Lens holder driving device and portable device

A driving device and lens holder technology, applied in electromechanical devices, focusing devices, installation, etc., to achieve the effect of ensuring linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

[0057] Embodiments of the present invention will be described below with reference to the drawings.

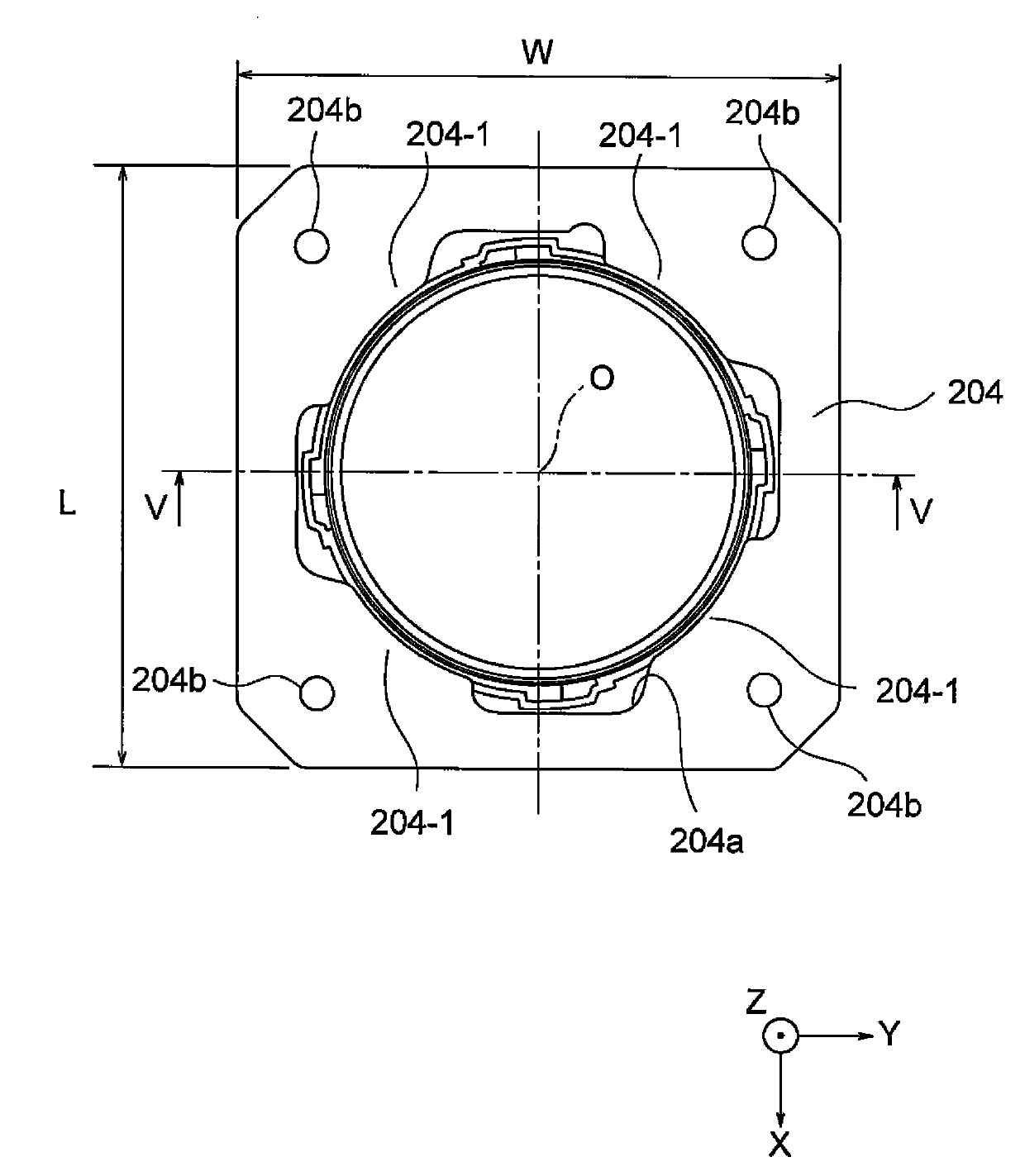

[0058] refer to Figure 3 to Figure 6 The lens holder driving device 10 according to the first embodiment of the present invention will be described. image 3 is a plan view showing the lens holder driving device 10, Figure 4 It is a right side view of the lens holder driving device 10 . Figure 5 its about image 3 Sectional view of the line V-V. Figure 6 It is an exploded perspective view of the lens holder driving device 10 .

