Quick locking and positioning mechanism for axis parts

A technology for locking and positioning shaft parts, used in mechanical equipment, connecting components, etc., can solve the problems of reduced accuracy of shaft parts, radial deviation of shaft parts, uneven force distribution, etc., to avoid radial deviation, Guaranteed precision and firm compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

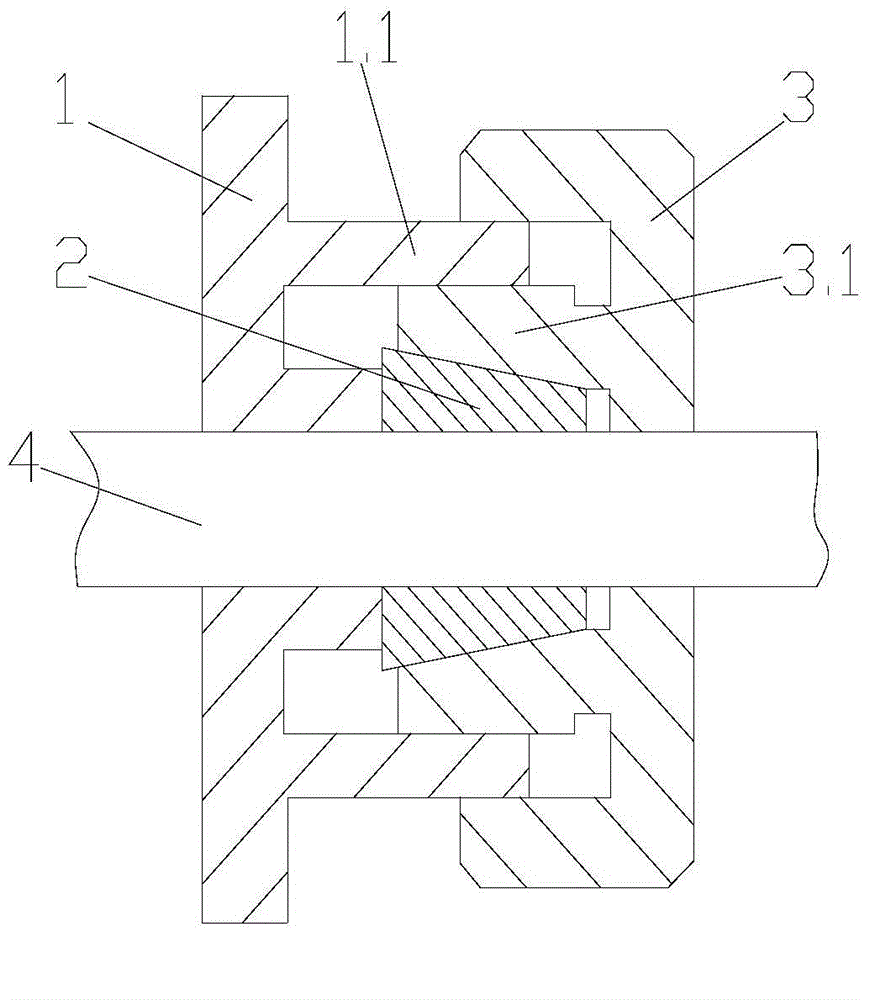

[0012] Such as figure 1 A fast locking and positioning mechanism for shaft parts is shown, including a coaxially arranged step-shaped bushing 1, a tapered elastic bushing 2, and a screw cap 3. The front end of the bushing 1 with a small diameter is a tubular connection Part 1.1, the shaft center of the shaft sleeve 1 is an axial center hole that is matched with the shaft, the elastic sleeve 2 is arranged in the connecting portion 1.1, the maximum diameter of the elastic sleeve 1.1 is smaller than the inner diameter of the connecting portion 1.1, and the end of the elastic sleeve 1.1 with a smaller diameter Towards the opening side of the connecting part, the junction of the rear end of the shaft sleeve 1 and the elastic sleeve 2 with a large diameter is a raised structure, which acts as a limit support for the elastic sleeve 2, and the connecting part of the screw cover 3 and the shaft sleeve 1 The outer peripheral surface of 1.1 is threaded, and the inside of the end cover 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com