Motor with small air gap, machining and assembling method of motorand electric tool

A small air gap, integrated technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of difficult to meet the demand, poor concentricity between the stator and the rotor, etc., to improve the efficiency of the motor, small air gap, guarantee The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

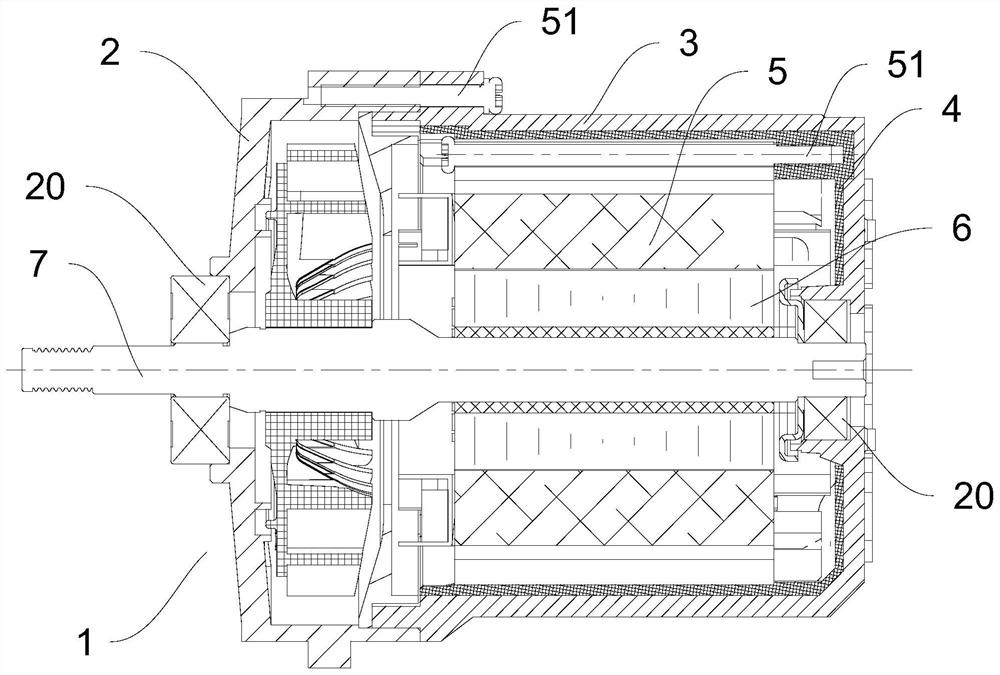

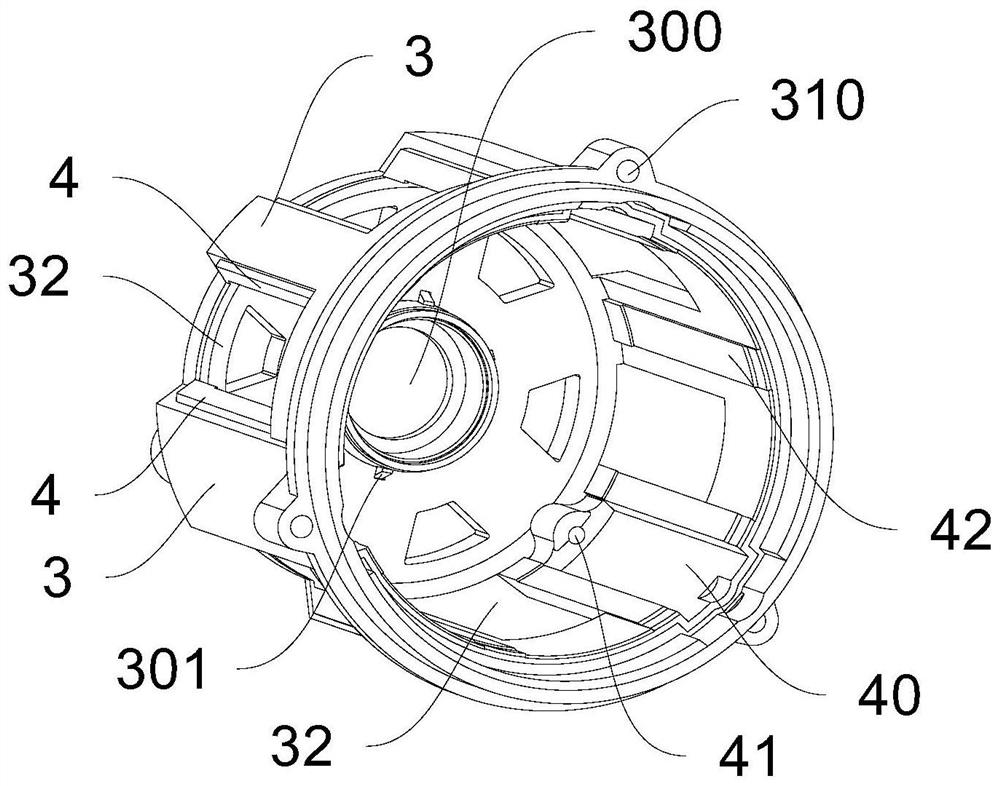

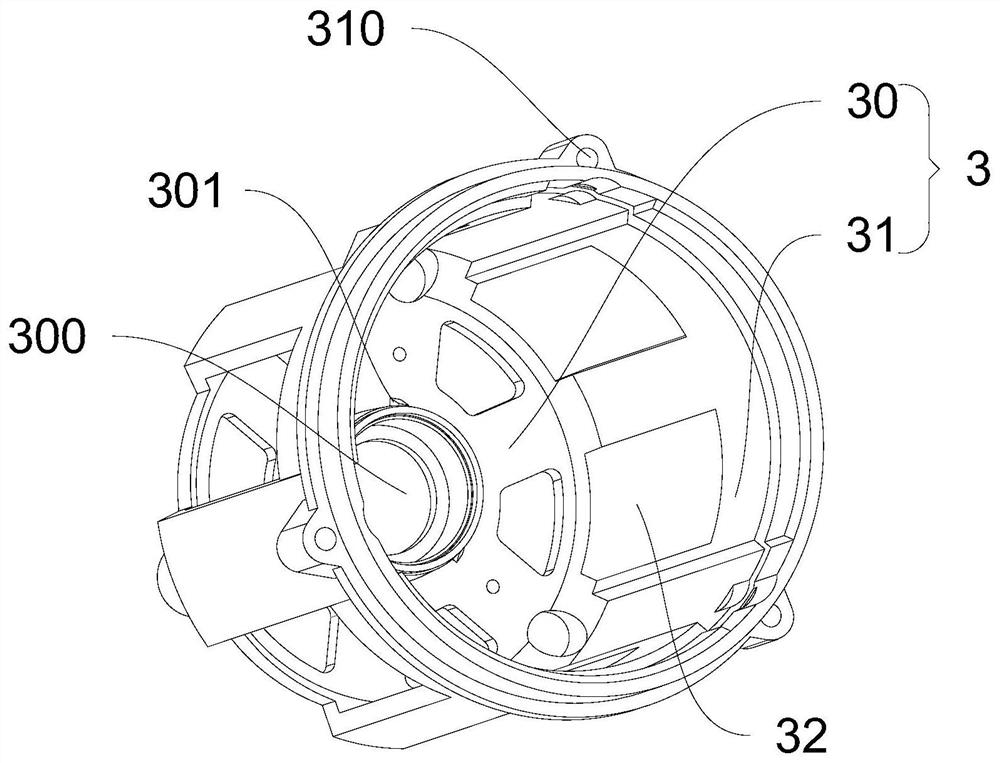

[0038] Embodiment one: if figure 1 , figure 2 , image 3 with Figure 4 As shown, a motor with a small air gap includes a front end cover 2, a casing 3, a stator 5, a rotor 6, a motor shaft 7 and a plastic insulating layer 4, wherein the casing 3 includes a rear end cover 30 and an annular shell 31, and the rotor 6 is fixed Connected on the motor shaft 7, the center of the front end cover 2 and the center of the rear end cover 30 are provided with a bearing chamber 300, and the two ends of the motor shaft 7 are respectively rotated and connected to the bearing 20 provided in the bearing chamber 300, and the front end cover 2 and the rear end cover 30 are fixedly connected with the stator 5 , the plastic insulating layer 4 is arranged outside the stator 5 to play an insulating role, and an air gap is formed between the stator 5 and the rotor 6 . The housing 3 in this embodiment forms an accommodating cavity for accommodating the stator 5, that is, the accommodating cavity i...

Embodiment 2

[0048] Embodiment 2: This embodiment provides a method for processing and assembling a motor with a small air gap, including the following steps, wherein the structure of the motor can be referred to Figure 1 to Figure 6 :

