Tensioning device for spoke out-of-roundness positioning check tool

A technology of out-of-roundness and inspection tools, which is applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of radial deviation of spokes and reduce the detection accuracy of spoke out-of-roundness, so as to achieve uniform extrusion deformation and prevent radial deviation Move, prevent the effect of local excessive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

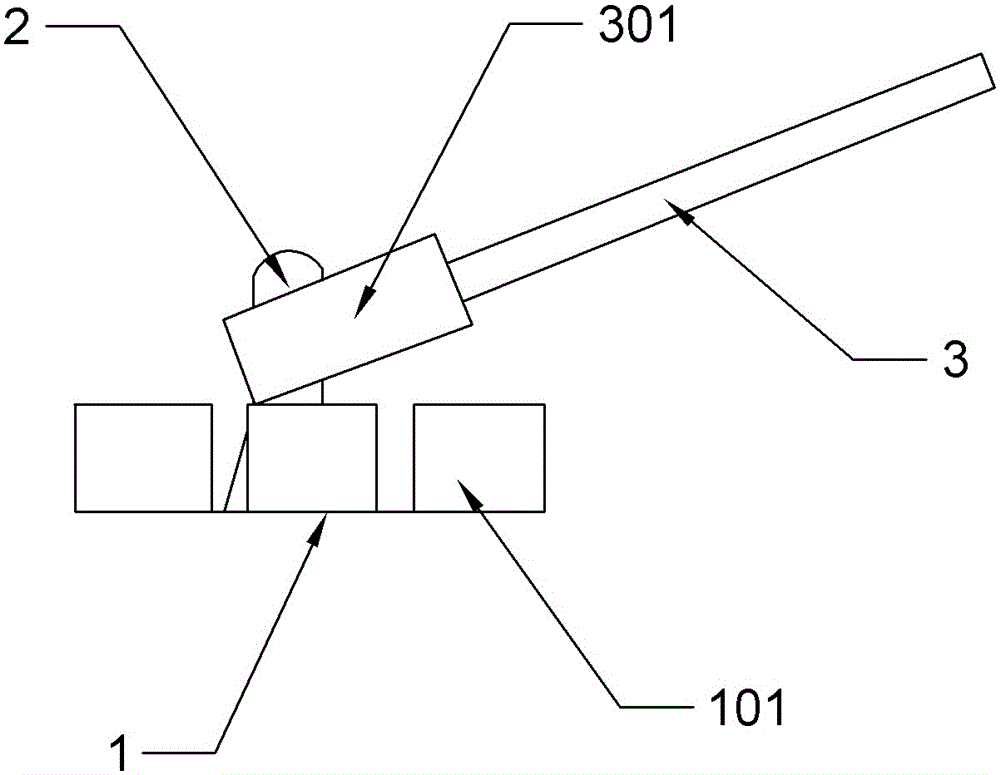

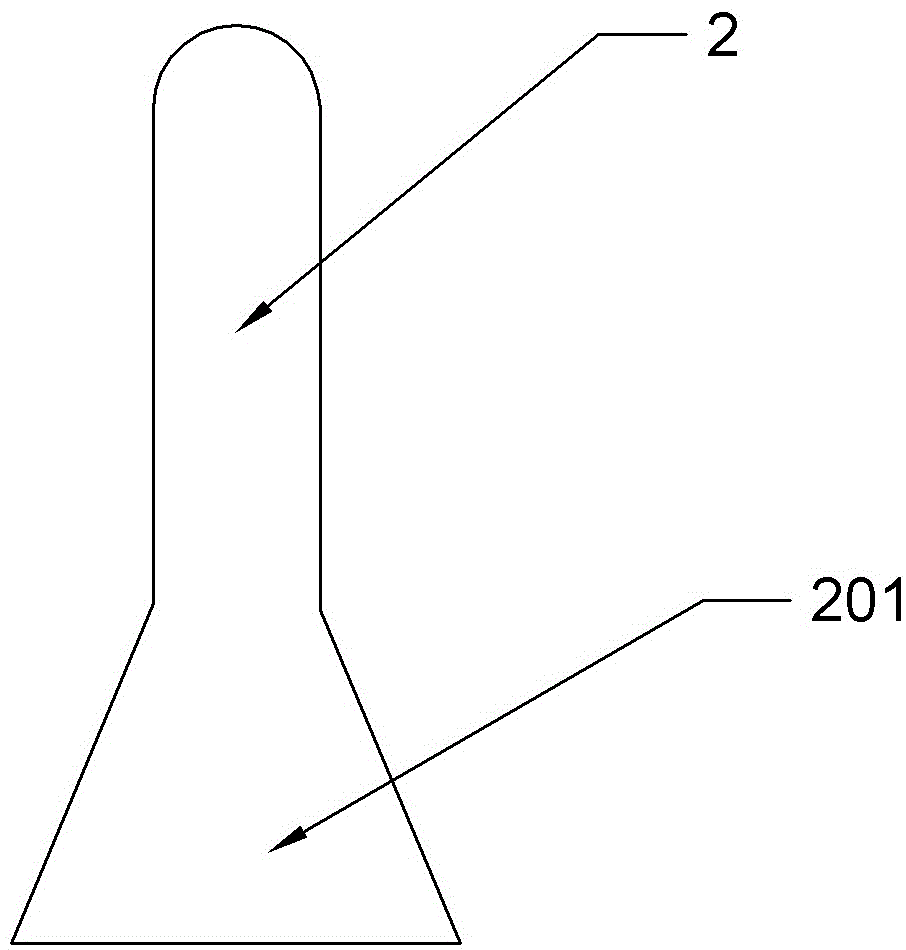

[0021] Example 1, such as figure 1 and figure 2 As shown, the tensioning device used for the spoke out-of-roundness positioning fixture includes a mandrel 1, a protruding rod 2 and a movable rod 3, wherein the protruding rod 2 is located at the center of the mandrel 1, and the movable rod 3 is connected to the top end of the protruding rod 2 . The mandrel 1 is a hollow ring, and there is an expansion groove 101 on the mandrel 1, and the bottom of the mandrel 1 is fixedly connected with the mounting seat of the positioning gauge, which is used to make the extrusion deformation between the mandrel 1 and the spokes more evenly. The protruding rod 2 is used to expand the mandrel 1, and the lower end surface