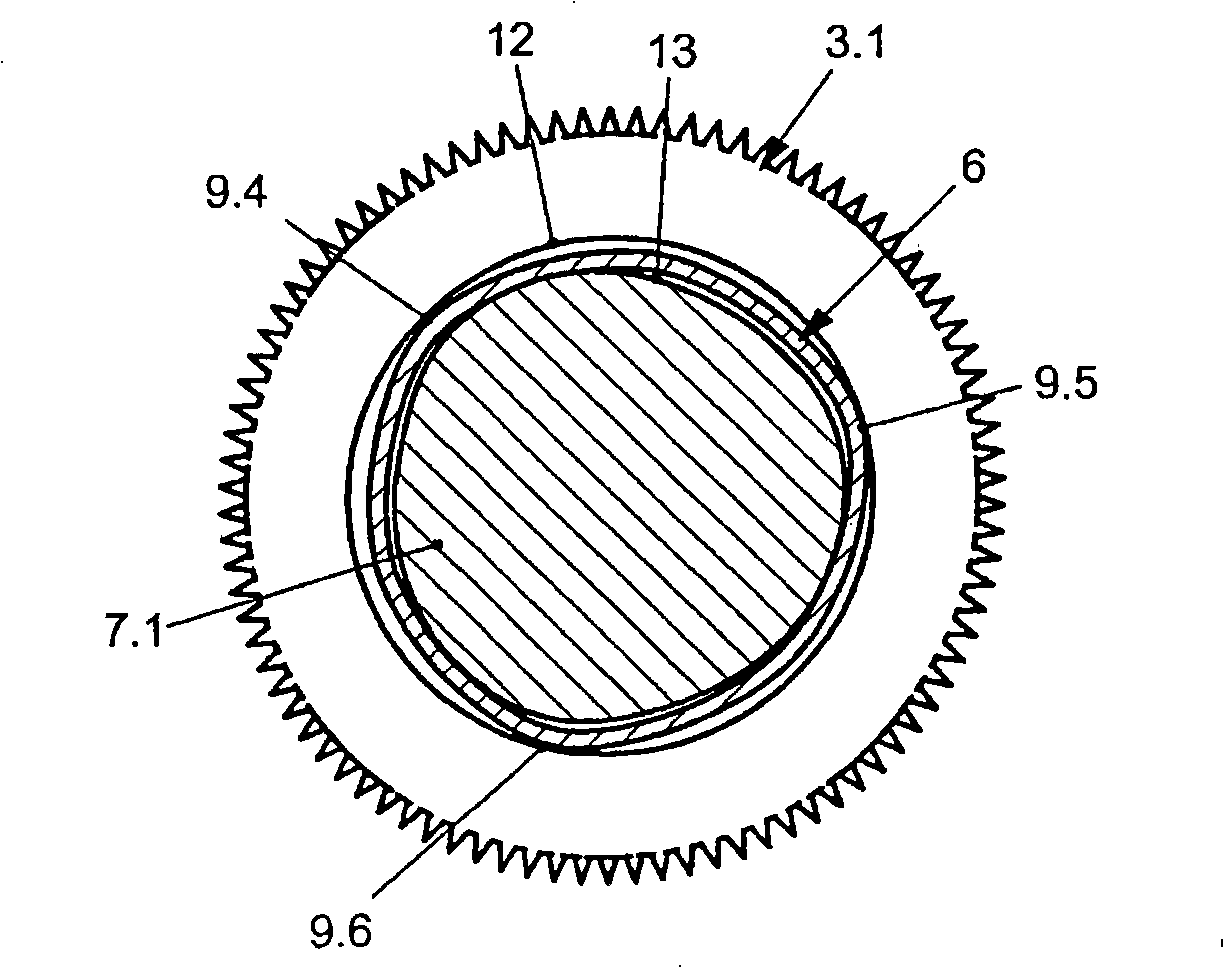

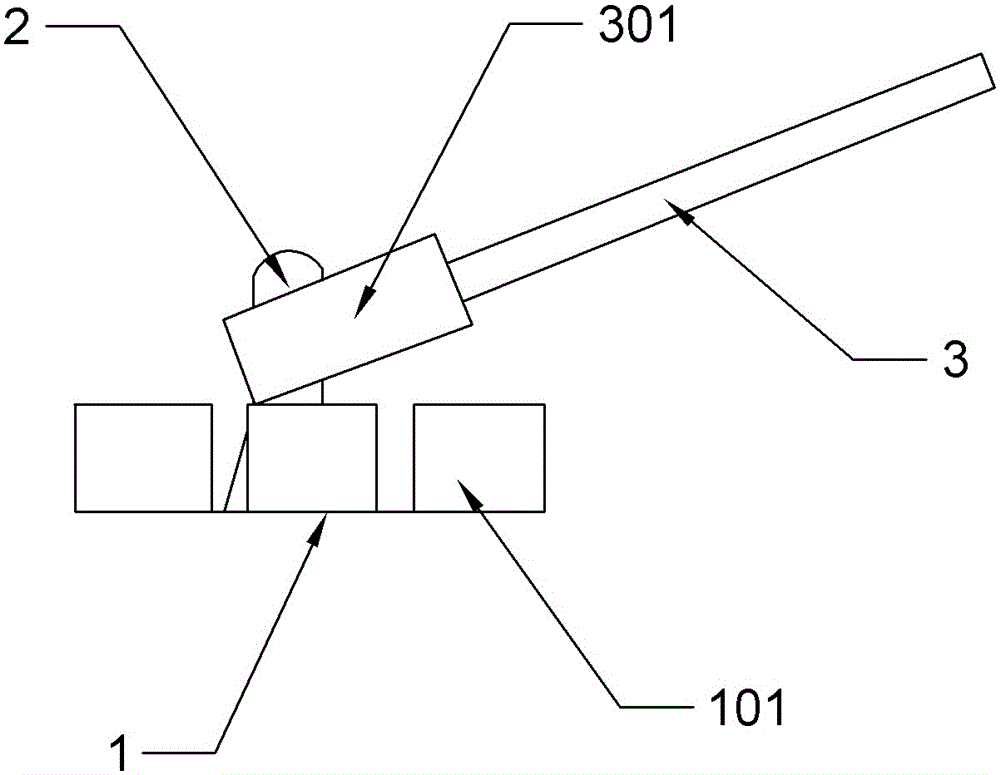

Clamping device for a device for machining workpiece

The invention relates to a device for machining workpieces, comprising a tool (3, 3.1) that is connected to a support (1) via a clamping device. The invention is characterized in that the support (1) is associated with an out-of-round, deformable cylinder (6) which receives the tool or which engages in a recess (12) in the tool (3.1).

Owner:赫曼利昆

Automated metal piece machining device

InactiveCN109227675AEasy to transportPrevent radial offsetMetal working apparatusMechanical engineeringMetal

The invention discloses an automated metal piece machining device. The device includes a conveying assembly used for conveying blank pipes, a cutting assembly used for cutting the blank pipes, a transferring assembly used for transferring cut finished pipe products and a PLC. The conveying assembly, the cutting assembly and the transferring assembly are distributed sequentially according to a conveying flow; the conveying assembly includes a pair of lateral support bases which are oppositely arranged at an interval, and the extension directions of the lateral support bases are identical to theconveying direction of the blank pipes. The conveying assembly also includes a magnetic butting strip and a linear feeding driving mechanism, the magnetic butting strip is used for butting against the axial ends of non-cutting sides of the blank pipes and has magnetism, the linear feeding driving mechanism is used for driving the magnetic butting strip to horizontally move and mounted on the ground, a gap penetrable for the magnetic butting strip during movement is formed between the two lateral support bases, and the length direction of the gap is identical to the conveying direction of theblank pipes. The automated metal piece machining device provides convenience for transferring and locking the finished pipe products.