[0049] S10: The housing 3 of the motor is made by die-casting technology. The housing 3 includes a rear end cover 30 and an annular shell 31. The rear end cover 30 of the housing 3 includes a bearing chamber 300 for installing the motor shaft 7. The annular shell 31 of the housing 3 includes The first mating end surface used to closely fit with the front end cover 2;

[0050] S20: putting the shell 3 as an insert into the injection cavity of the injection mold;

[0051] S30: filling the injection molding cavity with molten plastic, and injecting the inner surface of the shell 3 to form a plastic insulating layer 4;

[0052] S40: Manufacture the front end cover 2 of the motor. The front end cover 2 includes a second matching end surface for closely fitti...

Embodiment 3

[0056] Embodiment three: as Figure 7 As shown, this embodiment provides an electric grinding tool, including a casing 8, a working head 82, a controller 81 and a motor 1, wherein the rear end of the casing 8 is provided with a gripping portion 80 for the operator to grasp, A motor 1 is installed in the casing 8 , the output shaft of the motor 1 is connected with the working head 82 for driving the working head 82 to work, and the controller 81 is connected with the motor 1 for controlling the start and stop of the motor 1 . Wherein, the motor 1 installed in the tool is a motor with a small air gap provided in the first embodiment. Since the tool is equipped with the above-mentioned motor with a small air gap, the electric tool has the advantages of long service life and high reliability of the whole machine, and at the same time reduces the cost. It can be understood that the motor is not limited to be applied to the electric grinding tool provided in this embodiment, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com