of the protruding rod 2 is provided with a protruding block 201. The protruding block 201 is a positive trapezoid with a narrow top and a wide bottom. The variation of the cross-sectional area of the block 201 is such that the mandrel 1 is pressed outwards. The protrudin...

Embodiment 2

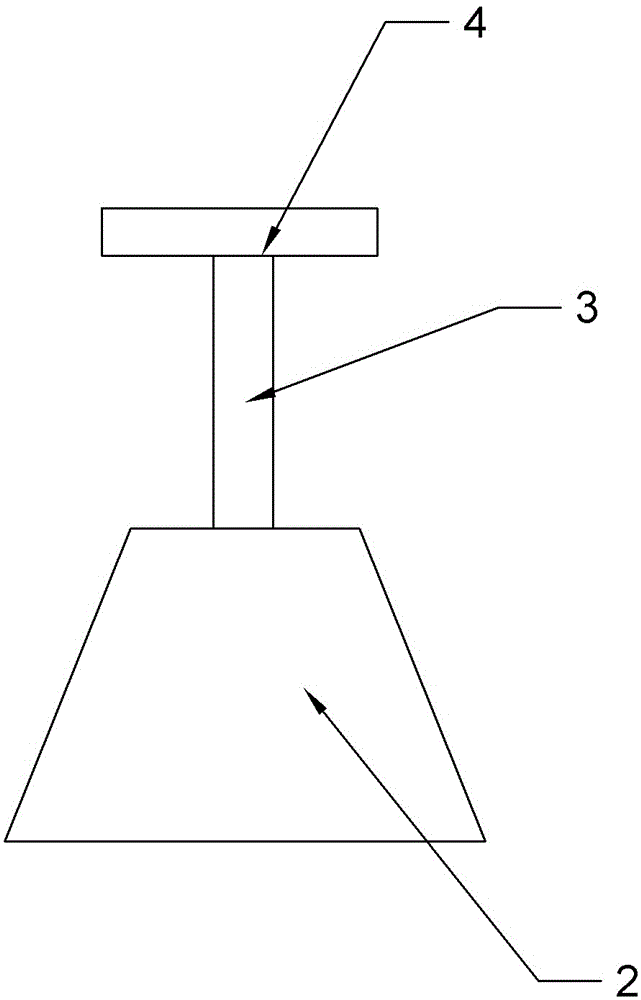

[0022] Example 2, such as image 3 As shown, the difference with Embodiment 1 is that the protruding rod 2 is a positive trapezoid as a whole, the movable rod 3 is located directly above the protruding rod 2, and a handle 4 is arranged on the movable rod 3, and the handle 4 is fixedly connected with the movable rod 3, and the handle 4 is covered with rubber sleeve above. By holding the handle 4 upwards, the protruding rod 2 is lifted up, so that the wide part below the protruding rod 2 presses the mandrel 1 outward.

Embodiment 3

[0023] Example 3, such as Figure 4 As shown, the difference from Embodiment 2 is that the protruding rod 2 is an inverted trapezoid with a wide top and a narrow bottom. By pressing down on the handle 4, the whole protruding rod 2 can be pressed down, so that the upper wide part of the protruding rod 2 presses the mandrel 1 outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com