Owner:镇江倍斯特曼新材料研究有限公司

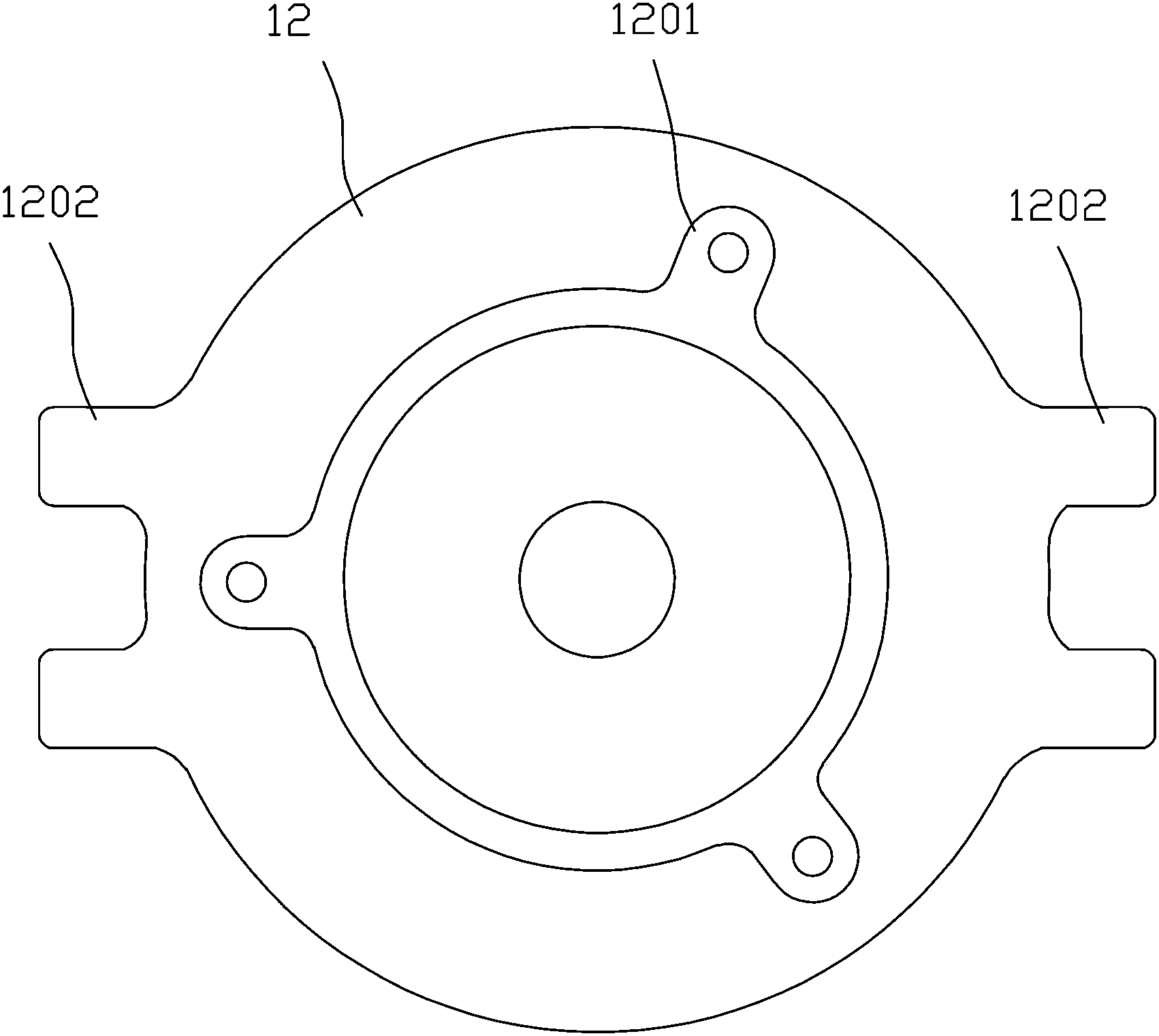

Tensioning device for spoke out-of-roundness positioning check tool

InactiveCN105091717AGuaranteed accuracyAccuracy impactMechanical counters/curvatures measurementsEngineeringRadial deviation

The invention belongs to the stamping detection field and relates to a spoke out-of-roundness positioning check tool, in particular, a tensioning device for the spoke out-of-roundness positioning check tool. The tensioning device comprises a core shaft and a protruding rod for distending the core shaft; the protruding rod is located in the core shaft; the core shaft is a hollow ring; a tensioning groove is formed in the core shaft along the axial direction of the core shaft; the protruding rod is provided with a protruding block; and the protruding rod is provided with a mobile rod which is used for making the protruding rod move up and down. According to the tensioning device of the invention, the core shaft which can be split into a plurality of core shafts, the protruding rod used for distending the core shaft, and the mobile rod are adopted, and therefore, no gap exists between the central hole of a spoke and the core shaft, and therefore, radial deviation of the spoke in a rotation process can be avoided, and the accuracy of the out-of-roundness detection of the spoke can be ensured.

