Object lifter structure

A sundry crane and jib technology, applied to cranes and other directions, can solve problems such as bulky and difficult jibs, and achieve the effects of simple operation, improved stability, and simple and convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

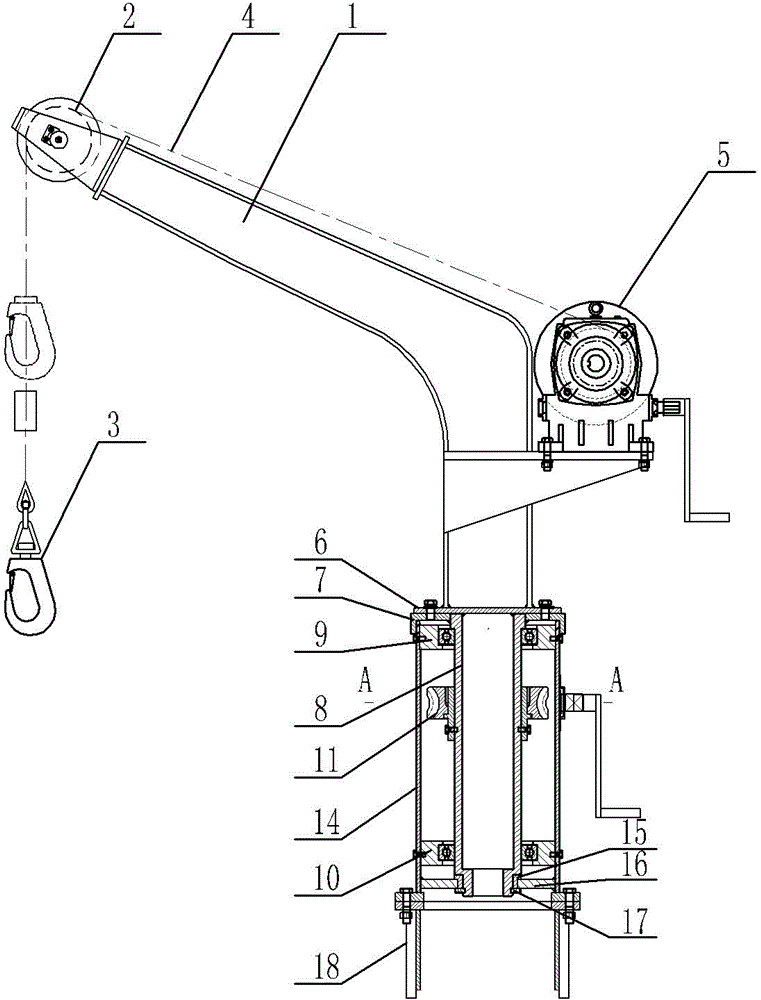

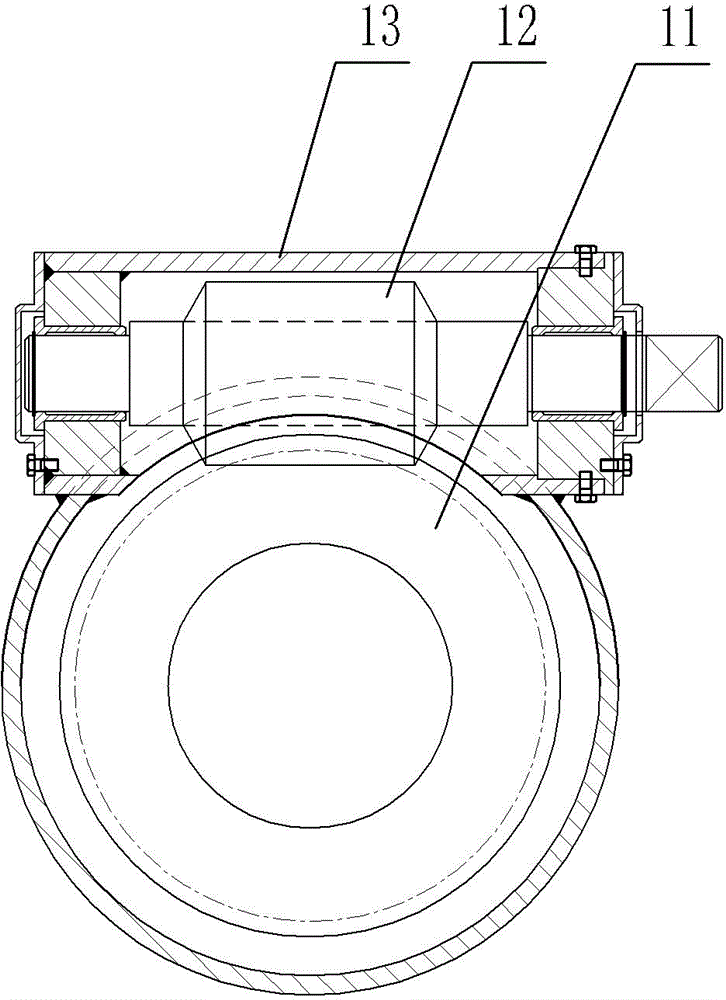

[0012] Such as Figure 1 to Figure 2 As shown, it includes a boom 1, a base 18, a lifting device 5, a pulley 2, a wire rope 4 and a hook group 3, and also includes a connecting rod 8, a worm wheel 11, a worm 12 and a support body 14. The root of the boom 1 is fixed with The connecting rod 8 is fixedly connected with a support body 14 on the base, and the support body is a cylindrical structure with openings at both ends. The connecting rod 8 is inserted into the support body along the axial direction. The bearing seat 10 is fixedly connected, the two ends of the connecting rod 8 are supported on the bearing seat, the worm gear 11 is set on the connecting rod 8, the supporting body is provided with a mounting seat 13, the two ends of the worm 12 are supported on the mounting seat 13, and are connected with the worm wheel 11 Mesh connection, the end of the worm 12 is fixed with a rocker arm; the opening at the lower end of the support body is fixed with a ring-shaped cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com