Method and inserting device for inserting a circular blank ring into an outer ring of a circular blank

A technology for inserting devices and blanks, applied in forging/pressing/hammer devices, applications, decorative arts, etc., can solve problems such as deformation and damage of circular blank rings, and achieve the effect of maintaining coaxial alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

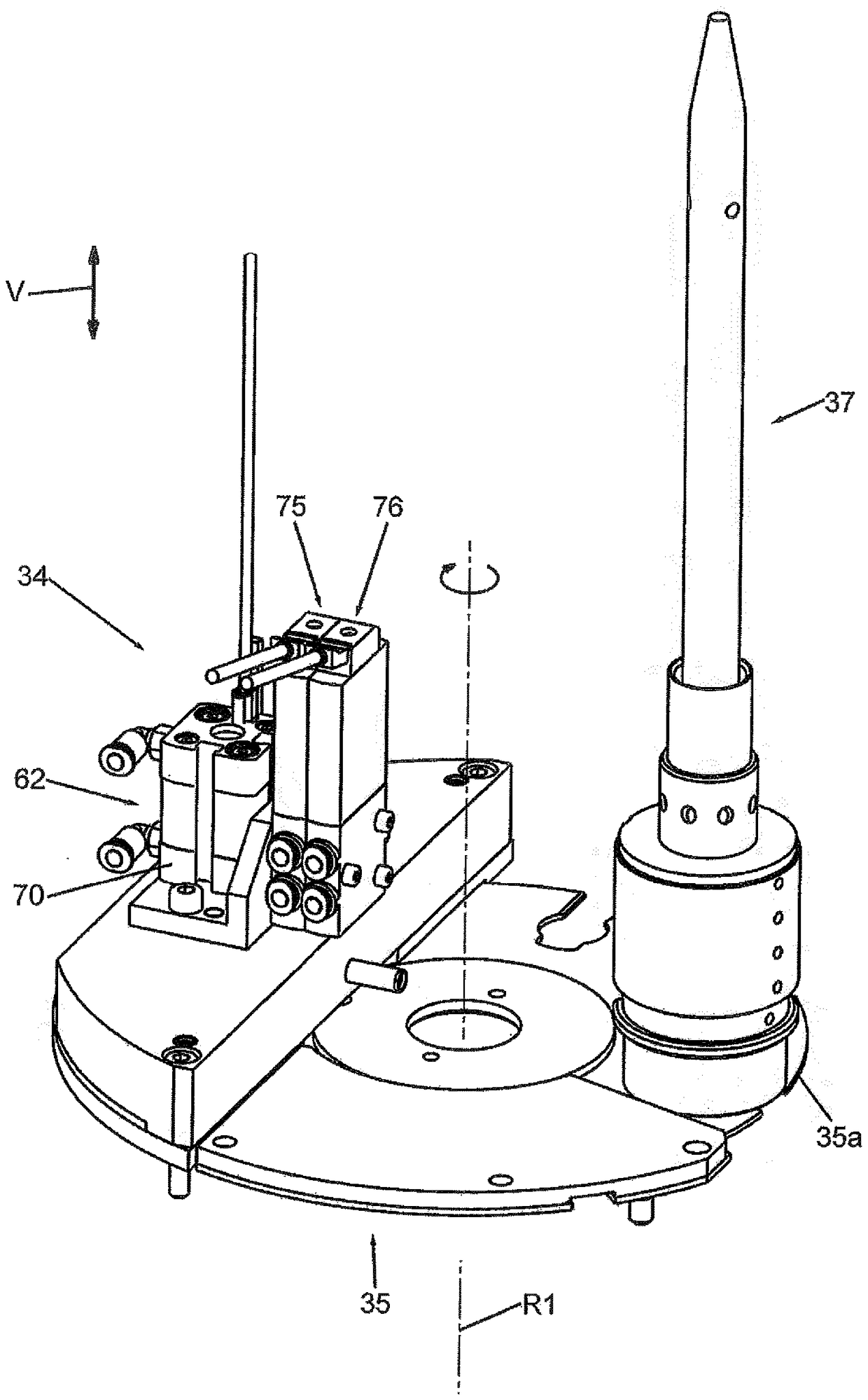

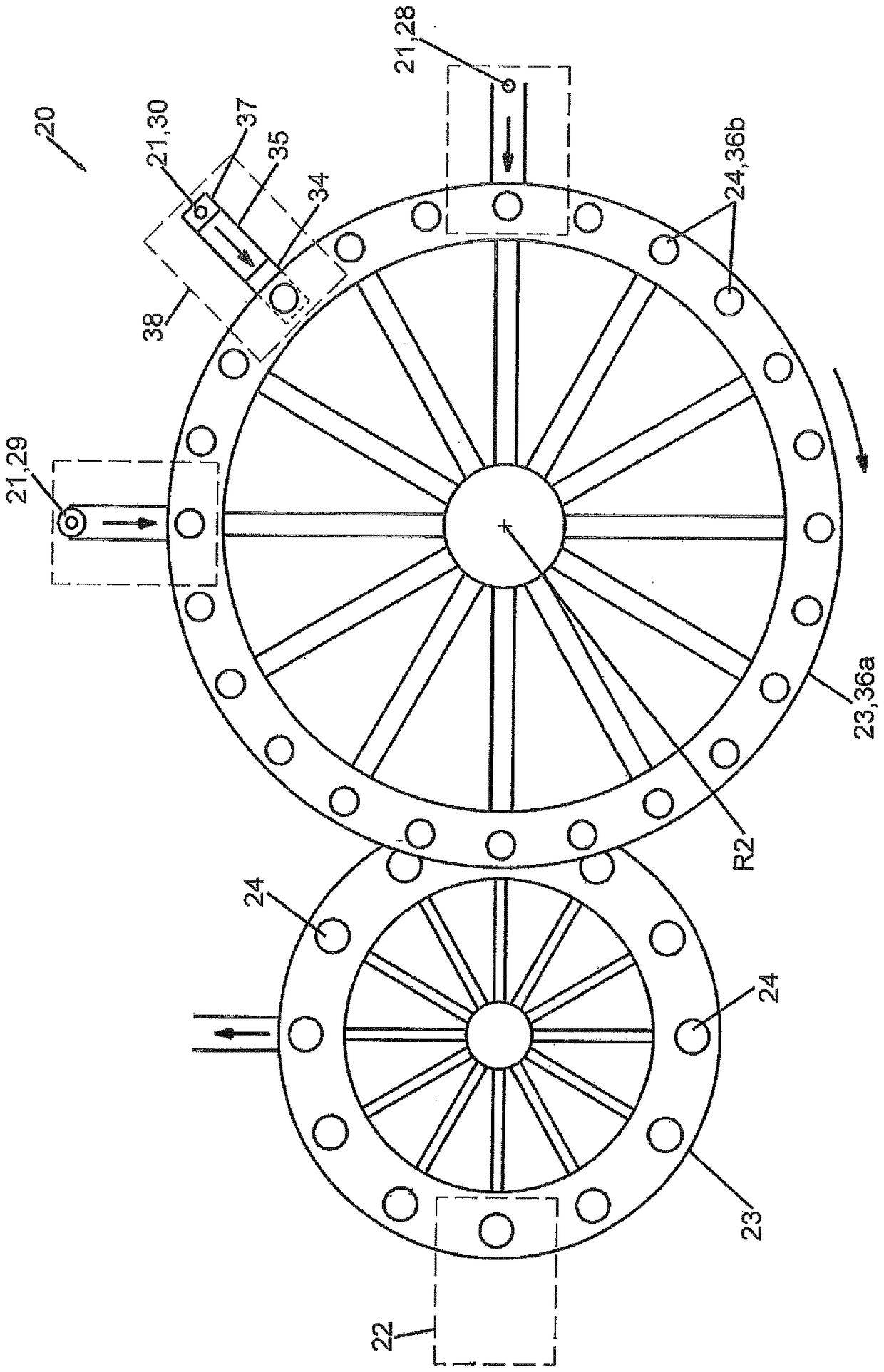

[0040] figure 1 A very schematic illustration of a transport device 20 is shown for transporting round blanks or for transporting round blank parts 21 to stamping stations 22 . The transport device 20 may comprise one or more carousel feed plates 23, each carousel feed plate comprising a plurality of notches 24 on its circumferential area. When a particular turntable feed plate is rotated about its turntable axis, a round blank comprising a plurality of round blank portions 21 or at least one of the round blank portions 21 may be present in the recess 24 and transported.