Owner:CHONGQING DINGHAN MACHINERY

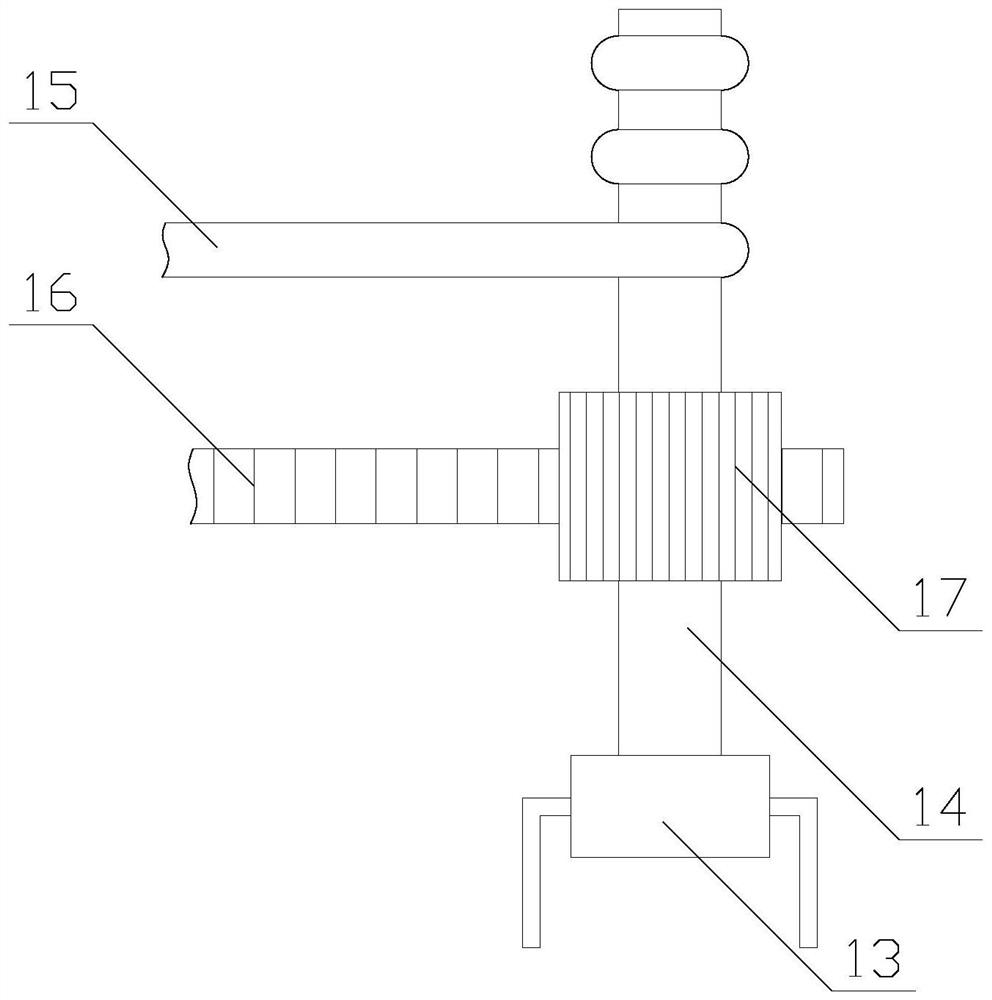

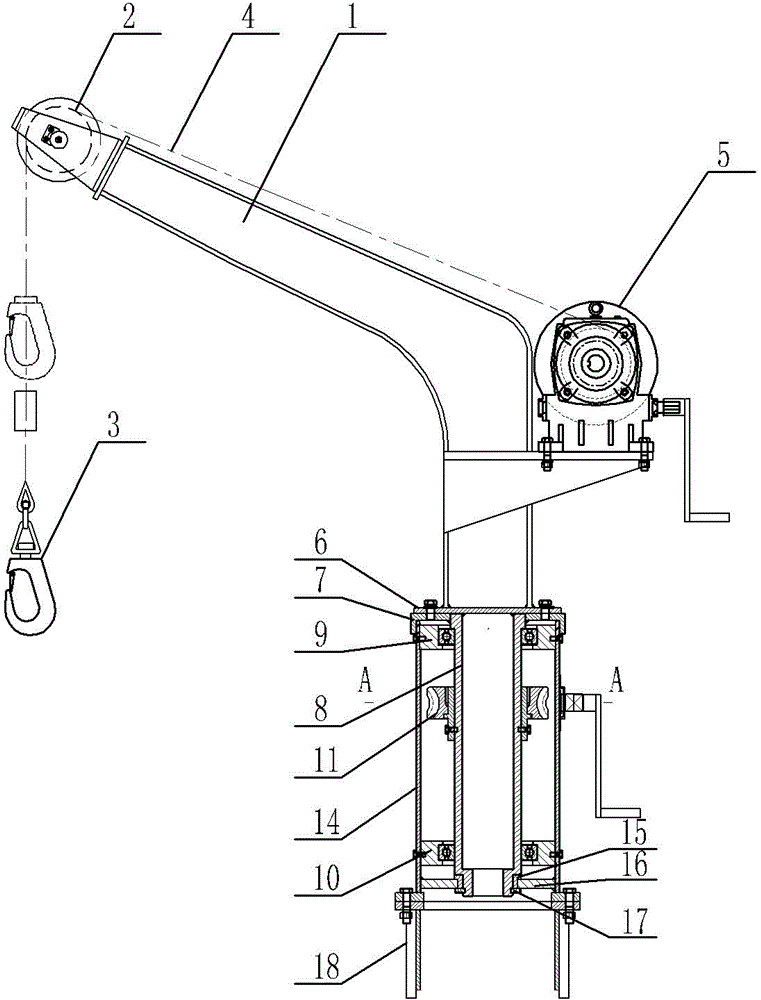

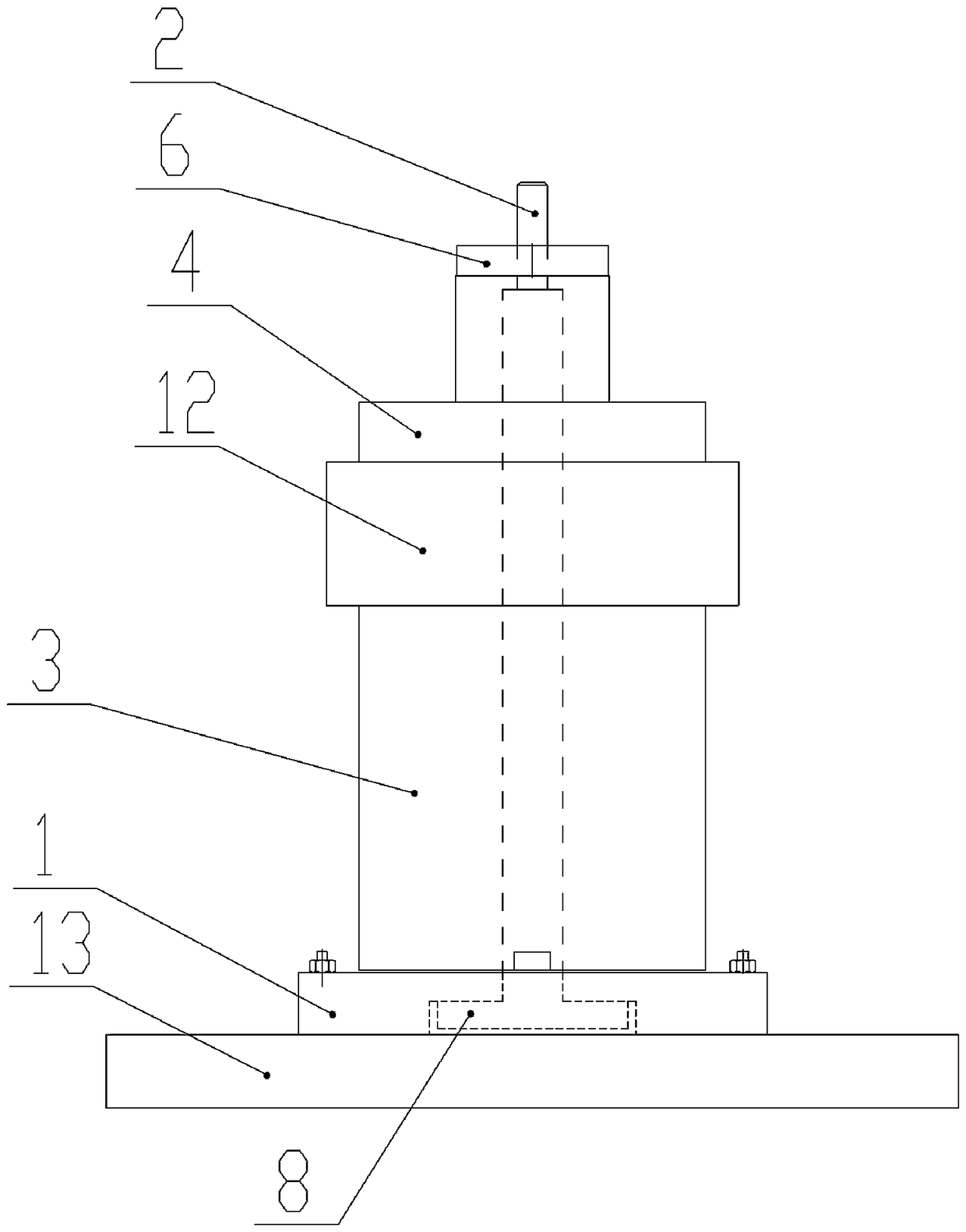

Object lifter structure

The present invention provides an object lifter structure, wherein the lifting arm can easily rotate so as to achieve lifting of the objects in different orientations. The object lifter structure comprises a lifting arm, a base, a lifting device, a pulley, a steel wire rope and a hanging hook group, and is characterized further comprising a connection rod, a worm wheel, a worm rod and a support body, wherein the root portion of the lifting arm is fixedly connected to the connection rod, the base is fixedly connected to the support body, the support body is a cylindrical structure with openings on both ends, the connection rod is axially inserted inside the support body, the upper end and the lower end of the support body are respectively fixedly connected to a group of bearing pedestals, both ends of the connection rod are supported on the bearing pedestals, the worm wheel is arranged on the connection rod, the support body is provided with an installation seat, both ends of the worm rod are supported on the installation seat and are engaged to the worm wheel, and the end portion of the worm rod is fixedly connected to a rocker arm.

Owner:WUXI SHENGOU MARINE EQUIP

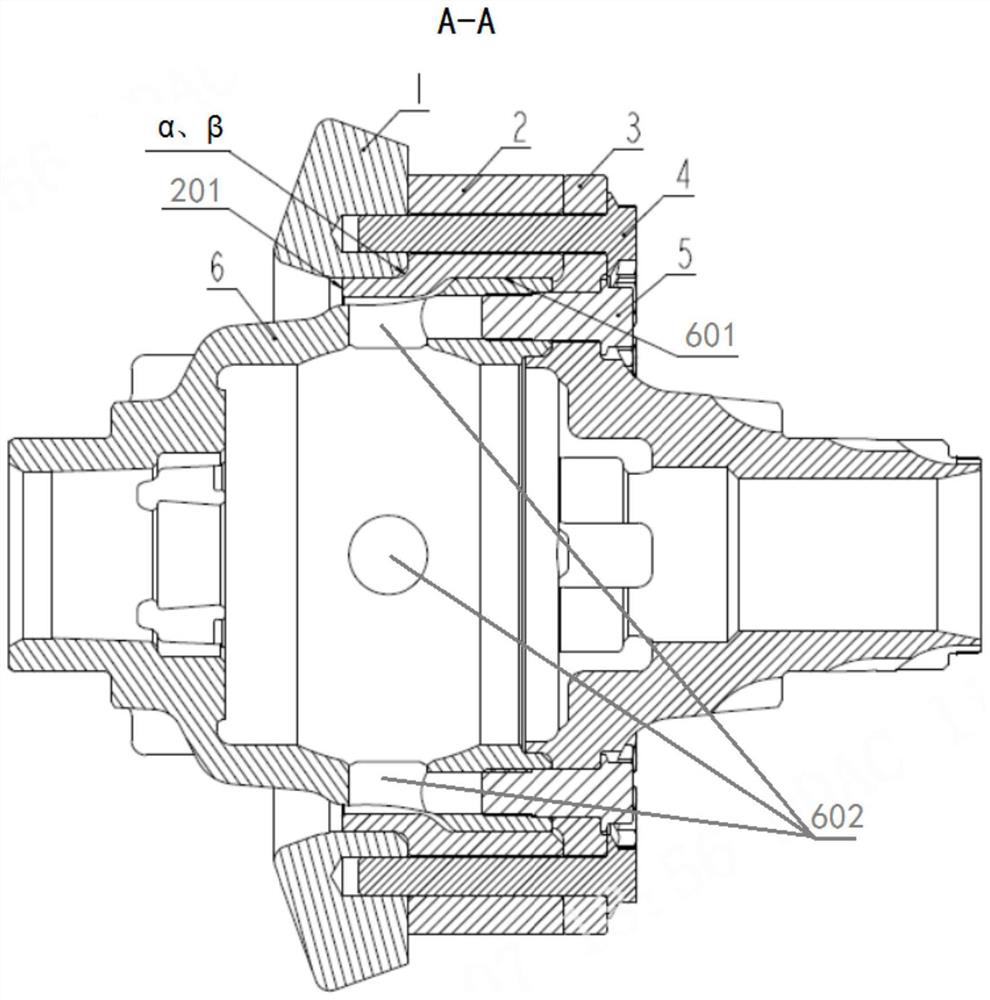

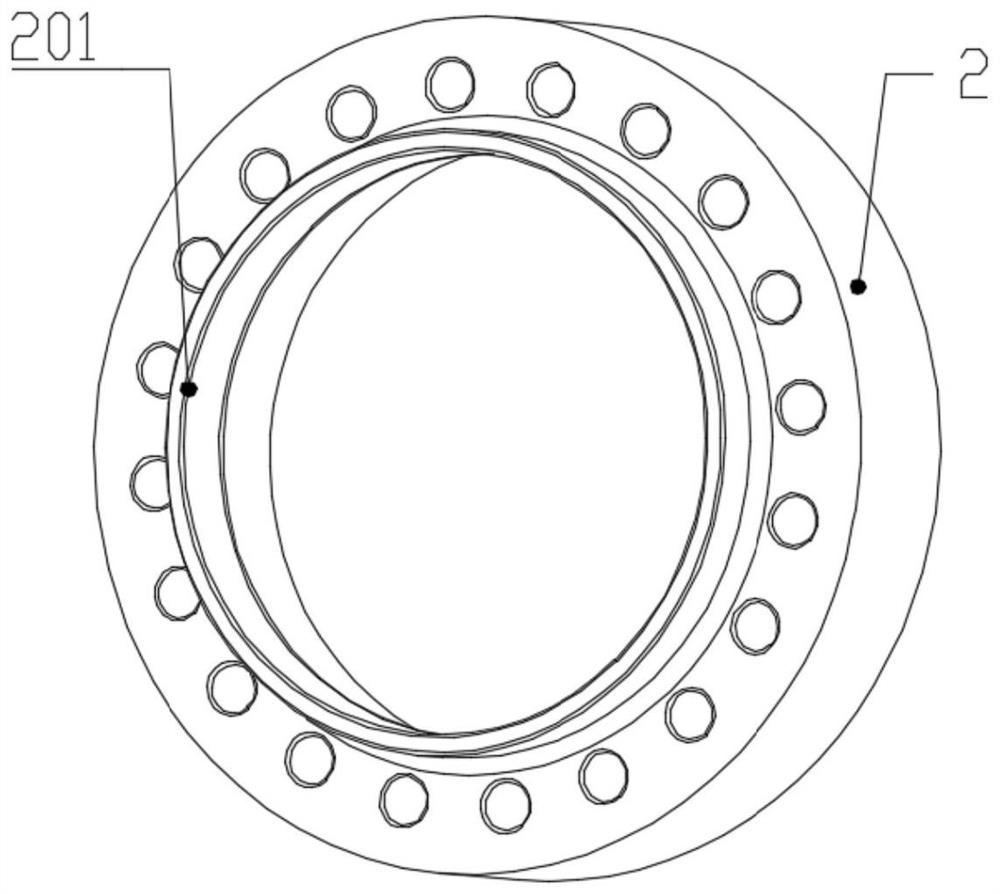

Ball valve with double radial stem bearings

InactiveCN102954247AAvoid enteringPrevent radial offsetSpindle sealingsPlug valvesEngineeringBall valve

The invention relates to a ball valve with double radial stem bearings. The ball valve comprises a valve body, a packing gland, a stem and packing, the packing gland comprises a cover plate and a gland, a packing box and a groove are disposed on the valve body, the gland is inserted into the packing box, the lower portion of the stem is connected with the valve body, and the upper portion of the stem sequentially penetrates through the groove, the packing box and the gland to penetrate out of the packing gland. The stem, the packing box and the gland enclose to form an annular packing cavity, the ball valve further comprises a first radial stem bearing, a second radial stem bearing and two packing gaskets, the first radial stem bearing is sleeved between the gland body and the stem, the second radial stem bearing is sleeved between the groove and the stem, one packing gasket is arranged at the top of the annular packing cavity, and the other packing gasket is arranged at the bottom of the annular packing cavity. Compared with the prior art, the ball valve with the double radial stem bearings has the advantages that the stem can be prevented from radial deflection, jamming and friction with the packing gland, medium leakage of the packing and the packing gaskets can also be prevented, and the like.

