Lifting device and semiconductor device processing equipment with same

A lifting device and processing equipment technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., can solve the problem that the central guide rod deviates from the axial centerline, etc., to reduce equipment costs, save costs, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the technical solution of the present invention, the lifting device provided by the present invention and the semiconductor device processing equipment provided with the device will be described in detail below with reference to the accompanying drawings. Wherein, the same or similar reference numerals from the beginning to the end indicate the same or similar elements or elements with the same or similar functions, and the terminology such as positional relationship above and below used in the description of the present invention is only for convenience The description of the present invention should not be interpreted as a limitation to the present invention.

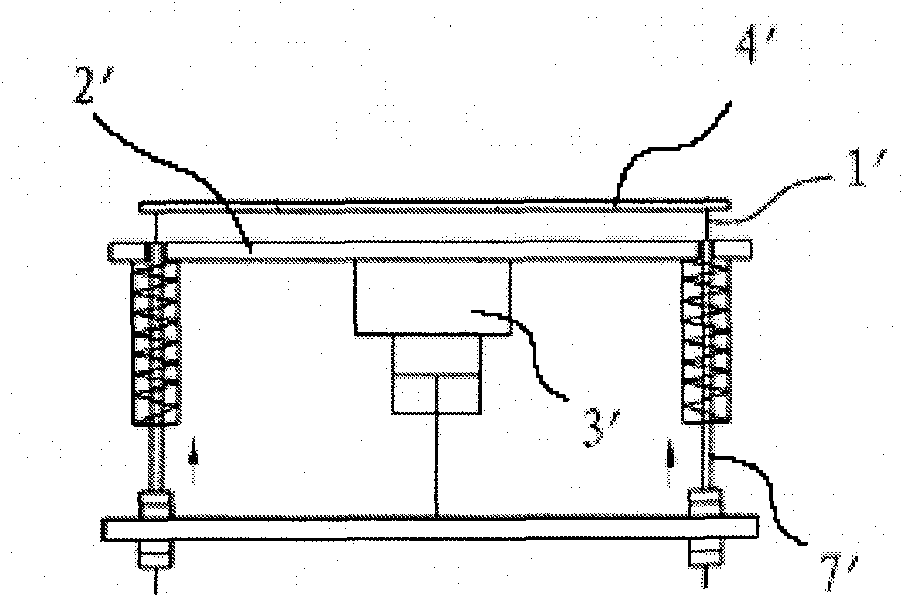

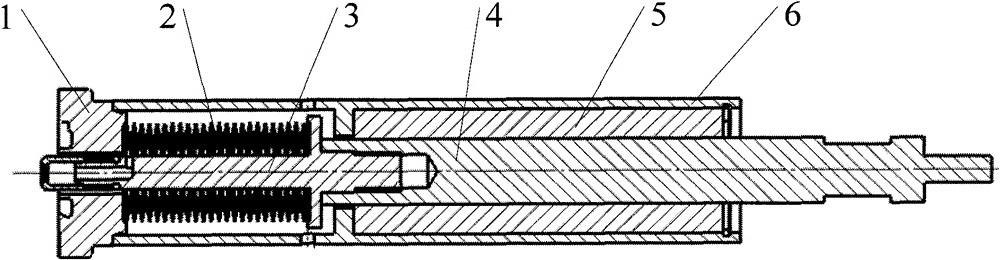

[0041] Please refer to Figure 4 with Figure 5 , Which shows the lifting device provided by the first embodiment of the present invention. The lifting device includes: a bellows 10, a hollow sleeve 11, a first constraining part 12, a second constrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com