[0059] Here, if Figure 3 to Figure 6 As shown, a Cartesian coordinate system (X, Y, Z) is used. exist Figure 3 to Figure 6 In the illustrated state, in the Cartesian coordinate system (X, Y, Z), the X-axis is the front-back direction (depth direction), the Y-axis is the left-right direction (width direction), and the Z-axis is the up-down direction (height direction). and, in Figure 3 to Figure 6 In the example shown, the up-down direct...

no. 2 approach )

[0100] In the lens holder driving device 10 of the first embodiment described above, without changing the material of the lens holder 14, the creases 146a are formed on the upper surface of the holder upper side protrusion 146 to reduce the contact area.

[0101] In contrast, in the lens holder driving device according to the second embodiment of the present invention, the material of the lens holder 14 is also changed. That is, as a molding material of the lens holder 14, a molding material containing conductive carbon (conductive carbon) is used. Thus, the volume resistivity of the lens holder 14 is 1×10 11 [Ω·cm].

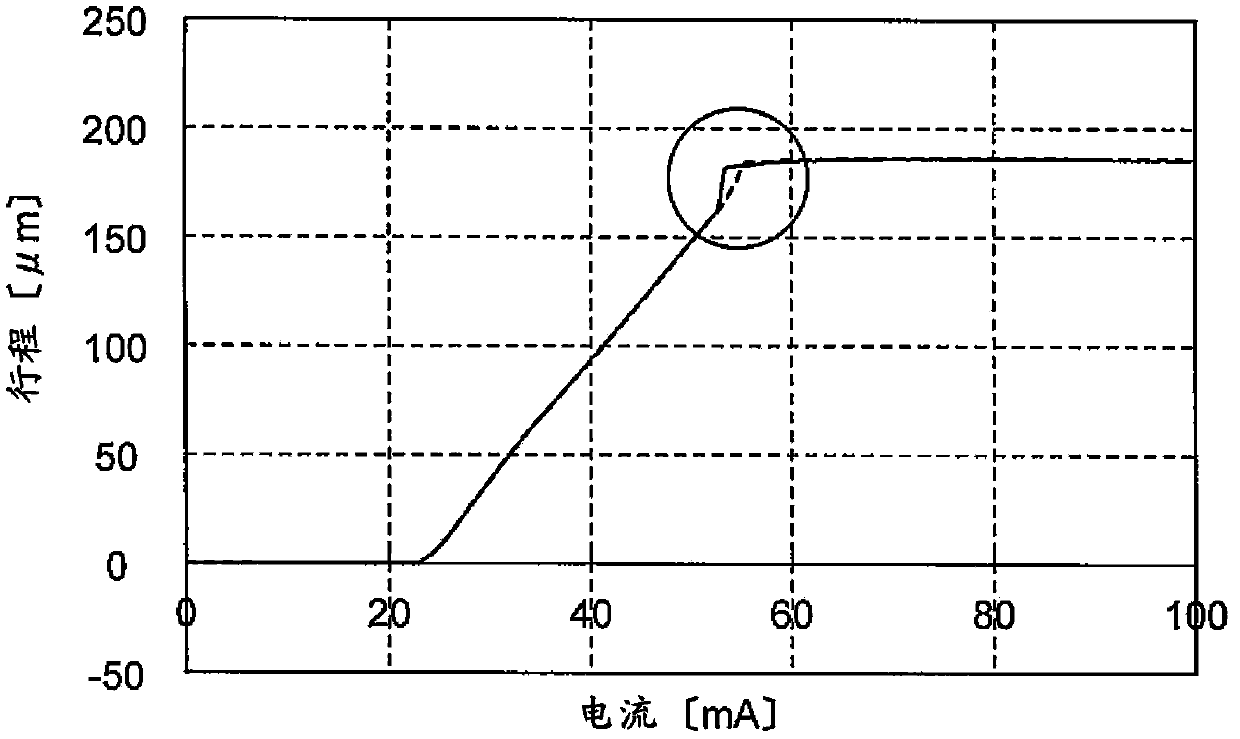

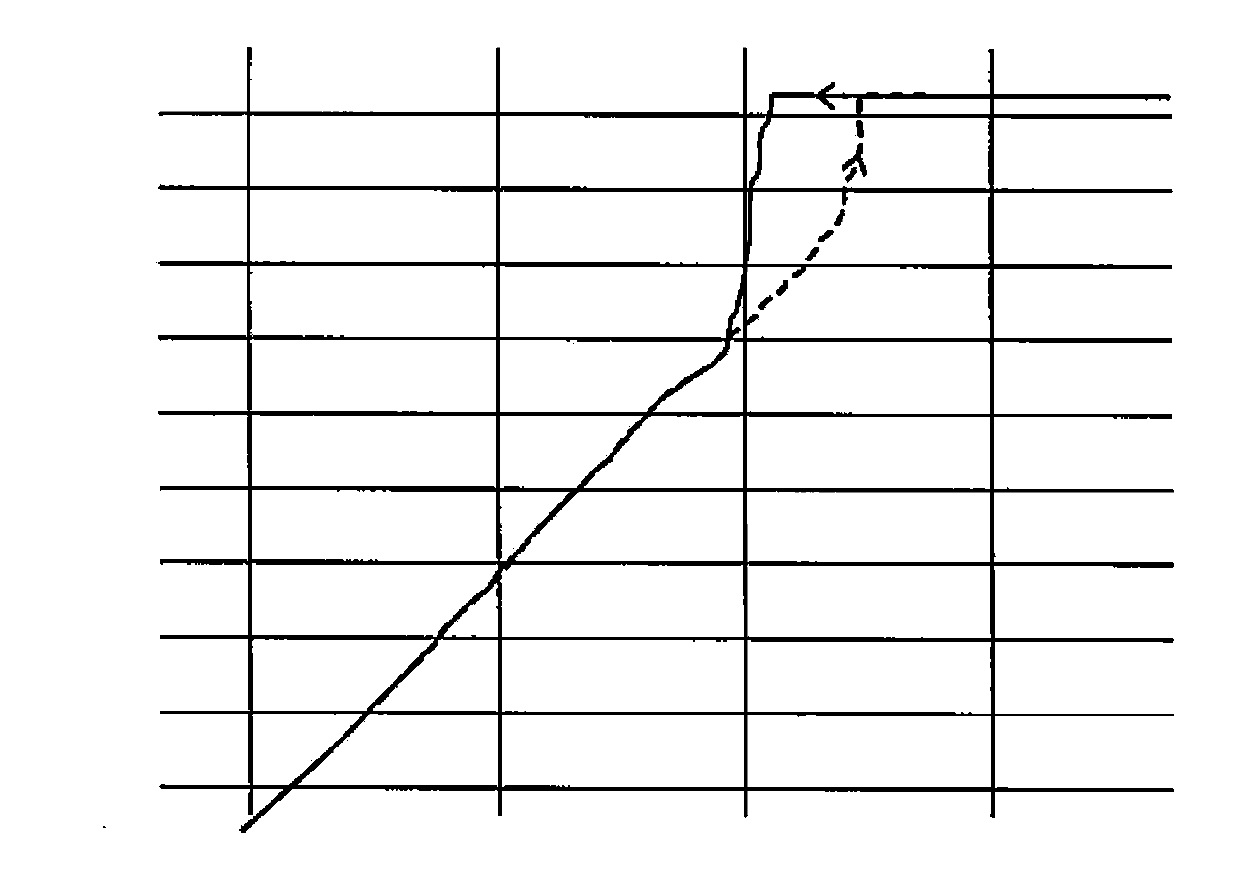

[0102] Figure 12 It is a graph showing the effect of improving the upper side hysteresis (μm) near the maximum stroke. exist Figure 11 In the figure, the left side shows the upper side hysteresis (μm) of the related art (NORMAL), the middle part shows the upper side hysteresis (μm) of the above-mentioned first embodiment (upper crease), and the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com