Owner:SHANGHAI KAIGONG VALVE CO LTD

Press tooling for large gear hobbing

The invention relates to a pressing tool for a large gear hob. The pressing tool comprises a base, wherein a center shaft which extends vertically upward is fixedly arranged on the base, the lower end of the center shaft is movably sleeved with a support sleeve, the upper end of the center shaft is movably sleeved with a press block, a space interval for instilling a workpiece is reserved between the support sleeve and the press block, the lower end of the support sleeve is fixed with the periphery of the base, a locating seam allowance which is used for centering the workpiece is arranged at the upper end of the support sleeve, a hydraulic nut is connected to an axial section, above the press block, of the center shaft through threads, and the hydraulic nut presses the press block. The pressing tool for the large gear hob is suitable for pressing the workpiece when the operation space is small and the hob is effectively and heavily cut, and enough clamping pressing force and clamping efficiency can be effectively guaranteed.

Owner:CHONGQING WANGJIANG IND

An omnidirectional wheel and an omnidirectional mobile platform using the omnidirectional wheel

The invention relates to the field of movement mechanism, in particular to an all-dimensional wheel and an all-dimensional mobile platform using the same. The all-dimensional wheel comprises a hub and an integral roller assembled on the hub through a roller shaft, two ends of the roller shaft protrude out of corresponding rollers, external threads are arranged on portions protruding out of the rollers, the hub comprises a left support rotation disc, a right support rotation disc and a shaft sleeve, the left support rotation disc and the right support rotation disc are relatively arranged, the shaft sleeve is coaxially connected between the left support rotation disc and the right support rotation disc, one end of the roller shaft is inserted in an installation hole arranged on the left support rotation disc and fixed through a nut, the right support rotation disc is close to the shaft sleeve and is detachably and fixedly connected with the shaft sleeve when the roller shaft is fixed on the left support rotation disc, an abdicating hole which abdicates for the roller shaft relative to movement of the right support rotation disc in a process that the right support rotation disc is close to the shaft sleeve from right to left is arranged on the right support rotation disc, one end of the roller shaft far away from the left support rotation disc is inserted in the corresponding abdicating hole and fixed through a nut, and a problem that the all-dimensional wheel is poor in strength and prone to lose efficiency is solved.

Owner:凯迈(洛阳)测控有限公司

Lifting device and semiconductor device processing equipment with same

ActiveCN102148176BGuaranteed linearityReduce radial offsetSemiconductor/solid-state device manufacturingConveyor partsSemiconductorBiomedical engineering

The invention provides a lifting device which is used for lifting so as to support a lifting needle of a device. The lifting device comprises a central guide rod, a mounting flange with a hollow structure, a hollow sleeve, a corrugated pipe and at least two central guide rod limiting parts with hollow structures, wherein the first limiting part is arranged in the hollow part of the mounting flange and the outer wall of the first limiting part is in tight fit with the inner wall of the mounting flange; the second limiting part is arranged at the lower region in the hollow sleeve and the outer wall of the second limiting part is in tight fit with the inner wall of the hollow sleeve; and the central guide rod penetrates through the first limiting part, the corrugated pipe and the second limiting part in the axial direction in sequence and is in tight fit with the inner walls of the first limiting part and the second limiting part. In addition, the invention provides semiconductor device processing equipment with the lifting device. Through the lifting device and the semiconductor device processing equipment provided by the invention, radial migration of the central guide rod can be reduced, product yield and production efficiency can be increased, reliable running of the system can be guaranteed, and cost is saved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Low-cost inter-wheel differential structure

PendingCN113202910AShortened major diameterImprove rigidityDifferential gearingsEngineeringBevel gear

The invention relates to a low-cost inter-wheel differential structure which comprises a left differential shell, a driven bevel gear and a right differential shell. The left differential shell, the driven bevel gear and the right differential shell are coaxially arranged, the end face of the left differential shell is fixedly connected with the end face of the right differential shell, the driven bevel gear is arranged on the periphery of the right differential shell in a sleeving mode and fixedly connected with the end of the left differential shell, an annular transition disc is coaxially arranged between the driven bevel gear and the left differential shell, the periphery of the right differential shell is sleeved with the transition disc, the transition disc is matched with the right differential shell through a radial spigot, and the driven bevel gear, the transition disc and the left differential shell are fixedly connected; and the end, facing the right differential shell, of the transition disc is provided with an outwards-extending spigot, and the outwards-extending spigot is tightly embedded between the driven bevel gear and the right differential shell. By additionally arranging the transition disc, the long-diameter size of the driven bevel gear can be shortened, and the proportion in the long-diameter direction is relatively harmonious. The outwards-extending spigot of the transition disc provides rigid support for the driven bevel gear, and the problem that the rigidity of the driven bevel gear is poor is solved.

Owner:DONGFENG DANA AXLE

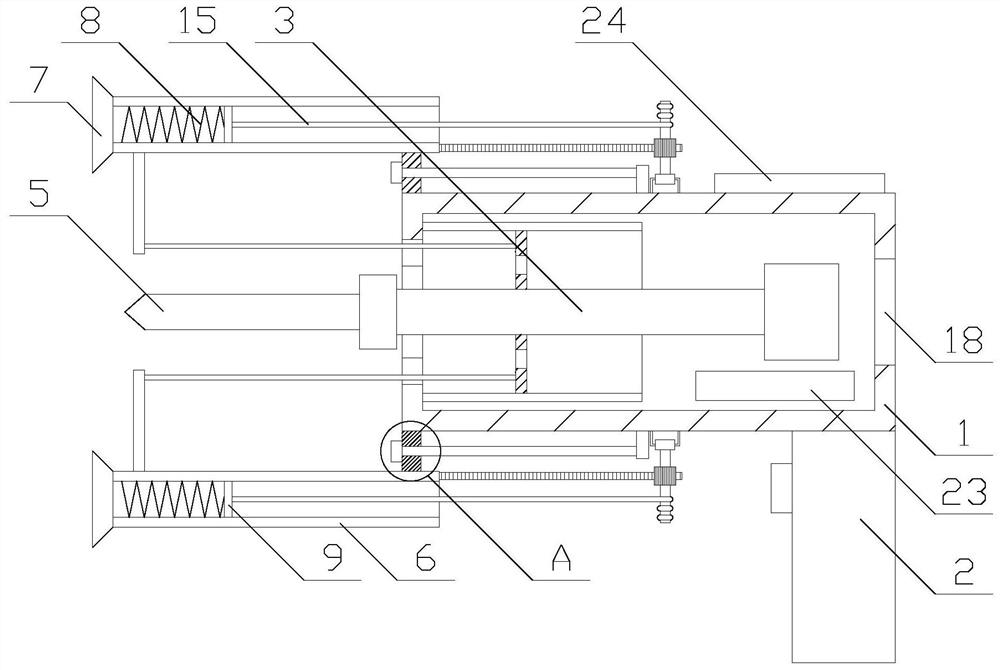

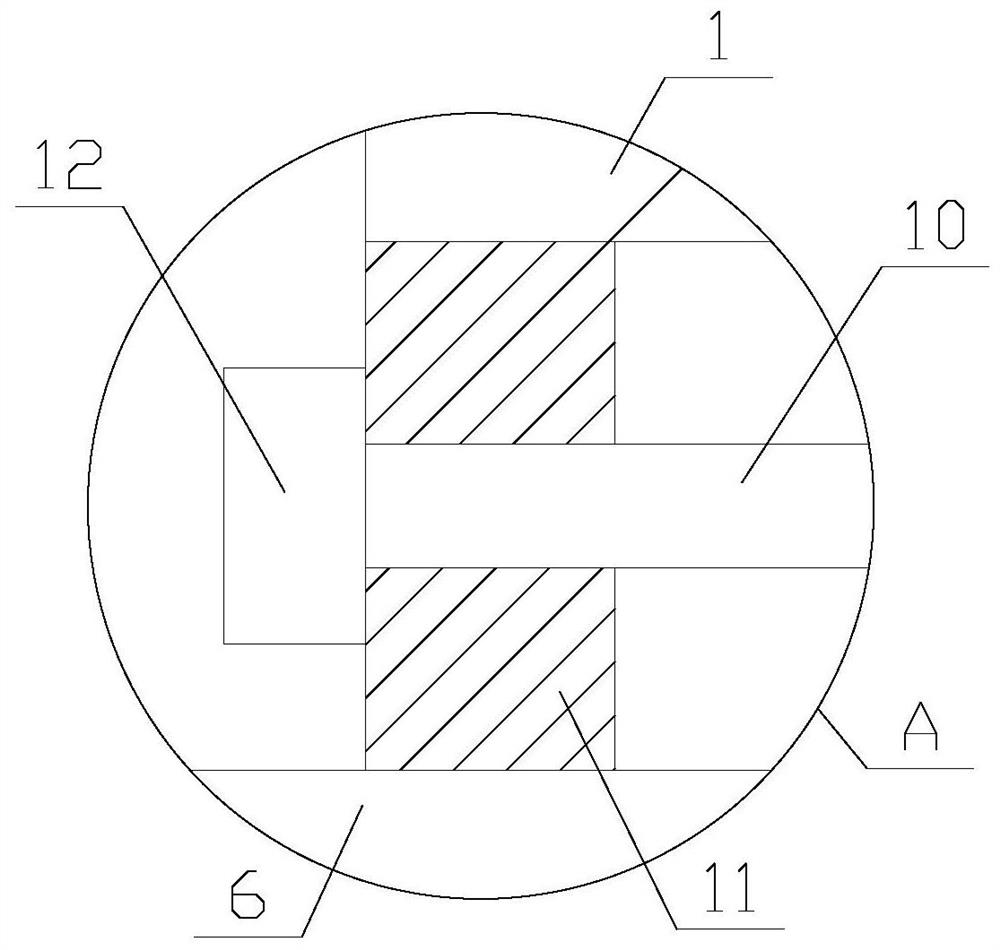

Switch assembly for washing machine and washing machine

ActiveCN109778498BAchieve openOptimize structure layoutOther washing machinesTextiles and paperLaundry washing machineControl engineering