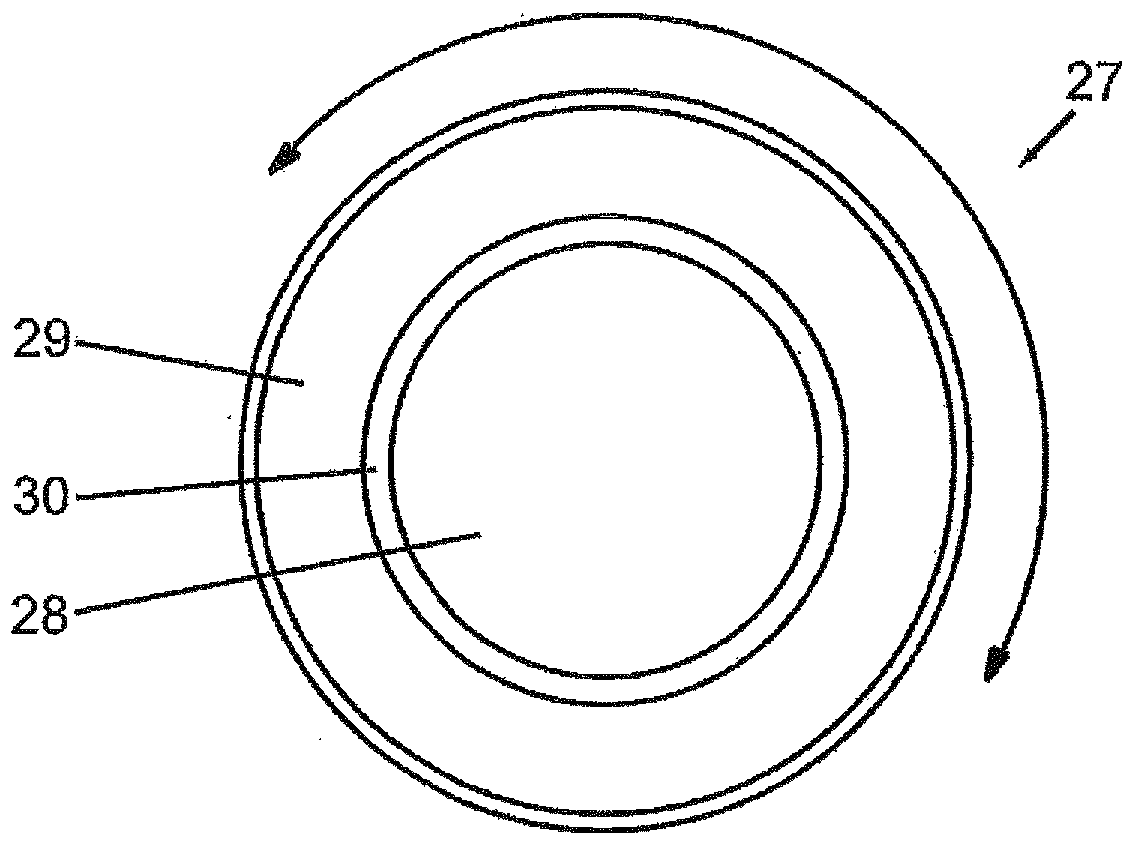

[0041] In an exemplary embodiment, a multi-piece circular blank is provided from which a coin 27 is stamped in a stamping station 22 ( Figure 7 and Figure 8 ). In the exemplary embodiment, coin 27 or circular blank includes three distinct circular blank portions 21 : circular blank core 28 , outer ring 29 , and circular blank ring 30 . A circular blank ring 30 is arranged between the circular blank cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com