The invention belongs to the technical field of washing machines and aims to solve the problem that the switch assembly of the existing washing machines takes up a large space, thus making it inconvenient to arrange the structural space of the washing machine. To this end, the present invention provides a switch assembly for a washing machine and a washing machine. The washing machine includes a mounting member and a lock body arranged on the mounting member. The screw transmission mechanism between the bodies, the button drives the lock body to open through the screw transmission mechanism, and the screw transmission mechanism can change the transmission direction of the force. The switch assembly of the present invention reduces the occupied space of the switch assembly by changing the conduction direction of the force. It is beneficial to the structural arrangement of the washing machine.

Owner:HEFEI HAIER WASHING MACHINE +1

Case punching and tapping device

InactiveCN104070362BReduce processing stepsShort processing timeDrilling/boring measurement devicesWork clamping meansPunchingEngineering

The invention discloses a tapping device for punching a chassis. The tapping device comprises a horizontally arranged workbench, a pedestal which can linearly move to and fro and is arranged on the workbench for holding the chassis, and a punching assembly and a tapping assembly sequentially arranged along the moving direction of the pedestal, wherein the punching assembly can be used for simultaneously punching in the left side, right side and bottom surface of the chassis; the tapping assembly can be used for simultaneously tapping on the left side, right side and bottom surface of the chassis. According to the tapping device for punching the chassis, the machining efficiency of thread holes in the chassis is high.

Owner:NINGBO LIONBALL VENTILATOR

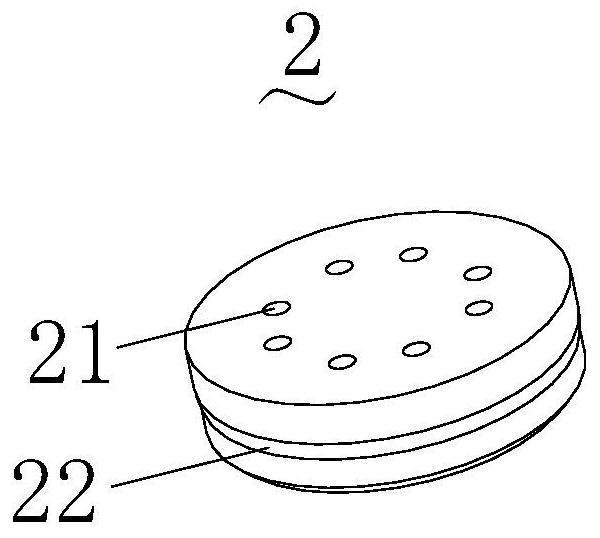

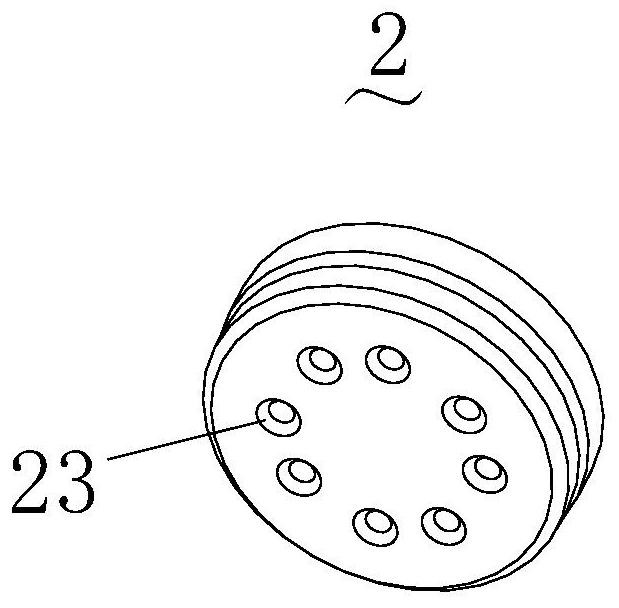

Eight-core circular 10G Ethernet contact

PendingCN112838405AImprove signal transmission qualityIncrease the number of signal transmissionsSecuring/insulating coupling contact membersEmbedded systemMechanical engineering

An eight-core circular 10G Ethernet contact comprises a medium body assembly and an outer conductor, and the medium body assembly is integrally sleeved in the outer conductor. The upper part of the medium body assembly and the outer conductor are fixed in an interference crimping manner, and the lower part of the medium body assembly and the outer conductor are fixed through a positioning pin. According to the invention, the overall dimension miniaturization of the Ethernet contact element is ensured, the signal transmission quantity is increased through the eight-core-number design, the interference among signals is reduced through the arrangement of the cross-shaped shielding element, the signal transmission rate is greatly improved, the requirement of high-speed communication is met, and in addition, compared with the traditional two-core or four-core-number design, as the use number of the Ethernet contacts is reduced, the weight of the Ethernet connector is indirectly saved by more than half.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

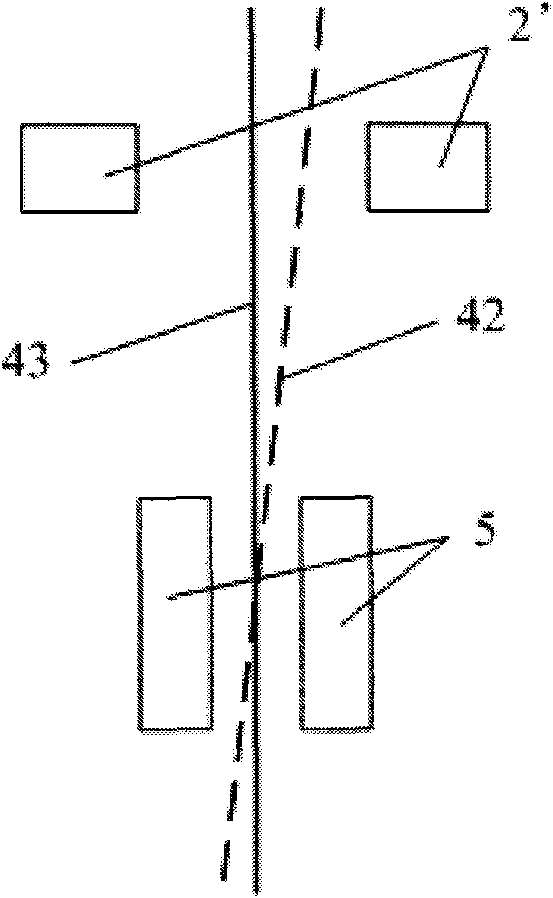

A displacement and vibration monitoring device

ActiveCN112556559BAchieve acquisitionHigh sampling frequencySubsonic/sonic/ultrasonic wave measurementUsing electrical meansEngineeringMechanical engineering

The invention discloses a displacement and vibration monitoring device, comprising a frame, a measuring mechanism and a sensing mechanism; the frame is arranged on the object to be measured; the measuring mechanism is arranged on the frame, and can measure the displacement parameters and vibration parameters of the object to be measured. Monitoring; the sensing mechanism is arranged on the frame, and includes a telescopic assembly and a sensing element; the telescopic assembly is in contact with the measuring mechanism and can move with the action of the measuring mechanism. The technical scheme of the present invention is applied, and a combination of a measuring mechanism and a sensing mechanism is adopted, and the effect is: the threshold value of the vibration of the object to be measured is monitored by the sensing mechanism, so that the sensing mechanism controls the measuring mechanism to increase the sampling frequency of displacement, and the object to be measured can be effectively treated in real time. The displacement parameters and vibration parameters are monitored.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

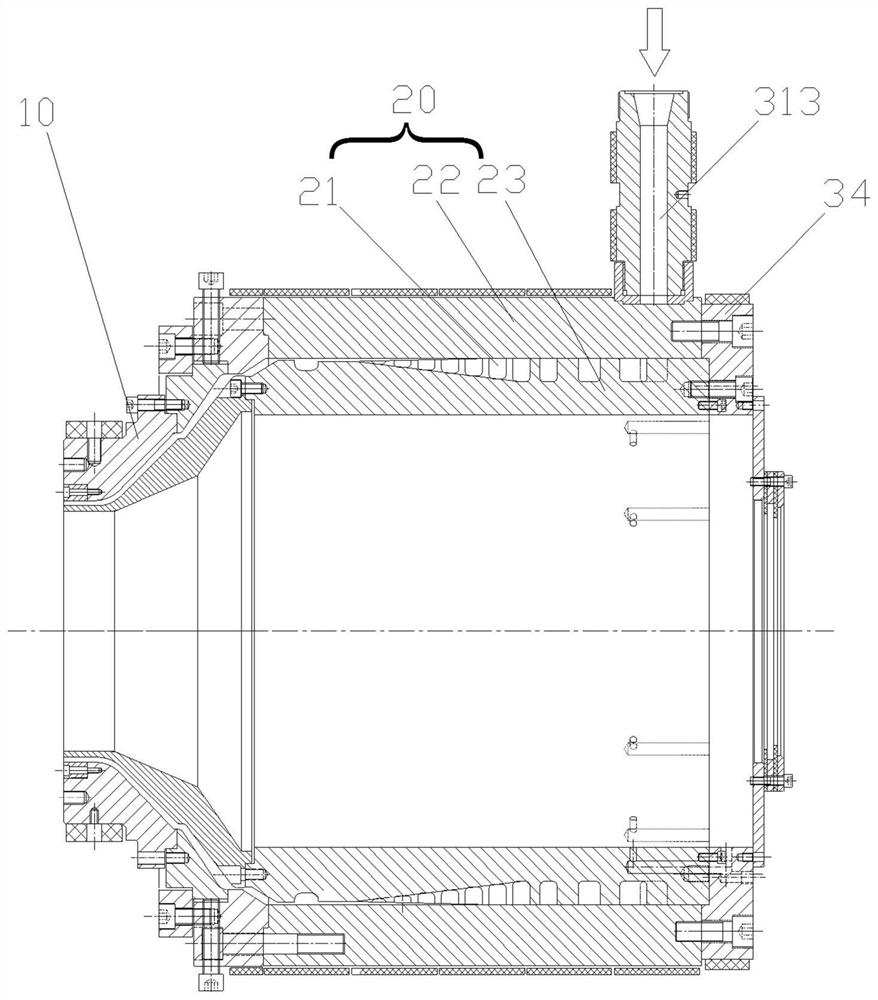

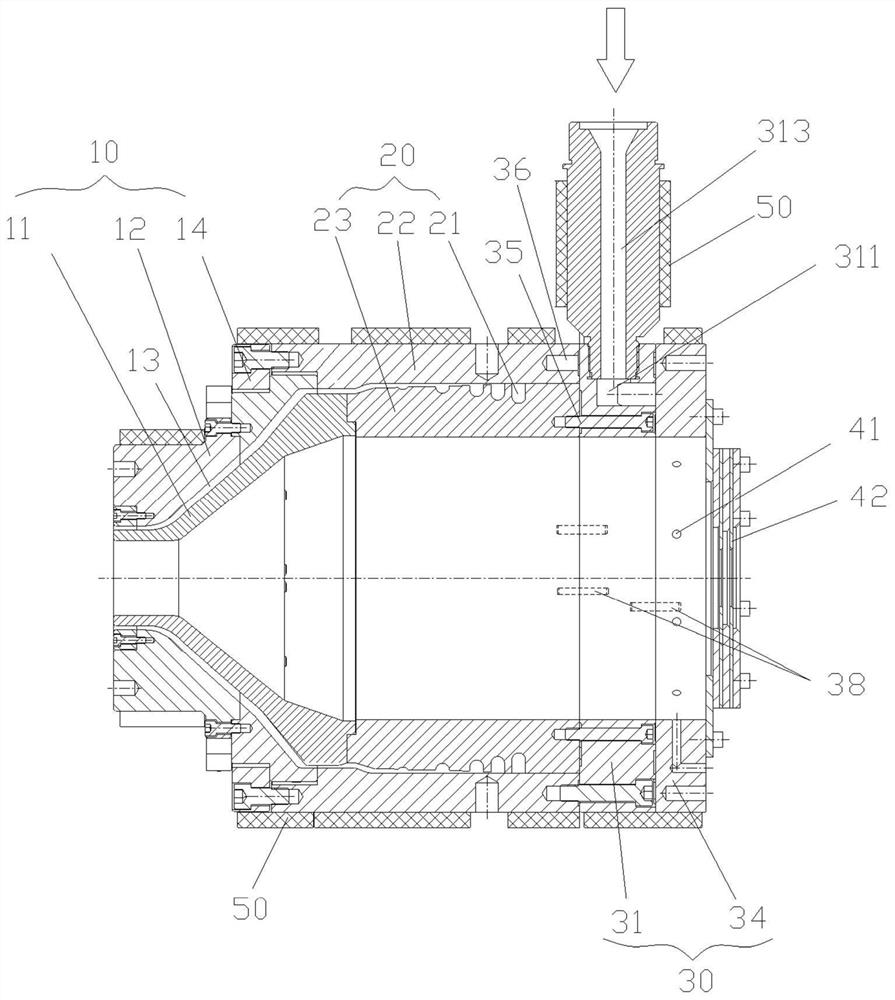

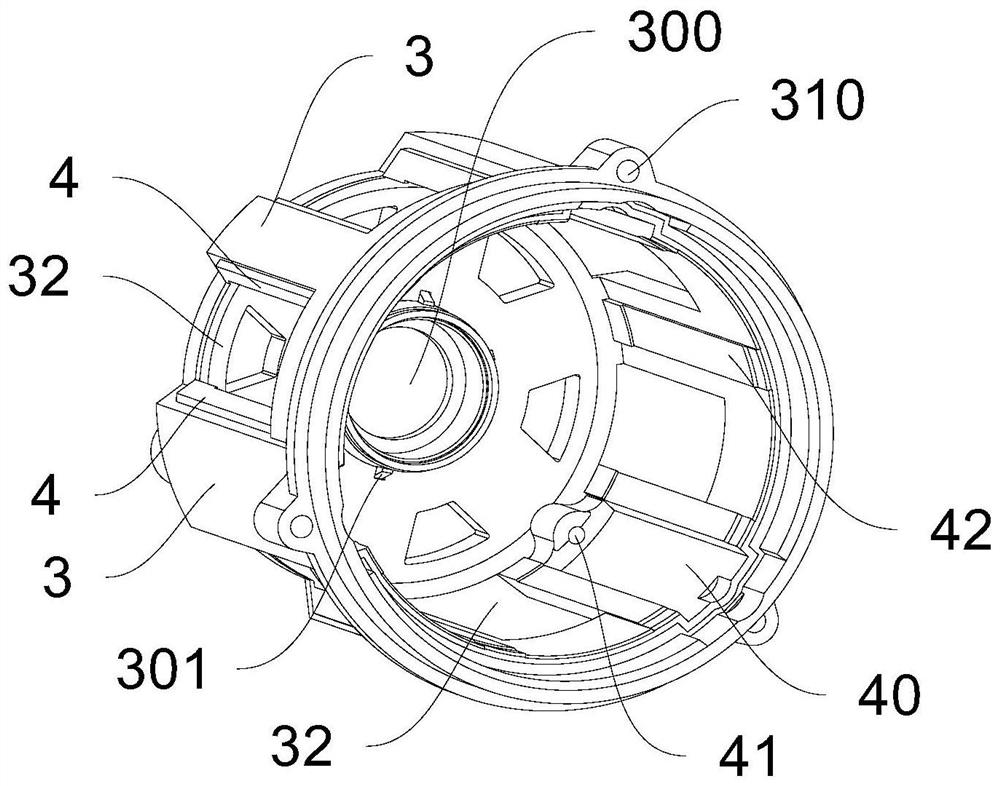

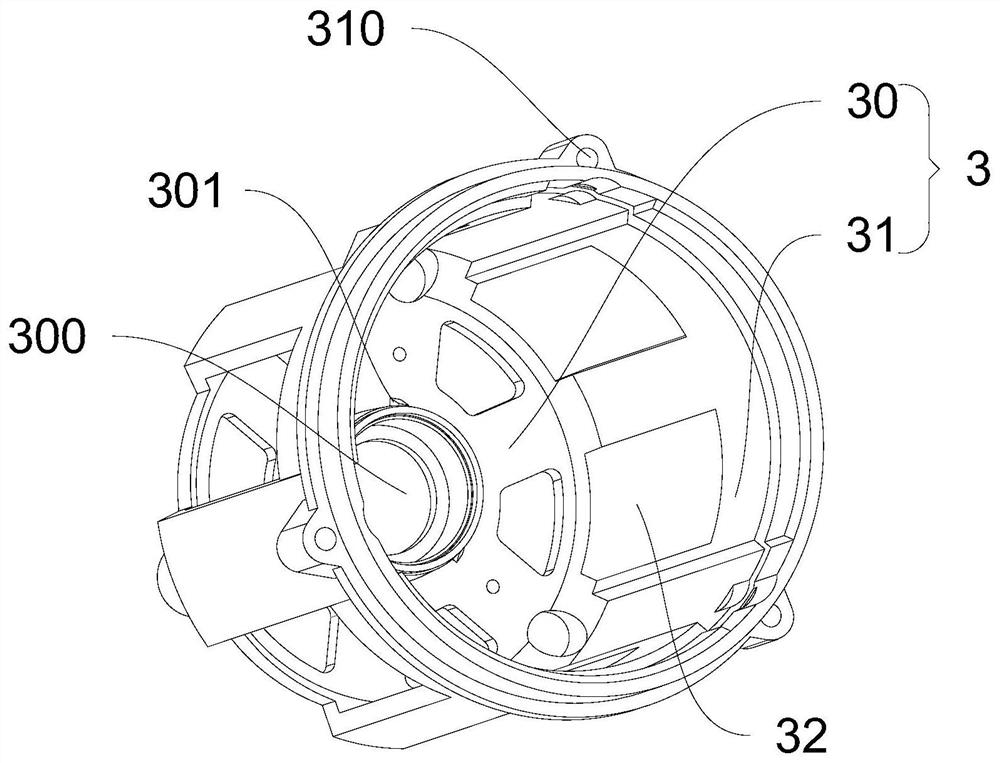

Spiral mold and pipeline composite equipment with spiral mold

The invention relates to the field of composite pipeline manufacturing equipment, and discloses a spiral mold and pipeline composite equipment with the spiral mold. The spiral mold comprises a spiral mold assembly (20) provided with a plurality of spiral flow channels (21) and a flow dividing assembly (30) at least comprising a first flow dividing ring (31), the flow dividing assembly (30) is arranged at the feeding end of the spiral mold assembly (20), the first flow dividing ring (31) is provided with a first arc-shaped flow channel (311) extending in the circumferential direction and first material passing holes (312) penetrating and extending from the two ends of the first arc-shaped flow channel (311) in the axial direction, and the first flow dividing ring (31) can divide and convey material flow to the multiple corresponding spiral flow channels (21) through the first material passing holes (312). According to the spiral mold, feeding pressure can be converted into axial pressure when the material flow enters the spiral mold assembly, meanwhile, uniform distribution of composite materials in the circumferential direction is achieved, radial deviation of the spiral flow channels can be effectively avoided, and a composite layer with the uniform wall thickness is extruded.

Owner:SICHUAN GOLDSTONE-ORIENT NEW MATERIAL TECH CO LTD

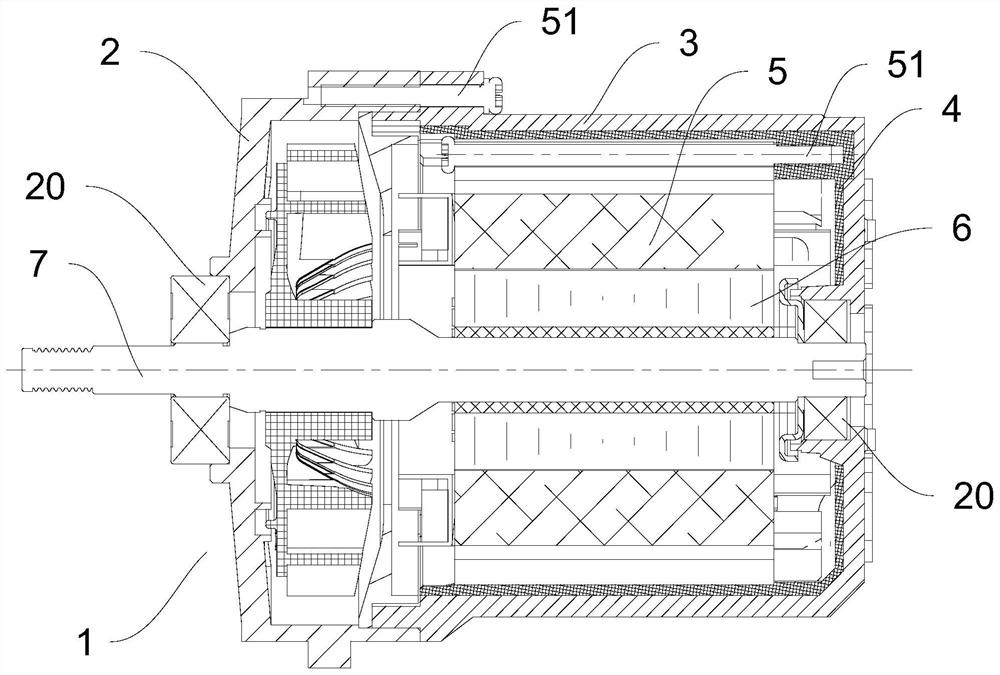

Motor with small air gap, machining and assembling method of motorand electric tool

PendingCN113364190AAvoid concentricity deviationGuaranteed concentricityManufacturing dynamo-electric machinesSupports/enclosures/casingsElectric machinePower tool

The invention discloses a motor with a small air gap. The motor comprises a stator and a plastic insulating layer, the plastic insulating layer is arranged outside the stator, the motor also comprises a shell, the shell comprises a rear end cover and an annular shell, the shell forms an accommodating cavity for accommodating the stator, the plastic insulating layer is integrally formed in the accommodating cavity through injection molding, and the plastic insulating layer and the shell are integrated through injection molding. The invention further discloses an electric tool based on the motor. The invention further discloses a machining and assembling method of the motor with the small air gap. According to the invention, the stator has high concentricity relative to the rear end cover in the assembling process, so that a required small air gap can be obtained between the stator and the rotor, and the efficiency of the motor is effectively improved.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

A kind of floating hoop floating shoe and using method thereof

ActiveCN112983348BReduce weightIncreased sensitivityWell/borehole valve arrangementsSealing/packingWell drillingStructural engineering

The present invention relates to the technical field of cementing tools in the oil drilling industry, in particular to a floating hoop shoe and its use method. The floating hoop shoe includes a shell, and a valve seat is arranged in the inner cavity of the shell from bottom to top and a spool assembly, the spool assembly includes a spool and a spring sleeved above the side wall of the spool, the other end of the spring is fixed in the inner cavity of the housing, and the spool includes a valve The core body, the valve core body is provided with a semi-closed flow channel in the axial direction, the side wall is provided with a first through hole communicating with the flow channel, and the end of the flow channel away from the valve seat is connected to the housing. lumen. The floating hoop shoe provided by the invention can improve the switching efficiency of the valve core, effectively reduce the tremor generated when the mud flows, and ensure the process stability.

Owner:DONGYING XIN HUALIAN PETROLEUM MACHINERY

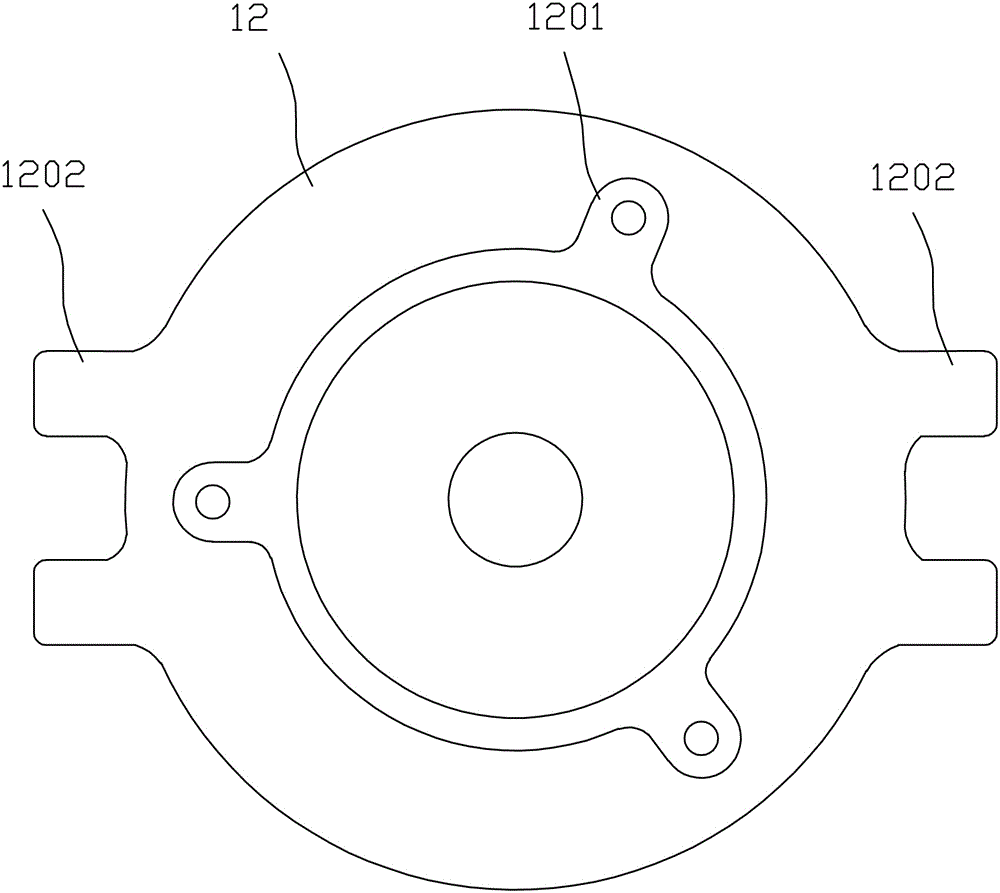

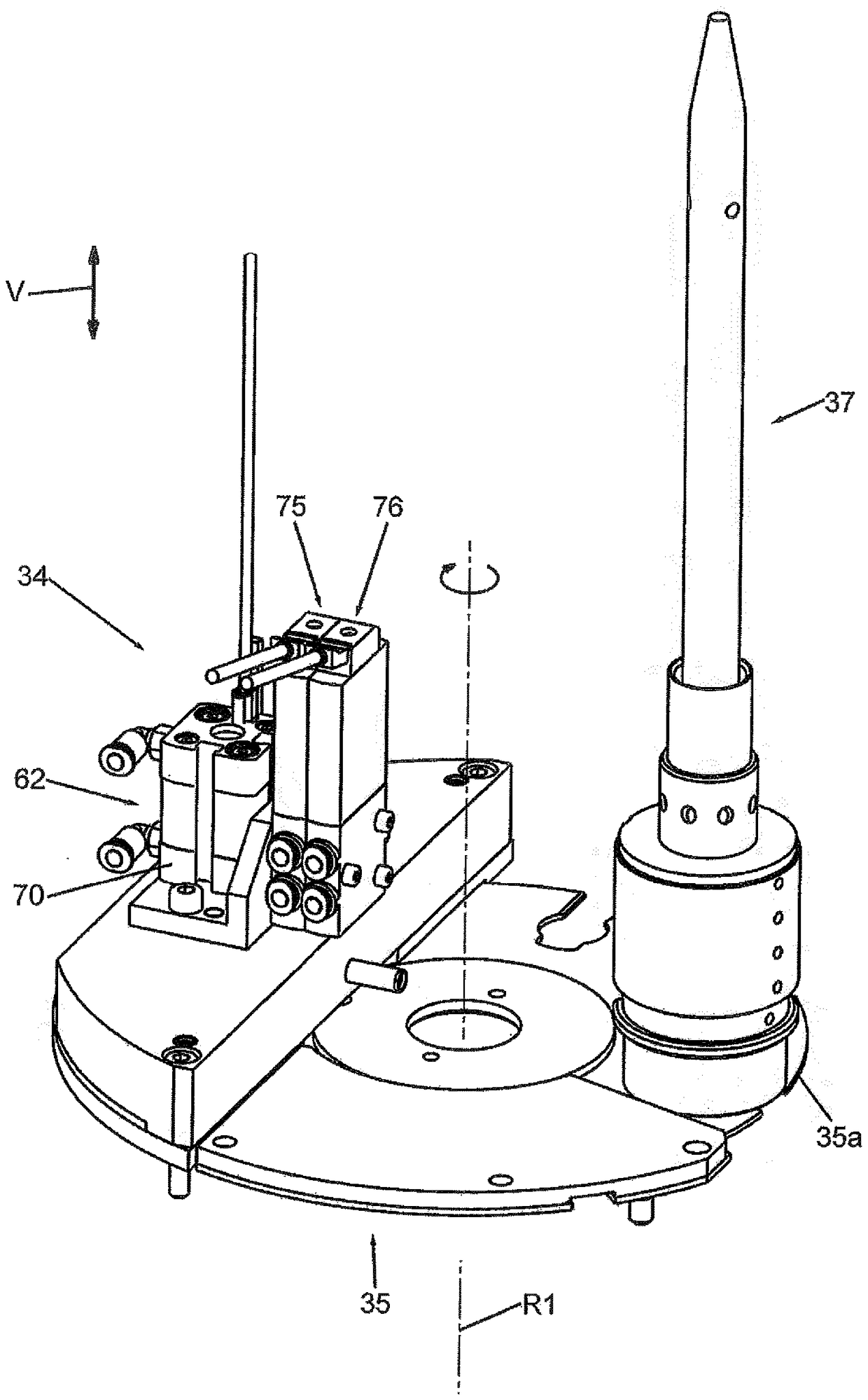

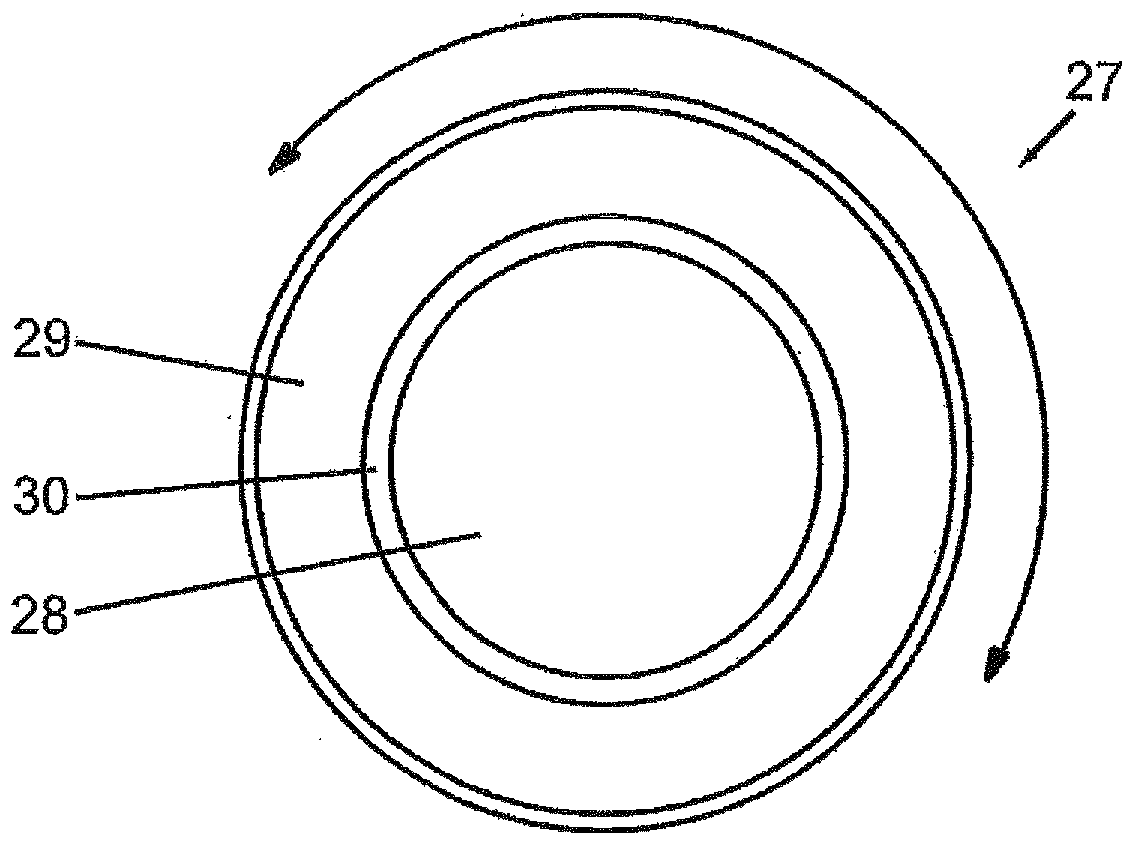

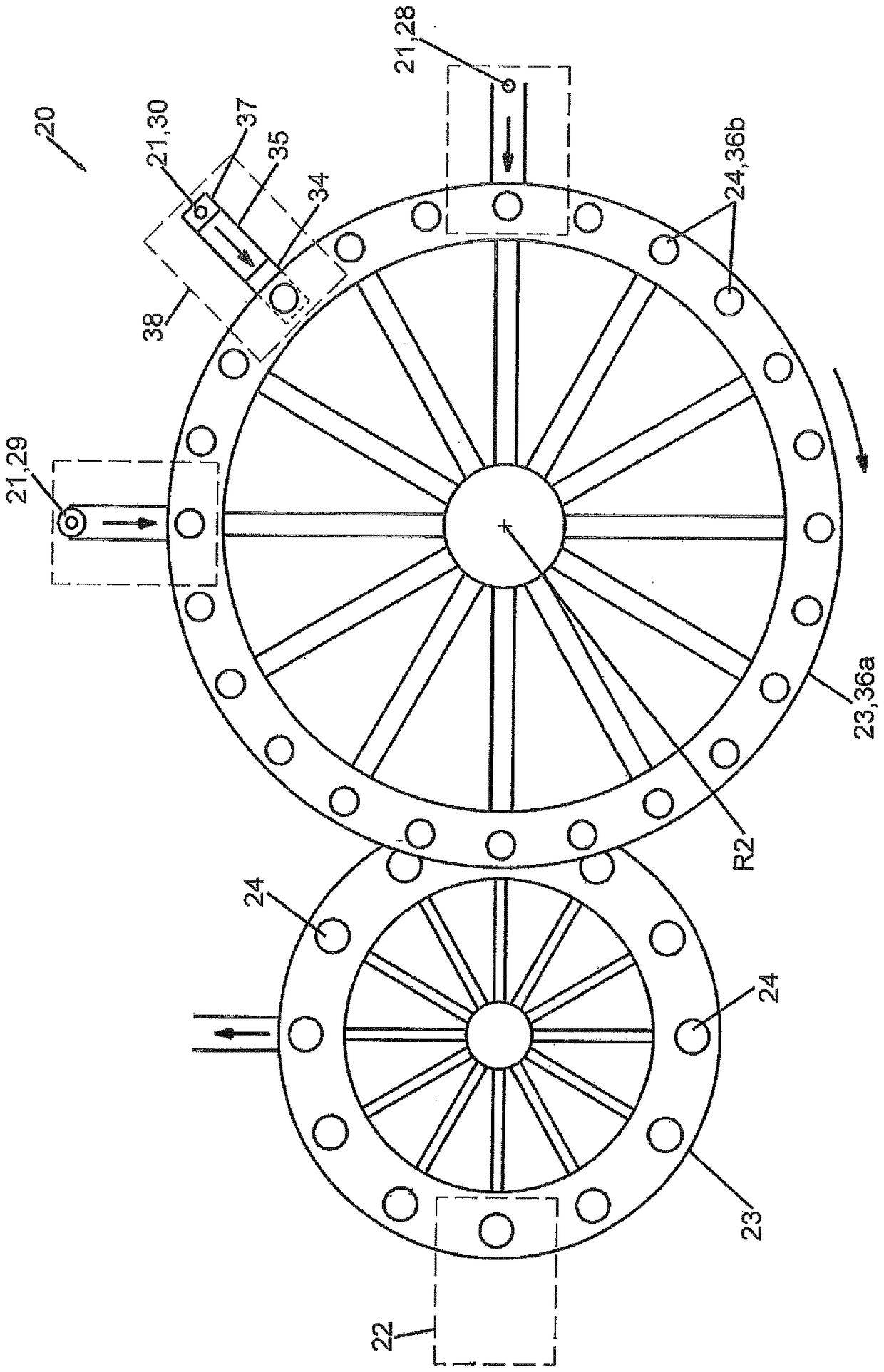

Method and inserting device for inserting a circular blank ring into an outer ring of a circular blank

ActiveCN108778614AEliminate pre-coaxial alignmentPrevent radial offsetMetal working apparatusCoinsEngineeringInsertion point

The invention relates to a method and an inserting device for inserting a circular blank ring into an outer ring. For this purpose, an outer ring is first transported to an insertion point in the supply device. At the same time, a circular blank ring is brought to a starting position (P) in the supply device. The circular blank ring is first aligned coaxially to an axis (A) via a centering body which is arranged coaxially to the axis (A). The circular blank ring moves solely radially to the axis (A). The circular blank ring is then inserted into the hole of the outer ring by means of a tappet.During the movement of the circular blank ring from the starting position (P) into the outer ring, the circular blank ring is aligned coaxially to the axis (A) by means of a centering means and preferably by means of a centering channel. The circular blank ring carries out a superimposed movement in the axial direction (V) and in the radial direction radially to the axis (A).

Owner:SCHULER PRESSEN GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com